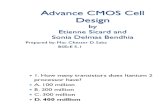

Portable cell-based biosensor system using integrated CMOS cell

Transcript of Portable cell-based biosensor system using integrated CMOS cell

Biosensors & Bioelectronics 16 (2001) 543–556

Portable cell-based biosensor system using integrated CMOScell-cartridges

B. Derek DeBusschere, Gregory T.A. Kovacs *Department of Electrical Engineering, Stanford Uni�ersity, CIS-202X, Stanford, CA 94305-4075, USA

Abstract

The use of cell-based biosensors outside of the laboratory has been limited due to many issues including preparation of thesample, maintenance of the biological environment, and integration of the electronics for data collection and analysis. This paperdescribes a system that addresses several of these issues with the development of an integrated silicon–polydimethylsiloxanecell-cartridge. The cell-cartridge contains a CMOS silicon chip that incorporates a digital interface, temperature control system,microelectrode electrophysiology sensors, and analog signal buffering. Additionally, the cell-cartridge supports two separate cellpopulations in two 10 �l sealed chambers that have independent fluidic channels for sample injection. A portable, microcontroller-based electronics system capable of monitoring the action potential (AP) activity within the cell-cartridges was also developed. TheAP activities of cardiomyocyte syncytia in the two chambers differentially responded to the flow of a control medium versus theflow of a biochemical agent. The cell-cartridges and portable electronics system were used to successfully record AP activity fromcardiomyocytes outside of the laboratory under realistic application conditions. © 2001 Elsevier Science B.V. All rights reserved.

Keywords: Cell-based biosensor; Portable biosensor; CMOS cell-cartridge

www.elsevier.com/locate/bios

1. Introduction

1.1. Moti�ation for portability

Cell-based biosensors (CBBs) utilize living cells as theprimary transducer to detect a biologically active agent.The motivation for the development of CBBs originatesfrom the desire to screen analytes for physiologicaleffects. By using intact, living cells as the sensors, agentscan be screened for functional activity without requiringspecific knowledge of the agent’s chemistry. The func-tional screening of unknown agents provides benefits inmany applications, such as pharmacology, cell biology,toxicology, and environmental monitoring (Bousse,1996; Pancrazio et al., 1999). At least two of thesepotential applications, toxin detection and environmen-tal monitoring, would benefit from the development ofa portable system. However, the difficulties that arisefrom the inclusion of a living component have previouslyconfined the use of CBBs to a laboratory environment.

1.2. Pre�ious work

Progress in the development of portable CBBshas been hampered by many issues including prepara-tion of the sample, maintenance of the biological envi-ronment, and integration of the electronics for datacollection and analysis. Additional barriers to producingsuch devices include the limited lifetime of the sensingcomponent, the difficulty of providing reliable fluidicand electrical interconnect, signal ‘noise’ due to cellularsensitivity to environmental fluctuations, and the needfor improved signal interpretation and analysistechniques.

The first published work on measurements from aportable mammalian CBB system is believed to bePancrazio et al. (1998). This system included planarmicroelectrodes in a hybrid dual-in-line 40-pin package(DIP-40) that used a 35-mm diameter petri dish (P-35)to contain the culture medium. The system electronicswere mounted in a 42×23×21 cm3 aluminum case, andthe system weighed over 12 kg including batteries (butwithout the recording equipment). The system had 36channels of preamplification that were then multiplexedto four output channels, and the total gain could

* Corresponding author. Tel.: +1-650-725-3637; fax: +1-650-725-5244.

E-mail address: [email protected] (G.T.A. Kovacs).

0956-5663/01/$ - see front matter © 2001 Elsevier Science B.V. All rights reserved.PII: S 0 9 5 6 -5663 (01 )00168 -3

B.D. DeBusschere, G.T.A. Ko�acs / Biosensors & Bioelectronics 16 (2001) 543–556544

be set at 1000× or 5000× . Temperature control wasprovided by a thin foil heater placed between theDIP-40 and the zero-insertion force (ZIF) socket of thesystem. The quiescent power consumption of the systemat an ambient temperature of 21–23 °C was 14 W,which resulted in a battery powered operational lifetimeof 2–3 h.

The design of this system had several limitations thatwould make routine field deployment difficult. The firstlimitation was the microelectrode array packaging of aDIP-40 package and a P-35 dish. Since this was not asealed fluidics system, fluid could leak out if the chipwere tilted. Additionally, the method of sample intro-duction was to open the lid of the briefcase, remove thepetri dish lid, and administer a manual bolus injectionusing a pipettor. Temperature shifts or mechanical dis-turbances created by the bolus injection could causefalse signals. The direct exposure of the culture mediumand the sample to non-sterile air also may limit thelifetime of the sensor. Since one of the goals was toutilize a high percentage of commercial off-the-shelfcomponents, the weight and power requirements werenot optimized. Despite these limitations, this systemrepresented a significant milestone in the field.

1.3. System design goals

It is believed that significant improvements in thepracticality and performance of a portable mammalianCBB system could be achieved with a custom, moreintegrated design. The integration of fluidics for sampleintroduction with a sealed chamber would allow formore robust handling and perfusion capability, whilethe integration of electronics would allow for lowerpower consumption and smaller size and weight. Sincethe projected single use nature of a CBB system after apositive exposure requires that the sensing element beeasily exchanged outside of the laboratory, the cell-car-tridge concept was developed. The overall objective isto create a cartridge that can sustain the cells in aportable package with minimal external support duringa storage period but could then be quickly connected toa monitoring system to perform experiments.

In order to achieve this objective, an integrated sili-con–polydimethylsiloxane (PDMS) cell-cartridge thatprovides electrical and fluidic interconnects and envi-ronmental control was developed (DeBusschere et al.,1998). The design goals for the cartridge included asealed cellular microenvironment, reduced power con-sumption, the inclusion of two independent cell popula-tions, and the ability to perform cartridge exchanges ina non-sterile environment. The cell-cartridge contains afunctional CMOS silicon chip that incorporates a digi-tal interface, temperature control system, microelec-trode sensors, and analog signal buffering.Additionally, the molded PDMS chamber provides a

sealed cellular environment and fluidic channels forsample injection. A portable, microcontroller-basedelectronics system that interfaces with the cell-cartridgesin order to monitor cellular action potential (AP) activ-ity was also developed.

The addition of integrated CMOS circuits to a mi-croelectrode array offers several advantages in aportable system. These advantages include lower powerconsumption through on-chip temperature regulation,reduced interconnect and size requirements throughsignal multiplexing, and reduced susceptibility to exter-nal electromagnetic interference through on-chipbuffering and amplification. In a passive microelectrodearray, the maximum number of electrodes is limited bythe area available for off-chip interconnects (typically,the size of the bondpads). A microelectrode array withintegrated CMOS multiplexers does not have this re-striction and can have significantly more signal chan-nels with fewer interconnect lines. The end result shouldbe a more compact system that uses fewer externalcomponents and less power than a system using apassive microelectrode array.

1.4. Transducer selection

Recent CBB efforts have utilized a variety of sec-ondary transduction methods in order to monitor theresponses of cells. These methods include monitoringmetabolism, fluorescent probes, motility and adhesion,electrophysiology, and neuronal network signaling pat-terns (Bousse, 1996; Pancrazio et al., 1999). For thepurposes of this work, it was decided that a planarmicroelectrode-based system that monitored the elec-trophysiology of mammalian cells would be the mostappropriate transducer approach to demonstrate aportable toxin detection system. Anchorage-dependentcells grow directly on the microelectrode sensor, result-ing in a compact cell-sensor interface that offers theadvantages of a non-invasive and potentially long-termcoupling between sensor and cell. The resulting extra-cellular signal from the cell’s spontaneous or stimulatedAP activity typically has an amplitude �0.1 mVpp,which can be amplified and filtered without requiringextensive electronics.

For the initial testing and validation of the portablesystem, the probability of recording AP activity from acell line was considered more important than any spe-cific toxin sensitivity. Therefore, cardiomyocytes, whichform a spontaneously beating syncytia with widespreadelectrical activity, were chosen as the transducer celltype. Specifically, the selected cell type was the HL-1cell line, which is a clonal cardiomyocyte cell line thatdivides and grows while expressing the phenotype of afully differentiated cardiomyocyte (Claycomb et al.,1998).

B.D. DeBusschere, G.T.A. Ko�acs / Biosensors & Bioelectronics 16 (2001) 543–556 545

1.5. O�er�iew of en�ironmental requirements

Mammalian cells require controlled environments forsurvival and in order to respond reproducibly to abiochemical agent. In most cases, it is desirable toreplicate the cell’s natural environment so that the cell’sin vitro agent response resembles its typical in vivoresponse. The major environmental properties thatmust be controlled for mammalian cell culture are theincubation temperature, the substrate material, thephysiochemical properties of the medium, and the dis-solved gas mixture (Freshney, 1994). Additionally, theculture environment should be kept aseptic (free frominvading microorganism), and all materials that contactthe media must be non-cytotoxic.

2. Methods

2.1. Cartridge physical design and modeling

In addition to the system design requirements men-tioned in Section 1, several other design constraintswere added due to practical concerns or as technologydemonstrations. The practical details ranged from con-cerns about sealing the chambers without leaching anadhesive material onto the electrodes to issues such asproviding optical access for monitoring cell growth.

The resulting cartridge design consists of a PDMSpart, a glass cover, and a silicon sensing die mountedon a printed circuit board (PCB; Fig. 1). The PDMSpart forms the fluidic channels, interconnect ports,septa, and two cell chambers over the active sensingareas. The silicon die contains microelectrodes for ex-tracellular AP measurements, a temperature controlsystem, and signal buffering and multiplexing circuits.The glass cover seals the chambers and allows the

additional use of microscopy to monitor the cells ifdesired. Electrical and fluidic connections are madesimultaneously as needles pierce septa on the cartridge,when it is plugged into a ZIF socket. The PCB acts asa rigid mounting structure and forms the electricalinterconnect from the silicon die to the ZIF socket. ThePCB also contains alignment holes for guideposts thatensure that the needles of the fluidic system contactonly the septa during cartridge removal and insertion.

The use of needles and septa for fluidic interconnectallows for a quick and simple method of fluidic inter-connect while minimizing the probability of injectingair bubbles or contaminating microorganisms into thecartridge. The cell growth chambers are elliptical inshape with axes of length 4 and 2 mm, and the mediumdepth of 1.6 mm results in a total chamber volume of10 �l. Fluid channels (1×0.5 mm2 cross-section) con-nect from the needle injection ports to the two ends ofthe elliptical growth chamber’s major axis to allow flowthrough of samples.

An early design decision made was the selection of agasket seal as the sealing method between the PDMSand the silicon substrate. A gasket seal was chosen,because it eliminates the need for an adhesive andcreates a reversible seal. An adhesive, such as an epoxy,is likely to leach onto the cell growth surface andpotentially cover the microelectrodes. The leaching ofthe adhesive could affect the cell growth area substrateproperties, block the microelectrodes from the solution,and add an additional material in contact with themedia. The small dimensions and alignment tolerancesof the chamber exacerbate this potential problem. Thesecond reason behind the selection of the gasket sealingapproach was the need for a reversible seal to allow thereplacement of the PDMS chamber part. The PDMSsepta, while functional and leak-free at low flow ratesand pressures, can only survive a limited number ofneedle piercings before failure becomes probable. In aresearch environment, the CMOS integrated circuit dieis a valuable reusable item, while the PDMS parts areeasily made and can be considered disposable.

The environmental requirements of the cells are pro-vided by a combination of silicon die temperatureregulation and PDMS gas permeability. The CMOS diecontains an integrated temperature controller thatkeeps both cell populations at the set temperature.Finite-element modeling (CFD Research Company,Huntsville, AL) predicted �0.3 °C variation in tem-perature across the cell growth area of the silicon die atthe assumed thermal loss rate of 100 mW and a flowrate of 10 �l/min. The supply of oxygen for metabolicrequirements and the removal of carbon dioxide tomaintain pH balance are allowed by the high perme-ability of PDMS. Additional finite-element modeling(Integrated Systems Engineering, San Jose, CA) pre-dicted that the oxygen partial pressure would not drop

Fig. 1. Top view of the fabricated cell-cartridge. The 6×9 mm2

silicon die is the central rectangle beneath the two elliptical cellchambers. The fluid channels, ports, and cell chamber have beenoutlined in white on the right side for clarity.

B.D. DeBusschere, G.T.A. Ko�acs / Biosensors & Bioelectronics 16 (2001) 543–556546

Fig. 2. Illustration of the fabrication cross-section showing the layersof the 12-mask CMOS cell-cartridge design. The conventional CMOSportion of the cross-section includes the two transistor types (PMOS-FET, NMOSFET), four dielectric oxide layers (FOX, LTO1, LTO2,LTO3) and two aluminum metal layers (METAL1, METAL2). Thegold electrode metal layer (GOLD) and silicon nitride passivationlayer (NITRIDE) were added to create the microelectrode sensors.

fabrication process, which are the only materials thatcome into contact with the cells, will be discussed inmore detail below. A rationale behind the two chosenfilms will be given followed by more specific processdetails.

The first additional thin-film deposited was the goldused for the microelectrode material. Gold was chosenfor its fabrication properties (ease of deposition andpatterning) and known biological compatibility. Sincethe interconnect metallization of the CMOS layers wasaluminum, a barrier layer material was required toprevent the formation of unreliable contacts at thealuminum–gold interfaces due to mismatched metal–metal solubilities (Footner et al., 1987). A 100 nmtitanium layer followed by a 100 nm titanium/tungstenlayer was deposited before the gold to form a barrierlayer that would prevent the mobile gold atoms frommigrating into the aluminum.

The second additional layer was the final dielectriclayer that forms the cell growth surface. This is a verycritical layer, as it must fulfill several tasks. First, itmust present a favorable surface for biological proteinadhesion. Additionally, it must be chemically stablewhen exposed to biological media and not leech toxinsinto the culture medium. It also needs to act as an ionbarrier to keep the mobile ions like sodium and potas-sium present in biological media from migrating downto the circuits below. Such ions could cause significantthreshold variations if they reached the transistor gateoxide, resulting in time varying offsets and other seri-ous reliability issues. Other important properties in-clude durability and strength to withstand repeatedcleaning and low deposition temperature to avoid goldroughening and further CMOS aluminum metallizationhillocking. A plasma-enhanced chemical vapor de-posited (PECVD) silicon nitride film was chosen as thedielectric, since it satisfies all of these criteria.

The standard CMOS fabrication process ended afterthe deposition of the top low temperature thermaloxide passivation layer (LTO3) above the second alu-minum metallization layer. In a conventional CMOSfabrication process, a subsequent oxide etch would thenexpose the bondpad metallization and complete thefabrication. Instead of performing a bondpad etch,LTO3 was anisotropically plasma etched to form viasthat would be used to connect between the secondaluminum layer and the electrode metal. The oxide overthe bondpads was left unetched to protect the alu-minum during a subsequent gold etch step. After strip-ping the resist, a 15 s 50:1 H2O:HF dip was done toremove residual oxide at the aluminum surface immedi-ately before sputter depositing 100 nm of Ti. This Tilayer formed a low resistance contact to the aluminumand eliminated the need for a sputter etch. The waferswere then transferred to an outside vendor (LanceGoddard Associates, Foster City, CA) for the deposi-

below 13 kPa inside the chamber under predicted max-imum consumption conditions (6000 cells/mm2 at 40amol/cell·per s).

2.2. Polydimethylsiloxane–glass chamber fabrication

The PDMS (184 Sylgard, Dow Corning, Midland,MI) was mixed per manufacturer’s specifications(base:cross-linker weight ratio of 10:1) and then pouredinto machined aluminum molds. The loaded moldswere vacuum degassed (5 kPa) for 20 min and thenbaked for 1 h at 100 °C to cure. The glass covers wereformed by cutting glass slides to size and then drillingscrew holes. The glass cover and PDMS part wereirreversibly sealed using a modified air plasma tech-nique (10 s, 100 Pa, maximum power, Plasmod barreletcher, Tegal Corporation, Sunnyvale, CA) derivedfrom one reported in Duffy et al. (1998). A repro-ducible, high-quality seal was achieved by cleaning theglass with a methanol spray followed by an isopropanolrinse. No surface treatment was required for thePDMS, although surface cleanliness was found to bevery important. After sealing, any excess PDMS leftfrom the molding process was trimmed with surgicalmicroscissors.

2.3. Integrated circuit fabrication and packaging

The integrated circuit dice of the cell-cartridge werefabricated at the Center for Integrated Systems at Stan-ford University. The entire fabrication process required12 mask layers, and an illustrative cross-section isshown in Fig. 2. The first nine mask layers were used tocreate a conventional 3 �m, p-well CMOS process thatincluded two aluminum metal layers. Three additionalmask layers were then used to pattern the final twothin-films of gold electrode metallization and siliconnitride passivation. Only the top two layers of the

B.D. DeBusschere, G.T.A. Ko�acs / Biosensors & Bioelectronics 16 (2001) 543–556 547

tion of a 100 nm thick TiW barrier layer followed by 750nm of Au electrode material. The gold-coated waferswere patterned using standard photolithographic tech-niques followed by an isotropic wet gold etch (Gold Etch,Arch Chemicals, Inc., Norwalk, CT; 90 s, room temper-ature). Continuous agitation was required during thisetch due to diffusion limited etching rate variationsbetween large gold etch areas and small areas. The samephotoresist mask was used in an anisotropic plasma etch(Drytek Systems DRIE 100; 100 sccm SF6, 100 sccmCF3Br, 20 Pa, 83 W) to remove the unetched Ti and TiWlayers.

After electrode layer patterning and resist stripping, atop passivation layer of 1 �m thick PECVD silicon nitridewas deposited at 350 °C. A near-zero-stress film wasdeposited by using a mixed frequency process thatalternated the deposition of tensile and compressivelystressed layers (STS PECVD System, Surface Technol-ogy Systems, Newport, UK; High frequency: 25 W, 4 s;Low-frequency: 25 W, 2 s; 85 Pa, 350 °C, 7000 sccm 2%SiH4, 35 sccm NH3). Following deposition of the siliconnitride, electrode openings were etched using an an-isotropic plasma etch (Drytek Systems DRIE 100; 50sccm SF6, 50 sccm C2ClF5, 20 Pa, 70 W). This step alsoremoved the silicon nitride over the bondpads, and a

subsequent final patterning step used an oxide etch toexpose the bondpad metallization.

The wafers were then diced, cleaned, and mountedusing epoxy (Supreme 42HT/T, Masterbond, Hacken-sack, NJ) in the cell-cartridge PCB package. Bondwireconnections were made between the die and PCB, andan insulative and protective epoxy (EP42LV, Master-bond) encapsulation layer was applied to the bondwires.A microcontroller-based automated test system was thenused to calibrate and test the cartridge electronics. Testedparameters included digital logic functionality, multi-plexer functionality, source follower transfer function,and temperature control system performance and offsets.

2.4. Integrated circuit design

A die microphotograph with a floorplan overlay isshown in Fig. 3. Each chamber has one large pseudo-ref-erence electrode, two stimulation electrodes, four arraysof 16 microelectrode, multiple temperature sensors, andnine 16-channel multiplexers. Digital logic, which uses athree wire serial interface, controls the multiplexers. ThePDMS gasket seal contacts the top surface of the dieexcept over the two elliptical chamber areas and over thebondpads.

Fig. 3. Microphotograph of the 6×9 mm2 die. The lightened elliptical shading was added to highlight the cell chamber surface areas. Eachchamber has four arrays (quadrants) of 16 microelectrodes each. The serial digital interface controls the 18 16-channel multiplexers.

B.D. DeBusschere, G.T.A. Ko�acs / Biosensors & Bioelectronics 16 (2001) 543–556548

Fig. 4. Circuit block diagrams of the CMOS cell-cartridge. (a) Temperature control system showing components and off-chip connections. (b)Block diagram of one microelectrode sensor channel showing the unbuffered and source-follower-buffered connections.

The goal of the temperature regulation system is tomaintain the substrate beneath the cells at a fixedtemperature even when exposed to environmental tran-sients. Analysis and modeling of the power require-ments were performed and a simple control systemapproach was chosen that locks the center of the silicondie at 37 °C. The system consists of a diode tempera-ture sensor, a control amplifier, and a NMOSFETheater connected in a closed loop system (Fig. 4(a)).The temperature control reference voltage is set off-chip, and the control loop is compensated with thethermal time constant of the silicon die. The heatersurrounds the temperature sensor at a distance of �50�m in order to maximize the bandwidth of this thermalpole. The close proximity of the sensor should alsoprevent any local overheating due to temperature gradi-ents from the heater to the feedback sensor.

FEM thermal modeling predicted a heater powerrequirement of �7 mW per 1 °C rise in temperatureabove ambient at a 10 �l/min fluid flow rate. Thesimplest approach to creating a heater is to use aNMOSFET connected from the positive to negativesupply. The advantages of this approach are simplicity,high input impedance, and all power consumed in theheater only. One disadvantage is its non-linearity, how-ever, while in the control loop, changes are small and alinear approximation is adequate. Separate power sup-ply pins were used for the heater power supply in orderto eliminate potential ‘heater noise’ in the analog signalpaths due to heater power fluctuations over time.

The primary biological sensors for the cell-cartridgeare multiple arrays of 16 gold planar microelectrodes.Both chambers have four arrays of 16 electrodes, result-ing in 128 total sensor channels on a single cartridge.Each microelectrode has a connection to two separatemultiplexers (Fig. 4(b)). One connection is direct to amultiplexer (for platinization, impedance measure-ments, and unbuffered AP measurements), while theother connection goes to a low-noise source follower,whose output is routed through the second multiplexer(for buffered AP measurements). This allows simulta-neous AP recordings from four buffered and four un-buffered microelectrodes per chamber. A largepseudo-reference/counter electrode in each chamber,�1000× the area of the sensor microelectrodes, isused to hold the solution at a near constant potentialduring the measurements.

The availability of source followers allows for on-chip signal buffering that presents an extremely highinput impedance while creating a much lower outputimpedance. However, the expense is an additional noisesource and increased power consumption. Since anysource follower power consumption assists the heatersystem, there is no net power consumption increase.PMOS source followers were chosen over NMOS fol-lowers primarily, because PMOS transistors have lowerflicker noise per unit area. Unfortunately, in the p-well,n-substrate CMOS fabrication process used, the lack ofa n-well to tie to the PMOS source results in signal

B.D. DeBusschere, G.T.A. Ko�acs / Biosensors & Bioelectronics 16 (2001) 543–556 549

attenuation. This attenuation does not necessarily resultin reduced signal-to-noise ratio (SNR) since the signaland the noise are attenuated the same amount as longas the source follower and following circuit elements donot contribute significant noise. The source followerswere designed to add �1.2 �Vrms of additional input-referred noise to the system at a bias current of 10 �A,while maintaining an input impedance of �1 G� at 1kHz. This noise level was expected to be less the lowestpredicted electrode noise (Section 2.6). The total powerconsumption of the 134 source followers on each die is�7 mW. From a system design perspective, the use ofPMOS source followers also allowed the solution to begrounded (no negative power supply available), whichis optimal for noise considerations (low impedance, lownoise reference) and for electrical field driven mobileion concerns. The thin-film gold electrode layer was leftunetched over most of the die in order to provide alight shield and to form a grounded mobile ion barrier.With both the solution and the light shield grounded,there are no electrical fields across the silicon nitridepassivation layer that might accelerate mobile ionpenetration.

Two auxiliary multiplexers provide analog channelsfor monitoring temperature and additional bufferedelectrodes across the chambers. Four auxiliary diodetemperature sensors are distributed across each cham-ber’s surface to monitor any temperature gradients dueto heating losses. The additional temperature sensorsare primarily included for initial testing and to verifythe theoretical modeling of heating losses. The addi-tional buffered electrodes, �100× the area of thesensing electrodes, were included to potentially be usedas thin-film pH sensors (Pasztor et al., 1993).

The digital logic controls the eighteen 16-channelmultiplexers through a three wire digital serial interface(LOAD, SCLK, SDIN). A fourth digital output line(SDO) can be used for cartridge detection, diagnostictesting, or to serially chain the cartridges. A digitalserial interface was chosen in order to minimize thenumber of required interconnect pins. An 8-bit com-mand word is loaded serially (least significant bit first)into an on-chip shift register and then decoded into theproper operation. The outputs of the on-chip digitallogic strobe the selected multiplexer to latch the pro-vided address. This circuitry is not clocked duringsignal recording.

2.5. Electrode design and noise

The circular sensor microelectrodes were fabricatedwith the proven successful size of 10 �m in diameter(Borkholder et al., 1998). The major tradeoff withelectrode size is spatial resolution versus increased elec-trode impedance and noise. As an electrode decreases insurface area, its electrical impedance increases; resulting

in increased thermal noise and increased signal attenua-tion due to parasitic shunt paths. Empirical measure-ments of in vitro thin film gold electrodes of similardiameters predict an electrode impedance of 500 M�/�m2 at a frequency of 1 kHz (Kovacs, 1990). Thisimpedance value scales down to an expected range of5–10 M� for the 10-�m diameter microelectrodes ofthe cell-cartridge. While this predicted electrodeimpedance will cause negligible signal attenuation dueto the �1 G� input impedance of the source followerbuffer, the resulting thermal noise will likely be thedominant noise source of the system.

One method to decrease electrode noise while main-taining spatial resolution is by increasing the surfaceroughness of the electrode. The traditional approachuses the deposition of dendritic platinum to lower theelectrode impedance by up to two orders of magnitude(Robinson, 1968). Since the dominant noise source inmicroelectrodes is thermal (Johnson) noise generated byits real impedance, a two order of magnitude reductionin the real impedance of the electrode would result inan order of magnitude of noise reduction.

The microelectrodes were spatially distributed in fourquadrants of 16 electrodes along the major axis of eachelliptical chamber. Interelectrode spacing was set at 100�m as a reasonable distance so that different electrodeswould likely be coupled to different cells and provides16 chances to obtain a good signal from each quadrant.

2.6. System electronics design

A handheld, portable microcontroller-based electron-ics system was designed and built in order to interfacewith the cell-cartridges (Fig. 5) and to create a completeAP recording system in a compact, lightweight pack-age. The unit’s dimensions are 22×12×4 cm3 and it

Fig. 5. Handheld CBB system. (a) Front view showing the cartridge,pump, display, and control buttons. (b) Back internal view showingthe electronic subsystems.

B.D. DeBusschere, G.T.A. Ko�acs / Biosensors & Bioelectronics 16 (2001) 543–556550

weighs 0.5 kg with batteries and pump installed. Thesystem includes power supplies, analog signal condi-tioning, user interface, data analysis, and fluidicssupport.

The handheld is powered by three rechargeablenickel-metal hybride batteries that provide a total of 4.4W h of power. A synchronized step-up DC–DC con-verter and three linear regulators were used to providethe separate 5 V digital, analog, and heater supplyvoltages. An onboard battery charger allows the systemto operate off external power while recharging thebatteries.

The digital system of the handheld uses a 16-bitMotorola 68HC12 (Motorola, Austin, TX) processorthat contains 32 kB of flash program memory and 1 kBof SRAM. An additional 2 kB buffer of externalSRAM was added for capturing AP waveforms. A4×20 character LCD display and three buttons areused to control the user interface, and the LCD candisplay output data as either bar graphs versus time oras numeric data. A serial 1 MB removable flash modulecan be used to record data for later analysis. Thehandheld can be connected to a computer through a57.6 kbaud RS-232 serial link for either real-time exper-iment monitoring or post-experiment analysis.

On-board analysis capability includes AP sponta-neous beat rate, positive and negative spike amplitude,and on-chip temperature monitoring. These parameterscan be displayed as a bar graph versus time or asnumeric data. An automatic routine simplifies experi-ment setup by selecting the channel with the highestmeasured SNR. The setup routine also automaticallysets the trigger levels based on each channel’s measuredroot mean square noise value. In addition to the LCDoutput, two LEDs provide a simple means of monitor-ing cellular activity by flashing at each detected AP.System parameters such as battery voltage, systempower, heater power, and temperature set pointvoltages are also monitored at rates of between 0.5 and7 Hz.

The analog portion of the handheld includes the lownoise AP amplifiers, the auxiliary channel amplifiersand ADC (temperature, system power, referencevoltage, battery voltage), the stimulation system, and apump control system. The low-noise AP amplifiersconnect to the 8-channels of buffered source followercartridge AP outputs. The AP amplifier system wasdesigned to provide a gain of 505× across a 16 Hz–3kHz bandwidth with �1 �Vrms of input referred noise(Fig. 6). This gain was a reasonable tradeoff betweenmaximum allowable input signal amplitude (10 mV forthe 5 V supply) and additional noise due to ADCquantization (10 �V LSB input referred). Each channelconsumes �5 mW of power. The 3 kHz upper band-width is set by a second-order, continuous time Besselfilter. The filtered output of the AP amplifiers goes to

Fig. 6. Schematic of the handheld AP amplifier system. The multi-plexed source follower outputs from the two chambers of the cell-car-tridge (A0–A3, B0–B3) are amplified (505× ), filtered (16 Hz–3kHz), and then digitized (10-bit).

the integrated 10-bit ADC of the microcontroller thatsamples at a rate of 12.5 kHz per channel. A multi-plexer routes one of the 4 channels per chamber to a 3.5mm speaker jack for either external data capture oraudio monitoring. Stimulation capability is provided bythe use of two serial 8-bit ADCs that can generatebipolar square waves of up to 4 Vpp. The software cancontrol the stimulation rate, amplitude, and electrode ineach chamber. The integrated heater of the cell-car-tridge is supported by providing a low-noise tempera-ture set voltage and a separate 5 V power supply. Thetemperature set point is automatically calculated fromuser-supplied cartridge calibration values of the temper-ature amplifier voltage offset and nominal temperaturesensing diode voltage. A software controlled pumpsystem can drive a dual-channel, miniature peristalticpump (P625-900, Instech Laboratories, Inc., PlymouthMeeting, PA) at flow rates between 10 and 80 �l/min ineach channel.

The performance of the handheld system analogelectronics was assessed by measuring the frequencyresponse of the amplifier channels and the input re-ferred noise. The gain and phase of the frequencyresponse was measured using the swept sine function ofa dynamic signal analyzer (SR780, Stanford ResearchSystems, Sunnyvale, CA). The input referred noise wasmeasured by grounding the inputs and measuring theFFT of the signal outputs. The resulting noise spectrumwas integrated over the system bandwidth and thendivided by the system gain to calculate the input re-ferred noise levels.

2.7. Biological protocols

Although the system was initially designed to useprimary-culture neurons or cardiomyocytes, the re-

B.D. DeBusschere, G.T.A. Ko�acs / Biosensors & Bioelectronics 16 (2001) 543–556 551

cently isolated HL-1 clonal cardiomyocyte cell line waschosen instead (Claycomb et al., 1998). The HL-1 cellline, derived from the AT-1 mouse atrial cardiomyocytetumor lineage, divides and grows to confluency in cul-ture while exhibiting the phenotype of a differentiatedcardiomyocyte. These properties allow HL-1 cells to beinjected at low plating densities and then grown to forma spontaneously beating syncytium over the electrodearray. The widespread and synchronized beating allowsfor the measurement of several parameters, such as beatrate, amplitude, and conduction velocity, with a highprobability of electrode signal coverage. The eventualhigh-density of the HL-1 was also attractive, since itwould test the environmental support capabilities of thecartridge under worst-case conditions. The toxin sensi-tivity of HL-1s, however, has not been thoroughlycharacterized.

The packaged cell-cartridges (PCB and CMOS die)were sterilized by ethanol spray and the glass-PDMSchamber was sterilized by autoclave. Both parts wereallowed to dry in a sterile hood, and then the two partswere bolted together using c0–80 nuts and bolts andan aluminum metal top that relieved the stress aroundthe drilled screw holes. A surface modification mixture(0.001% fibronectin/0.02% gelatin) was injected into thecartridges and the cartridges were transferred to anincubator. Six hours later, HL-1s were passaged andresuspended at a cell density of 1×106 cells/ml (Clay-comb et al., 1998). This cell suspension was slowlyseeded into the cartridges at a flow rate of �100�l/min through a 27-gauge needle. The cartridges werethen transferred to an incubator (37 °C, 5% CO2, 100%RH). The cells were monitored visually by microscopydaily and refed every second day by a 100 �l/mininjection of fresh culture media.2.8. Laboratory experiments

Four functional cartridges (eight chambers) wereseeded with HL-1s on Day 0 as described in Section2.8. The cells were monitored daily by microscopy toobserve proliferation and to monitor any visible beat-ing, and the cells were refed with fresh media everysecond day. The cartridges were removed from theincubator and plugged into the handheld instrument tomonitor AP activity starting on Day 3. All recordings,except for the ones using the fluidic pump system, weredone outside of a shielded faraday cage using thehandheld instrument. On Day 4, the responses of thetwo separate cell populations to temperature variationswere tested by toggling the integrated heater on and off.On Day 5, the ability to detect a differential response toa toxin was tested in one cartridge using the integratedfluidic channels. The pump of the handheld system wasused to flow the samples through the cell-cartridge. Theexperiment was repeated with a lower agent concentra-tion on Day 6 in a different cell-cartridge.

2.9. Field test experiments

Three functional cartridges and five electrically non-functional cartridges were seeded with HL-1s on Day 0as described in Section 2.8. Cells were refed with freshmedia on Day 2, allowed to incubate for 2 h, and thenmonitored for activity both by microscopy and byplugging into the handheld system. On Day 3, the cellswere transported in a portable incubator (37 °C, 5%CO2, 100% RH) (Gilchrist, submitted for publication)by car and airplane (cabin pressurized to 8000 feet)from Stanford, CA to the United States Marine Corpsbase at Twentynine Palms, CA. The cells were thensubjected to several miles of off-road driving conditionsin military vehicles to reach the desert test site. Approx-imately 12 h after starting the transport, cell-cartridgeswere removed from the portable incubator and pluggedinto the handheld system to determine if any AP activ-ity was measurable.

3. Experimental

3.1. Cartridge characterization

Thirty-seven out of 50 packaged dice were classifiedas electrically functional (defined as a working tempera-ture controller and three or more fully functional quad-rants in each chamber), resulting in a usable yield of74%. Individual electrode channel failures were ob-served to be quite rare (�1%) as typically entire quad-rants would either work or fail. Since entire quadrantswere failing, this implies a yield problem with either themultiplexers or the biasing circuitry for the sourcefollowers.

The functionality of the digital logic and analogchannels was determined by a custom-built automatedtest system. A 10 mV sinewave was driven through thedirect connection multiplexer and the amplitude of theoutput source follower was measured for proper con-nectivity and channel cross-talk. The transfer functionfor each source follower was also measured at this time.The mean of the transfer function amplitude was mea-sured as 0.855�0.15 (mean�S.D.; n=300 channels infive cartridges). This measured value was in good agree-ment with the theoretical prediction (0.87) for the bodyeffect. Channel-to-channel cross-talk between activeand off-channels was �50 dB. The digital interfaceworked at the maximum serial clock speed of theexternal microcontroller used for testing (2 MHz), al-lowing all 18 multiplexers to be loaded with separateaddresses in under 100 �s.

The noise of the source followers was measured bygrounding the direct multiplexer inputs and recordingthe output noise of the entire system. The measurednoise power of the handheld electronics (Section 3.2)

B.D. DeBusschere, G.T.A. Ko�acs / Biosensors & Bioelectronics 16 (2001) 543–556552

was subtracted from the total output noise power tocalculate the additional noise contributed by thesource followers. The measured system input-referrednoise was 2.0�0.1 �Vrms (n=8), and the calculatedsource follower noise was 1.9 �Vrms.

Electrode noise was measured by using an externalplatinum wire to ground the solution and then moni-toring the total system noise. The electrodes didprove to be the dominant noise source of the system,as the total input referred system noise increased to21�3 �Vrms (n=10). The noise power at 1 kHz wasmeasured as 200 nV/(Hz)1/2, corresponding to anequivalent Johnson noise source impedance of 2.5M�, which is in reasonable agreement with theoreti-cal values. Although some initial attempts at pla-tinization were attempted and a small reduction innoise was observed, not enough data was collected toform definite conclusions.

The temperature regulation system of the cartridgewas also tested to measure nominal diode voltages,control amplifier offsets, closed loop performance,and power consumption. The forward voltage of thetemperature sense diodes at the 2 �A bias currentwere calibrated and recorded for each cartridge. Thetemperature sensitivity of the diode-connected bipolarjunction transistor was −2.7 mV/ °C, which variedsignificantly from the standard −2.3 mV/ °C of ap–n junction. The voltage offset of the temperaturecontrol amplifier was +3.6�1.6 mV (mean�S.D.,n=25). The closed loop temperature system had anoise level of �100 �Vpp (n=10), which results inbetter than �0.1 °C regulation to the temperatureset point. The power consumption was 100 mW for a10 °C rise in cartridge temperature above ambient.

The ability of the silicon nitride passivation layerto block mobile ions appears adequate as cartridgessurvived 7 days with culture media on them withoutany measurable performance shifts. However, cell-car-tridge damage was observed in some cartridges aftercleaning for reuse. The source of this damage hasbeen identified as occurring during ethanol spraysthat contacted the bondwire encapsulation epoxy(EP42LV). A working explanation is that liquid in-duced swelling of the epoxy caused mechanicalstresses on the bondwires. Alternative encapsulationmethods are under investigation.

3.2. System electronics performance

The measured transfer function of the handheld APamplifier system closely matches that of the designwith a bandwidth of 16 Hz–3 kHz and a gain of505�1%. An input referred noise power density of11�0.6 nVrms/(Hz−1/2) (n=8 channels) was mea-sured at 1 kHz and the total noise power across thesystem bandwidth was 0.60�0.03 �Vrms (n=8). This

noise level is significantly smaller then the quantiza-tion step of the 5 V, 10-bit ADC converter (1 LSB=10 �V input referred) and can thus be considerednegligible. Simulated APs (gated 1 kHz sinewave sin-gle bursts) of 50 �Vpp were captured by the handheldsystem without any false triggering.

In order to test the handheld system before thefabrication of the cell-cartridges was completed, anadapter was created to allow the use of passive car-tridges with the handheld. Primary embryonic chickcardiomyocytes were plated on the hybrid ceramicDIP package/petri dish passive arrays as described inBorkholder et al. (1998) and then monitored by thehandheld system. The handheld system was able tocapture the AP waveforms and extract beat rate andextracellular AP amplitude, and the digitized wave-forms were transmitted to a client PC across the se-rial link (Fig. 7). The noise level on these platinized,10-�m diameter electrode channels varied from 30 to40 �Vpp (3–4 LSBs of the ADC), while the largestamplitude AP recorded was 7 mVpp. This correspondsto a �40 dB SNR.

The power consumption of the system without theheater and pump active but while processing a simu-lated 4 Hz AP stream in both chambers was 210mW. This power figure includes the DC–DC and lin-ear regulator conversion losses of the power supplies,which is estimated to be �15%. The power require-ments of the pump control system varied from 70 to160 mW as the flow rate was varied from 10 to 80�l/min. The total system power consumption with thecartridge at 10 °C above ambient and the pump run-ning at 10 �l/min was measured as 500 mW resultingin an estimated battery lifetime of 8 h.

Fig. 7. Simultaneous extracellular AP recordings from embryonic(11-day incubation) chick cardiomyocytes 2 days after plating on apassive microelectrode array (10-�m diameter platinized microelec-trodes) using the handheld system. The SNRs of several channelswere �40 dB. The time offset between channels was due to thepropagation delay across the syncytium.

B.D. DeBusschere, G.T.A. Ko�acs / Biosensors & Bioelectronics 16 (2001) 543–556 553

Fig. 8. Differential interference contrast microphotograph of HL-1cells growing in cell-cartridges over the CMOS electrode arrays 8days after seeding. The microelectrode was formed by a 10-�mdiameter passivation cut over a tombstone-shaped gold electrode pad.The electrode pad was electrically isolated from the gold light shieldby an etched moat. A via connects the electrode pad to the aluminummetallization of the source follower below. Fig. 10. Changes in spontaneous beat rate (averaged over a moving

20 s window) of chamber A and chamber B of a cell-cartridge inresponse to switching the cartridge’s heater on and off. The beat rateof both chambers responded to temperature changes. The perfor-mance of the temperature control system of the cartridge is shownwith better than �0.1 °C regulation to the 33 °C set point.

3.3. Laboratory experimental data

Growth of the HL-1 cells was monitored by mi-croscopy (Fig. 8). There was no evidence of significantcell death caused by the injection protocol. HL-1s wereobserved to adhere, proliferate, and grow to confluencywith similar morphology to that of cells cultured inpetri dishes on a similar silicon nitride substrate. ByDay 2, beating was visible in at least one chamber of allfour cartridges. On Day 3, APs were recorded fromthree of the four cartridges. The fourth cartridge faileddue to a small leak caused by misassembly. Signalswere recorded for over 5 days from two of the fourcartridges and up to 8 days after seeding (Fig. 9). The

typical amplitude of recorded signals was in the 300–400 �Vpp range with the largest observed 1.3 mVpp. ByDay 9, the HL-1s had become overconfluent such thatpulsatile activity was no longer apparent.

The response of the two separate cell populations ofa single cell-cartridge to 8 °C temperature swings isshown in Fig. 10. The cells in both chambers exhibitedan increase in spontaneous beat rate with increasedtemperature. The performance of the integrated tem-perature control system was also demonstrated with�2 s rise time and negligible overshoot. Due to acalibration error, the temperature set point of theheater system was 33 °C. This experiment was repeatedmultiple times over several days in two cell-cartridgeswith similar qualitative results.

The ability to use one cell chamber as a control andthe other as a test subject is shown in Fig. 11. The cellpopulations of both chambers responded to the infu-sion of fresh culture media at 10 �l/min by increasingtheir spontaneous beat rate. The beat rates of bothchambers eventually stabilized and a test agent waspumped (control medium spiked with 50 �M nifedipine,a calcium channel blocker; 20 �l/min) over chamber Awhile the control medium was pumped (20 �l/min) overchamber B. The AP activity of chamber A ceased whilethe activity of chamber B remained unaffected. Cham-ber B exhibited a negligible response to three consecu-tive infusions of the control medium but demonstratedits sensitivity to the agent by responding to it in the

Fig. 9. Extracellular AP waveforms recorded with the handheldsystem from HL-1s growing for 8 days in chamber A (VA2) andchamber B (VB3) of a cell-cartridge. These signals were averaged 16×and are of typical shape and amplitude (300–400 �Vpp).

B.D. DeBusschere, G.T.A. Ko�acs / Biosensors & Bioelectronics 16 (2001) 543–556554

final pumping period. The results of this experimentwere reproduced the following day in a separate cell-cartridge using a much lower agent concentration (5�M) of nifedipine.

Before replacing the cells in the commercial incuba-tor, the chambers were flushed with clean controlmedium at 80 �l/min for 2 min. No leaking around thePDMS septa was observed, and the temperature con-trol system maintained its regulation. AP activity hadrecovered in both cartridges by the following day andsignals were recorded from both cartridges throughDay 8.

3.4. Field test data

Cell signals were successfully recorded on two of thethree functional cartridges transported to TwentyninePalms. The largest signal amplitude recorded was 500�Vpp. The transportation did not have any apparenteffects on the cells shown by the good matching be-tween signals recorded in the laboratory and those 18 hlater in the field (Fig. 12).

The temperature performance of the system achievedbetter than �0.1 °C regulation around the 33 °C tem-perature set point at an ambient temperature of �15 °C with a slight breeze. The cool ambienttemperature and slight breeze resulted in a heaterpower consumption of nearly 250 mW. The entiresystem power consumption (without the pump active)was �500 mW (including DC–DC converter losses),which would result in �8 h of battery lifetime.

Fig. 12. Extracellular AP waveforms recorded from the same mi-croelectrode first in the laboratory (Vlab) and then 18 h later duringthe field-test (Vfield). No obvious changes in waveform amplitude ormorphology were observed as a result of the transportation of thecell-cartridges. These signals were not averaged.

4. Discussion

The duration of the HL-1 extracellular AP signalsrecorded in the field test and previously in lab-basedexperiments have deviated significantly from the dura-tion of reported primary cardiomyocyte signals in theliterature (Thomas et al., 1972; Israel et al., 1990;Borkholder et al., 1998). The general model for extra-cellular cardiomyocyte APs is based on a propagatingtraveling wave that occurs as the cells depolarize (Spachet al., 1973). The well-modeled biphasic signal shapetypically has a time scale on the order of 1–2 ms withthe sodium ion influx as the dominant ionic current.The HL-1 cells have reproducibly generated extracellu-lar signals with time scales on the order of 20–100 msthat have been recorded both by the cell-cartridges andby passive microelectrode arrays. These low-frequencysignals have significant signal power at frequencies be-low the 16 Hz low-frequency cutoff of the handheldinstrument. This high-pass filtering of the signal ispresumed to be the reason why the typical amplitude ofHL-1s in the cell-cartridges (300–400 �Vpp) is slightlylower than that recorded with passive microelectrodes(500 �Vpp). The front-end circuit of the handheld (Fig.6) could be modified to lower the cutoff frequencybelow 1 Hz by using different passive components if theadditional sensitivity is required.

The temperature set point used during these experi-ments was based on an incorrect calibration of thetemperature coefficient of the diode-connected BJTused as a temperature sensor. The theoretical tempera-ture coefficient of a p–n junction, −2.3 mV/ °C, wasassumed, and initially appeared to be correct, but thatassumption proved erroneous after data was taken.After careful calibration measurements of the sense

Fig. 11. Assay experiment with a cell-cartridge showing the ability touse one chamber as a control and the second as the test. Thickhorizontal lines along the x-axes mark the regions, where recordingwas stopped due to pump noise. The spontaneous beat rate (averagedover a moving 20 s window) of both chambers increased in responseto the initial flow of control media at 10 �l/min. After the beat ratesstabilized, subsequent flows of control media at 20 �l/min did notcause substantial changes in beat rate. The flow of the test agent(control media spiked with 50 �M nifedipine) at 20 �l/min eliminatedall measurable AP activity in chamber A at time=2000 s and inchamber B at time=3300 s.

B.D. DeBusschere, G.T.A. Ko�acs / Biosensors & Bioelectronics 16 (2001) 543–556 555

diode, the software code of the handheld instrumenthas been modified and the system correctly regulates ata 37 °C set point. While temperature does have bothobvious (Fig. 10) and subtle effects on AP activity, thelower temperature used during these experiments doesnot significantly affect the results or analysis presentedherein.

The field test demonstrated the ability to culture cellsin the cartridge, transport them to a remote testing site,and then record cellular activity with the handheldsystem. The recorded AP signals were similar in shapeand amplitude to those recorded in the laboratory. Thecartridge temperature regulation worked well underchallenging environmental conditions, and the tightregulation demonstrated the advantages of usingCMOS to embed the temperature control system in thecell growth substrate.

The ability of the system to act as a field deployablerecording platform for mammalian cells was demon-strated during the field test, but in order to achieve afully useful CBB, further work is required. The lack ofa portable sample preparation system prevented effortsto perform toxin assays on, e.g., drinking water orenvironmental samples during the field test. Addition-ally, a specific cell type (or group of cells) needs to bechosen to reflect the pharmacology of the physiologicsystem of interest. While the HL-1 cardiomyocytes area good cell line for testing the cell-cartridges and otherhardware, they may not be the most appropriate choicefor general-purpose use in the detection of unknowntoxins.

The performance of the cell-cartridges and handheldsystem compares favorably to the results published inPancrazio et al. (1998). The use of an integrated cell-cartridge and custom electronics resulted in a �20-foldreduction in power consumption, weight, and systemvolume while providing 3.5× the number of sensorchannels in a test chamber �1/100th the volume.

5. Conclusions

To our knowledge, this is the first demonstration of ahandheld, portable CBB, and the entire system wasvalidated by successfully recording signals in the field.It demonstrated the advantages of CMOS in achievingprecise temperature control with minimal power con-sumption, and the on-chip multiplexers allowed forchannel selection based on signal quality. The hybridglass/PDMS/silicon chamber microenvironment sup-ported the growth of a confluent syncytium of activecardiomyocytes for several days and provided a practi-cal method for transporting the cells to the field. Thecell-cartridge is the first integrated mammalian CBBthat includes fluidic interconnects, physiological sen-sors, and environmental regulation in an exchangeablepackage.

Acknowledgements

DeBusschere was partially supported by a NDSEGResearch Fellowship, and project funding was providedby the DARPA MicroFlumes (Contract Number:N66001-96-C-8631) and Tissue Based Biosensor Pro-gram (Contract Number: N66001-99-C-8642). The inte-grated circuit fabrication was performed at a NationalNanofabrication Users Network facility. The authorswould like to thank C. Kiers and T. Murphy (USMC)for facilitating the field tests, C.W. Storment for hisvaluable advice and assistance during the fabricationprocess, K.H. Gilchrist for her assistance with the cellculture, and W.C. Claycomb/Procter & Gamble forproviding access to the HL-1 cell line.

References

Borkholder, D.A., DeBusschere, B.D., Kovacs, G.T.A., 1998. Anapproach to the classification of unknown biological agents withcell based sensors. Technical Digest Solid-State Sensor and Actua-tor Workshop, Hilton Head Island, SC, USA, 8–11 June 1998,Transducer Research Foundation, 178–182.

Bousse, L., 1996. Whole cell biosensors. Sensors Actuat. B (Chem.)B34 (1–3), 270–275.

Claycomb, W.C., Lanson, N.A. Jr., Stallworth, B.S., Egeland, D.B.,Delcarpio, J.B., Bahinski, A., Izzo, N.J. Jr., 1998. HL-1 cells: acardiac muscle cell line that contracts and retains phenotypiccharacteristics of the adult cardiomyocyte. Proc. Natl. Acad. Sci.USA 95 (6), 2979–2984.

DeBusschere, B.D., Borkholder, D.A., Kovacs, G.T.A., 1998. Designof an integrated silicon-PDMS cell cartridge. Technical DigestSolid-State Sensor and Actuator Workshop, Hilton Head Island,SC, USA, 8–11 June 1998, Transducer Research Foundation,358–362.

Duffy, D.C., McDonald, J.C., Schueller, O.J.A., 1998. Rapid proto-typing of microfluidic systems in poly(dimethylsiloxane). Anal.Chem. 70 (23), 4974–4984.

Footner, P.K., Richards, B.P., Yates, R.B., 1987. Purple plague:eliminated or just forgotten? Qual. Reliabil. Int. 3 (3), 177–184.

Freshney, R.I., 1994. Culture of Animal Cells: A Manual of BasicTechnique, third ed. Wiley, New York.

Gilchrist, K.H. General-purpose, field-portable cell-based biosensorplatform, BIOS 16(7-8), 557–564.

Israel, D.A., Edell, D.J., Mark, R.G., 1990. Time delays in propaga-tion of cardiac action potential. Am. J. Physiol. 258 (6-2),H1906–H1917.

Kovacs, G.T.A., 1990. Technology development for a chronic neuralinterface. Doctoral Dissertation. Department of Electrical Engi-neering, Stanford University, Stanford, CA.

Pancrazio, J.J., Bey, P.P. Jr., Cuttino, D.S., Kusel, J.K., Borkholder,D.A., Shaffer, K.M., Kovacs, G.T.A., Stenger, D.A., 1998.Portable cell-based biosensor system for toxin detection. SensorsActuat. B (Chem.) B53 (3), 179–185.

Pancrazio, J.J., Whelan, J.P., Borkholder, D.A., Ma, W., Stenger,D.A., 1999. Development and application of cell-based biosen-sors. Ann. Biomed. Eng. 27 (6), 697–711.

Pasztor, K., Sekiguchi, A., Shimo, N., Kitamura, N., Masuhara, H.,1993. Iridium oxide-based microelectrochemical transistors for pHsensing. Sensors Actuat. B (Chem.) B12 (3), 225–230.

Robinson, D.A., 1968. The electrical properties of metal microelec-trodes. Proc. IEEE 56 (6), 1065–1071.

B.D. DeBusschere, G.T.A. Ko�acs / Biosensors & Bioelectronics 16 (2001) 543–556556

Spach, M.S., Barr, R.C., Johnson, E.A., Kootsey, J.M., 1973.Cardiac extracellular potentials analysis of complex wave formsabout the Purkinje networks in dogs. Circ. Res. 33 (4), 465–473.

Thomas, C.A.J., Springer, P.A., Loeb, G.E., Berwald Netter, Y.,Okun, L.M., 1972. A miniature micro electrode array to monitorthe bio electric activity of cultured cells. Exp. Cell Res. 74 (1),61–66.