Electrospinning of nanofiber

-

Upload

prem-kumar-sr -

Category

Technology

-

view

116 -

download

0

Transcript of Electrospinning of nanofiber

OUTLINE:

• Introduction• Background

Apparatus Working principle Variables Fiber alignment Applications

• Future Research• Reference

Introduction

• Nanofibers are created by a process called electrospinning.

• Electrospinning is a major way to engineer (without self-assembly) nanostructures that vary in:

▫ Fiber Diameter

▫ Mesh Size

▫ Porosity

▫ Texture

▫ Pattern Formation

Burger, Christian, et. al. Nanofibrous Materials and Their Applications. 2006. http://en.wikipedia.org/wiki/File:Taylor_cone_photo.jpg

An Example

• Take the distance between the Earth and the Moon, L, to be 384,400 km.

• It takes only x grams of a polymer fiber filament to make up this distance

• ρ = 1 g cm-3 and the fiber diameter d = 2r = 100 nm

• X = Vρ = πr2Lρ = π (50 nm)2

(380,000 km) (1 g cm-3 )

• ≈ 3 grams

Burger, Christian, et. al. Nanofibrous Materials and Their Applications. 2006.

Schematic Representation of the Reactive

Electrospinning Apparatus

• Fibers are irradiated with UV light during spinning in order to form crosslinked graft scaffolds

Electrospinning - Procedure• An electrostatic potential is applied between a

spinneret and a collector

• A fluid is slowly pumped through the spinneret.

• The fluid is usually a solution where the solvent can evaporate during the spinning.

• The droplet is held by its own surface tension at the spinneret tip, until it gets electrostatically charged.

• The polymer fluid assumes a conical shape (Taylor cone).

• When the surface tension of the fluid is overcome, the droplet becomes unstable, and a liquid jet is ejected

Burger, Christian, et. al. Nanofibrous Materials and Their Applications. 2006.

Electrospinning Polymers

• The small size between the fibers allows the capture of particles in the 100- to 300-nanometer range

• That is the same size of viruses and bacteria

• Used as air-filter: Airplanes, office, etc.

Burger, Christian, et. al. Nanofibrous Materials and Their Applications. 2006.

Polymer Solvent Concentration Potential Application

Nylon 6,6 Formic Acid 10 wt% Protective Clothing

Polyurethanes Dimethylformamide 10 wt% Protective Clothing

Polycarbonate Dichloromethane 15 wt% Sensor, Filter

Polylactic Acid Dichloromethane 14 wt% Drug Delivery System

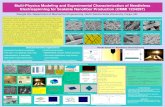

Electrospinning Variables

Burger, Christian, et. al. Nanofibrous Materials and Their Applications. 2006.

Fibre alignment

• A cylinder collector with high rotating speed

• A thin wheel with sharp edge

• An auxiliary electrode/electrical field

Improvements and Further Research

• Develop more precise electrospinning techniques▫ Mechanisms of electrospinning

Growth rates

Bending Instability

▫ Producing nanofabrics with specific mechanical properties.

▫ Creating 3-dimensional shapes Capable of being used in controlled

release of drugs.

Burger, Christian, et. al. Nanofibrous Materials and Their Applications. 2006.

Improvements and Further Research

• Optimization of parameters

▫ Intrinsic properties of solution

Polarity, surface tension of solvent,

MW of polymer, etc.

• Safety

▫ Solvents

Dangerous to health and environment

"Electrospin Nanofibers for Neural Tissue Engineering."

http://www.rsc.org/ejga/NR/2010/b9nr00243j-ga.gif

References

• [1] Abdel-Ghani MS, Davies GA. Simulation of non-woven fibre mats and the application to

coalesces. Chemical Engineering Science 1985; 40(1):117–29.

• [2] Adanur S, Liao T. Computer imulation of mechanical properties of nonwoven

geotextiles in soil-fabric interaction. Textile Res J 1998; 68:155–62.

• [3] Angadjivand SA, Schwartz MG, Eitzman PD, Jones ME. US patent, 6375886. 2002.

• [4] Athreya SA, Martin DC. Impedance spectroscopy of protein polymer modified silicon

micromachined probes. Sensors and Actuators a—Physical 1999; 72(3):203–16.

• [5] Bognitzki M, Czado W, Frese T, Schaper A, Hellwig M, Steinhart M, et al.

Nanostructured fibres via electrospinning. Adv Mater 2001; 13:70–2.

• [6] Demir MM, Yilgor I, Yilgor E, Erman B. Electrospinning of polyurethane fibres.

Polymer 2002; 43:3303–9.