Pharmaceutical Innovations: Academia meets Industry abstract book.pdf · homogenous solid dosage...

Transcript of Pharmaceutical Innovations: Academia meets Industry abstract book.pdf · homogenous solid dosage...

Thematic workshop of

Controlled Release Society

Italy Chapter

Pharmaceutical Innovations: Academia meets Industry

Topics

Formulation and Technological Aspects, Manufacturing, Equipments

Milan, November 3rd – 4th 2016

University of Milan, Sala Napoleonica,

Via S. Antonio 10 Milan (Italy)

Underground M3 (yellow line) Missori stop

Program

Thursday November 3rd

14.00-14.30 Registration

14.30-14.45 - Workshop Introduction

Pablo Panella, componente della Giunta di Farmindustria, Presidente e

Amministratore Delegato di AstraZeneca.

Pietro Iamartino, Andrea Gazzaniga, Bice Conti,

Chairs: Pietro Matricardi, Andrea Gazzaniga

15.00-15.35 - Salvatore Mascia - CONTINUUS Pharmaceuticals, Inc, USA. Integrated

Continuous Manufacturing of Pharmaceuticals.

15.35-16.10 - Marco Sanvito - Pall Corporation Marketing Manager BioPharmaceuticals ,

Single Use Technology: Technology Advances Enabling Integrated Continuous

BioProcessing.

16.10-16.30 - Break

16.30-17.05 - Alice Melocchi - University of Milan, Italy, 3D printing and injection

molding.

17.05-17.40 - Peter Kleinebudde - University of Dusserdolf, Germany, Encapsulation of

liquids via extrusion

17.40 – 18.00 - Franz Kainz - Evonik Nutrition & Care GmbH, From an idea to a

commercial nanomedicine: Design, Scale-up and GMP manufacturing of PLGA or Lipid-

based nano- and microparticles

18.00 – 18.30 - Rapporteur presentation and discussion

Pietro Matricardi, Andrea Gazzaniga, Paolo Caliceti

Welcome cocktail

Pharmaceutical Innovations:

Academia meets Industry

Friday November 4th

Chairs: Paolo Caliceti, Giovanna Pitarresi

9.15 – 9.40 - Nadia Tagnaouti - Drug Formulation Precision NanoSystems Inc., Canada, Discovery, Development, Scalability, Clinics - Thinking Forward with the NanoAssemblr Platform; and Enrica Chiesa Polymerix srl, University of Pavia Italy, Set-up microfluidic-assisted nanoprecipitation method intended for the loading of hydrophilic drugs into PLGA nanoparticles.

9.40-10.15 - Giuseppina Sandri - University of Pavia, Italy, Innovation in wound healing.

10,15-10,35 - AESICA Technical presentation

10.35-11.00 - Coffee break

Chairs: Giuseppe DeRosa, Paola Minghetti

11.00-11.20 - Alice Brun - ALFATEST s.r.l., Microfluidizer® processors for the

development and production of Nanotechnology products

11,20-11,55 - Francesco Puoci and Ortensia Ilaria Parisi - University of Calabria and

MACROFARM , Beyond the Article: How to Move from Scientific Research to the Product

11.55-12.30 - Flavio Fabiani - Novartis, Italy, NCE’s Development Strategy: decision

criteria for selecting traditional or enabling technologies

12.30-12.50 - PolycrystalLine technical presentation

12.50 – 14.15 - Free time for lunch

Pharmaceutical Innovations:

Academia meets Industry

Friday November 4th

Chairs: Piero Iamartino, Marco Adami

14.15 – 14.50 - Fabio Salvatore Palumbo - University of Palermo, Italy, Hyaluronic acid

based hydrogels for antibiotic and enzyme release: from academic research to industry

14.50 – 15.25 - Gino Martini – Roche, London, UK, How can Academia and Industry learn

from each other to stimulate innovation?

15.25 – 15.45 - Ilona Pescher – Meggle, Sustained release-Formulations: Synergies in

Manufacturing and Performance.

15.45 – 16.00 – Break

16.00 – 16.20 - QI technical presentation

16.20 – 16.55 - Roberto Pisano -Turin Politecnico, Turin, Italy, Lyophilization process

modeling

16.55 – 17.30 - Sergio Mauri (R&D FEDEGARI) Italy, Robotics in process

automation/present and future

17.30 – 18.00 - Rapporteur presentation and discussion

Pietro Iamartino, Paola Minghetti, Marco Adami, Giuseppe DeRosa

Pharmaceutical Innovations:

Academia meets Industry

Pharmaceutical Innovations:

Academia meets Industry

With the kind support

Organizing Committee

Dr. Piero Iamartino

Dr. Marco Adami

Prof. Andrea Gazzaniga

Prof. Paola Minghetti

Prof. Pietro Matricardi

Prof. Giuseppe De Rosa

Prof. Giovanna Pitarresi

ABSTRACTS

Pharmaceutical Innovations:

Academia meets Industry

Salvatore Mascia - CONTINUUS Pharmaceuticals, Inc, USA. Integrated Continuous

Manufacturing of Pharmaceuticals.

Integrated Continuous Manufacturing with Novel Technologies

ABSTRACT

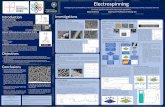

The development of novel manufacturing technologies has the potential for reaping the full benefits of

continuous manufacturing. Moreover, their integration into an end-to-end continuous manufacturing

process, including both chemical and pharmaceutical operations, i.e. integrated continuous manufacturing

(ICM), can open a new manufacturing paradigm for this industry.

Implementation of flow reactors that can handle solids; liquid-liquid membrane separations with clean-in-

place to prevent fouling; tailored continuous homogenous and heterogeneous crystallization processes

with integrated rotary vacuum filtration and drying; co-processing of polymeric excipients and API into

homogenous solid dosage forms by hot melt extrusion-molding, thin-film and electrospinning can all be

integrated into a modular, plug-and-play ICM line.

The development of an integrated control strategy for ICM is crucial to ensure release of pharmaceutical

products that conform to specifications. In addition, the development of a model that run real time during

the manufacturing process permits to continuously establish optimal operating conditions, by means of

model-based predictive control. The opportunity to design and run the process within its acceptable critical

process parameters guarantees the necessary flexibility to respond to unpredicted disturbances and

maintain quality. ICM relies on proven principles of quality by design and the use of process analytical

technologies to monitor and control the manufacturing operation.

ICM will enable “on-demand” manufacturing of pharmaceuticals: high quality medicines will be produced

quickly when needed, in a fully integrated continuous manner with automated control. This vision employs

concepts of continuous flow, end-to-end integration, a systems approach, and an integrated control

strategy.

Pharmaceutical Innovations:

Academia meets Industry

Pharmaceutical Innovations:

Academia meets Industry

Pharmaceutical Innovations:

Academia meets Industry

Pharmaceutical Innovations:

Academia meets Industry

Pharmaceutical Innovations:

Academia meets Industry

Pharmaceutical Innovations:

Academia meets Industry

Set-up microfluidic-assisted nanoprecipitation method intended for the loading of hydrophilic drugs into PLGA nanoparticles

Enrica Chiesa, Polymerix s.r.l., University of Pavia, Italy

The aim of the work was to evaluate the critical parameters in a microfluidic process in order to achieve a

more effective and easily scalable preparation technique for PLGA NPs when compared with the well-

established nanoprecipitation method, chosen as control.

At first uncapped polylactide-co-glycolide (PLGA; DLG 7525, 25 kDa) was the selected polymer and N-

Acetylcysteine (N-Ac ) was chosen as small, hydrophilic model drug because of its challenging loading

capacity into PLGA NPs, widely reported in literature.

The comparison between the two different preparation methods concerned i) NPs physical

characteristics, size and polydispersity index (PDI) detected by dynamic light scattering apparatus; ii) the

effective amount of N-acetyl cysteine (N-Ac), a small hydrophilic model drug, loaded into PLGA NPs and iii) in

vitro release profile of N-Ac from PLGA NPs.

Among microfluidic mixing devices already on the market, a chaotic advection micromixer with a

staggered herringbone architectures (SHM) was selected (Precision NanoSystem, Vancouver, Canada). PLGA

was dissolved in acetonitrile as organic solvent and aqueous Tris buffer (10 mM, pH 6.8) was chosen as non-

solvent.

A Full Factorial Design (FFD; 16, 2*4) was used to optimize the process parameters of the microfluidics

assisted nanoprecipitation method. Total flow rate (TFR), flow rate ratio (FRR), polymer concentration and

polymer:drug ratio were selected as critical factors (input factors). Particle size, encapsulation efficiency were

the outcomes considered. Moreover the NPs morphology was also evaluated through transmission electron

microscopy (TEM).

The models obtained by the statistical analysis carried out on runs of FFD allowed to identify the effect of

each factor on the specific outcome. Significant effects on NPs physical properties were highlighted for FRR

and TFR. In particular increasing TFR (from 5 to 15 mL/min) and FRR (from 1:1 to 5:1 v/v, buffer: acetonitrile)

NPs mean diameter decreased from 382.3 ±18.9 to 126.4± 10.2 for the TFR and from 889.3 ±21.6 to 126.4±

10.2 for the FRR, respectively. The effect of process parameters was also verified by TEM analysis; TEM

images revealed spherical, regular shape and low particle size for NPs obtained at high FRR while for a ratio

of 1:1 (buffer: acetonitrile) the micrographs showed NPs with irregular morphology and high particle size

confirming data recorded with dynamic light scattering. Finally, hopeful results were also obtained in terms of

N-Ac encapsulation into PLGA NPs: an optimal N-Ac encapsulation efficiency was obtained (68 %wt) by the

set-up microfluidic-based method in comparison with traditional method (21.3%).

Pharmaceutical Innovations:

Academia meets Industry

Platforms For Wound Reparation G. Sandri, M.C. Bonferoni, S. Rossi, C. Caramella, F. Ferrari

Department of Drug Sciences, University of Pavia, Pavia, 27100, Italy

Purpose: The presentation will deal with different technological approaches for the treatment of

chronic/difficult to heal wounds. The developed formulations involve dressings and scaffolds capable to

cover the lesion (with flexible area and shape), to maintain optimal hydration and to absorb excess of fluids,

to form barrier against microbial contaminations and to release antimicrobial agents. The employment of

bioactive polymers and the loading of antioxidant agents, growth factors and natural substances help to

improve the tissue reparation.

Methods: The formulations developed can be classified as follows: powders based on clay/nanocomposites

(montmorillonite/chitosan and halloysite/chitosan oligosaccharide nanocomposites), nanoemulsions (1),

dressings (sponge-like systems delivering SLN, sponge-like systems delivering micelles, beads loaded with

Manuka honey (2)), scaffolds (sponge-like systems (3) and nanofibers).

Results: All the systems developed are characterized by suitable technological (particle size, mechanical

properties, hydration capacity) and biopharmaceutical properties (bioadhesion, cytotoxicity, in vitro cell

proliferation and in vitro wound healing on normal human dermal fibroblasts).

As an example, Figure 1 reports the characterization of an alginate/chondroitin sulfate scaffold (3) by means

of optical and confocal microscopy.

Figure 1: a) macroscopic image; b) microscopic image evidencing the bubble like structure; c) CLSM image

with z-axis projection showing fibroblast growth on bubble surface.

The most promising formulations were evaluated in vivo in a murine model showing accelerated closure of

burn lesions with respect to control (untreated lesion).

Conclusions:

The good in vitro biocompatibility and the in vivo preliminary results of safety and efficacy obtained with

the proposed platforms might encourage further investigations for a possible industrial development.

a) c) b)

Pharmaceutical Innovations:

Academia meets Industry

References:

1. Bonferoni M. C., Sandri G., Rossi S., Ferrari F., Caramella C., WO2016063119(A1) 2016-04-28

2. Tenci M., Rossi S.,Bonferoni M.C., Sandri G., Boselli C.,Di Lorenzo A., Daglia M., Icaro

Cornaglia A., Gioglio L., Perotti C., Caramella C., Ferrari F., Int. J. Pharm. 509 (2016) 59-70 3. Sandri G., Bonferoni M.C., Rossi S., Ferrari F., Mori M., Cervio M., Riva F., Liakos I., Athanassiou A.,

Saporito F., Marini L., Caramella C., Exp. Opin. Drug Deliv., 12 (2015) 525-545

Pharmaceutical Innovations:

Academia meets Industry

Pharmaceutical Innovations:

Academia meets Industry

Pharmaceutical Innovations:

Academia meets Industry

Pharmaceutical Innovations:

Academia meets Industry

Title: NCE’s Development Strategy: decision criteria for selecting traditional or enabling

technologies

F.Fabiani, DP Project Leader, Novartis Pharma AG

PURPOSE: The aim of this document is to provide people involved in drug product development of oral solid dosage

forms with enough and robust scientific criteria to build a decision-support tool aimed to guide

formulation/technology selection, in particular to drive the selection of the most suitable approach for poorly

water-soluble compounds.

ABSTRACT To improve efficiency and predictability in drug product development is without doubts an important

necessity of the pharmaceutical industry.

Development of orally active poor water-soluble compounds by using enabling technologies implies higher

risk of failure, longer time to market, and higher cost of goods if compared with the dosage forms based on

conventional technologies.

Crystal modification such as salt, co-crystal and polymorph can be considered a valid alternative to the use

of enabling technologies; if a suitable form can be identified to get over solubility limited absorption, this

can enable to the development of a simple formulation based on conventional technologies.

The first decision point is then to define if the development must and/or can be dealt with the use of

conventional or enabling technologies1. Conventional technologies are defined as not intended to alter the

availability for absorption of the drug2.

For compounds requiring enabling technologies a second decision point is the definition of which among the

available technologies (solid dispersion, lipidic/surfactant systems, and crystalline nanoparticles the most

diffused) is the most appropriate for the specific API.

For a rational selection of the most suitable technology for poorly water-soluble compounds, it is necessary

as first to deeply understand the main drug characteristics affecting absorption and distribution of a drug

after oral administration, at the end its bioavailability.

The Biopharmaceutical Classification (BCS) introduced the criteria to classify a compound based on the

factors governing the rate and the extent of drug absorption from an Immediate Release Dosage Form3, 4

:

dissolution, solubility, permeability and the dose. The relationships linking the four factors are described by

the equations describing the following parameters5:

1. Dissolution Number (Dn)

2. Dose Number (D0)

3. Absorption Number (An) Only a deep and full comprehension of the above parameters will allow the selection of the most suitable

technology to be exploited for developing poorly soluble compound.

Furthermore, other technological factors such as melting point, thermal stability, solubility in organic

solvents etc., are key drivers for the technology selection.

The combination of the above described factors, both those coming from BCS that those of technological

nature, allows to define the Decision Tree for selecting the most suitable approach for developing Immediate

Release Oral Dosage Forms with particular focus for poorly water-soluble compounds.

References:

1. Branchu S., Rogueda P.G., Plumb A.P., Cook W.G. – European Journal of Pharmaceutical

Sciences. 2007 (32) 128-139

2. Leuner C., Dressman J. – European J. Pharm. Biopharm. 2000 (50) 47-60

3. Dressman J.B., Amidon G.L., Reppas C., Shah V.P. – Pharm. Res. 1998 )15) 11

Pharmaceutical Innovations:

Academia meets Industry

4. Guidance for Industry - Waiver of In Vivo Bioavailability and Bioequivalence Studies for

Immediate-Release Solid Oral Dosage Forms Based on a Biopharmaceutics Classification

System

5. Lobenberg R., Amidon G.L. – European J. Pharm. Biopharm. 2000 (50) 3-12

Pharmaceutical Innovations:

Academia meets Industry

Pharmaceutical Innovations:

Academia meets Industry

Can the principles of mass customization be applied to pharmacy? Professor Gino Martini Roche Innovation and Outreach Lead

Roche Products Ltd, 6 Falcon Way, Shire Park, Welwyn Garden City, AL7 1TW

Purpose:

With advances in Precision Medicine it is evident that current philosophy of ‘one size fits’ therapy is

becoming more and more obsolete. What is needed are methods which deliver a more bespoke method of

treatment.

This presentation will cover the challenges that clinicians, formulators, manufacturers and logistic experts

face in delivering bespoke or customized medicines to patients, with a particular emphasis on drug

combinations.

The presentation will also discover how lessons learned from FMCG sectors could be applied to Pharma and

a number of technical solutions discussed, evaluated and proposed.

Pharmaceutical Innovations:

Academia meets Industry

Quality by Design in Process Development and Scale-up for Lyophilized Parenteral Products R. Pisano, D. Fissore, and A.A. Barresi

Politecnico di Torino, Torino, Italy, 10129, Italy;

Purpose: In the last decade FDA invited pharmaceutical industry to modernize their manufacturing,

applying the most recent Process Analytical Technologies and the Quality by Design paradigm. The final

goal is the promotion of more efficient and cost-effective processes, building drug product quality within the

process rather than testing it off-line at the end of the process (1). This article shows how this goal can be

achieved in the case of freeze-drying of parenteral products. In particular, the problem of design and scale-up

is shown for a real case in industry, i.e., the freeze-drying of an antiviral drug. Examples are given of cycles

designed varying either freezing conditions or scale of equipment.

Methods: A non-steady state mathematical model, parameterized with experimentally determined heat and

mass transfer coefficients, was used to manipulate the critical process parameters within predefined limits of

the so-called “design space” (2). The overall heat transfer coefficient was determined by gravimetric

procedure, while the resistance to vapor flow through the product temperature response method. Calculations

could also recognize equipment and product constraints, and take into account model parameter uncertainty.

Mathematical modeling was finally used to expedite scale-up operations, so as to transfer lyophilization

cycles from small-scale equipment to manufacturing scale (3).

Results: Figure 1 shows an example of design space for primary drying of an antiviral drug in the case of

two freezing protocols: (a) shelf-ramped freezing and (b) shelf-ramped freezing + annealing. Annealing

promoted the formation of larger ice crystals, smaller resistance to mass transfer, and hence resulted in

enlargement of design space. It follows that the cycle with annealing can be carried out at higher shelf

temperature and pressure, reducing the drying time while still satisfying drug product quality. The cycle with

annealing was then scaled-up in the industrial equipment, replicating the same thermal history observed in

the small-scale dryer (data not shown). The scaled-up cycle needed a higher shelf temperature so as to

replicate, in the industrial unit, temperature profile and drying time observed in the lab-scale equipment. The

impact of inter-vial variability on design space, and thus on the optimized cycle, could also addressed.

Pharmaceutical Innovations:

Academia meets Industry

Figure 1. (Left-graph) Resistance to mass transfer (top) and design space (bottom) in the case of shelf-

ramped freezing with (right, top graph) and without annealing (right, bottom graph; grey curves).

Conclusions: The use of mathematical modeling is demonstrated to be very effective not only for cycle

development, but also for solving problem of process transfer. Furthermore, the use of mathematical

modeling can reduce the experimental effort required for system qualification.

References:

4. Pisano R., Fissore D., Barresi A.A., Rastelli M. AAPS PharmSciTech. 2013 (14) 1137-1149.

5. Pisano R., Fissore D., Barresi A.A. Drying Technology. 2013 (31) 905-919.

6. Pisano R., Fissore D., Barresi A.A., Brayard P., Chouvenc P., Woinet B. Pharmaceutical Development

and Technology. 2013 (18) 280-295.

Pharmaceutical Innovations:

Academia meets Industry

Robotics in Process Automation: Present and Future

Sergio Mauri (R&D FEDEGARI) Italy

Robotics have been used for industrial application since 1970’s and nowadays a massive use of

this technology for material handling, welding, assembly, dispensing and processing has become

very popular and effective. Robot arms are also extensively used in semiconductor fabs where the

personnel has been moved out from ultra clean areas to improve the manufacturing yield. Since

aseptic manufacturing is considered one of the most challenging processes in pharmaceutical

application, the use of isolation technology and RABS to separate critical areas from operators are

becoming more and more frequent within sterile facilities. The future of aseptic manufacturing is

now also linked to a different model of development more focused on personalized medicine with

small batches, short run and the highest process flexibility demand. The 2020 goal will be “cluster

tool” arrangement with a GMP stainless steel robot arms connecting different process and

technologies. Zero human intervention with gloveless isolators will be required and a thorough

grade “A” continuity will be finally achieved. The overall Sterility Assurance Level of the aseptic

process will be improved to the terminal sterilization level providing the patients a more effective

and safe drug.

Key-words: aseptic manufacturing; gloveless isolators; cluster tool; GMP robot; Grade A

continuity; sterility assurance level.

Pharmaceutical Innovations:

Academia meets Industry