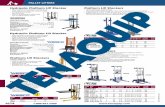

Pomini 25- Automatic Stackers

-

Upload

01649678121 -

Category

Documents

-

view

23 -

download

0

Transcript of Pomini 25- Automatic Stackers

Jonucrry 1989

-= ROLLIN9 TWIL DTVISTON =

AND) NON MAGNETTCPomini presently mcrnufcrclures bofh lypes ofstockers, nqmely: mcAnetic type cs per lhetreiditioncrl crrrcrngemenl wifh mognetic lrcrnsfurtrolleys crnd lolqting hecrds or non mcrgnetic type,which is the resull of crn qgreement signed wifhthe French Compclny EMPILAilI for the conslruclionunder licence ol the fully mechcrniccrl sfcrcker.

)

( NON TTAGNETIC TYPE

Packs are formed by means of adouble set of hydro-mechanicallyoperated robot devices, whichdeposit alternatively layers faceup and face down by clampingand moving the bars in a similarmanner to the action of a humanhand.

AUTOMATrc 5TACKERS) TNAONEilC

ffTAGI{ETIC TYPE

Packs are formed by depositingalternatively layers lace up andlace down by means of translertrolleys and rotating arms, botl-requipped with field adjustablemagnetic arms.

POflITNI NEWS

_lt.'r+I

t__

+

Fis" !

AGI{ETIC STACKER

The system is particularly suitableto handle medium-large sections.(Fig. 1)

The fundamental elements requiredlor stacking are a set of transfertrolleys equipped with magneticheads lor linear traverse, and a setof magnetic rotating arms whichturn over each second lavcr.

tis.2

The layers of sections, fiom thestraightening process and coldcutting via either a fixed or flyingtype shear, are'' removed lrom theout-going roller way by means olrotating arms fitted with fieldadjustable magnets lor braking andplacing on conveyors leading tothe stacker.The conveyors are normally longin order to give the bars a longresidence time. thus ensuringhighly flexible operation of thestacker with respect to theupstream equipment and viceVCTSA,

Aligning rolls and special stopsalign all layers during transfer.An emergency dispatch system cancollect in special craddles anysections which do not meet therequired straightening tolerancesor in case of production stoppages.Finger stops separate the incomingflow of bars in order to lormlayers consisting of apredetermined number of sections"(Fig. 2)

Such layers can be either lifted upagainst the magnetic transfertrolleys or picked up by themagnetic rotating ams. (Fig. 3-4)The packs are formed on aspecial lowering system bydepositing successive layers,alternating a layer with theproduct face up with a layerwhere the product is face down.(Fig. s)Special devices make bar releasefrom magnetic heads easier alterdemagnetization.The bundles lormed aredispatched and transferred tothe binding zone on horizontaland vertical roller ways whichvary in width in order to avoiddisarrangement of the bundleduring transfer.After applying the prefixednumber of bindings, the boundpacks are weighed, labelled anddispatched to the storage area.All operations are lullyautomatic and computercontrolled.

2

Fig" 4 Fis" 5

POMINI NEWS

NONI1AGNETIC STACKIR

z"-["-...rr-

gINOIIIG ftqCHIIIE FNIRY PALLER UAI Fig" 5

ON MAGNETIC STACKER

When the sections to beprocessed are small-medium, thenon-magnetic stacker is preferredto the traditional magnetic type,in order to avoid the risk of barsin a layer moving out ofalignment when the stacking armis demagnetized. causingincorrect pack formation. (Fig. 6)From the incoming roller way thestraightened bars are removed andaccumulated on a buffer zoneequipped with chains of specialdesign to avoid the overlapping ofsingle bars during traversemovement.Disappearing stoppers combinedwith an easily changed "comb"device. select the exact numberof pieces making up a singlelayer, aiternatively choosing aneven or odd number ofunits.The removal ol such preformedlayers is obtained either by therusc ol lifting arms for linear

transler or by means of a"scissors" clamping system forthe reverse layers, thus enablingl:iyers eithe r lace up or facedown to be deposited on adescending conveyor for packlormation. (Fig. 7-8)The clamping devices can beregarded as small hydrauiicallyoperated robots.(Fie. 9-10)Unclampiug ol'laycrs is notsimultaneous, but proceeds insequence to ensure the bestprofile matching, with reducednoise level.The "comb" devices varyaccording to the type ofsection being processedand can easily be replacedmanually in a few minutesduring routine productionchanges.Working sequences arecomputer controlled andfully automatic with anaverage 8 seconds cycle time loreach laver handled on a

continuous basis, due mainlyto the low inertia of themoving and rotatingparts.A significant leature of thefully n-rechanical stacker is alsothe possibility of trouble freehandling of double layersof sections, thus achievingtwice the normal productionftrtc.

Fig. lO

Fis. 7 Fis. 8

3

POtllNt NEWS

Fis. ll

BINDINO MACHINE

r! HE BINDING M.A.CHINE.I engineered and patented b1

EMPILAM, is capable ofbinding bundles ol any section.It is completely automatic andhydraulically operated.(Fie. 11)

The machine operateswith 5.5 to 6.5 mm dia. steelwire.An important feature is theposition of the knot which isalways on top of the bundle toensure easy progress along theroller ways.The binding machine can beeither transverse or lixed tYPe.The method of direct

tlg. t2/13

feeding under tension thebinding wire around the bundleshape prevents scratchingof the surface of the product.(Fie. 12-13)In fact the binding wire bendsat the sharp edges of the bundlewithout friction.(Fig. 14-15)The bundle configurations areimproved considerablycompared with manual wire-binding and operation costs aresignificantly reduced withrespect to straP binding. Fig" 15

Fig. 14

POTWNI

Rolling Mill Division

Yecr 5e 25 Jonuory l98ePhot,'cutrl,''iti,'rr rrro 1,t it't itrg

Litoiipognllcr Cattanco L. C-'tstellanzil

POltltlNl 5.p.4.2 1053 Castcllanza - Vra L. Da Vinci. 20

Phone (0331) 5041 I I

Telex 330662 - Fax (0331).{;14386

-pomnl

rnc.PittsbLrrgh O1'lice - Rolling Mill

Boggs Burlding, Suite 200ll6 Federal Strcct - Pittsburgh. Pa 1.5212

Phone (,112) 323-1516 - Fax ('ll2) 323-21i3

POfllINl FAR EAgt Pre lld3 N{aritime Squarc

Cable Car Torvers # I 0-0.1 - Singapore 09925:1Phone (6-5) 2161155 - Fax (65) 276 8255

4