Objectives of Pletronics Quality System Providing well defined quality metrics for each department...

-

Upload

christian-hunt -

Category

Documents

-

view

213 -

download

1

Transcript of Objectives of Pletronics Quality System Providing well defined quality metrics for each department...

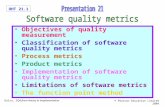

Objectives of Pletronics Quality System

Providing well defined quality metrics for each department within Pletronics, bringing problem areas into the open and undertaking a focused approach towards resolution leading to quality improvement

Methods to achieve Objectives

• Establishing metrics and standards for each department within Pletronics

•Analyzing and identifying Root Causes

•Preventing reoccurrence of Root Causes

•Formulating and executing effective Permanent Corrective Actions

•Developing accurate prediction and prevention of quality problems by insuring effective communication between departments and with Pletronics allied foundries

Improving the Quality Management System

•Maintaining certification of International Standards for the Quality Management System within Pletronics and our allied foundries

•Setting Quality targets based on Management review and quality policy, establishing actions to achieve targets and executing improvement plans

•Ensuring effective communication exists within Pletronics and between Pletronics and our allied foundries

Pletronics Component Quality• Design Engineering

– Develop product concept and specifications

– Directs the design effort

– Follows the product and makes requested changes and corrections throughout the life of the product

• Material Quality-Material Quality Engineering

– Provides procedures and criteria to insure quality of assembly components

• Process Control-Process Engineering

– Provides process flow , assembly procedures, machine setup and maintenance, process control points and continuous process improvement

• Test Engineering

– Provides measurement capability analysis to ensure testing is accurate repeatable and reproducible.

– Insures components meet required specifications

• Quality Engineering

– Provide analysis of the manufacturing process at all stages to improve the quality of the production process and its products.

– Focusing on Quality Control and Quality assurance management through the use of technology, international standards and statistical tools.

Pletronics Component Testing

• Qualification

• Production Testing

• Factory Quality Audit Testing

• Reliability Audit

Pletronics Qualification

Test Name

General Requirements HAST

ESD HBM Marking Permanency

ESD MM Mechanical Vibration

Latch-up Mechanical Shock

Characterization Physical Dimensions

Thermal specifications External Visual

HTOL Solderability

Pre/post HTOL Characterization Low Temperature Storage

Infant Mortality/EFR Leak Test

Temperature Cycle Lead Integrity

High Temperature Storage Bond Stength

Moisture Sensitivity Level Die Shear

Temperature Humidity Bias Resistance to Soldering Heat

IQC

Blank Wash

Hi-Temp

Epoxy Cure

Crystal MountEpoxy Dispense

Base Plate

Carrier Preparation

1

IncomingFreq.

B/P Maskdimension

Carrierdimension

F/P MaskDimension

OutgoingFreq.

B/P OCAP

Scrap

Coplanarity

C/M OCAP

Scrap

MisalignmentDot size

Scrap

Scrap

2

Dot Size

C/M OCAP

IC Assembly and Vacuum Bake

Bubble Leak Test

He Leak Test

Laser Mark

Seam Weld

Tuning

Pre-Tack

Pre-Age

1

3

Freq.Check

Visual Insp

Yield Check

2

Tuning OCAP

Scrap

S/W OCAP

Scrap

FC-40 Bomb

T&R

Final Test 1

AQL SampleTC

3

Ship

O defects?

DLD

100%TC

Final Test 2

Leak Test

Freq. Test

Reflow

Pass

Fail

Fail

Engineering Gate

Pletronics FQA

• Factory Quality Audit – The primary goal of factory audit testing is

to validate all units have been produced and tested to meet critical requirements.

– Test conditions are identical to the specification of the Datasheet Including, voltages, temperatures, frequency,

power, rise time, fall time and loading

Pletronics Reliability Audit• Reliability Audit

– Reliability audits are conducted to validate that a process and product maintains

the required level of quality and reliability throughout the life of the product

– The reliability environments are a subset of those used for product qualification

Test Name

Characterization

Thermal specifications

HTOL

Pre/post HTOL Characterization

Temperature Cycle

High Temperature Storage

Die Shear

Resistance to Soldering Heat

Physical Dimensions

External Visual

Solderability

Low Temperature Storage

Leak Test

Lead Integrity

Bond Stength

Typical FA Flow

Thank you.