SMaRT –Electrospinning (IME)€¦ · SMaRT –Electrospinning (IME) The electrospinning device...

Transcript of SMaRT –Electrospinning (IME)€¦ · SMaRT –Electrospinning (IME) The electrospinning device...

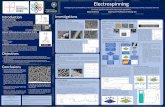

Device specifications

Due to a high voltage electric field, the electrical forces at the surface of a polymer solution or melt overcome the surface tension and cause an electrically charged jet to be ejected. After evaporation of the solvent, thin and continuous fibers with diameters of the order of nanometers are obtained.

Two electrospinning chambers from IME Technologies are available. Voltages between 0 and 25 kV can be applied. Harvard infusion pumps and specific nozzle diameters are used to control the flow rates. The inter-plate distance can be varied within the working area dimensions.

Environmental control

One of the chambers (EC-CLI) is climate-controlled with a temperature range from 20° C to 45 °C and a humidity range from 10 %RH to 90 %RH.

Typical applications

• Development of new ultra-high strength hydrogel membranes as wet wound dressing.

• Design of new morphologies of nano-structured fillers or compounds..

• Development of thin nanofibers from renewable resources.

• Electrospraying of core-shell particles with micron or nanoscale dimensions.

High speed camera

In-line observation of the spinning process is possible using an optical setup with a Photron high-speed camera and a 3D precision positioning setup.

SMaRT – Electrospinning (IME)

The electrospinning device uses electrical forces under controlled environmental conditions to produce fibers with nanometer scale diameters and high surface to volume ratios from different materials such as polymers, composites and ceramics.

ContactAnja Vananroye

[email protected]+32 16 32 23 62

http://cit.kuleuven.be/smart/