Moeller Solutions 09 En

description

Transcript of Moeller Solutions 09 En

-

Think future. Switch to green.

www.moeller.net

Key of the Future

Automation solutions in machine and system building

SOLUTIONS 09

|

GB-MoellerSol09_RZ_V3.qxd 07.03.2005 13:38 Uhr Seite 1

-

PAGE

News . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

xSystem: Natural wood shaped to perfection . . . . . . . . . . . . . . . 8-9Flexible and open Moeller automation systems

XV400: Production of Italian delicatessen products . . . . . . . . . 10-11Transparent access from production to logistics

MFD-Titan: Text-free visualization . . . . . . . . . . . . . . . . . . . . . . . 12-13Moeller uses symbols that are understood worldwide

XC200: Modular furniture production made in Brazil . . . . . . 14-15Powerful PLC integrates the IT world

xEnergy: High availability low-voltage power distribution system for server farm . . . . . . . . . . . . . . . . . . . . . . 16-17Safe and reliable power distribution

Visualisation Designed Quickly and Reliablywith Microsoft Excel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18-19XSoft-EPAM graphical user interface for Touch Panels

Moeller Field Service: always at the ready . . . . . . . . . . . . . . . . 20-21Qualified service round the clock

Trend: The key of the future . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22Access control with biometric finger scanning

Imprint

Moeller Solutions is the Moeller customer publication for industrialautomation

Published:Moeller GmbH

Editors:Dirk Bolz ( v.i.S.d.P.)Frank SpelterIntegral Dr. SchumacherKerstin Reitz

Authors:Andreas FrevelPaul KnodelAndreas SchumacherDr. Monika SchumacherFrank Spelter

Hein-Moeller-Strae 7-1153115 BonnTel.: +49 228 602-0Fax : +49 228 602-62275E-mail: [email protected]/solutions

Copyright 2005 by Moeller GmbHKM 0213-4261GBArticle. No.: 290230

Layout: buntebrause agenturPrinted in Germany (04/05)

2

www.moeller.net/aktuell

MFD-Titan controlling a rip saw

xSystem Automation in parquet floorproduction

XSoft-EPAM uses standards

Further information is now available via the newMoeller link. Simply enterthe link of the article inyour Internet browser.

Moeller Link

GB-MoellerSol09_RZ_V3.qxd 07.03.2005 13:38 Uhr Seite 2

-

DF51 and DV51 More Flexibility for the Drive

N E W S N E W S

www.moeller.netSOLUTIONS09+ + + N E W S + + + N E W S + + + N E W S + + + N E W S + + + N E W S + + +

www.moeller.net/aktuell/s908.jsp

The new Moeller DF51 and DV51series of frequency inverters offersoptimum flexibility for drives inthe rating ranges 0.25 to 2.2 kWfor 230 V and 0.37 to 7.5 kW for400 V versions. DF51 and DV51are fully compatible with the previous DF5/DV5 series. Moeller has reduced the size ofthe inverters by 40 percent and considerably increased their functionality. Furthermore, devicescan be installed adjacent to eachother without any spacing required. These features thereforesave valuable space in the controlpanel. The new devices feature anRS 485 interface onboard with aModbus RTU protocol. An extensive range of accessories with direct type coordinationfrom cable protection up to thesinusoidal filter enables a complete electrical drive trainsystem to be created. Certificationin compliance with CE, UL, c-UL, c-Tick and the extended mains voltage range enables devices tobe used worldwide.

The DF51 is a compact device witha permanently integrated keypad,setpoint potentiometer and afunction set similar to the DV51.DF51 is suitable for a wide rangeof drive applications such as thoseinvolving pumps, fans and

conveyors. The keypad is providedwith an interface port to whichthe new communication optionsof the DV51 such as Profibus DPand CANopen can be connectedeasily.

DV51 frequency inverters have amodular design. The new optionboxes are adapted to the application at hand and are simplyplugged in or onto the device. The keypad or communicationoption boxes can be fitted directlyon the front. Pluggable controlterminals also simplify terminationon the DV51.

The new sensorless vector operation of the DV51 series simplifies and shortens commissioning. The new frequency inverters do not requireany setting. Even an Autotuningprocedure for optimising the driveis no longer necessary. The drive isimmediately operational. A higherstarting torque of more than 200percent compared to the DV5series is available already at anapproximate output frequency of1Hz. Even applications with heavystarting characteristics can betransformed to speedy drive units.In advanced applications, the analog input can likewise be usedfor torque limitation.

New parametersoftware

The new Drives-Soft3.0 parameter softwareenables users to configuredrives quickly and simply, aswell as being fully compatible with previous device series. All the parameters can be set to suit individual requirements, and areeasy to document and save. An oscilloscope function is alsoprovided which graphicallydisplays important operating dataand continuously supplies information about the status ofthe drive.

Functions at I/O level

The I/O level of the DF51 andDV51 also offers a number of newfunctions that would otherwisehave to be connected or controlledexternally with additional components. For example, thetype of activation of configurabledigital inputs and outputs can be selected. Users can assign reference value inputs to differentsources as required or link them in mathematical operations. Bus, terminal or keypad controlcan be activated via digital inputs,whilst the digital outputs can alsobe programmed flexibly.

Keypad (optional)

Basic unit

Communication module(optional)

3

GB-MoellerSol09_RZ_V3.qxd 07.03.2005 13:38 Uhr Seite 3

-

N E W S + + + N E W S + + + N E W S + + + N E W S + + + N E W S + + + N E W S + + + N E W S + + + N E W

4

www.moeller.net/aktuell/s911.jsp

Moeller's XVH300 series touchpanels were specially developedto support cost efficiency inmachine building and industrialautomation: XVH340 panels withinfra-red touch technology andXVH330 panels with resistivetouch technology are designed as

optimised low budget systems,and can be used as HMI devicesfor data management and visualization. The touch panelscome with integrated CANopen,Ethernet (10/100 Mbit) and USBslave on board for communication. The systems

feature a RISC processor (32-bit,200 MHz) and a 64 MB memorywhich ensures sufficient memorycapacity.

A high level of flexibility is alsooffered thanks to the use ofremovable CompactFlash cards.CompactFlash cards enable usersto adapt the memory capacity fordata (such as project or recipedata) to actual requirements, andselect the optimum visualizationsystem for the application. Theuser is free to choose betweenthe XSoft GALILEO graphical visualization tool and the XSoftEPAM software that runs as anMS Excel plug-in. The Compact-Flash card can simply be changedas required.

Thanks to their compact designand minimum mounting depth,touch panels can also be used in

machines with small dimensions.The devices have a rugged designand the front panel is protectedto IP 65.

The touch panels have beendeveloped for international markets and industrial applications, and come with CE, ZL/CSA, CCC and EX22 approvals.

A free demo version of the XSoft GALILEO and XSoft EPAM visualization tools can be downloaded from the Moellerwebsite.

The XSoft EasyPageMachine(EPAM) visualization tool is speciallydesigned for graphical operatorguidance using touch screens, andenables the visualization to be configured easily with parameterswithout the need for complicatedprogramming. The integratedRemoteControl client/server function is provided for users requiring mobile applications. The current screen content of thelocal visualization is compressedand transferred with a minimumdata volume via wireless LAN to the remote client. In this way, anyapplication created with EPAM isalso available as a mobile application without the need forany additional project design.

The RemoteControl client can berun on several different standarddevices using Windows Pocket PC2003, WindowsCE and Windows.The Pocket PC iPAQ from Hewlett-Packard, for example, can be used

as a mobile visualization device forall Moeller HMI-PLCs of theXVC/XCC-601 and MC-HPG200/300series.

The wireless communication to theiPAQ is implemented using a standard WLAN access point. The integrated password protectionprevents unauthorised access to the system.

A scroll function is also provided for screens with higher resolutions.A JAVA client is used for calling inweb browsers.

www.moeller.net/aktuell/s912.jsp

Mobile Visualisation with XSoft-EPAM RemoteControl Client

New Moeller XVH300 Touch Panels Offer Outstanding CostEfficiency: High Performance at an Affordable Price

GB-MoellerSol09_RZ_V3.qxd 07.03.2005 13:38 Uhr Seite 4

-

LSE-Titan Analog Electronic Position Switches

www.moeller.netSOLUTIONS09E W S + + + N E W S + + + N E W S + + + N E W S + + + N E W S + + + N E W S + + + N E W S + + + N E W S

5

EASY-SOFT: New Functions for easy800 and MFD-Titan

The software for Moeller's easycontrol relay and MFD-Titanmulti-function display is nowavailable in a new version. EASY-SOFT now comes in twoversions: EASY-SOFT-BASIC foreasy500 and easy700, and EASY-SOFT-PRO (Professional) for alleasy400, 500, 600, 700, 800 devices and MFD-Titan. This therefore provides one software for all easy devices,which also comes with an integrated OPC server and a newlabel editor. This last tool is used

for customising the laserinscription of labels on

the devices. EASY-SOFT can likewisesimulate all devicefunctions on the PC.

The new and extensive functions

of easy800 andMFD-Titan can be

programmed and assig-ned parameters using EASY-SOFT-PRO. easy800 and

MFD-Titan now support 13 languages with specific nationalcodes and appropriate fonts. The character sets includeWestern and Central Europeanfonts, as well as Cyrillic.

easy800 can now control steppermotors: The pulse output is usedfor controlling stepper motorsand power modules directly. The serial log output functionblock allows you to output messages for which the data isoutput serially via the

appropriate interface. In the Button Editor, a special functionhas been added to the four Pbuttons on the MFD-Titan: the cursor buttons are assignedto the variables P1 to P4 and canbe used like in the Status display.The P button function is anexclusive function and thus haspriority over any other buttonfunctions. The P buttons canthus be used for manually actuated functions (On/Off,Start/Stop) and other operatorfunctions. The new passwordconcept enables the display of aparticular screen to be protectedby a password.

MFD-Titan now supports Terminal mode, in which userscan easily access all stations onthe easy.NET. Access to networkstations is thus possible from anystation and is not reserved to afew particular stations.

MFD-Titan also supports newvisualization functions and

screen elements, such as yearand 7-day time switch entry,timing relay value entry anddisplay, date and time entry. Thismakes it possible to set the timeswitches from the visualizationapplication. The entry values arethen stored permanently in theprogram (FRAM). The bar graphfunction is also new, and provides a display element thatcan represent a value in the formof a freely scalable bar. Thedisplay direction can also be set, as well as a flash function to indicate out of range values.EASY-SOFT-PRO also supportsother programmable visualization functions such aslatching buttons and interlockedbutton fields, message bitmaps,rolling text display, running textand screen menues.

www.moeller.net/aktuell/s909.jsp

www.moeller.net/aktuell/s910.jsp

LS-Titan is the name of Moeller'snew generation of tried andtested position switches. The LSE(Limit Switch Electronic) positionswitch stands out as the first ofits kind in the world, with LSE-AI(4-20mA) and LSE-AU (0-10V)analog position switches offeringyet another advancement in thisfield. The actual position of a fluegas flap or an actuator can nowbe monitored continuously forthe first time. The position data isconverted to an analog current orvoltage value and continuouslyfed to the automation environment. Even the data ofobjects with different sizes orthicknesses such as brake blockscan now be monitored and processed further.

Simple speed-based controlsystems for fan motors or

ventilation systems indicate theextent of the air flap opening(e.g. 25, 50 and 75 percent), thusallowing savings in energy andmaterials. The analog positionswitches also feature a diagnostics output for additionaldata processing. This ensures thata safe operating state can bemonitored and evaluated at anytime. The position switch also hasa self-test function. Outputs Q1and Q2 are continuously testedfor overloads, short-circuits to 0Vand short-circuits to +Ue.

Like the electromechanical posi-tion switches, LSE-Titan positionswitches ensure safety category 3or 4 of the EN 954-1 standard formachine safety when configuredas a redundant system. All devices are thus suitable forsafety applications that are used

for the protection of persons or processes.

Control circuit devices from theRMQ-Titan range can be usedin combination with the LS-Titan position switches, the entire unit at least offeringprotection to IP66 frontand rear.

GB-MoellerSol09_RZ_V3.qxd 07.03.2005 13:38 Uhr Seite 5

-

N E W S + + + N E W S + + + N E W S + + + N E W S + + + N E W S + + + N E W S + + + N E W S + + + N E W

6

Contactors up to 75 kW Create Space in the Control Panel

The new xStart contactors up to 75 kW represent a seamless expansion of the contactor rangeup to 15 kW that has been available since June 2004. Considerably reduced dimensionsand an extremely low sealingpower of 0.5 W on DC contactorsprovide a number of benefits.

The particularly narrow 55 mmmounting width of contactors upto 65 A saves valuable space in thecontrol panel. The mechanicalinterlock mostly used with Moeller's reversing starter combinations has no additionalspace requirements. This patentedand smart solution consists of a plastic sphere. It is simply inserted

in the specially designed recesseson the side of both contactorswhere it can reliably prevent simultaneous switching. A lateralclearance between the contactors isnot required, and the contactorscan be mounted and wired directlynext to each other.

DC contactors up to 65 A normallyhave a deeper construction thanAC contactors. However, thedimensions of xStart DC and ACversions are identical thanks toelectronically supported drives. If aseries machine manufacturer usesdifferent control voltages, checkingthe cabinet layout is no longernecessary, and DC contactors canbe positioned on the mounting rail

or mounting plate just like the ACversions.

In panel building the permissiblepacking density is limited by theheat dissipation. Solutions that aremechanically possible cannot therefore be implemented due tothe high temperatures involved.The extremely low sealing power of 0.5 W for Moeller DC contactorsnow offers options that werepreviously impossible.

Contactors from 185 A to 500 Aas Inexpensive Standard Version

In addition to the popular premium version of its DILM185to DILM500 contactors, Moeller is now offering an affordablestandard version DILM185-S toDILM500-S: In the list price tenpercent cheaper, with the same

specifications for mechanical lifespan and maximum switchingfrequency. The offer is an attractive alternative for manyapplications. DILM...-S types arecontrolled in the conventionalway. The control circuit terminalsare available either as screw orspring-loaded terminals.

Toolless Combination of DIUL andSDAINL up to 16 AMoeller has drastically reducedthe wiring costs on its reversingand star-delta combinations,thanks to the combination plugconnector design. Sockets havebeen added to Moeller's DIL contactor series up to 16 A at noextra cost, enabling users to simply plug in the connection elements. Time consuming andcostly operations such as cuttingcables to length, cable stripping,preparing cable ends, labellingand screwing to a defined torqueare thus no longer necessary. The 21 electrical connectionpoints between the mains, starand delta contactor now onlyrequire a visual inspection. Measurements with the test probes of measuring devices can now be carried out at a latertime without having to removethe connection elements.

www.moeller.net/aktuell/s913.jsp

www.moeller.net/aktuell/s917.jsp

www.moeller.net/aktuell/s918.jsp

GB-MoellerSol09_RZ_V3.qxd 07.03.2005 13:38 Uhr Seite 6

-

www.moeller.netSOLUTIONS09E W S + + + N E W S + + + N E W S + + + N E W S + + + N E W S + + + N E W S + + + N E W S + + + N E W S

www.moeller.net/aktuell/s915.jsp

New Moeller softwaretool: Displaying Several Tripping Curves According to SettingsFor several protective devices towork together effectively in acontrol panel, tripping characteristics must be compared in order to ensureoptimum system availability.Whilst fuses are designed withfixed characteristics, those of circuit-breakers can largely beadjusted to suit individual requirements. However, differentequipment and operating configurations require a widerange of differently equippedcircuit-breakers.

Up to now it has been virtuallyimpossible to graphically compare the curves of individualsettings. Any evaluation failedbecause of the different scales ofcurve coordinates for protectiveswitches and fuses. A new andeasy-to-use software tool from

Moeller offers an ideal solutionfor displaying selectivity in theoverload range. It consists of asingle Excel file. The Characteristics program tool shows simply on PC the curves of several protective devices together with the sametime and current scales. Thismakes it easier to assess theinteraction of Moeller NZM andIZM circuit-breakers, as well asany h.b.c. fuses used in combination with them. The program can show thetripping curves on the screen or

can generate a clear printout asrequired. The curve sets can besaved, printed or exported toother documents with passwordprotection for project documentation and with individual project data.

The program and notes on theselection criteria for protectivedevices are available fromwww.moeller.net/de/support/support.jsp. Free of charge registration is all that is necessary in order to use thesoftware. The file can be usedfor any number of projects andcan be run in German or Englishversions in Microsoft Excel.Saving projects separately andalways reusing the original program file are recommended.

The tool will soon be expandedto include other componentssuch as the PKZM motor-protective circuit-breaker andthe ZB overload relay.

www.moeller.net/aktuell/s914.jsp

The new residual current protective device from Moeller isspecially designed for use wherespace is scarce, such as in a service distribution board. Ring-type transducers and measuringrelays are combined together to form one functional unit. The ring-type transducers arecompactly installed in the cablerun, whilst the measuring relay isclipped on a DIN rail as required.

The new Moeller relay/transducercombinations cover the operatingcurrents between 1 and 1800 A.The range of possible applica-tions is particularly wide, fromgeneral power distribution toindividual motor feeders.

The adjustable relay features apre-warning function that is triggered when the set residualcurrent is exceeded. A red LEDthen flashes at different frequencies to indicate the levelof the particular residual currentin stages of 25, 50 and 75 percent. This enables users to

implement preventative maintenance in order to avoidpower supply disconnections. The residual currents monitoredand processed by the relay arebetween 30 mA and 5 A. Thetype A tripping characteristicensures tripping with sinusoidalAC residual currents and pulsating DC residual currentsthat may increase suddenly orslowly.

After the preset residual currenthas been exceeded, the PFR outputs a signal via a changeovercontact. Depending on the application, the contact signalcan be used as an indication incontrollers or to trigger a protective switch via the shunt or undervoltage release. Relaysand transducers can be combinedflexibly with any protectiveswitch.

Moeller PFR Residual Current Protective Relay: Compact, Reliable, Flexible

7

GB-MoellerSol09_RZ_V3.qxd 07.03.2005 13:39 Uhr Seite 7

-

88

Natural Wood Shaped to Perfection

Hi-tech and state-of-the-art process engineering have for a long time beenused in the wood industry. The production of parquet flooring, for example,requires a great deal of experience and know-how if perfect results are tobe achieved. Four Moeller text display HMI-PLCs are used to control a flexible system for producing semi-finished parquet products. Using XI/ON,eight servo axes and CANopen, the parquet manufacturer can now combine different networked sections of the system to suit actual requirements.

GB-MoellerSol09_RZ_V3.qxd 07.03.2005 13:39 Uhr Seite 8

-

9SOLUTIONS09

functionality are programmed using XSoft-Professional. XSoft-Professional is a programming system that is based on the CoDeSys 3S software in compliance with the international IEC 61131-3standard. Benefit for the customer: A singletool keeps development times for both functions to a minimum and simplifies commissioning and maintenance.

The system control was largely programmed ininstruction list, whilst the HMI-PLC and variousmonitoring functions were programmed instructured text. The visualization applicationcan be created simply, whilst program sectionscan be tested before or during commissioning.

The inexpensive PLC of the XC100 series enables the entire system to be optimally divided into several autonomous functionmodules. Its scalability, modularity and integrated CANopen interface combine to form a both technically and economicallymature solution.

Flexible network structure

Bauwerk Parkett AG also uses the XI/ONremote I/O system one of the fastest CANopen I/O systems on the market. Evenhigh-speed processes can be logged withoutany additional installation requirements for special signals, and the seamless remoteconcept could be implemented without anyrestriction. Additional customer benefit ofXI/ON: All XI/ON modules can be hot swappedduring operation, and the removal of an electronic unit does not cause any interferencein the other electronic modules. This is a clearadvantage on the Bauwerk TADO 3 systemwhere the overall operation was divided intodifferent function modules. The entire systemdoes not therefore have to be shut downwhen one section is maintained.

This increases system availability and reducesoperating costs.

CANopen is primarily used for networkingelectrical and hydraulic drives, programmablecontroller systems, I/O systems and sensors. It has enjoyed a well-established reputation in networks for many years and has consequently been the chosen bus system ofmany device manufacturers. It allows users tomake the optimum device selection for theirrequirements at an outstanding price/performance ratio.

The TADO 3 system at Bauwerk Parkett AG,Switzerland produces semi-finished parquetproducts. It consists of several system sectionsthat are all networked together. For example,system sections handle the cutting of parquetblocks from spruce and pine planks as well assorting, separating and making them intocomplete batches. The covering, which laterbecomes the visible layer, is separated from amagazine and bonded. It is this bonding ofthe covering layer that has to be visually monitored. The covering layer and blocks arefinally joined together, arranged into one unitand then pressed.

As Bauwerk places particular importance onquality assurance, they monitor, for example,the time taken for every covering layer fromthe bonding machine to the press, and removethem if the set time is exceeded.

The user-friendliness of the control system isanother important requirement. Operator control should be as easy as possible duringoperation and service. Bauwerk also requiredan open, flexible communication system thatprovides flexibility for further device integration.

Combining system sections flexibly

Four CPUs of the XC100 series are used for theflexible and freely combinable control of systemsections. These form a CANopen networktogether with two local MI4 visualizationsystems, XI/ON remote I/Os and eight servo controllers. All specific product parameters canbe entered centrally via a text display HMI-PLC a combination of text display and XC100. Its display and also those of the two MI4sensure a fast response in the event of systemmalfunctions.

The text display of the HMI-PLC can be programmed without any additional visualization software required: PLC and HMI

CONCLUSION

Bauwerk Parkett AG chose Moeller's XSystem since XSystem components canbe networked flexibly in open CANopenstructures and the devices can be combined with those of any other manufacturer. The system is divided intoseveral units, and different system sections are combined. The Moeller HMI-PLCs enable commissioning to be carriedout quickly. Communication between theCPUs runs problem-free using networkvariables and the same applies to communication from the master to theservo axes, the XI/ON stations and thetext displays.

THE COMPANY

Bauwerk Parkett AG is based in St. Margrethen, Switzerland, and belongsto Nybron Flooring International, the largest parquet manufacturers in Europe.Over fifty years of experience, combinedwith know-how in the latest building andapplication technology, provide the basisfor the development and production ofBauwerk's modern finished parquet flooring. Apart from project developments, R & D and consulting forapplication technology, the range of products and services also includes training courses and exhibitions.

www.moeller.net/aktuell/s901.jsp

GB-MoellerSol09_RZ_V3.qxd 07.03.2005 13:39 Uhr Seite 9

-

10

XV400: Production of ItalianDelicatessen Products

Open communication standards such as Ethernet TCP/IP form the backbone of FratelliBeretta's new plant that was commissioned in2004. The installation covers three floors witha total area of 15,000 square metres. The final constellation implements a drainingand curing process at the hundred cells inplace, and these are controlled by HMI-PLCsfrom the Moeller XV 400 series.

HMI or HMI-PLC: It's the Compact Flash thatdecides, not the hardware

The XV400 series provides automation solutions that are scalable, flexible and cost-efficient. The series is based on one hardwareplatform, with an interchangeable CompactFlash card that determines whether HMI orHMI-PLC functions are implemented. The required software function is simplyadded to the XV400 basic unit via the Compact Flash card, as well as an optionalcommunication card.

At its new Brianza factory in Garbagnate Monastero in the province ofLecco, the Italian company Fratelli Beretta is using an automation solutionthat is based on product and communication standards. The companystrategy aims to move away from proprietary solutions towards

interoperable units. From receiving an order to production, logistics andcontrol, open communication systems are required to ensure short and problem-free work flows, as well as increasing production reliability, quality and efficiency.

GB-MoellerSol09_RZ_V3.qxd 07.03.2005 13:39 Uhr Seite 10

-

11

SOLUTIONS09

XV400 devices are available either as infra-redor resistive touch devices with 5.7 STN color,10.4 or 12.1 TFT color displays. The infra-redtouch screens also feature a scratch-proofsafety glass front. The basic units come with aRISC-CPU (32-bit, 400 MHz) and integratedinterfaces such as RS232, USB, Ethernet10/100 MBit and CAN. One (5.7 device) ortwo (10.4 and 12.1 devices) communicationslots can take a variety of different communication boards such as the multi-protocol communication board with MPI, Profibus DP master or slave, and DeviceNet,thus enabling a wide range of communicationand networking options.

Three software packages for any user andany application

Moeller offers two software packages forexclusively HMI applications: Galileo or XSoft-EPAM. Galileo is an easy-to-use Windows-based graphical configurator.

XSoft-EPAM is a Moeller add-in that is integrated in Microsoft Excel. For HMI-PLCapplications, the XSoft-Professional PLC programming tool is used in addition to thevisualization tool. This CoDeSys-based programming tool supports the multi-taskingcapabilities of the HMI-PLC in compliance withIEC 61131-3. The complete package, togetherwith the Compact Flash memory cards of 32MB to 512 MB, ensure that XV400 devices can be used flexibly whether as an HMI unit,HMI-PLC solution, panel with a gateway function or as a connection to the management level via Ethernet.

Free web, FTP and OPC client server

The IT functionality of the HMI-PLC XV400,both in terms of hardware and software, werethe decisive factors in Fratelli Beretta's choiceof device. The HMI-PLC, for example, comeswith a free web, FTP and OPC client server asstandard, making remote maintenance andvisualization easy to implement with XV400.Every visualization application created withXSoft-EPAM is thus automatically web-enabled. In this case, a Java applet is loadedthat generates a 1:1 image of the visualizationin any standard Java-compatible browser, thussupporting remote operation of the system.

For Fratelli Beretta the option of networking atotal of number 75 XV400 touch displays viaEthernet was equally important. This ensuresreliable data exchange between the differentPLCs and the five SCADA display/control stations, whilst also transparently integratingthe Movicon Millenium supervisor unit fromProgea into the system.

Open and flexible communication to thefield level

The field devices exchange their data with the PLCs via two standard communication networks: CANopen and Profibus DP. This iswhere Moeller's XI/ON modular remote I/Osystem is used. DF5/6 series frequency inverters, DIL series remote switches, as well as PKZ motor-protective circuit-breakers complete the range of additional electromechanical components in the system.

Ten MFD-Titan micro PLCs from the Moellereasy range are installed on the local level.With a full-featured 132 x 64 pixel graphicdisplay they provide problem-free interactionbetween man and machine inside the production cell. The MFD-Titan multi-functiondisplay combines the functions of a displayand operator unit in one device, meeting allthe relevant industrial standards. MFD-Titanhas an optional backlight and meets the highprotection requirements of IP65.

www.moeller.net/aktuell/s904.jsp

CONCLUSION

The various XV400 devices can also becontrolled directly from a remote SCADAstation using a graphical emulation software. It provides an exact replica ofthe graphical display contents on thesupervisor PC. Process phases can thus be controlled remotely and any modifications to the field microcontrollerscan be carried out. Fratelli Beretta nowhas transparent access to all production,control and logistics operations. Thesystems have an open design and offerproblem-free communication beyondhierarchical limits. For Fratelli Beretta, the new plant is a showcase project forits demanding and quality-consciouscustomers.

THE COMPANY

The Beretta brothers have been active inthe food industry since 1812. For overfive generations they handed down theirexperience and recipes for the productionof high quality sausages and pork products. The family run business nowhas 600 employees. Fratelli Beretta S.p.A.has its headquarters in Trezzo d'Adda andin its ten plants processes approximately27,000 tons with more than 300 singleproducts. This ranges from salami to mortadella, from the renowned Parmaand San Daniele ham to wrstel and theDOP certified Salami Brianza.

Up to 5 PC scada

PC Scada

Ethernet backbone / OPC

75 Moeller HMI-PLC

Remote I/O XI/ON

1 2 5

1 2 75

HMI-PLC

Up to 10 MFDsvia PB DP network

1 2 10

GB-MoellerSol09_RZ_V3.qxd 07.03.2005 13:39 Uhr Seite 11

-

12

MFD-Titan: Text-free Visualization

Machine builders generally export their productsall over the world. In their visualization systemsthey either use multi-lingual texts or none at all,favouring symbols that are internationally understood. Whatever the case, important operating data and fault signals must bedisplayed correctly, and Raimann, the machinebuilders, chose Moeller's fully graphical compactMFD-Titan controller for this purpose. The MFD-Titan multi-function display from the easy rangeis a cost-effective alternative to conventionalHMIs, combining HMI and control functions inone compact device.

The Freiburg-based company, Raimann Holzoptimierung, developed a visualizationsystem for the ProfiRip KM310 rip saw. All therelevant operating data and fault messageshad to be displayed cost-effectively and usinga fully matured technology. A visualizationsystem was required that could operatewithout the use of text if possible.

Moeller's MFD-Titan fully meets these requirements, and the entireapplication is runwithout a singleword. All machine

faults are visualised using symbols, thuseliminating the need for any translations intoindividual languages. Moreover, the nationallanguage of a country does not play any partin the construction of the machine nor in thedelivery to the end customer.

MFD-Titan meets all the relevant industrialstandards, ensuring reliable and universal use.The full-featured MFD graphic display with132 x 64 pixels comes with an optional backlight and meets the demanding industrial

GB-MoellerSol09_RZ_V3.qxd 07.03.2005 13:39 Uhr Seite 12

-

protection requirements of IP65. Two freelyconfigurable status LEDs are provided to indicate additional operating states and signalalarms. The operating temperature range is 25 to +55C and therefore allows the electronic controls to be used in machines orsystems. All connections are fitted with maintenance free and vibration-proof cage-clamp terminals to ensure optimum operational reliability.

Data acquisition and evaluation

MFD-Titan can visualise important operationaldata in addition to fault indications: Machineoperating hours, current consumption inAmps, as a percentage as well as in bar graphdisplay. However, MFD-Titan can do a lotmore. Raimann thus uses the compact controllerfor logging, evaluating and storing relevantmachine data. Operating hours, maximumoperating current and the number of eachindividual fault are logged for further processing.

The non-volatile memory integrated in MFD-Titan and easy800 makes them ideal for dataacquisition. This offers memory for data,timers, marker ranges and for counters.

Versatile, open communication

MFD-Titan offers open communication optionsand complies with a wide range of standards:AS-Interface, Profibus DP, CANopen, DeviceNet, serial interface, Windows DLLs,OPC. The MFD-Titan compact controller cantherefore also be integrated in larger automation solutions, and Raimann uses existing Windows DLLs for this. A simplehigh-level language program enables any service employee to read out data from theMFD-Titan and transfer it to MS Excel. EveryRaimann machine has its own device passportthat can be updated with every service operation if required via modem.

Visualization, networking, counting, controlling

MFD-Titan is not only a display and operatorunit but also a full-featured easy800 with anadditional graphical display. The user-friendlygraphic editor enables up to 255 screens to becreated, consisting of text, graphics or both. If required, each screen can be given its ownbutton assignment, thus enabling user-friendlyparameter entry or the simple on/off switchingof auxiliary units.

Up to eight MFD-Titans or easy800s can benetworked together using easy.NET for morecomplex tasks. Users can thus implementapplications with up to 320 I/O points.

MFD-Titan and easy800 run with a 32-bitinternal resolution, so that numbers between -2,147,483,648 and +2,147,483,647 can bedisplayed. Virtually all function blocks such ascounters or timers use this number range. Alarge number of marker bytes, marker wordsand double words are available in addition tomarker bits.

Four high-speed counters (5KHz), or alternatively also two incremental value counters (3KHz) are provided in addition tothe 32 elementary counters.

Apart from basic two-step controllers, ready-to-use PID controllers are also available,which simply have to be activated and assigned parameters. With arithmetic and scaling function blocks also available, closed-loop control solutions with MFD-Titanare astonishingly simple to create.

Display marking

For a small extra charge, the MFD display canalso be provided with customised laser printedmarkings. The supplied Labeleditor allowscustomers to create their individual layout. Inaddition to adding a logo, the two LEDs andall buttons can be provided with customermarkings.

13

SOLUTIONS09

CONCLUSION

In the woodworkingindustry, machinebuilders worldwideoften come acrossuntrained machineoperators. Raimanntherefore uses

symbols exclusively in its visualization inorder to reduce operating errors as wellas costs. As Pius Gretzmaier, electricalengineering designer at Raimann, said:The graphical error display eliminatesany language problems. MFD-Titan offersus a user-friendly package of hardwareand software with an impressiveprice/performance ratio.

www.moeller.net/aktuell/s902.jsp

THE COMPANY

Raimann Holzoptimierung GmbH & Co.KG is based in Freiburg and is the top supplier of user-friendly saws and economical woodworking systems. The machine builder produces around400 machines a year and has a turnoverof around 17 million euros with 113 employees. Raimann has been part of the Weinig Group in Tauberbischofsheimsince 2001.

GB-MoellerSol09_RZ_V3.qxd 07.03.2005 13:39 Uhr Seite 13

-

14

Todeschini is a Brazilian company based in Bento Goncalves Rio Grande do Sul, and produces modularwooden furniture, such as kitchens or shelves.

The company is continuously investing in new technologies and automationsolutions, and for a long time has relied on Moeller products and solutionsin this field. Todeschini is currently using the affordable XC200 modular PLCin order to integrate a woodworking machine in a system line.

XC200: Modular Furniture Production made in Brazil

GB-MoellerSol09_RZ_V3.qxd 07.03.2005 13:40 Uhr Seite 14

-

Todeschini, the Brazilian furniture manufacturer, uses a modular XC200 PLC forindividually tailored automation concepts onaccount of its scalable design. The XC200 PLCis used to integrate a woodworking machinein a system line. The machine operator canload and start the required program with asimple button actuation on the HMI. In thisway, the machine in the system line can adjustsettings for axes, speed, generators andmotors, edge lengths and other parametersrequired for production.

XC200 for high-speed processing

The compact XC200 modular PLC from theXControl series offers several outstanding features, not only in traditional PLC areas such as memory and processing speed (512 K program, 256 K data, 0.04 ms/K). The multi-tasking operating system ensures optimum use of the CPU resources. Eight digital inputs and six digital outputs are already integrated for connecting peripheraldevices, and an incremental encoder can beconnected directly for positioning tasks. Interrupt inputs ensure fast reactions to criticalevents. I/O expansions can be implementedusing XI/OC modules, and can be connectedlocally or remotely with screw or cage clamp

terminals. XC200 is also provided with a slotfor multi-media memory cards (MMC). Thesecan store programs or recipe data and areread into the PLC. Other features include theintegrated battery-backed real-time clock andup to 32 K of retentive data.

Open for multiple communication

The connection to other peripheral devices isan important feature for users: A freely pro-grammable serial interface, USB, a CANopenfieldbus master and a 10/100Mbit Ethernetinterface are standard features. The Ethernetconnection is used for programming access,for effective networking between PLCs, andthanks to the integrated OPC server, as a dataprovider for OPC clients such as visualizationsystems. A web server that is also integratedallows user-defined web pages to be loaded without any additional tools. Any browser canthus display data, for example for diagnosticstasks, without the need for any additionalvisualization tool. The Ethernet interface likewise supports remote programming andremote diagnostics.

Instead of mounting on standard top-hat rails,users can also fit the XC200 PLC directly onXVision display fronts in order to upgrade theXC200 to a compact HMI-PLC. This opens up with a range of different equipment versions the possibility of other applications and spacesaving automation solutions.

SOLUTIONS09

XControl XC200 modular PLC

The XC200 PLC integrates a number of I/Opoints in a compact design: With a 60 mmmounting width 14 inputs/outputs areintegrated, 238 input/outputs with a mounting width of 270 mm and up to 495I/O with a mounting width of 510 mm.

XC200 features on board:

8 digital inputs, 6 digital outputs, MMC multi-media memory card, Expandable with up to 15 XI/OC

modules, CANopen (1 MBaud), OPC server, Web server, RS232, USB, 10/100 Mbit Ethernet, Optional 256/ 512 Kbyte data memory, Optional 256/ 512 Kbyte program

memory.

www.moeller.net/aktuell/s903.jsp

CONCLUSION

As Paulo Csar Malvessi, responsible forengineering at Todeschine, confirmed:The use of XC200 optimises the reliability of our production line and thefinishing of parts. Having integrated the XC200 modular PLC in our companynetwork, we can connect it to our Intranet, making production data accessible, as well as offering extensivediagnostics options in the event of faults.

15

GB-MoellerSol09_RZ_V3.qxd 07.03.2005 13:40 Uhr Seite 15

-

16

High Availability Low-Voltage Power DistributionSystem for Server Farm

With power demands increasing all over the world and the continuedincreasing pressure to cut costs, there is an even greater need for secureinvestments through which efficient planning, assembly, installation and operation are ensured. This requires the use of cost-efficient and standardised power distribution systems that customers can adapt to theindividual requirements of their projects. Thats why Moellers xEnergyprovides this capability in full: xEnergy stands for maximum flexibility,economy and reliability.

GB-MoellerSol09_RZ_V3.qxd 07.03.2005 13:40 Uhr Seite 16

-

17

SOLUTIONS09

xEnergy - the integrated and flexibly combinable system range - consists of switching and protective devices, the mounting system design, the switchboardsystem, and the planning and calculation tools.The Moeller KIT system is ideally tailored toensure safe and reliable power distribution.Individual projects, either in functional buildings, offices and industrial buildings canbe implemented quickly and economically. Not only does the customer save time, moneyand space, but also benefits from Moellersexcellent reputation for safety and withoutrestriction in the entire world of IEC/EN applications.

Reliability, safety, availability

An IT centre or server farm has demandingrequirements with regard to reliability, safetyand availability. Any failure mainly results inextremely high direct and indirect costs.

Together with MESA, the panel builders fromMaintal, Moeller received the tender for a2500 A low-voltage power distribution systembased on xEnergy. The order covered all stagesfrom planning to commissioning, and thesystem, consisting of nine sections with cornersections and a further seven sections on therear, was required for a server farm of around1300 sq metres in size. This required two feeder sections each of up to 2500A. Theother sections are outgoers for UPS systems,transformer feeders and feeder section forgenerators. The sections are equipped withMoeller IZM and NZM4 circuit-breakers inwithdrawable units.

Apart from reliability, safety and availability,the completion date for commissioning wasalso a key requirement of the IT centre. The production plant for xEnergy fully manufactured and supplied the sections within six workings days. The panel builders,MESA, installed the power distribution systemwithin 14 days and commissioned the systemin the same period.

Safe energy control

xEnergy is Moellers new system range, andconsists of power distribution systems speciallydesigned for the building infrastructure up to4000 A. Moeller offers an intelligent systemplatform for switching and protective devicesthat panel builders can customise, assemblequickly and handle easily.

The Moeller power distribution system incorporates the latest trends and combinesessential features. The individual switchingand protective devices, the associated mounting system design and also the switchgear are combined to form one technical unit. This kind of system is both economical and reliable at the same time, asperfectly matched and type-tested functionalunits have been developed as a modularsystem. Exactly tailored function modules thathave been type-tested in accordance with IEC60439 with an internal separation from Form1 to Form 4, comply with local installationrequirements such as DIN VDE, CEI, NF or UNE.

The xEnergy range consists of:

- Feeder and coupling sections for circuit-breakers up to 4000 A,

- Individually equipped outgoer sections with fixed compartment modules for switching and protective devices including motor starter combinations up to 630 A,

- Outgoing sections up to 630 A for flush- mounted switch-fuse strips, fuse rails and fuse switch-disconnectors,

- Control sections and empty sections for ancillary components such as motor starters, PFC modules, frequency inverters, softstarters or for automation solutions,

- Mounting systems for rail-mounted serviceinstallation devices for conventional service distribution boards up to 630 A.

Moeller supplies the full range, functionallypacked in individual elements (flat pack) oraccording to customer requirements as pre-assembled switchboards. The system platform enables panel builders to create individual solutions that can be optimally designed to meet the requirements of the end customer.

Efficient software tools

Components on their own, however, are notenough. A future-proof planning of low-voltage switchboard systems must be supported and documented with suitabletools such as for network calculations,dimensioning and configuration. This providesa verifiable guarantee of the quality requiredfor safe and reliable power distribution. Moeller offers software tools with this in mind,enabling panel builders to plan and documentall their projects simply. These range fromtools for network calculation, configuration,quotations, system engineering to order handling. Moeller tools, regardless of thesystem data involved, allow the switchboardsystem required to be selected and configuredprecisely and quickly, in accordance with international requirements.

CONCLUSION

The engineering and calculation programs used from planning to theproduction of the sections impressed

Olaf Sulatycki, MESAs owner: They enabled us to dimension and calculatethe technical and financial requirementsof the IT centre exactly, thus producinga technically functional and economicalunit. This project laid the foundation for a partnership agreement betweenMESA and Moeller, and brought about a follow-up order and additional offersfor 26 sections in total.

THE COMPANY

MESA Mess- und SteuerungsanlagenGmbH, based in Maintal, was founded in1973 by its current owner Olaf Sulatycki.MESA is a competent partner for electricalengineering and automation, focusing onPLC/CNC automation, control systems,industrial power supply and control, low and medium voltage systems, buildingservices management, industrial installations and engineering, consulting,service and services.

www.moeller.net/aktuell/s905.jsp

GB-MoellerSol09_RZ_V3.qxd 07.03.2005 13:40 Uhr Seite 17

-

Moeller's XSoft-EPAM (Easy PAge Machine)visualization tool is specially designed for creating graphical user interfaces for touchpanels, enabling visualization parameters tobe defined simply. XSoft-EPAM creates aninterpreter for the visualization project, i.e. the objects and screen pages are stored in astructured and tabular ASCII file. EPAM then converts this script file into a graphical presentation on the touch screen. The scriptfile itself contains the definitions of the individual screen pages and their objects,

and is created with Microsoft Excel. Users provide graphics as PCX image files with astandard graphics program and referencethem via the file name to the script file. Thesame technique is also used for the font files.

Graphical standard objects such as buttons,switches, alphanumeric variables, bars or messages are provided for creating individualscreens. These objects are configured in astructured ASCII file, linked with the PLC variables and combined to form complete

screen pages. The linked screen pages can alsobe called with button objects. Thanks to thetransparent data format, users can documentthe project automatically at the same time.

The interpreter is used to test the applicationdirectly on the PC, enabling changes to be carried out and tested without any problems.The application is then finally loaded onto thetarget system. The open design concept alsoenables recurring functions to be automatedusing Excel macros, so that you can adapt the

18

Visualization Designed Quickly and Reliably with Microsoft Excel

The innovative combination of HMI and PLC into an HMI-PLC (display controller) reduces the hardware and software interfaces required, thusreducing the costs for hardware and engineering. The interplay betweenthe visualization and PLC software is a key factor in the efficiency of theoverall system. Moeller, the automation specialists from Bonn, offer anextensive system of 5.7 to 15 touch display controllers (HMI-PLCs) witheither resistive or infra-red technology.

GB-MoellerSol09_RZ_V3.qxd 07.03.2005 13:40 Uhr Seite 18

-

development environment to your individualrequirements.

The tried and tested Windows scroll bar function also eliminates the need for screenchanges, so that even large parameter sets andrecipes can be displayed on one screen page.

Remote diagnostics and maintenance already installed

EPAM's Remote Control object enables thescreen pages of other touch screens to bedisplayed. The operating states of individualsystem sections can thus be displayed and controlled from one central display. Variablevalues can also be displayed and modified on a separate picture-in-picture visualizationpage. The remote technology also allows users to access the variables of other stationslinked via Ethernet.

The Ethernet interface with TCP/IP is not onlyused as a programming interface or for networking all the controllers. It also allows avertical integration, such as the linking to themanagement level. This can be implementedwith Web-EPAM or EPAM Remote Control.Both tools are not individual software packages. A Java applet is simply loaded via the integrated web server and generates a 1:1 image of the visualization in any standardJava-compatible browser, thus enabling thesystem to be operated remotely. The integrated OPC client-server offers anopen interface using MS WindowsCOM/DCOM technology, enabling even conventional office programs and their data to be linked to the automation environment.

A central operator station can also be designed on an office PC using EPAM runtimefor MS Windows. For this the project is onlystored once on your target system and doesnot have to be converted again when changesare made.

Standardisation with IEC 61131-3

XSoft-EPAM is an Excel Add-in for designingvisualization applications and is used for HMI-PLC functions in conjunction with theXSoft-Professional PLC programming tool.XSoft-Professional (3S CoDeSys) is the programming tool used for multitasking-capable HMI-PLCs in compliance with IEC 61131-3.

The factory integrated Ethernet interface onthe Moeller HMI/PLC, with a transfer rate of10/100 MBit, enables a communication

connection to be establishedto virtually all Ethernetsystems via UDP. The function blocks provided by XSoft-Professional make this task simple and problem-free.

Data exchange is just as simple to devices from othersuppliers with the 3S CoDeSys runtime systemand an Ethernet interface. In this case, the physical connection is implementedvia standard Ethernet TCP/IPand the SymArti driver integrated in 3S. For this asymbol file containing theglobal visualization variablesis simply created in the supplier's device. The symbol file just has to be loaded in the visualization system and the required variablecalled.

Programming in compliance with IEC 61131-3also meets the requirements of OMAC (openmodular architecture controls), a North American association of end users, machineand automation manufacturers with international operations for the promotion of open automation architectures, and therefore also with packaging machines.

Application software libraries expand thestandard PLC

True to the principle of Parameter definitioninstead of programming, Moeller is offeringready-to-use closed-loop and motion controlfunction block libraries for its PLC devices. All libraries can be imported in the IEC 61131-3programming software. These function blocks,which have been quality assured and tested,can then be used as standard or applicationfunction blocks inside the PLC program. All toolboxes are being continually furtheradvanced.

The Motion Control toolbox contains approximately 40 function blocks that can beindividually integrated. The toolbox containsbasic positioning function blocks for elementary tasks and also more powerfulfunction blocks, such as for asynchronouspoint-to-point positioning, master-slave positioning, incremental coordinate positioning, rotary axis positioning and muchmore. The Motion Control toolbox also contains synchronisation function blocks forelectronic gears and the flying saw function.

The closed-loop control toolbox containsaround 120 function blocks. The standardfunction blocks allow full utilisation of theknow-how implemented, and it is also possibleto create special application solutions by combining and cascading function blocks. PID controllers, three-point step controllers,pulse width modulation, fuzzy controllers, and function blocks for signal processing andsimulation are provided.

19

SOLUTIONS09

www.moeller.net/aktuell/s907.jsp

ready to run!

Import of variablesfrom XSoft

1

2

3

4

Simple and efficient projectdesign with Excel

Simplepositioning

GB-MoellerSol09_RZ_V3.qxd 07.03.2005 13:40 Uhr Seite 19

-

The term "service" coversmany features, however,customers often feel left ontheir own. A Field Service hasbeen in place at Moeller foryears. Dr. Frank Vlker, FieldService manager, describesthe services offered, costsand customer benefits.

MS: Is the Field Service an on site service?

Vlker: Yes and no, we use the term to coverall after-sales services and to express its specialproximity to the customer. Our Field Service isestablished worldwide and is made up of fourelements: the Helpline, the Onsite and OnlineService and Repairs. The Helpline is availableto customers round the clock as a service hotline for support in the event of a malfunction. The Onsite Service offers faultrectification onsite, support with installationand commissioning, or the measuring andtesting of complex control and energy distribution systems. The Online Service offersour customers access to the Field Service database with which they can carry out online diagnostics and troubleshooting. Answers toFAQs are available, as well as the latest software updates or documentation. TheRepairs area includes the fast Direct ExchangeService for Moeller products and inexpensiverepairs. This includes Service training coursesfor selected Moeller products. Our range ofservices complies with the service structure stipulated by the German Electrical and Electronic Manufacturers' Association (ZVEI).

20

Moeller Field Service: always at the ready

INTERVIEW

Dr. Ing. Frank Vlker, Field Service manager

www.moeller.net/aktuell/s906.jsp

PLANNING

ENGINEERING

PROGRAMMING

INSTALLATION

COMMISSIONING

TRAINING

SERVICE

GB-MoellerSol09_RZ_V3.qxd 07.03.2005 13:41 Uhr Seite 20

-

MS: What does the Field Service offerexactly?

Vlker: The Field Service provides customerswith fast and flexible support. Our staff haveseveral years of experience and are specialistsin their field. They are available round theclock. This guarantees short downtimes andprevents long production stoppages. We also carry out regular inspections andmaintenance, enabling any possible faults tobe detected in advance, so that preventativemeasures, such as repairs or parts exchangecan be carried out. Our Field Service also offers a conversion service in which existingsystems are examined and possible conversions presented and implemented on request. This offers customers significantcost benefits.

MS: Who are your customers and what costbenefits do you mean?

Vlker: For the user, malfunctions on devicesand machines can bring about unwanted production stoppages, downtimes or restrictedavailability often involving considerablecosts. Our Field Service can rectify faults swiftlyor even prevent them in some cases. In addition to system users, our customersinclude OEMs, consisting primarily of machinebuilders and panel builders. They appreciatethe benefits of a reliable service and do nothave to set up resources of their own. Withregard to cost benefits, the following exampleillustrates the benefits a direct exchange ofMoeller products. Ceratizit Austria GmbH,based in Reutte in the Austrian Tirol, receiveda shutdown signal in one of its plants inHungary. We were able to send the replacement part by express courier on thesame day so that the downtime costs could be kept to a minimum. We were able todeploy a wide range of options in order toprovide fast and straightforward support.

MS: Moeller operates globally, can youguarantee a worldwide service?

Vlker: We offer 24-hour support on our Helpline for the whole of Europe. Worldwidesupport and problem solving is offered by ourtelephone Service Centre, which is mannedduring normal business hours. The Online Service, the Email Service and the Online Diagnostics service are also available. This lastservice is currently being set up for selectedautomation products, and requires the customer to enter more detailed informationabout the symptoms and faults until the causeof the fault is determined. We also offer invaluable remote diagnostics services forseveral products.

MS: What service operations have you recently completed? Were they all successful?

Vlker: Without wanting to exaggerate, wehave been very successful. The operation atthe Frankfurt Main Tower is one example ofthis. One Saturday night, a circuit-breaker tripped and indicated a fault in the coolingsupply of the district-heating power stations.Any failure on a weekday would incur personnel costs of about 175 000 euros perday, as well as a loss in sales. We had alreadyrectified the fault by Sunday. Another examplewas a fault in the main feeder of a hospital. In this critical area human life can naturally beput at risk. We restored the power supply within the shortest possible time since a stand-by generating set is not a permanent solution.An operation in Saudi Arabia demonstratesthe capabilities of our worldwide service.Together with our Italian colleagues fromMoeller Electric S.r.I. we developed a tailoredsolution for the parameter assignment of softstarters at the Mohammed A.Sharbatly Corp.in Saudi Arabia.

MS: What are the costs for your customers?

Vlker: The Moeller Field Service continuously adapts its terms and conditionsto market requirements. The costs are basedon hourly rates and material prices. However,every order and every contract is tailored individually to suit customers according to their requirements and the resulting service provisions. We offer tailor-made package prices for inspections, maintenance, conversions and retrofits. Preventative service charges are relatively low compared to the considerable expenditure involved in malfunctions, and their consequences in particular. The 24-hour hotline for malfunctions is free of charge to our customers. We can offer special contracts for special requirements in terms of availabilityof material, personnel and know-how.

MS: How do you adapt your offers to pre-sent and future requirements?

Vlker: We have maintained close contactwith our customers over several years and arecurrently expanding our service. As well as theresponse service that we have improved, wealso offer the active service previously mentioned. This is designed for the conversionof PLCs and circuit-breakers, as well as for preventative maintenance in the form ofinspections and maintenance of componentsor systems. We are also expanding the database support of customized processes(CRM) and the telephone Service Centre. Furthermore, our service team is highly motivated and is continuously increasing itslevel of expertise.

MS: Where can prospective customers findinformation about the Field Service?

Vlker: All important information and telephone numbers are available on our homepage at (www.moeller.net/fieldservice). Our customers can reach us directly via [email protected] and via our hotline.

21

SOLUTIONS09

GB-MoellerSol09_RZ_V3.qxd 07.03.2005 13:41 Uhr Seite 21

-

22

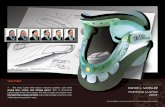

In today's world, there is a rapidly growingneed for the security of persons, buildings anddata, and a large number of sensitive areasrequire a special type of access control. Moeller has developed the M22-ESA fingerprint system for these kinds of access controls.The electronic locking system can detect andmemorise the structure of the human fingertipand thus reliably identify authorised persons.Unlike ID cards, keys or PIN codes, the featuresof the human finger print cannot be transferred to third parties and do not changeduring the life of the person. Administrativecosts incurred through the loss or forgettingof conventional access systems are no longeran issue. The system prevents any possibility of faking a finger print by restricting the evaluation surface. This means, for example,that only a certain section of the finger print isstored and scanned accordingly. This preventsthe possibility of any finger prints accidentally

left behind on objects from being copied andmisused. The number of failed authenticationattempts can also be restricted or the level ofsecurity can be increased by combining theuse of a finger print with that of a key switch.

Function

The M22-ESA finger print system is designedas a thermal line sensor and operates usingthe so-called infra-red process. The finger ismoved in a line across a linear array of thermosensors. The varying arrangement of lines onthe finger produces different formations ofridges and furrows (minutiae) on the finger. By making contact, the ridges emit heat betterthan the furrows, and these temperature differences are registered by thermo sensors.Over several scans the composed digital imageof the finger or finger print is produced. Thisimage is stored and compared by the fingerprint system with the finger prints in the database. If the finger print is identified, agreen LED indicates access authorisation and

the protected area is made accessible.The M22-ESA finger print system offers sufficient memory for 100 finger prints. Its parameters can be set easily via the MFD-Titan multi-function display.

Access to machines and installations is normallyprotected by keys, ID cards or PIN codes. However, these items are frequently lost, forgotten or illegally copied. Biometric accesssystems operate completely differently: they areunique, unchangeable and are unambiguouslyassigned to a person. They therefore offer areliable alternative to conventionalaccess and control systems, particularlywhere special requirements are involved.

CONCLUSION

The M22-ESA finger print system uses the benefits of biometric features, andthus not only provides a simple and economical alternative to conventionalaccess controls but also one that is reallyreliable.

Trend: The Key of the Future

www.moeller.net/aktuell/s916.jsp

GB-MoellerSol09_RZ_V3.qxd 07.03.2005 13:41 Uhr Seite 22

-

FAX Reply: +49 (0)228 602-2275

Think future. Switch to green

Automation 2004 product overview

HMI-PLC XV400

HMI XVH300

DF51, DV51 frequency inverters

LSE-Titan position switch

easy control relay, MFD-Titan

Characteristics program software

PFR residual current relay

M22-ESA finger print system

xEnergy, MODAN power distribution system

Electronic catalog

Moeller Field Service - service on site

Information where it'sneeded. Information direct,clear and reliable bydownload, mail or fax.

FAX REPLY+49 (0)228 602-2275

INTERNETwww.moeller.net

NEWSLETTER

ELECTRONIC CATALOGUEcatalogue.moeller.net

Please send me Moeller Solutions regularly

Company: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Name/First Name: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Department/Function: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Street: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Post code/Town: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Country: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Telephone: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E-mail: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Please include me in the distribution

list for your electronic newsletter.

Moeller Info Service: Fast, Simple, Direct

MOELLER INFO SERVICE

www.moeller.net

GB-MoellerSol09_RZ_V3.qxd 07.03.2005 13:41 Uhr Seite 23

-

www.moeller.net/m1

Just what you are looking for Ingenious automation solutions

Creative ways of handling electricalenergy and giving it direction, form andpurpose this is our business. Whetherfor the installation of electrical systems inbuildings and industry or the automationof production processes, quality productsby Moeller will enable you to implementeconomical solutions all over the world.

Moeller GmbH Hein-Moeller-Strae 71153115 Bonn GermanyFax: +49 228 602-2275

A05

|02A

GB-MoellerSol09_RZ_V3.qxd 07.03.2005 13:38 Uhr Seite 24