Portside Magazine - Spring 2010

-

Upload

ports-of-indiana -

Category

Documents

-

view

223 -

download

5

description

Transcript of Portside Magazine - Spring 2010

www.portsofindiana.com

In Memoriam: Mount Vernon’s Art Bayer, pg. 5

Port of Indiana-Burns Harbor opens 40th international shipping season, pg. 10

Last operational WWII LST ship refuels at Mount Vernon port, pg. 11

iNSiDe tHiS iSSUe:

www.portsofindiana.comwww.portsofindiana.com

FROM LOADING DOCKS FROM LOADING DOCKS FROM LOADING DOCKS FROM LOADING DOCKS FROM LOADING DOCKS FROM LOADING DOCKS FROM LOADING DOCKS FROM LOADING DOCKS FROM LOADING DOCKS TO LOADED BASESTO LOADED BASESTO LOADED BASESJeffersonville port supplies infi eld dirt for region’s ball fi elds

A Ports of Indiana Publication · Spring 2010

www.1si.orgWant some help in taking your business to the next level?

Contact Kathleen Crowley at [email protected] or call 812-945-0266

Tie-in to business resources.

“1SI helped tie us into the tax credits, tax abatement programs and workforce training grants we needed to expand our business at the Port of Indiana-Jeffersonville.”

Chuck Moore, President, Eagle Steel Products, Inc.on completion of $3 million expansion at the company’s 270,000 square foot riverfront facility in Jeffersonville.

www.portsofindiana.com · Spring 2010 3

tABLe oF coNteNtS

PORTS OF INDIANA CONTACT INFORMATION

Rich Cooper, Chief Executive Offi cer(317) 232-9200; rcooper@portsofi ndiana.comMatt Smolek, Port Director - Jeffersonville(812) 283-9662; msmolek@portsofi ndiana.comPhil Wilzbacher, Port Director - Mount Vernon(812) 833-2166; pwilzbacher@portsofi ndiana.comPeter Laman, Port Director - Burns Harbor(219) 787-5101; plaman@portsofi ndiana.comJody Peacock, Director of Corporate Affairs(317) 233-6225; jpeacock@portsofi ndiana.comDavid Haniford, General Counsel(317) 232-9204; dhaniford@portsofi ndiana.comLaurie Peckham, Controller(317) 233-6227; lpeckham@portsofi ndiana.comLiz Folkerts, Communications Specialist(317) 232-9205; lfolkerts@portsofi ndiana.comJohn Hughes, Engineering Director(219) 787-8045; jhughes@portsofi ndiana.comWarren Fasone, Security Manager(219) 787-5056; wfasone@portsofi ndiana.com

150 W. Market St., Ste. 100, Indianapolis, IN 46204(317) 232-9200 / fx (317) 232-0137 / info@portsofi ndiana.com

www.portsofi ndiana.com www.indianalogistics.com

SUBSCRIBE TO PORTSIDE!Sign up now and receive your free copy of Portside Magazine. Register online at www.portsofi ndiana.com or contact Liz Folkerts (317) 232-9205; lfolkerts@portsofi ndiana.com

FROM THE CEOIndiana’s lakeshore businesses depend on Chicago locks............................................ 4

NEWS & NOTES ........................................................................................................ 5In Memoriam: Mount Vernon’s Art Bayer Ports of Indiana welcomes new controller

FEATURE STORYFrom loading docks to loaded bases ........................................................................ 6

FROM THE BOARD ROOM Commission approves business expansions at February meeting .............................. 8

ENVIRO•FOCUS ............................................................................................................. 9Report shows no unmanaged ballast water released in Lakes during ‘09EPA announces fi ve-year, $457 million Great Lakes Restoration Initiative

PORT REPORTSBurns Harbor: Port opens 40th international shipping season .............................. 10Mount Vernon: Last operational WWII LST ship refuels at Mount Vernon port ............. 11Jeffersonville: Port improvements keep commerce fl owing smoothly ..................... 12

FOREIGN TRADE ZONES Ports’ newest foreign-trade zone customer sees dramatic growth ..................... 13

PORTS OF INDIANA DIRECTORY .............................................................................. 14

� e Port of Indiana-Mount Vernon is the eighth largest inland port in the country based on trip ton-miles. In 2009, it handled 4.58 million tons of grain, coal, fertilizer, steel, minerals, cement and project cargo.

4 · Spring 2010 PORTSIDE MAGAZINE

Indiana’s lakeshore businesses depend on Chicago locks � e Chicago locks are vital to the Port of Indiana-Burns Harbor. Roughly one-third of the port’s shipments transit those locks which connect Lake Michigan to the Missis-sippi River system. � ey provide a critical link to the Gulf of Mexico where cargoes can be transloaded between river barges and ocean-going vessels for shipment to and from anywhere in the world. Since the St. Lawrence Seaway closes every winter, this river con-nection is the only waterway with year-round access to the port. On average, the Port of Indiana-Burns Harbor ships more than 400 barges and 700,000 tons of cargo through the locks every year. � ese shipments create more than 3,000 total jobs and $350 million in business revenues. � is fi gure does not include major northwest Indiana companies that use the locks, such as BP, ArcelorMittal and U.S. Steel. � e combined tonnage of all cargo shipments along Indiana’s lakeshore ranks that region among the 25 biggest ports in the country – 50 percent bigger than Chicago. Some people are calling for the closing of the Chicago locks in a hasty reaction to a threat of Asian carp getting into the Great Lakes. No carp – dead or alive – have been found north of the electric barriers in Romeoville, Ill., despite a recent six-week hunt for the fi sh. � ese locks are the only connection for shipping between the Great Lakes and the inland river system. A study released recently by the Illinois Chamber of Commerce found that closing the locks would result in a $4.7 billion hit to the region’s economy over the course of 20 years. � is extends far beyond the shipping industry, with the potential for fl ooding, additional costs for highway maintenance and even impacts on the region’s recreational businesses. Without access to the Mississippi River, even companies that do not ship by barge would suff er. � e slightest change in logistics costs often determine whether Indiana grain is shipped around the world or down the road. Having multiple transportation modes provides companies with options to secure the most favorable prices, and having options makes all the diff erence when there are supply-chain disruptions. Barge shipments are one of the most effi cient modes of transportation when you con-sider that one tugboat with a 15-barge tow can haul the same amount of cargo as 1,050 trucks or 240 railcars. If the average annual barge shipments moving through the Port of Indiana-Burns Harbor were switched to trucks, it would add more than 28,000 semi-trucks to one of the most highly congested highway systems in the country. Shipping by barge is also the most environmentally-friendly mode of moving goods, requiring less fuel and releasing fewer ozone emissions. It is also less expensive and safer than other modes of transportation. Closing the locks is not a viable solution. It would have a negative impact on our economy, environment and public safety. We must avoid knee-jerk reactions to the hyste-ria. Our focus must be on a comprehensive approach that provides long-term solutions to the problem at hand without creating a whole new series of complications.

FROM THE CEO

Rich CooperChief Executive Offi cer, Ports of Indiana

� e Port of Indiana-Burns Harbor ships more than 700,000 tons of cargo through the Chicago locks each year.

www.portsofindiana.com · Spring 2010 5

MOUNT VERNON, Ind. – Art “Junior” Bayer, friend of the inland waterways and founder of port company Mount Vernon Barge Service, passed away on March 3 at age 84. “� e inland waterways lost one of their biggest advocates and the Port of Indiana-Mount Vernon lost one of our best friends and strongest supporters,” said Rich Cooper, CEO of Ports of Indiana. “He had a passion like none other for the Ohio River and dedicated his life to advancing the inland waterways. His contribution is immeasurable.” Bayer always had a fascination with the river and his career on the water began when he was just 16. In 1962, he and his wife Marty started Mount Vernon Barge Service, which he owned and operated for 45 years until selling to TPG Mount Vernon Marine in 2007. Bayer lobbied for the state’s second port to be located in his hometown of Mount Vernon and his company became the port’s fi rst service tenant in 1977. Bayer was a World War II veteran who fought in the Battle of the Bulge in Gen. George Patton’s � ird Army, 5th Division, 11th Infantry Regiment and earned a Purple Heart. He was on the board of many organizations, including maritime groups such as the National Waterways Conference, Inland River Ports and Terminals, Paducah Propeller Club and the Water Resource Congress. A charter member of the Evansville Propeller Club, he was

NeWS & NoteS

named the “Maritime Person of the Year” by the International Propeller Club in 2009. Last year he also received the Distinguished Hoosier Award from the state of Indiana and the city of Mount Vernon declared Dec. 16 as Arthur “Junior” Bayer Day. “About a month before he passed away, I had the opportunity to have dinner with Art,” said Phil Wilzbacher, port director of the Port of Indiana-Mount Vernon. “Even though he and his family sold Mount Vernon Barge Service a couple of years ago, Art’s commitment to the inland river industry and his desire to help the port grow never diminished. � at evening, Art off ered his time and assistance on any project where he could be of some help. He will be missed.”

Ports of Indiana welcomes new controllerINDIANAPOLIS – From air to water, Laurie Peckham knows her way around a port’s fi nances. Peckham joined the Ports of Indiana as controller in March just off a stint as interim controller at the Indianapolis International Airport. “I am very excited to be joining the Ports of Indiana and look forward to making a contribution towards optimizing Indiana’s unique maritime port system,” Peckham said. Prior to her airport responsibilities, Peckham was the chief fi nancial offi cer at U.S. Medical Management Services in Indianapolis. She is a CPA and holds a master’s degree in accounting from the University of Colorado-Denver and a bachelor’s degree in accounting from Avila University in Kansas City, Mo. A Missouri native, Peckham lived in Denver for 17 years prior to coming to Indiana. She and her husband Greg enjoy cooking and adventure travel – she once toured the Galapagos Islands for 10 days on a 104-foot motorized sailboat. “We are pleased to welcome Laurie,” said Rich Cooper, CEO of Ports of Indiana. “Her energy, education and professional experiences have allowed her to hit the ground running. We are looking forward to the contribution that we know she will make to our accounting group and our management team.”

Wreaths adorn Mount Vernon Barge tugboats named after Art Bayer and his late wife Marty during Bayer’s funeral procession past the Ohio River.

In Memoriam: Mount Vernon’s Art Bayer

Laurie Peckham

A Ports of Indiana Publication · Spring 2007

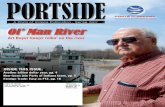

Art Bayer keeps rollin’ on the river

www.portsofindiana.com

INSIDE THIS ISSUE:Another billion dollar year, pg. 4New faces join Ports of Indiana team, pg. 5Foreign Trade: Easy as FTZ, pg. 16

Ol’ Man River

Art Bayer was a fi xture at the Port of Indiana-Mount Vernon since 1977.

6 · Spring 2010 PORTSIDE MAGAZINE

FROM LOADING DOCKS FROM LOADING DOCKS FROM LOADING DOCKS Jeffersonville port supplies infi eld dirt for region’s ball fi eldsJEFFERSONVILLE, Ind. – What does the Port of Indiana-Jeff ersonville have in common with the Cincinnati Reds, Indianapolis Indians and Fort Wayne TinCaps? Cheering fans? � e crack of the bat on a cool Midwest night? Hot dogs and Crackerjacks? Not exactly ... But the port does handle and store Diamond Pro® infi eld conditioner for delivery to numerous fi elds around the Midwest. “We use Diamond Pro simply because, in my opinion, it’s the best product line,” said Joey Stevenson, head groundskeeper for the Indianapolis Indians, a Triple-A affi liate of the Pittsburgh Pirates. “� e quality control is excellent, the products work, the color is nice and doesn’t stick to uniforms and uniformity is excellent.” Diamond Pro is a subsidiary of Dallas-based Texas Industries Inc. (TXI), a leading supplier of cement, aggregate and consumer product building materials. TXI began using expanded shale and clay as an infi eld conditioner on a Houston-area high school baseball fi eld in the late 1980s. By the mid-1990s, TXI launched Diamond Pro, which now includes a full line of infi eld conditioners, mound and home plate clay products, marking dust and other products used to maintain athletic fi elds – primarily baseball and softball. � e product moving through the port is Diamond Pro’s Red Infi eld Conditioner, also known as a vitrifi ed clay infi eld conditioner. Made from an expanded shale and clay, vitrifi ed clay infi eld conditioners are heated in a rotary kiln at over 2,000 degrees Fahrenheit. � is creates a durable, porous product that helps retain moisture on the fi eld during hot summer days.

Port company Consolidated Terminals and Logistics Co. (CTLC), a division of Consolidated Grain and Barge, handles the Diamond Pro cargo. � e clay comes into the port by rail from Colorado and goes out by truck to regional baseball and softball fi elds in Indiana, Kentucky, Ohio and Michigan. According to Kenzie Cosner, CTLC terminal & logistic manager, the product was distributed from the company’s Aurora, Ind., terminal, but Diamond Pro moved from barge transport to rail.

� e Aurora facility does not handle railcars, so the cargo moved 100 miles down the river to the company’s terminal at the Port of Indiana-Jeff ersonville, which has barge, rail and truck access. CTLC has the capacity to store 2,000 tons of the product and Cosner said they moved out roughly that amount over the course of a year. “� is location is a good one for Diamond Pro because Indiana is the ‘Crossroads of America,’” said Matt Smolek, port director at the Port of Indiana-Jeff ersonville. “� ere are also plenty of ball fi elds here in the Midwest, and from the port we can get this product wherever it needs to go by truck, rail or water.” Brad Garrison, who is responsible for sports fi elds and horticulture sales and logistics for Diamond Pro, says shipments from the port are generally in quantities of 10, 15 or, the most popular, 24 tons. Spring is the busy season with shipments moving daily. � e raw clay and shale for Red Infi eld Conditioner is mined at the production plant site in Boulder, Colo. TXI also produces the product at plants in Texas and California. When a bulk order

Diamond Pro ships its vitrifi ed clay infi eld conditioner to customers through the Port of Indiana-Jeff ersonville. Made up of shale and clay, the conditioner is fi red in a rotary kiln at over 2,000 degrees Fahrenheit, making it porous and absorbent to maintain proper moisture levels on ball fi elds. (Ballplayer photo at right courtesy of the Indianapolis Indians and Bill Gentry. Cover photo courtesy of the Indianapolis Indians.)

FROM LOADING DOCKS FROM LOADING DOCKS FROM LOADING DOCKS

Diamond Pro ships its vitrifi ed clay infi eld conditioner to customers through the Port of Indiana-Jeff ersonville. Made up of shale and clay, the conditioner is fi red in a rotary kiln at over 2,000 degrees Fahrenheit, making it porous and absorbent to maintain proper moisture levels on ball fi elds. (Ballplayer photo at right courtesy of the Indianapolis Indians and Bill Gentry.

www.portsofindiana.com · Spring 2010 7

TO LOADED BASESTO LOADED BASESTO LOADED BASESTO LOADED BASESTO LOADED BASESTO LOADED BASESTO LOADED BASESTO LOADED BASESTO LOADED BASESTO LOADED BASESTO LOADED BASESTO LOADED BASES

is placed with a distributor, delivery is organized from the nearest plant or regional stockpile, such as the facility at the Port of Indiana-Jeff ersonville. Diamond Pro has numerous distributors throughout the country ranging from companies that move other products like chemicals and fertilizers to those that perform athletic fi eld construction or renovation work. “� e Midwest has been a great area for Diamond Pro for many years.” said Garrison. “� e ability to store Red Infi eld Conditioner at regional stockpile sites enables us to eff ectively and economically serve our customers in the region.” Most fans’ experience with ball fi eld groundskeeping is limited to what they see right before each game – the crew dragging and watering the fi eld, changing a few bases and pulling the tarp if rain starts to fall. According to Stevenson, Victory Field, home of the Indianapolis Indians, takes roughly 24 man-hours of prep each day to keep it in top condition. His responsibilities include overseeing the turf and dirt surfaces, dugouts, wallpads and outside irrigation.

“We try each day to make fans feel like everything is brand new each game they come to,” Stevenson said. “Similar to umpires, if our name is mentioned it’s usually not a good thing.” Mitch McClary, director of fi eld maintenance and head groundskeeper at Fort Wayne’s Parkview Field, says the grounds crew can work 80 to 100 hour weeks during the baseball season. Parkview Field, home of the Fort Wayne TinCaps – a Class A affi liate of the San Diego Padres – hosts more than 70 TinCaps games as well as 25 to 30 high school and college games over the course of the season. � e ballpark’s schedule also features concerts, fi reworks shows and community events, such as marathon fi nishes, scout campout sleepovers and Easter egg hunts, and the fi eld has to stay in top condition throughout. “Diamond Pro’s products not only make my job easier, but they allow me to put my eff orts into other variables on the fi eld because

I know everything they provide will work beyond my expectations,” said McClary. “It takes a big load off my plate knowing their products are the best in the industry.” More information about Diamond Pro or TXI can be found at www.diamondpro.com or www.txi.com.

Left: Parkview Field, home of the Fort Wayne TinCaps, is the site of the 2010 Midwest League All-Star Game and Home Run Derby. � e TinCaps won the Midwest League Championship in 2009. (Photo courtesy of the Fort Wayne TinCaps.)

Above: � e grounds crew waters the infi eld at Victory Field, home of the Indianapolis Indians. According to Head Groundskeeper Joey Stevenson, the Indians use a combination of Diamond Pro’s vitrifi ed clay infi eld conditioner and another of the company’s clay products to manage and retain moisture in the fi eld. (Photo courtesy of the Indianapolis Indians.)

FROM LOADING DOCKS FROM LOADING DOCKS FROM LOADING DOCKS FROM LOADING DOCKS FROM LOADING DOCKS FROM LOADING DOCKS TO LOADED BASESTO LOADED BASESTO LOADED BASES

is placed with a distributor, delivery is organized from the nearest plant or regional stockpile, such as the facility at the Port of Indiana-Jeff ersonville. Diamond Pro has numerous distributors throughout the country ranging from companies that move other products like chemicals and fertilizers to those that perform athletic fi eld construction or renovation work. “� e Midwest has been a great area for Diamond Pro for many years.” said Garrison. “� e ability to store Red Infi eld Conditioner at regional stockpile sites enables us to eff ectively and economically serve our customers in the region.” Most fans’ experience with ball fi eld groundskeeping is limited to what they see right before each game – the crew dragging and watering the fi eld, changing a few bases and pulling the tarp if rain starts to fall. According to Stevenson, Victory Field, home of the Indianapolis Indians, takes roughly 24 man-hours of prep each day to keep it in top condition. His responsibilities include overseeing the turf and dirt surfaces, dugouts, wallpads and outside irrigation.

8 · Spring 2010 PORTSIDE MAGAZINE

Commission approves business expansions at February meeting

Ken Kaczmarek Marvin Ferguson Ramon Arredondo David Fagan H.C. “Bud” FarmerGreg Gibson Phil McCauley Jay Potesta

Main Terminal & General Offi ce… 4600 East 15th Avenue · Gary, Indiana 46403219-938-7020 · 800-426-1827 · Fax: 219-938-6866

Lakes and Rivers Transfer,

experts within the entire spectrum of

bulk cargo handling.

Located at � e Port of Indiana · Burns International Harbor www.jackgray.com

Lakes and Rivers Transfer, a division of Jack Gray Transport, Inc.115 Steel Dr., Portage, IN 46368

219-787-9280 Fax: 219-787-8511

INDIANAPOLIS – � e Ports of Indiana commission approved new business expansions for each of the three ports’ foreign-trade zones (FTZs) and for dock operations at the Port of Indiana-Mount Vernon during its February meeting. � e commission approved proposals to fi le applications to the U.S. Foreign-Trade Zones board under a new Alternative Site Framework (ASF) program that would essentially expand the Ports of Indiana territory to a 21-county area, and allow companies within the area to streamline the FTZ application process – reducing the time it takes to activate an FTZ from one year to 30 days. � e commission also approved an agreement for Consolidated Grain and Barge (CGB) to lease approximately three acres of land to build and operate a bulk cargo rail-to-barge loading facility at the Port of Indiana-Mount Vernon. CGB operated a similar facility on the same site from 1992 to 1997, but the company plans to enlarge the existing receiving pit, re-install conveying equipment and provide a work barge and other equipment to resume operations at the site. � e Ports of Indiana annual audit was approved at the meeting. Crowe Horwath performed the audit, which it has done since 1993.

Consolidated Grain and Barge is constructing a bulk cargo loading facility at the Mount Vernon port on three acres leased from the Ports of Indiana.

www.portsofindiana.com · Spring 2010 9

Report shows no unmanaged ballast water released in Lakes during ‘09E n v i r o • F o c u s

One-hundred percent of ocean vessels bound for the Great Lakes and St. Lawrence Seaway in 2009 received a ballast tank exam according to the annual report released by the Great Lakes Seaway Ballast Water Working Group (BWWG). Ballast water is essential for stabilizing cargo ships. Ships take on water in ballast tanks when carrying a light load to maintain balance. As cargo is loaded, the ballast water is released. Transporting ballast water from one part of the world to another can sometimes introduce tiny non-native organisms that stowaway in ballast tanks, if not properly regulated. � e goal of the BWWG is to minimize the introduction of invasive species to the Great Lakes by way of ballast water. � e bi-national group develops and coordinates enforcement and compliance eff orts. Formed in 2006, the BWWG is made up of representatives from the Canadian St. Lawrence Seaway Management Corp., Transport Canada –

Marine Safety, U.S. Coast Guard and U.S. Saint Lawrence Seaway Development Corp. “� e seaway’s ballast water regulations require the inspection of the tanks of every international vessel entering the seaway, with successful results now documented,” said Collister “Terry” Johnson, Jr., administrator of the U.S. Saint Lawrence Seaway Development Corp. “Since 2006, there have been no new reported establishments of aquatic invasive species into the seaway system.” According to the 2009 report, all 295 vessels bound for the Great Lakes via the St. Lawrence Seaway were sampled. � e 100 percent inspection rate was up from 99 percent in 2008 and 74 percent in 2007. Out of 5,576 tanks capable of carrying ballast water, 97.9 percent were in compliance with ballast water management regulations. Vessels that were not in compliance had two options: retain the ballast water or exchange the ballast in an approved zone. � ese red-fl agged ships were all later found to be in compliance – meaning no unmanaged ballast water was released into the Great Lakes in 2009. Vessels on the St. Lawrence Seaway must adhere to ballast water regulations from both the U.S. and Canada. Measures to ensure compliance include increased inspections, civil penalties and documentation requirements. � ere are also regulations for ships with “no ballast onboard” (NOBOBs) that require those vessels to do a complete ballast water exchange before entering the Great Lakes. “� is is further confi rmation of just how serious the shipping industry is about addressing this issue,” said Ports of Indiana CEO Rich Cooper. “Our industry stakeholders take great responsibility for maintaining and preserving the environmental integrity of our lakes.”

Environmental issues are very important to the Ports of Indiana.As a port authority, the Ports of Indiana has the dual responsibilityof protecting and enhancing our environment while building infrastructure that facilitates economic development.

According to a report by the Great Lakes Seaway Ballast Water Working Group, 100 percent of ships bound for the Great Lakes in 2009 received a ballast water tank exam.

� e U.S. Environmental Protection Agency (EPA) announced in February a $475 million action plan to restore and protect the Great Lakes. “We have an historic opportunity to restore and protect these waters,” EPA Administrator Lisa P. Jackson said in a release. “� is action plan outlines our strategy to protect the environmental, human health and economic interests of the millions of people who rely on the Great Lakes. We’re committed to creating a new standard of care that will leave the Great Lakes better for the next generation.” � e fi ve-year plan, spanning 2010 to 2014, outlines fi ve priority areas: • Cleanup and protection of polluted areas • Fighting invasive species • Protection of watersheds and reduction of polluted runoff • Restoration of wetlands • Carrying out accountability measures, learning initiatives, outreach and strategic partnerships President Barack Obama proposed $475 million for the Great Lakes in February of 2009. It was the nation’s largest investment in the Great Lakes in two decades. � e EPA held public meetings in the Great Lakes states with stakeholders and agencies to get feedback on the focus areas and a task force made up of representatives from 16 federal agencies developed the EPA’s action plan.

“� e Great Lakes ports commend both the Obama administration and Congress for funding the Great Lakes Restoration Initiative,” said Steven Fisher, executive director of the American Great Lakes Ports Association. “Among other things, the restoration initiative will provide critical resources to help advance the development

of ballast water treatment technology. Such technology is key to protecting the Great Lakes aquatic ecosystem while maintaining the viability of Great Lakes maritime commerce.” More information on the Great Lakes Restoration Initiative action plan can be found at www.greatlakesrestoration.us.

� e EPA’s $475 million Great Lakes Restoration Initiative focuses on several protection and rehabilitation programs including fi ghting invasive species, cleanup of polluted areas and reduction of polluted runoff .

EPA announces fi ve-year, $457 million Great Lakes Restoration Initiative

10 · Spring 2010 PORTSIDE MAGAZINE

PORTAGE, Ind. – � e Port of Indiana-Burns Harbor opened its 40th shipping season April 8 with the arrival of the fi rst international vessel – the “Iryda.” For 40 years, this Great Lakes port has provided an international connection for local businesses to reach world markets. � e fi rst ship signifi es the start of the shipping season, the arrival of vital materials for local business and the start of another work season for longshoremen, crane operators, truckers and businesses that depend on the port.

� e Iryda was built in 1999 in Chiba, Japan, located on Tokyo Bay. It brought roughly 9,000 tons of steel coils to the port from Ijmuiden, Holland. � e ship made a stop in Cleveland on its way to Burns Harbor, continued on to Milwaukee and was reloaded in Duluth, Minn., before heading back across the Atlantic Ocean.

Flagged for the Republic of Cyprus, the Iryda is manned by a crew from Poland and Capt. Andrzej Kazmierski. � e ship visited the port twice during the 2009 season, in April and October. Since 1970, the Port of Indiana-Burns Harbor has grown from a single tenant to the 29 companies that call the port home today. � e port now handles more ocean-going cargo than any other U.S. Great Lakes port and 15 percent of U.S. steel trade with Europe. � ese past 40 years have been a time of dynamic growth for

the Ports of Indiana, and as the fi rst of Indiana’s three ports, Burns Harbor is a shining example that our state is not landlocked. Indiana is just one of a few interior states that has direct connections to two global trade corridors via the Gulf of Mexico and Atlantic Ocean, and those corridors play a vital role in our state’s economy.

Walsh and Kelly receives national recognition Port company Walsh & Kelly Inc. was awarded the Diamond Achievement and Diamond Quality commendations by the National Asphalt Pavement Assoc. for its asphalt processing facility at the port, as well as the company’s four other Indiana locations in Griffi th, Lowell, South Bend and Valparaiso. � e Diamond Achievement is given to facilities exhibiting good corporate citizenship and community relations by way of appearance, operations, safety and more. � e quality commendation is focused on the quality of pavement produced and environmental practices. While the company has only been a port tenant since

2007, Walsh & Kelly has been around for over 60 years. It specializes in asphalt paving, excavation, sidewalks, curbs and pavement. For more information on the company, visit www.walshkelly.com.

Contact Peter Laman at (219) 787-5101; plaman@portsofi ndiana.com

PORT OF INDIANA – BURNS HARBOR

Port opens 40th international shipping season

� e Port of Indiana-Burns Harbor opened its 40th international shipping season on April 8 with the arrival of the ship Iryda.

� e port, shown at the far left in 1970, has grown considerably in the last 40 years, and is now home to 29 port companies.

NowNow� en

PORTREPORT

Peter LamanPort Director

www.portsofindiana.com · Spring 2010 11

MOUNT VERNON, Ind. – � e last operational World War II tank-landing ship, the “USS LST-325,” refueled at the Port of Indiana-Mount Vernon on April 20 during a weekend visit to the city’s riverfront. � is “LST” – which stands for “Landing Ship, Tanks” – is one of only two such ships preserved in the U.S. and the only one capable of sailing on its own. It was added to the National Register of Historic Places in 2009. � e ship is one of 1,051 made during World War II to carry large amounts of battle-ready vehicles, cargo and troops. LSTs were unique because they could land and unload on shores with no docks. � e LST-325 was built at the Philadelphia Navy Yard and fi rst launched in 1942. During the war, the ship made 44 trips across the English Channel and was part of the backup force on D-Day, unloading troops and vehicles at Omaha Beach in Normandy, France, on June 7, 1944. � e LST-325 was taken out of service after World War II, but was recommissioned in 1951. For 10 years it was used by Military Sea Transport Service in arctic operations for building radar outposts along the coasts of Canada and Greenland. � e ship was transferred to Greece in 1964, where it served in the Greek Navy until 1999. � e Greek Navy had plans to scrap the LST-325 when USS Ship Memorial Inc. acquired it in 2000 and sailed it 6,500 miles back to the U.S. After LST-325 was restored and confi gured to how it was during the war, it found a homeport in Evansville, Ind., the city that produced 167 LSTs during World War II – more than any other inland shipyard. � e LST-325 Memorial, which features a $3 million dock facility, opened in 2005. � e ship is open for tours at the memorial site and makes trips to other cities, including Pittsburgh this August. It was an honor to have the LST-325 dock at the port. To think this ship took part in one of the most revered occasions in our nation’s wartime history, the D-Day invasion – the chronicle of this vessel from the time of her launch in 1942 is incredible.

Port welcomes school tours On March 12, students from Yankeetown School in Newburgh, Ind., visited the port. � e fourth graders were part of teachers Teresa Kramer and Chad McAtee’s classes studying Indiana history. After watching a short cartoon about the Ports of Indiana, the group took a bus tour around the port and got a close-up look at our dock operations. Here’s a sampling of what these enterprising young minds took away from their port visit: “I saw a big barge that had fertilizer in it and those trains that had coal in it. I had a good time! We never get to see that stuff every day.” – Katy “My favorite part was when we got to see the water and crane. Maybe, you should do that more often, because you did wonderful explaining everything.” – Brianna “Is working there very hard? I was just wondering because if I don’t become an NBA player I might want to work there.” – Tyler

Port tours are available to schools. � ey are especially popular for fourth grade classes studying Indiana history. If you are interested in setting one up, please contact Sally Denning at the port offi ce.

Contact Phil Wilzbacher at (812) 838-4382; pwilzbacher@portsofi ndiana.com

PORT OF INDIANA – MOUNT VERNON

PORTREPORT

Phil WilzbacherPort Director

� e LST-325, the last of the functional World War II “Landing Ship, Tanks” class, docks at the Port of Indiana-Mount Vernon in April.

Port Director Phil Wilzbacher (right) chats with LST-325 crew while the World War II ship refuels at the Port of Indiana-Mount Vernon.

Last operational WWII LST ship refuels at Mount Vernon port

12 · Spring 2010 PORTSIDE MAGAZINE

JEFFERSONVILLE, Ind. – � e mission of the Ports of Indiana is to develop and maintain a world-class port system that grows our state’s economy. We realize that being “world-class” takes continual improvement and hence – continual investment. � is year, we plan on spending roughly $400,000 on projects that will improve the safety, effi ciency and appearance of the Port of Indiana-Jeff ersonville. � is August, we will install a new railroad crossing at the intersection of Port Road and Utica Pike. � e Ports of Indiana is partnering with the Indiana Department of Transportation on this project which will improve the safety of the intersection and comply with state mandates. � ere will be a minor detour during construction, but we plan on working with our port companies to keep the disturbance to a minimum. � is April, we paved a section of the dock located near Eagle Steel that connects Loop Road along the outer edge of the port. � is is the fi rst time this site has been paved. More than 20 years ago, the area was covered in “chip and seal,” a mix of asphalt and gravel, to prevent erosion. � e surface was only meant to be a temporary hold but held up far beyond expectations, only recently requiring an update. On our roadways, we are in the process of making sign upgrades, improving the lighting at stops and adding new signage in diff erent areas. � ese upgrades may be small, but they will have a positive impact on the appearance and safety around the port. We will also be cleaning ditches on port property over the summer months – removing silt and vegetation – to improve storm water drainage. � e port administration building is also receiving some updates with the addition of a metal roof, new conference room and three offi ces. Two of the new offi ces are available for rent, and port companies are welcome to rent the conference room for meetings on a daily basis. Please contact the port offi ce if you are interested.

Duke Energy invests in port’s infrastructure We are not the only one investing in the port’s future. On March 16, Duke Energy, electricity provider at the port, energized a new 138 KV transmission line to connect the Port of Indiana-Jeff ersonville and the Charlestown substation. Duke Energy began the $10 million transmission project in April of 2008 to improve electrical reliability in the port and surrounding area. � e project has been in Duke Energy’s growth plans for many years. � e new transmission line also runs through the nearby River Ridge Commerce Center. Duke hopes this new line will facilitate industrial expansion in the port and the commerce center for many years to come.

Contact Matt Smolek at (812) 283-9662; msmolek@portsofi ndiana.com

Port improvements keep commerce fl owing smoothly

PORT OF INDIANA – JEFFERSONVILLE

PORTREPORT

Matt SmolekPort Director

Duke Energy energized a new 138 KV transmission line through the Port of Indiana-Jeff ersonville in March.

Paving of the dock near Eagle Steel is part of $400,000 in improvements planned for the Port of Indiana-Jeff ersonville in 2010.

www.portsofindiana.com · Spring 2010 13

GARY, Ind. – When Katoen Natie joined Foreign-Trade Zone #152, the company was looking to grow its business. But to outgrow its existing facility within one year was certainly a surprise. In February 2009, Katoen Natie (KTN) became the newest addition to the Ports of Indiana’s three foreign-trade zones (FTZs). � e Gary facility is part of FTZ #152, which is based out of the Port of Indiana-Burns Harbor. KTN has six locations in the nation and three are located in an FTZ. “Since we acquired the FTZ in Gary, we have seen a huge increase in our workload and a huge increase in our inventory totals,” said Ben Swank, president of specialty chemicals for KTN. “So much so we had to secure an overfl ow warehouse. It is defi nitely a good thing.” � e 750,000-square-foot warehouse, opened in 2000, does a variety of logistics duties – including bulk handling, transloading, packaging and storage – for metals, plastics and chemicals. Katoen Natie was established in 1855 at the Port of Antwerp,

handling goods on the dock. Cargos handled included coff ee, cocoa, wool, and most of all, cotton, which gave the company its name – Katoen means “cotton” in Dutch. Today the company employs 9,300 people in 24 countries. � e third-party

logistics provider off ers a variety of services, including warehousing, packaging, distribution, quality-control and value-added services for industries as broad as retail, automotive and specialty chemicals. “Our goal for all of our facilities is always to fully maximize our

assets,” Swank said. “To do new things, to bring more value to our customers, to optimize our costs. FTZs help us do that.” � e additional warehouse space allowed KTN to double the monthly average of materials stored – now usually around 175,000 tons. According to Brandon Huynh, vice president of sales for KTN, the growth was fueled by an abrupt turnaround in domestic demand for some of its products. When domestic demand was low it caused stateside production to decrease. As the economy started to turn the corner, demand spiked suddenly and domestic producers could not keep up, which drove substantial increases in KTN’s business. Huynh expects KTN’s 2010 growth to be about fi ve percent. “We are a global company and can spread the word much faster to help promote the FTZ,” Huynh said. “We have the whole world we can deal with, not just state and local business.” FTZs are areas considered outside of U.S. Customs and Border

Patrol territory. � is allows companies within the zones to reduce or delay the payment of customs duties on foreign products brought in, making locations in the U.S. cost-competitive with overseas facilities. � e Ports of Indiana is a statewide grantee of FTZs and operates zones at each of its three ports.

Contact Jody Peacock at (317) 233-6225; jpeacock@portsofi ndiana.com

Contact David Haniford at (317) 232-9204; dhaniford@portsofi ndiana.com

Ports’ newest foreign-trade zone customer sees dramatic growth

David Haniford General Counsel

Jody PeacockDirector of Corporate Aff airs

Katoen Natie, a third-party logistics provider, off ers clients a variety of services, including warehousing, packaging and distribution. (Photo courtesy of Katoen Natie.)

Foreign-Trade Zone #152 Port of Indiana-Burns Harbor6625 S. Boundary DrivePortage, IN 46368(219) 787-8636

Foreign-Trade Zone #170Port of Indiana-Jeff ersonville5100 Port RoadJeff ersonville, IN 47130(812) 283-9662

Foreign-Trade Zone #177Port of Indiana-Mount Vernon2751 Bluff RoadMount Vernon, IN 47620(812) 838-4382

Katoen Natie employs 9,300 people in 24 countries. (Photo courtesy of Katoen Natie.)

14 · Spring 2010 PORTSIDE MAGAZINE

DirectoryListed below are companies with facilities and services at Indiana’s three ports

150 W. Market St., Suite 100, Indianapolis, IN 46204(317) 232-9200 / fx (317) 232-0137 / [email protected]

www.portsofindiana.com www.indianalogistics.com

ADS Logistics Roll & Hold Division725 George Nelson DrivePortage, IN 46368219-787-5015Transportation, warehousing, inventory management

Aqua-Land Communications Inc.60 Stagecoach RoadPortage, IN 46368219-762-1541Communications provider

ArcelorMittalBurns Harbor250 W. U.S. Highway 12Burns Harbor, IN 46304219-787-2120 Steel mill

Behr Iron & Steel6735 Waterway DrivePortage, IN 46368219-787-1020Scrap bailing operation

Beta Steel Corp.6500 S. Boundary DrivePortage, IN 46368219-787-8200Hot-rolled steel processing

Calumite Co.900 George Nelson DrivePortage, IN 46368219-787-5045Calumite processing

Cargill Inc.6640 Ship DrivePortage, IN 46368219-787-9461Grain handling and ag products

Carmeuse Lime and Stone165 Steel RoadPortage, IN 46368219-787-9190Limestone processing

Central Coil Processing501 George Nelson DrivePortage, IN 46368219-787-5000Steel processing

Federal Marine Terminals Inc.415 Salmon DrivePortage, IN 46368219-787-1017Stevedoring

Feralloy Midwest Portage6755 Waterway DrivePortage, IN 46368219-787-9698Steel processing

Feralloy Processing Co.600 George Nelson DrivePortage, IN 46368219-787-8773Steel processing

Frick Services800 Sun DrivePortage, IN 46368219-787-9475Dry/liquid bulk storage/distribution

Great Lakes Towing Co.1800 Terminal Tower, 50 Public Sq.Cleveland, OH 44113216-621-4854Tugboat, towing, barge services

HealtheACCESS Clinic6615 S. Boundary DrivePortage, IN 46368219-787-8662Occupational healthcare facility

Indiana Pickling & Processing6650 Nautical DrivePortage, IN 46368219-787-8889Steel pickling

International Longshoremen’s Assoc. Local 19696031 Melton RoadU.S. Highway 20Portage, IN 46368219-764-9715Maritime union

Lakes and Rivers Transfer4600 E. 15th Ave.Gary, IN 46403219-787-9280Bulk stevedoring, trucking

Leeco Steel1000 E. Boundary RoadPortage, IN 46368800-621-4366Steel plate service center

Levy Co.900 George Nelson DrivePortage, IN 46368219-787-8666Aggregate processing

Metro International Trade Services LLC345 Salmon DrivePortage, IN 46368219-787-8690Metals distribution and storage

Mid-Continent Coal & Coke Co.915 W. 175th St.Homewood, IL 60430708-798-1110Steel processing and distributor

Precision Strip Inc. 6720 Waterway DrivePortage, Indiana 46368219-787-1602Steel coil processing

S&L Great Lakes Transportation 1175 George Nelson DrivePortage, Indiana 46368219-764-3700Transportation

Steel Warehouse Co. Inc.6780 Waterway DrivePortage, IN 46368219-787-8887Liquid storage, handling

Tanco Terminals Inc. 400 E. Boundary DrivePortage, Indiana 46368219-787-8159Liquid storage, handling

Tube City IMS Division by Beta Steel6500 S. Boundary DrivePortage, Indiana 46368219-787-0004Transportation

United States Steel Corp. U.S. Highway 12 Portage, IN 46368 219-762-3131 Steel mill

Walsh & Kelly24358 State Road 23South Bend, IN 46614574-288-4811Asphalt processing

Agrium U.S. Inc.2501 Bluff RoadMount Vernon, IN 47620812-838-9779Fertilizer distribution

CEMEX/Kosmos Cement3301 Port East-West Road 570Mount Vernon, IN 47620812-838-3465Cement distribution

CIMBAR Performance Minerals2700 Bluff RoadMount Vernon, IN 47620812-838-5236Minerals processing

Consolidated Grain & Barge Co.Merchandising Division2801 Bluff RoadMount Vernon, IN 47620812-833-3214Grain terminal

Consolidated Grain & Barge Co.Soybean Processing DivisionP.O. Box 547Mount Vernon, IN 47620812-838-3214Soybean processing plant

Consolidated Terminals & Logistics Co.P.O. Box 547Mount Vernon, IN 47620812-833-3208General cargo stevedoring and logistics

Evansville Western Railway724 W. 3rd St.Mount Vernon, IN 47620866-812-3897Full-service railroad

Mead Johnson Nutrition/Kenco Logistic Services3101 Highway 62 EastMount Vernon, IN 47620812-833-3416Distribution and warehousing

Mount Vernon Transfer Terminal3300 Bluff RoadMount Vernon, IN 47620812-838-5532Coal transloading to barge

TPG Mount Vernon MarineMount Vernon Barge ServiceP.O. Box 607Mount Vernon, IN 47620812-838-4889Towing, fleeting, barge cleaning/repair, stevedoring

Tri-County Agronomics1711 Bluff RoadMount Vernon, IN 47620812-838-1755Liquid fertilizer, pesticide and herbicide distribution

Airgas Specialty Products5142 Port RoadJeffersonville, IN 47130812-283-6932Chemical mfg. and distribution

Chemtrusion Inc.1403 Port RoadJeffersonville, IN 47130812-280-2910Plastic resin processing

Consolidated Grain & Barge Co.5143 Port RoadJeffersonville, IN 47130812-283-9500Grain terminal, bulk stevedore, logistical services

Consolidated Terminals & Logistics Co.5143 Port RoadJeffersonville, IN 47130812-283-9500General cargo stevedoring and logistics

Cylicron Engineered Cylinders5171 Maritime RoadJeffersonville, IN 47130812-283-4600Industrial cylinder mfg.

Eagle Steel Products Inc.5150 Loop RoadJeffersonville, IN 47130812-282-4770Steel processing and distributor

FedEx Ground5153 Maritime RoadJeffersonville, IN 47130812-218-0781Parcel distribution logistics

Flexible Materials Inc.1202 Port RoadJeffersonville, IN 47130812-280-7000Wood-panel processing

Green Lines Transportation Inc.702 Port Road Jeffersonville, IN 47130812-258-3515 Transportation, common carrier

Idemitsu LubricantsAmerica Corp.701 Port RoadJeffersonville, IN 47130812-284-3300Lubrication for auto industry

Interstate Structures - A division of Mid-Park Inc.1302 Port RoadJeffersonville, IN 47130812-284-6430Steel fabrication

Jeffersonville River Terminal5130 Port RoadJeffersonville, IN 47130812-282-0471Steel galvanizing

Kasle Metal Processing5146 Maritime RoadJeffersonville, IN 47130812-282-0471Metal Processing

Kinder Morgan5146 Loop RoadJeffersonville, IN 47130812-282-4938Warehousing, stevedoring, logistics

Metals USA702 Port RoadJeffersonville, IN 47130812-288-8906Metals processing, distribution

MG Rail 5130 Port RoadJeffersonville, IN 47130812-288-8906Rail services

Mytex Polymers Inc.1403 Port RoadJeffersonville, IN 47130812-280-2900Plastic resin distribution

Namasco5150 Maritime RoadJeffersonville, IN 47130812-284-4141Steel warehousing and distribution

Nova Tube Indiana1195 Port RoadJeffersonville, IN 47130812-285-9796Steel tube mfg.

OmniSource – A division of Steel Dynamics Inc. 5134 Loop Road Jeffersonville, IN 47130812-280-2268 Scrap metal processing

Roll Forming Corp. Indiana1205 N. Access RoadJeffersonville, IN 47130812-284-0650Roll-forming of steel components, structural tubes

Steel Dynamics Inc.5134 Loop RoadJeffersonville, IN 47130812-218-1490Steel coils galvanizing

Tanco Clark Maritime5144 Utica PikeJeffersonville, IN 47130812-280-7300Liquid storage, handling

TMSi1251 Port RoadJeffersonville, IN 47130812-280-5850Distribution and warehousing

Valmont Industries Inc.1117 Brown Forman RoadJeffersonville, IN 47130812-284-5241Steel galvanizing

Vitran Express1402 Port RoadJeffersonville, IN 47130812-280-7211Freight services, distributions

Voss/Clark Industries701 Loop RoadJeffersonville, IN 47130812-283-7700Steel processing and distributor

PORT OF INDIANAMOUNT VERNON2751 Bluff Road,

Mount Vernon, IN 47620812-838-4382

PORT OF INDIANAJEFFERSONVILLE

5100 Port RoadJeffersonville, IN 47130

812-283-9662

PORT OF INDIANABURNS HARBOR

6625 S. Boundary DrivePortage, IN 46368

219-787-8636

www.portsofindiana.com · Spring 2010 15

www.portsofi ndiana.com | 800.232.PORT [7678]

INDIANA RANKS…· 1st in pass-through interstates· 1st in movement of primary metals· 3rd in number of railroads· 5th in truck tonnage· 5th in rail carloads· 7th in U.S. waterborne shipping· 15th in foreign and domestic waterborne shipping

Moving more freight per capita than any state with at least 3 million in population

Burns Harbor | Jeffersonville | Mount Vernon

PORTS OF INDIANA PRSRT STD150 W. Market St., Ste. 100 US POSTAGE PD Indianapolis, IN 46204 MUNCIE, IN PERMIT 860