MELT ELECTROSPINNING AS AN ADDITIVE MANUFACTURING … · The use of scaffolds to replace lost bone...

Transcript of MELT ELECTROSPINNING AS AN ADDITIVE MANUFACTURING … · The use of scaffolds to replace lost bone...

Melt electrospinning as an additive manufacturing technique

© 2018 Nikola Ristovski Page i

MELT ELECTROSPINNING AS AN

ADDITIVE MANUFACTURING TECHNIQUE

Nikola Ristovski

B. Eng (Medical)

Submitted in fulfilment of the requirements for the degree of

Master of Engineering (Research)

Science and Engineering Faculty (SEF)

Institute of Health and Biomedical Innovation (IHBI)

School of Chemistry, Physics and Mechanical Engineering (CPME)

Queensland University of Technology

2018

Melt electrospinning as an additive manufacturing technique

© 2018 Nikola Ristovski Page ii

Keywords

Additive Manufacturing; Biomimetic Scaffold; Bone Fracture; Bone Tissue; Bone Tissue

Engineering; Electrospinning; Electrospinning Electric Field; Electrospinning Humidity;

Fibre Deposition; Fibre Laydown; Melt Electrospinning; Microfibres; Order Quantification;

Polycaprolactone; Polymer Charge; Polymer Melt; Scaffold Order; Scaffold Production;

Scaffolds; Tissue Engineering

Melt electrospinning as an additive manufacturing technique

© 2018 Nikola Ristovski Page iii

Abstract

Bone tissue engineering aims to study and produce bone tissue for patients who have

undergone physical trauma or disease related losses in bone tissue that is unable to repair naturally.

The use of scaffolds to replace lost bone tissue is a major field within bone tissue engineering, and

the use of melt electrospinning is gaining momentum as a method of production. Recent studies

show that melt electrospinning is capable of producing highly ordered scaffolds with fibres on the

micrometre scale. This allows bone tissue engineers to have unprecedented control over scaffold

microarchitecture, allowing for the production of biomimetic scaffolds. The aim of this study is to

demonstrate that melt electrospinning is capable of producing highly ordered structures.. This was

completed by first determining the locus and rate of discharge of charge stored in the polymer.

Results showed that charge build up was minimized by distributing the application of the electric

field between the emitter and collector. Further studies to determine whether residual charge would

affect cell proliferation throughout the scaffold and whether humidity played a key role in charge

dissipation was completed. Using a distributed charge produced scaffolds up to 200 layers high

with little to no loss in laydown accuracy, almost an order of magnitude greater than what was

previously possible. Murine calvarial cells were seeded onto the structure, showing little evidence

of cell death. A study completed in conjunction with S. Liao et al. showed little effect to the

structural order of scaffolds with changes to ambient humidity. This study concluded that it was

possible to use melt electrospinning as a method to produce highly ordered scaffolds. It

demonstrated that the method is a promising candidate to produce scaffolds for tissue engineering.

Melt electrospinning as an additive manufacturing technique

© 2018 Nikola Ristovski Page iv

Table of Contents

Keywords ............................................................................................................................................... ii

Table of Contents ...................................................................................................................................iv

List of Figures ........................................................................................................................................vi

Acknowledgments ................................................................................................................................ xii

1 CHAPTER 1: INTRODUCTION ................................................................................................... 1

1.1 Aims and Hypothesis ................................................................................................................... 3 1.1.1 Aims ................................................................................................................................. 3 1.1.2 Hypothesis ........................................................................................................................ 6

1.2 Overview ...................................................................................................................................... 1

1.3 Purpose of Research ..................................................................................................................... 6

1.4 Significance of Research .............................................................................................................. 7

1.5 Thesis Outline .............................................................................................................................. 8

2 CHAPTER 2: LITERATURE REVIEW ....................................................................................... 9

2.1 Bone Fracture Healing and tissue engineering ............................................................................. 9 2.1.1 Bone Anatomy .................................................................................................................. 9 2.1.2 Tissue Engineering ......................................................................................................... 12

2.2 Melt Electrospinning .................................................................................................................. 20 2.2.1 The Physics of Electrospinning ...................................................................................... 21 2.2.2 The Governing Equations of Electrospinning ................................................................. 27

2.3 Charge Transport in Electric Jets ............................................................................................... 27 2.3.1 Coronal Discharge in Taylor Cone and Fibres................................................................ 29 2.3.2 Parasitic Electrospraying ................................................................................................ 31 2.3.3 Atmosphere and Charge Evaporation ............................................................................. 31 2.3.4 Residual Charge in the Polymer ..................................................................................... 32

2.4 Implications for Melt Electrospinning as an Additive Manufacturing Technique ..................... 34

3 CHAPTER 3: POLYMER EXTRUDER DESIGN ..................................................................... 36

3.1 Outline of the Requirements ...................................................................................................... 38

3.2 Design and Implementation ....................................................................................................... 38 3.2.1 Heating Jacket ................................................................................................................. 39

3.3 Pressure System ......................................................................................................................... 41

4 CHAPTER 4: HUMIDITY SYSTEM DESIGN ........................................................................... 43

4.1 Outline of the Requirements ...................................................................................................... 43

4.2 Design and Implementation ....................................................................................................... 44 4.2.1 The Saturator .................................................................................................................. 44 4.2.2 The Desiccator ................................................................................................................ 44 4.2.3 The Mixing Chamber ...................................................................................................... 46

5 CHAPTER 5: IMPROVED FABRICATION OF MELT ELECTROSPUN TISSUE

ENGINEERING SCAFFOLDS USING DIRECT WRITING AND ADVANCED ELECTRIC

FIELD CONTROL. ........................................................................................................................... 49

5.1 Introduction ................................................................................................................................ 51

5.2 Materials and Methods ............................................................................................................... 53 5.2.1 Melt Electrospun Scaffolds ............................................................................................. 53 5.2.2 Scaffold Characterisation ................................................................................................ 55

Melt electrospinning as an additive manufacturing technique

© 2018 Nikola Ristovski Page v

5.2.3 In Vitro Characterisation ................................................................................................ 56 5.2.4 Statistical Analysis.......................................................................................................... 58

5.3 Results and Discussion .............................................................................................................. 58 5.3.1 Physical Characterisation ................................................................................................ 58 5.3.2 Zonal Characterisation of structure order ....................................................................... 65 5.3.3 In Vitro Characterisation ................................................................................................ 67

5.4 Conclusion ................................................................................................................................. 69

5.5 Acknowledgements .................................................................................................................... 70

6 CHAPTER 6: CONCLUSIONS .................................................................................................... 71

6.1 Research Summary .................................................................................................................... 71 6.1.1 Summary of Research Paper ........................................................................................... 71

6.2 Limitations and Recommendations for Future Work ................................................................. 72 6.2.1 Charge Storage, Charge Dissipation ............................................................................... 72 6.2.2 Other Factors Causing Disorder and Near Field Melt Electrospinning .......................... 73 6.2.3 Scaffold Architecture and Order ..................................................................................... 74 6.2.4 Dynamically Controlled Electric Potential ..................................................................... 74

6.3 Final Discussion and Conclusion ............................................................................................... 74

7 CHAPTER 7: BIBLIOGRAPHY................................................................................................... 77

8 CHAPTER 8: APPENDICES ........................................................................................................ 86

8.1 Appendix B: Matlab code for order quantization ....................................................................... 86 8.1.1 Image Importer ............................................................................................................... 86 8.1.2 Image Analysis ............................................................................................................... 87 8.1.3 Fibre Positions ................................................................................................................ 88

8.2 Appendix C ................................................................................................................................ 89 8.2.1 Sample of Fibre Raw Image Data ................................................................................... 89

Melt electrospinning as an additive manufacturing technique

© 2018 Nikola Ristovski Page vi

List of Figures

Figure 2-1: The human skeleton indicating the different structures of bone. The axial skeleton forms the

pelvis, spine, ribs and skull. Appendicular skeleton is formed from the bones of the limbs [28]. . 9

Figure 2-2: Schematic diagram of long bone with close up’s showing sections of the marrow cavity and

structure of trabecular and cortical bone [30]. .............................................................................. 10

Figure 2-3: Stages of bone healing [31] ................................................................................................ 11

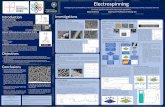

Figure 2-4: Different structures that are capable with a single type of polymer (PCL) that has been used

in a number of Additive manufacturing techniques and other fabrication techniques. Micro-

spheres (a, b). Nano-fibres (c, d). Foams (e, f). Knitted textiles (g, h, i). SLS scaffold (j-o). Fused

deposition modelled scaffolds (p–u) [20][38][39][40][41][42] .................................................... 13

Figure 2-5: A vascular stent, generally made from stainless steel 316L or titanium used to expand

sections of the artery [148]. .......................................................... Error! Bookmark not defined.

Figure 2-6: Schematic image of the fused deposition modelling system [149] ..................................... 15

Figure 2-7: Schematic diagram of a stereo-lithography system [150]................................................... 16

Figure 2-8: Schematic diagram of a selective laser sintering device [151] ........................................... 17

Figure 2-9: Tensile stress-strain curve of cortical bone with multiple strain rates [63] ........................ 18

Figure 2-10: An image illustrating Wolff’s law of bone, demonstrating he cancellous bone remodels

itself to the stress lines via mechano-transduction ....................................................................... 19

Figure 2-11: Schematic of an electrospinning apparatus. [75] .............................................................. 21

Figure 2-12: The dependence of melt viscosity on molecular weight. [82] .......................................... 22

Figure 2-13: Diagram showing the effect of creep and stress relaxation .............................................. 23

Figure 2-14: Schematic diagram of the emitter of an electrospinning system [88] ............................... 25

Figure 2-15: Momentum balance on a short section of the jet [79] ....................................................... 26

Figure 2-16: Visible coronal discharge in an electrospinning apparatus [103] ..................................... 29

Figure 2-17: Oscilloscope snapshot of the discharge current at different time points. The number on the

left corresponds to fibre accumulations for times of (1) 10 s, (2) 30 s, (3) 2 min, (4) 5 min, (5) 10

min, (6) 20 min [102] ................................................................................................................... 30

Figure 2-18: schematic diagram showing trapped charge (A, C) and empty sites (B, D) in a polymer

matrix [88] .................................................................................................................................... 33

Figure 2-19: Residual charge against time for positively and negatively biased polystyrene (PS)

scaffolds. [5] ................................................................................................................................. 34

Figure 3-1: Schematic of various heating approaches performed for melt electrospinning [9]............. 36

Figure 3-2: Melt electrospinning extruder designed by Hacker et al. [117] .......................................... 37

Figure 3-3: Line-like laser beam melting electrospinning developed by Shimada et al. [118]. ............ 37

Figure 3-4: Li et al.’s umbellate melt electrospinning extruder [119]................................................... 38

Figure 3-5: A comparison of the updated extrusion system (A) and the syringe pump extrusion system

(B) ................................................................................................................................................ 39

Figure 3-6: (A) Graph showing the dependence on the input temperature against the temperature at the

needle tip. (B) Imaging showing the distribution of temperature across the extruder, with the

extrusion tip facing the bottom. Modelled using ANSYS static thermal package (ANSYS,

USA)............................................................................................................................................. 40

Figure 3-7: Initial Design (A) vs. Final Design (B) of the extrusion system for the melt

electrospinner ............................................................................................................................... 41

Melt electrospinning as an additive manufacturing technique

© 2018 Nikola Ristovski Page vii

Figure 3-8: Schematic diagram of the pressure extrusion system ......................................................... 42

Figure 4-1: Image of saturator designed by Johnson et al. .................................................................... 44

Figure 4-2: Absorbance characteristics of common desiccants ............................................................. 45

Figure 4-3: Initial design for humidity control system. Control box is the melt electrospinning device,

which will act like a mixing chamber in this configuration. Temperature and filtering have since

been removed from the system ..................................................................................................... 46

Figure 4-4: Simulink model of humidity controller .............................................................................. 48

Figure 4-5: Transient response of humidity system .............................................................................. 48

Figure 5-1: Novel direct writing melt electrospinning platform with dual voltage power supplies for

improved fibre deposition control. The negative power supply attached to the collector plate being

the defining difference in this system. .......................................................................................... 54

Figure 5-2: Distribution of pore sizes for group D (+7 kV tip: -3.5 kV collector). The data shows two

apparent peaks at 282 μm and 378 μm which can be attributed to the fibre separation in the x-y

plane. ............................................................................................................................................ 59

Figure 5-3: Fibre diameter for different voltage distributions as measured via SEM. Each value was

taken by manually measuring the diameter using ImageJ software (n = 48 fibres). The data shows

no statistical significance between any groups (p > 0.05). ........................................................... 60

Figure 5-4: Image of µCT reconstruction of scaffold from group D (+7 kV tip: -3.5 kV collector) with

an x-y fibre spacing of 500 µm..................................................................................................... 60

Figure 5-5: SEM cross-sectional images (x-z plane) of melt electrospun scaffolds with distributions of

voltages, varying from 0 to 10.5 kV, between the tip and the collector (see Table 1). (A-D) show

scaffolds produced using negative voltage on the collector plate. Scaffold (E) is the control; it is

produced by grounding the collector plate. (F) Illustrates the Structure order calculated via Eq. 1

for scaffolds of group A-D and Control. Os=1 indicates perfect fibre stacking across all layers,

Os>1 indicates fibre stacking disorder. * indicates a statistical significant mean against control (p

< 0.05). Uncertainties are computed from the standard deviation. ............................................... 62

Figure 5-6: Change in fibre order as the number of layers increases. The vertical inter-fibre distance

taken from the axial centre of the fibres indicates fibre order. The results correspond to scaffolds

from group D (+7 kV tip: -3.5kV collector). ................................................................................ 63

Figure 5-7: A scaffold with 1 mm fibre spacing produced using group D (+7 kV tip: -3.5 kV collector).

The scaffold reached a height of 200 layers (2 mm thickness). This illustrates that by decreasing

the density of fibres, the stacking increases. ................................................................................. 64

Figure 5-8: SEM micrographs of a scaffold from group B showing x-z cross section. This illustrates the

zonal arrangement of the fibre networks. Sections a, b, and c, are magnified sections of scaffold.

The first zone shows a highly ordered structure with large levels of control on fibre deposition.

The secondary zone (semi-ordered) demonstrates some level of control; however the position of

fibre deposition is largely influenced by electrostatic forces. The final zone (disordered) shows a

complete lack of fibre control with deposition dominated by electrostatic forces. ...................... 66

Figure 5-9: Maximum heights of the ordered zone for scaffolds fabricated for phase 1. Groups A –D

had significantly larger ordered zones compared to the control group (p < 0.05). ....................... 67

Figure 5-10: (A) and (B) Cell distribution illustrated using a live/dead stain indicating the presence of

cells across the surface of the scaffold. Images (C) and (D) show cell morphology as imaged

through a DAPI/Phalloidin stain, illustrating cells attaching and spreading on the scaffold fibres

illustrating good cellular interaction. ............................................................................................ 68

Figure 5-11: MTT data of the percentage increase in cell growth showing an approximately uniform

level of cell proliferation for all scaffolds (n = 6) (p < 0.05). Errors bars indicate standard

error. ............................................................................................................................................. 69

Melt electrospinning as an additive manufacturing technique

© 2018 Nikola Ristovski Page viii

List of Tables

Table 1-1: Table indicating the effects of the independent parameters on the electrospinning jet. ......... 4

Table 1-2 : Table outlining the range with which the parameters were adjusted during the melt

electrospinning optimization. ......................................................................................................... 4

Table 1-3: Table describing the parameters associated with electrospinning. TTC described the distance

between the needle tip to the collector plate and translational speed is the speed of the X/Y/Z

stages. ............................................................................................................................................. 4

Table 5-1: Phase 1 scaffold groups and their corresponding needle tip and collector plate voltages. Six

scaffolds were produced for each group. ...................................................................................... 55

Table 5-2: Number of scaffolds and structural parameters produced for phase 2 of the study. ............ 55

Melt electrospinning as an additive manufacturing technique

© 2018 Nikola Ristovski Page ix

List of Publications

Ristovski, N., Bock, N., Liao, S., Powell, S.K., Ren, J., Kirby, G.T., Blackwood, K.A. and

Woodruff, M.A., 2015. Improved fabrication of melt electrospun tissue engineering scaffolds

using direct writing and advanced electric field control. Biointerphases, 10(1), p.011006.

Melt electrospinning as an additive manufacturing technique

© 2018 Nikola Ristovski Page x

List of Abbreviations

One Dimension..................................................................................................................................... 1D

Two Dimensions .................................................................................................................................. 2D

Three Dimensions ................................................................................................................................ 3D

4', 6-diamidino-2-phenylindole ....................................................................................................... DAPI

Dimethyl Sulfoxide ....................................................................................................................... DMSO

Extra Cellular Matrix ...................................................................................................................... ECM

Food and Drug Administration ........................................................................................................ FDA

Fused Deposition Modelling ............................................................................................................ FDM

Fluorescein Diacetate ....................................................................................................................... FDA

3-(4, 5-Dimethylthiazol-2-yl)-2, 5-Diphenyltetrazolium Bromide .................................................. MTT

Polycaprolactone .............................................................................................................................. PCL

Poly vinyl alcohol ........................................................................................................................ PVOH

Propidium Iodine .................................................................................................................................. PI

Polystyrene .......................................................................................................................................... PS

Scanning electron microscopy ........................................................................................................ SEM

Selective laser sintering ..................................................................................................................... SLS

Stereo lithography ............................................................................................................................ SLA

Tip to collector ................................................................................................................................ TTC

William-Landel-Ferry ..................................................................................................................... WLF

Melt electrospinning as an additive manufacturing technique

© 2018 Nikola Ristovski Page xi

Statement of Original Authorship

The work contained in this thesis has not been previously submitted to meet requirements

for an award at this or any other higher education institution. To the best of my knowledge and

belief, the thesis contains no material previously published or written by another person except

where due reference is made.

Signature:

Date: __17/04/2018______________

QUT Verified Signature

Melt electrospinning as an additive manufacturing technique

© 2018 Nikola Ristovski Page xii

Acknowledgments

I would like to acknowledge the entire biofabrication and tissue morphology group for their

help throughout my Masters. In particular I’d like to thank my supervisors Dr. Sean Powell,

Assoc. Prof. Mia Woodruff and Dr. Keith Blackwood for all their help and guidance

throughout. I’d like to thank my family for all of their support during my masters and finally

(in no particular order) I’d also like to thank Sha Pather, Pelin Tufekci, Nicole and Michael

Bartnikowski, Kristopher Bogoevski, Andy Yaun, Stephanie Fontaine and Sam Liao. A

special mention to Giles Kirby, Patrina Poe and Nathalie Bock for helping me out at the

beginning of my studies, and Christina Theodoropoulos and Soniya Yambem for the help at

the end of my studies. For anyone else I forgot to mention, I thank you as well.

Chapter 1: Introduction

© 2015 Nikola Ristovski Page 1

1Chapter 1: Introduction

1.1 OVERVIEW

Musculoskeletal injuries make up approximately 10.3% of all medical spending in the United

States (which in 2008 equated to USD$117.2 billion). In the US, long bone, non-union

fractures make up approximately 10% of all non-fatal injuries and are the number one category

for inpatient expenditure [1]. Australia alone spends approximately AUD$15 billion per

annum on musculoskeletal disorders [2]. These statistics illustrate that musculoskeletal

conditions are currently a major burden on the medical industry globally and this challenge is

predicted to increase with an ageing population [2].

Bone is capable of remarkable repair and regeneration; however, it is not able to fully heal if

the fracture site is too large. In addition, current surgical intervention techniques often lead to

inconsistent results [3]. Post-operative complications in bone healing occur in approximately

14-28% of cases, with non-union being a major outcome [2], [3]. Current methods of treatment

for non-union fracture sites include the autograft and allograft. An autograft is the removal of

the patients own tissue from a donor site for placement into the fracture site whereas an

allograft transplants the required tissue from another human to the fracture site. While these

treatments are the current gold standards in non-union fractures, drawbacks exist [4]. For

autografts, complications include surgical (in more than 30% of cases), donor site morbidity,

and limited availability of donor material [5]. Allografts also suffer similar problems and have

the added issue of immune response complications. Hence, an approach must be formulated

that is capable of using minimal autologous tissue, or alternatively, negating its use entirely

through the development of implantable scaffolds. This scaffold based approach will provide

a high degree of flexibility to tackle the social, economic, and personal issues facing tissue

regeneration and repair.

Bone Tissue Engineering is the study of growth of new connective tissue and organs for the

production of devices to be implanted back into the donor site as replacements or for assisted

recovery, particularly for bone tissue. This field involves a range of diverse skills, including

mechanical and materials engineering, medicine and cell biology. Scaffold production for

insertion into the donor site is a major field within bone tissue engineering. This approach

provides physical support for cells to proliferate during the healing process. In the case of bio-

resorbable constructs, the supportive scaffolds degrade as the fracture heals leaving only

natural human bone [5].

Chapter 1: Introduction

© 2015 Nikola Ristovski Page 2

The central aim of tissue engineering involves combining the body’s natural healing capacity

with an engineered solution in order to produce better outcomes [6]. As the influences of

micro-architecture, cell signalling and the local micro and macro environment on tissue growth

become clearer, tissue engineers will be able to produce optimal scaffolds for bone tissue

repair. The current generation of scaffolds are predominantly polymer based and consequently

are only osteoconductive but not osteoinductive. Osteoconductive implies that the scaffolds

are able to guide cell growth and osteoinductive implies that they are able to induce cell

differentiation and proliferation into the tissue of interest. Porter et al. [6] suggest that the

following list of requirements for a biomimetic scaffold be met:

1. Provide temporary mechanical support to the affect area.

2. Act as a substrate for osteoid deposition.

3. Contain a porous architecture to allow for vascularisation and bone ingrowth.

4. Encourage bone cell migration into the scaffold.

5. Support and promote osteogenic differentiation in the non-osseous, synthetic

scaffold (osteoinduction).

6. Enhance cellular activity towards scaffold-host tissue integration

(osteointegration).

7. Degrade in a controlled manner to facilitate load transfer to developing bone.

8. Produce non-toxic degradation products.

9. Not incite an active chronic inflammatory response.

10. Be capable of sterilization without loss of bioactivity and.

11. Deliver bioactive molecules or drugs in a controlled manner to accelerate

healing and prevent pathology.

A number of approaches to solving these problems have been developed and used

concurrently, including changes to microarchitecture [7], functionalization of the scaffold

surface [8], polymer modification, and incorporation of bioactive particles in the polymer

scaffold [9]. When appropriately combined, it is possible to solve a large number of these

challenges using these methods; this being a primary objective of tissue engineers today.

The microarchitecture of a tissue engineering scaffold can be produced using additive

manufacturing techniques. By producing the scaffolds in a layer-by-layer manner, it is possible

to introduce internal structures which are not easy to add using other fabrication methods.

Additive manufacturing is able to fabricate tissue engineered scaffolds using a range of

methods, the most popular being fused deposition modelling (FDM), selective laser sintering

(SLS) and stereo-lithography (SLA). Electrospinning (ES), which has traditionally been used

as a technique to produce fine disordered meshes, is another method with promise as an

Chapter 1: Introduction

© 2015 Nikola Ristovski Page 3

advanced additive manufacturing technique [10]. Electrospun fibres are produced by drawing

a polymer/solvent solution through a large electric potential (greater than 10 kV) onto a

collector plate. Melt-electrospinning is an application of electrospinning where a polymer melt

is deposited onto a collector in a more controlled manner, producing 3D constructs in a method

akin to FDM. Due to the lack of solvent and much higher viscosity of the polymer, the

whipping experienced in solvent electrospinning is mitigated, allowing controlled fibre

deposition for 3D printing.

The overall aim of this master’s project is to advance direct writing melt electrospinning as a

superior additive manufacturing technique for tissue engineering by quantifying the

relationship between electric charges in the polymer, the electric field, and fabrication

stability. Polycaprolactone (PCL) is a commonly used polymer in tissue engineering [5] and

will be used in this study owning to its low melting point (60 °C), approval from the American

Food and Drug Administration (FDA) for clinical use, and its established use as a material

with melt electrospinning [7, 8]. Melt electrospinning is a process that was brought to the

attention of tissue engineers in the early 2000’s [13] due to its greater viscosity and subsequent

higher fabrication stability compared to its solution electrospinning counterpart. Due to this,

it enabled electrospinning to be applied as an additive manufacturing technique [12], however,

problems existed which prevented it from creating truly ordered structures above certain layer

heights [14]. This is, in part, due to charge build-up in the polymer preventing the scaffold

from being stacked accurately beyond a certain number of layers.

This project therefore seeks to:

Improve the understanding of charge build-up in a polymer in a high electric field

Quantify the degree of disorder due to the residual charge

Produce scaffolds to determine the effect of residual charge on stacking

1.2 AIMS AND HYPOTHESIS

1.2.1 Aims

The aim of this master’s thesis was to observe the effective of distributing charge across the

emitter and collector of a melt electrospinning device to determine whether this would have a

positive impact on fiber laydown accuracy.

1.2.1.1 Optimizing the fabrication method in a melt electrospinner to produce 0-

90° cross-hatch scaffolds

Optimization of the melt electrospinning process was completed using Poly-Caprolactone

(PCL) (Perstop, Capa6430®). Each parameter was varied over a range determined by

Chapter 1: Introduction

© 2015 Nikola Ristovski Page 4

previously reported values which successfully produced melt electrospun fibres [12], [11].

Studies completed from Table 1-1 were used to determine which parameters would be varied

and Table 1-2 lists the parameters that were adjusted in the study.

Table 1-1: Table indicating the effects of the independent parameters on the electrospinning jet.

Parameter Effect Study

Electric Field

- Decreases fibre diameter for increases field

- Increases charge storage for increased field

- Dictates the location of deposition

Lyons et al. [13] Zhmayev et al. [15] Zhang and Jan [16] Teo and Ramakrishna [17] Ristovski et al. [14]

TTC Distance

- Effects the electric field - Increases the cooling time before

deposition - Effects the position of deposition

with respect to the whipping zone

Dalton et al. [18] Hutmacher and Dalton [10] Huang et al. [19]

Temperature

- Effects the viscosity of fluids - Increase in temperature reduces

fibre diameter

Lee et al. [20] Dalton et al. [11] Zhmayev et al. [21] Deng et al.[22]

Translation Speed

- Changes the morphology of laydown of fibres

- Increases/decreases the accuracy of deposition

- Introduces whipping effects

Brown et al. [12] Sun et al. [23]

Polymer Flow Rate - Should be adjusted based on the

velocity of fibre extruded by the electric field

Lyons et al. [13] Deitzel et al. [24]

Table 1-2 : Table outlining the range with which the parameters were adjusted during the melt

electrospinning optimization.

Potential Difference TTC Distance Temperature Translation speed Polymer flow rate

5-15 kV 5-50 mm 60-90 °C 300-1200 mm/min 30-90 µL/min

The properties of the scaffold, such as diameter and order, were observed throughout the

optimization phase until the parameters from Table 1-3were determined to produce optimal

scaffolds:

Table 1-3: Parameter used to produce scaffolds. TTC described the distance between the needle tip to

the collector plate, and translational speed is the speed of the X/Y/Z stages.

Voltage (+) Voltage (-) TTC Distance Temperature Translation speed Polymer flow rate

7 kV -3.5 kV 10 mm 73 °C 1000 mm/min 45 µL/min

Chapter 1: Introduction

© 2015 Nikola Ristovski Page 5

1.2.1.2 SEM analysis of cross sections of electrospun scaffolds to determine order

and heights of ordered regions

A method associated with tortuosity was created to determine the order of a scaffold produced

in the electrospinning device (tortuosity being the ratio of the length of a path taken and the

distance between the starting and ending points). Scaffolds were produced and the distribution

of the voltage between the tip and the collector was varied in 2 kV intervals. The distribution

in electric charge was then assessed by imaging the cross-section of scaffolds in using scanning

electro microscopy (SEM). The data was used to determine the height of the ordered region as

well as the order in the scaffold.

1.2.1.3 µCT analysis of electrospun scaffolds to determine the pore size and

distribution

An analysis of the internal structure of the electrospun scaffolds was completed using micro

tomography (µCT). The optimal scaffolds were determined using the SEM analysis. They

were then analysed using the µCT to determine the size and distribution of pores in the

scaffolds.

1.2.1.4 Assessment of the in vitro biocompatibility of a scaffold via live/dead

staining, DAPI/Phalloidin and MTT assay

Electrospinning parameters from the optimal group were used to produce scaffolds for cell

culture. Sterilized scaffolds were used to determine the biocompatibility of highly ordered melt

electrospun scaffolds. The scaffolds were seeded using MC3T3 cells for a period of 7 days. 3-

(4,5-dimethylthiazol-2-yl)-2,5-diphenyltetrazolium bromide (MTT) assays were performed on

days 1 and 7 to determine the change in metabolic activity over the culture period. Live/dead

(fluorescein diacetate (FDA) (live) and propidium iodide (PI) (dead)) and 4', 6-diamidino-2-

phenylindole (DAPI)/ phalloidin assay were performed on the 3rd day of the trial as a

qualitative measure of biocompatibility and to determine the cell morphology, respectively.

This study was completed and published:

Ristovski, Nikola, Nathalie Bock, Sam Liao, Sean K. Powell, Jiongyu Ren, Giles TS Kirby,

Keith A. Blackwood, and Maria A. Woodruff. "Improved fabrication of melt electrospun

tissue engineering scaffolds using direct writing and advanced electric field

control." Biointerphases 10, no. 1 (2015): 011006.

Full details of the study are presented in-depth in chapter 4 as per publication [14].

Chapter 1: Introduction

© 2015 Nikola Ristovski Page 6

1.2.2 Hypothesis

1.2.2.1 Negative voltage on the collector plate

The addition of a negative voltage power supply to the collector of the melt electrospinning

device will increase the deposition accuracy of the fibre over a larger period of overlapping

fibres (this study has been published in Biointerphases and comprises Chapter 5). When fibres

lay down onto the collector plate, residual charge is stored in the polymer, or on the polymer

surface. Studies have shown that the charge can remain on or in the polymer for days at a time.

The addition of a negative voltage to the collector plate will increase the potential difference

felt by the charges in their local environment. This will encourage the emission of charge from

the polymer to the collector plate. The smaller charge that is stored in the polymer, the less

columbic forces are felt on the fibre when it is being stacked, which will result in more order

in the scaffold as fibres are layered.

1.2.2.2 Quantifying order

Quantifying the order in a cross-hatch scaffold is necessary for comparing scaffolds produced

using the negative charge applied to the collector plate. Using a method analogous to

tortuosity, it is possible to do this. Tortuosity is the arc-chord ratio, or the ratio of the length

of a path to the distance between its ends. This property is used in a number of physical

characterisations, including porosity and interconnectivity of porous scaffolds. By measuring

the distance from the top and bottom fibres in a scaffold and finding the path taken from each

fibre, it is possible to calculate the tortuosity which will be used to quantify order within the

scaffold.

1.2.2.3 Incrementally improved melt electrospinning device

The melt electrospinning system that is currently used in the laboratory is a culmination of

years of research and development in the Biofabrication and Tissue Morphology (BTM) group

at QUT. However, as direct writing melt electrospinning is a fairly new technology, the system

is constantly improved based upon the outcome of current research. The following research

aims at improvements to the melt electrospinning device, as well as determining the effect of

a negatively charged collector plate on ordered scaffold production.

Chapter 1: Introduction

© 2015 Nikola Ristovski Page 7

1.3 PURPOSE OF RESEARCH

The purpose of this research is to develop the hardware, theoretical models and experimental

results to improve the ability of direct writing melt electrospinning to produce morphologically

relevant scaffolds for tissue engineering. To achieve this, we grouped the research into four

aims; (1) Determine whether the melt-electrospinning fabrication process is dominated by

surface or volume charges and the relative charge-diffusion time-scales using a first principles

modelling approach. This is to provide a theoretical basis in order to understand how to

mitigate the unwanted charge effects. (2) To establish a method to characterise scaffold

structural order to enable quantitative comparisons between different samples, and (3) perform

an experimental study of electric field and polymer interactions in order to mitigate

undesirable electric charge accumulation and improve melt-electrospinning as a technique for

producing morphologically relevant tissue engineering scaffolds. This third aim involved

systematically varying the electric potentials on both the polymer extruder and the collector in

a custom made melt electrospinning system and conducting scaffold fabrication experiments.

Due to the tissue engineering application of these scaffolds, In vitro studies were also

undertaken to demonstrate that our fabrication technique had no adverse effect on cell

proliferation and morphology.

1.4 SIGNIFICANCE OF RESEARCH

Within the field of tissue engineered, additive manufacturing has become an established

technique for producing scaffolds. However, limitations exist with current approaches in their

application to this field. Methods such as FDM are able to produce complex structures but on

a scale larger than optimal for cell attachment and proliferation [25]. Conversely, techniques

such as SLA are able to produce extremely fine structural detail, but are limited to photo-

curable polymers, which are generally cytotoxic. Melt electrospinning enables the production

of fibres on a scale much smaller than FDM and any other plastic extrusion method, while

allowing for a relatively high degree of deposition control. However, advanced knowledge of

electric field/polymer interaction is required in order to produce scaffolds with high degrees

of structural order at a scale appropriate for tissue engineered constructs. The results of this

research have led to changes in the design and function of the BTM machines in subsequent

research.

Chapter 1: Introduction

© 2015 Nikola Ristovski Page 8

1.5 THESIS OUTLINE

The aim of this project was to determine whether charge had an effect on stacking order and

whether that charge could be minimized to achieve improved layer structure in melt

electrospun scaffolds. This thesis presents the research involved to determine the effect of

charge on ordered melt electrospun scaffolds.

Chapter 2 provides a comprehensive literature review which was used to guide the decision

making during this research. Chapter 2.1 through to 2.3 provides the background of bone tissue

repair and the clinical need which motivated this study. Section 2.4 is an in-depth investigation

on the current research into melt electrospinning which, at the inception of this project, was a

little known field and has since become a major contender in the field of tissue engineering.

Section 2.5 presents why tortuosity was used as a method for quantifying stacking order in

melt electrospun fibres. Section 6 outlines the literature and reasoning behind the theory that

charge is the major cause of disorder in melt electrospun scaffolds. The final section outlines

the aims and hypothesis.

In chapter 3 and 4, this thesis will outline the hardware that was built to support the research

during the master’s project. An extensive amount of time went into building devices; chapter

3 discusses the construction of the polymer extruder, chapter 4 discusses the construction of

the humidity control system used for further research by Sam Lioa et al [26].

Chapter 5 discusses the effect that the addition of a negative voltage has on the stacking of

fibres.

Finally, chapter 6 is a collective summary of the work completed in the masters, including a

discussion on the limitations of the project as well as recommendations for future work. A

conclusion is then provided after an analysis of all available data from the project.

Chapter 2: Literature review

© 2015 Nikola Ristovski Page 9

2Chapter 2: Literature review

2.1 BONE FRACTURE HEALING AND TISSUE ENGINEERING

2.1.1 Bone Anatomy

The adult human skeleton contains 206 bones, with variations between individuals (not

including sesamoid bones). The appendicular skeleton has 126 bones, axial contains 74 bones

and the auditory ossicles comprise 6 bones [27]. There are five general categories of bone,

long bones, short bones, flat bones, irregular bones and sesamoid bones [27]. Flat bones are

formed by membranous bone formation while long bones are a combination of endochondral

and membranous bone formation [27]. Figure 2-1 illustrates the shapes and positions of the

four categories of bone.

Figure 2-1: The human skeleton indicating the different structures of bone. The axial skeleton forms the

pelvis, spine, ribs and skull. Appendicular skeleton is formed from the bones of the limbs [28].

The bones in the skeleton provide structural support for the body, form attachment points for

muscle to use as lever systems and also protect vital organs from external forces. They also

serve physiological roles in homeostasis of mineral and acid-base balance, as reservoirs for

Chapter 2: Literature review

© 2015 Nikola Ristovski Page 10

signalling proteins and cytokines and the production of blood cells within the marrow spaces

[27].

The skeletal system consists of 80% cortical (compact) bone and 20% trabecular (spongy)

bone [29]. The cortical bone is dense and solid and is the major load bearing component of

bone. Trabecular bone consists of a honeycomb network of plates and rods in the bone marrow

cavity. Figure 2-2 illustrates the relative position and morphology of cortical (compact) and

cancellous (spongy) bone.

Figure 2-2: Schematic diagram of long bone with close up’s showing sections of the marrow cavity and

structure of trabecular and cortical bone [30].

Cortical osteons are known as the Haversian system. They form a network within the cortical

bone consisting of a system of cylinders surrounded by concentric lamellae of 400 µm (length)

and 200 µm (width). The porosity of cortical bone is less than 5%; however, this number

depends highly on the activity of the remodelling system, with increased Haversian

remodelling causing an increase in cortical porosity [27].

The trabecular osteons, known as packets, consist of rods and cones with an average thickness

between 50 to 400 µm. remodelling within the trabecular bone occurs at a faster rate than

cortical bone.

Bone’s unique multi-phase architecture, with cortical bone’s high strength and stiffness and

trabecular bone’s low moduli give it the property of high tensile strength and high fracture

Chapter 2: Literature review

© 2015 Nikola Ristovski Page 11

toughness. Bone is constantly remodelling to mechanical and physiological cues and a

microscopic view of bone shows a highly complex, ever changing tissue. There are three types

of cells that make up bone; osteoclasts, osteoblasts and osteocytes and they are all involved in

the remodelling of the bone structure [27].

2.1.1.1 Fracture Healing

The process of bone fracture healing is known as secondary healing. It involves the normal

embryonic process coupled with bone remodelling. The process is split into the inflammation

phase, soft callus formation, hard callus formation, and remodelling [31]. Figure 2-3 illustrates

the process along with rough timescales for each step.

Figure 2-3: Stages of bone healing [31]

The first stage of fracture healing, fracture haemotoma, involves clotting of blood, which

initiates an inflammatory response including the dilation of capillaries, release of white blood

cells and the budding of new capillary formation [31]. Within the first 2 to 3 days, phagocytes

remove dead tissue and fibroblasts enter the fracture site, forming granulation tissue. Bone

remodelling and callus formation begins at this stage as well, along with neovascularisation.

Chondrocytes secrete new extra cellular matrix (ECM) forming fibrocartilage, creating the soft

Chapter 2: Literature review

© 2015 Nikola Ristovski Page 12

callus. Hard callus begins to form as the soft callus mineralises through endochondral and

intramembranous ossification [31].

In certain cases the healing process may be compromised, such as in a critical sized defect, or

due to infection. These cases may become non-union fractures if clinical intervention does not

take place. The gold standard for treating critical sized defects is the bone graft. A bone graft

is a procedure where a section of bone is sourced from a donor site and placed into the fracture

site, providing a matrix for bone to bridge the fracture gap. Three types of bone graft exist;

autograft, allograft and xenograft. The autograft is the current gold standard for treatment. It

involves the removal of bone from a donor site in the patient’s own body and placement into

the fracture site. Allograft is similar, except the donor site is in another human being. And in

certain rare cases, xenografts are taken from a donor animal.

Despite the autograft being the gold standard in treatment, complications still occur and

progress has been slow in improving the technique over the past 20 years. Approximately 20%

to 30% of autografts patients experience donor site morbidity, and greater than 30% of

allograft cases experience complications such as non-unions and infections [32].

Due to the shortcomings of the autograft and allograft, bone tissue engineering as a field was

created [33]. It combines the principles of engineering with life sciences and material science,

to produce biological substitutes that are capable of restoration, maintenance and improvement

of tissue function and repair [34]. Since the early 2000s, tissue engineering has entered the

spotlight as a method to treat various diseases including cardiovascular, respiratory,

musculoskeletal, eye, oral and renal.

2.1.2 Tissue Engineering

In the past ten years, tissue engineering has seen dramatic advancements in human tissue

regeneration. The aims of tissue engineering is to restore, maintain and/or improve the function

of tissue by developing a biological substitute or reconstructing tissues [35]. Bone tissue

engineering is a subfield which concentrates on fracture healing in the skeletal system.

Scaffolds for bone tissue engineering have seen an exponential rise in the number of

publications over the past decade, mainly due to promising results of new bone formation and

repair of segmental defects in both small and large animal studies [36]. The number of novel

scaffolds produced for bone tissue engineering has increased over the past few years and an

investigation into the production, functionalization and materials used should be reviewed to

determine the efficacy of each system.

Chapter 2: Literature review

© 2015 Nikola Ristovski Page 13

There are three research topics in scaffold production for bone tissue engineering; materials,

biofabrication and drug delivery systems. Biofabrication deals with methods for scaffold

production, this includes additive manufacturing techniques. The materials used to produce

these scaffolds is its own research field and can be split into polymers, ceramics, metals and

composites. Tissue engineering scaffolds as drug delivery systems are a combination of the

above with the inclusion of bioactive compounds to stimulate bone healing.

2.1.2.1 Materials for Tissue Engineering

Polymer analysis and synthesis is a key focus area for materials engineers in tissue

engineering. Recent trends in literature suggest that biodegradable polymers are the preferred

material of choice [36]. The advantage associated with biodegradability is its ability to support

tissue for a period of time before being resorbed by the body after its functional lifespan [37].

Two subgroups of polymers are used; natural polymers (including collagen, chitosan) which

have lower immune response and (in certain cases) a bioactive component, and synthetic

polymers whose advantage lies in easier tailoring of its physical properties (biodegradation

rate, more predictable properties and consistency) than its natural counterpart [37]. Figure 2-4

illustrates the breadth of structures which can be produced using polycaprolactone (PCL).

Figure 2-4: Different structures that are capable with a single type of polymer (PCL) that has been used

in a number of Additive manufacturing techniques and other fabrication techniques. Micro-spheres (a,

b). Nano-fibres (c, d). Foams (e, f). Knitted textiles (g, h, i). SLS scaffold (j-o). Fused deposition

modelled scaffolds (p–u) [5], [38], [39], [40], [41], [42]

Chapter 2: Literature review

© 2015 Nikola Ristovski Page 14

Ceramics for bone tissue engineering show promise due to their biocompatibility and

extremely low wear rates. The most common ceramic available in the field are calcium

phosphates (CaP) (Hydroxyapatite, tri-calcium phosphate). The advantages of ceramics come

from their high Young’s modulus, however they conversely have low fracture toughness and

are brittle. This makes them exceptional substitutes in compressive loading cases [43]. Low

wear and high Young’s moduli allow ceramics to be used in an articulating surface, which has

seen use in artificial joints [44]. Manufacturing of complex structures with ceramics is a costly

and difficult process, hence it has seen little use as a stand-alone solution in tissue engineering.

Metals have high compressive strengths and

excellent fatigue resistance. The predominant

metal used in tissue engineering is titanium [45].

Metal has a number of advantages over polymers

and ceramics due to its high tensile strength and

toughness, making it a flexible candidate to be

used for both compressive and tensile loads.

However, unlike degradable polymers which are

able to degrade in the body with little side

effects, and ceramics which have very low wear,

metals are known to release ions into the surrounding tissue, which has been known (with

certain metals) to cause immune responses and necrosis [46]. Production processes for metal

implants are expensive, but are well established and products produced with SLS have gone

to preclinical, in vivo trials [47].

Composite materials are a blend of polymers, ceramics and metals designed to provide a

system which has desirable physical properties from two or all three fields. Composites are

made of two phases, the matrix and the dispersed phase. The matrix phase is the stress transfer

medium, while the dispersed phase is a constrictor, preventing movement of the matrix phase

[48]. This system can be split into three groups, particle reinforcement, fibre reinforcement or

structural reinforcement. Each system describes the method that the dispersed phase is mixed

with the matrix phase Polymer-ceramic composites have yielded promising results [9].

Additionally, PCC materials combined with metals have seen improvements in osteogenesis

[49] as well as physical properties for the material. The use of composite materials is promising

due to its customisable physical and biological properties; however, changes to the material

properties requires re-optimization of the manufacturing techniques.

Figure 2-5: A vascular stent, generally made

from stainless steel 316L or titanium used to

expand sections of the artery [148].

Chapter 2: Literature review

© 2015 Nikola Ristovski Page 15

2.1.2.2 Additive Manufacturing for Tissue Engineering

Additive manufacturing has become the main fabrication technique for tissue engineering. A

large number of techniques exist within the field; hence, this section focuses on the three most

popular techniques currently available. Additive manufacturing is a manufacturing technique

which allows the production of an object by the addition of material; the three most common

methods are fused deposition modelling (FDM), stereo-lithography (SLA) and selective laser

sintering (SLS). Hereafter these techniques will be examined.

FDM (also known as melt extrusion manufacturing) is a technique using a thermoplastic

filament which is fed through a heating liquefier. The solid filament acts as a piston and pushes

the melt through a print head [50]. The system is attached to a gantry which allows the printing

head to extrude the polymer in the horizontal plane. Each layer is filled in by the polymer and

consecutive layers are then stacked to produce a 3D structure. This technique is one of the

oldest 3D printing methods and is well established. It is used extensively in tissue engineering

for solid polymer scaffolds [51] as well as hydrogel scaffolds [52]. The advantages of FDM

lie in its flexibility. The basic extrusion method is applicable to many different polymers and

composites and therefore it has been used to produce structural scaffolds as well as cell loaded

polymers and even composites with drug-loaded polymers [53].

Figure 2-6: Schematic image of the fused deposition

modelling system [149]

Chapter 2: Literature review

© 2015 Nikola Ristovski Page 16

SLA uses a photo-curable polymer which solidifies under the selected photo-initiated cure

reaction [54]. Two methods exist to initiate curing; the first is a mask-based method which

involves the irradiation of the polymer by an image through a patterned mask, the second

method involves direct writing onto the polymer via a focused ultra-violet beam. This

technique produces the highest resolution of scaffolds of the three common additive

manufacturing processes (resolution as low as 20 µm [55]). Despite the high resolution and

the product existing for nearly 20 years, the technique has not seen as wide spread use as other

3D printing techniques [56]. Increased interest in SLA in tissue engineering has occurred

recently, partly due to its high resolution constructs as well as recent advances in non-cytotoxic

photocurable polymers. Bioactive compounds [57], specific binding proteins in and on the

resin [58], and recently natural polymers have been printed using this technique [59].

Figure 2-7: Schematic diagram of a stereo-

lithography system [150]

Chapter 2: Literature review

© 2015 Nikola Ristovski Page 17

SLS involves heating a powdered material just beyond its melting point via an infrared laser

[54]. The laser files the shape by melting selected sections of powder, retreats as a new layer

of powder is added and repeats the process until the object is formed. This technique is

generally used for ceramics and metals; however is also used in polymer based systems. SLS’s

advantage lies in its ability to produce 3D printed metal parts; however, due the inherent nature

of melting a powder, it is limited in its ability to 3D print living organism which the previous

two systems were capable of [54].

The final group of tissue engineering falls within drug delivery. Briefly, this can be a

combination of any appropriate material and manufacturing technique to produce a system

which can release drugs to a target location and maintain a target dose for a desired period of

time. Despite many biomaterials’ ability to provide essential mechanical support and

attachment, most are not able to produce direct changes in cellular differentiation as efficiently

as drugs and signalling proteins [60]. Hence, tissue engineering scaffolds must act as both a

construct for cell adhesion and proliferation as well as provide the correct physiological cues

to regenerate non-union fractures in bone tissue engineering.

2.1.2.3 Bone characterisation: composition, architecture, biomechanics

Design of biomimetic scaffolds relies heavily on the reliable and accurate characterisation of

natural bone. A comprehensive review of the biomechanical, structural and compositional

characteristics of bone will be detailed here.

Figure 2-8: Schematic diagram of a

selective laser sintering device [151]

Chapter 2: Literature review

© 2015 Nikola Ristovski Page 18

The musculoskeletal system is composed of 10 to 20% collagen, 60 to 70% bone mineral and

9 to 20% water (measurements in weight percentage) [29].

The architecture of bone varies based on the type of bone, as discussed in section 2.1.1 (Bone

anatomy). The mass of long bone is comprised of 80% cortical bone and cancellous bone

makes up the other 20% [29]. Cortical bone is load bearing, having a much higher Young’s

modulus; however, cancellous bone is associated with stress and the viscoelastic properties of

bone. The internal structure of cortical bone is complex, containing a network of canals,

canaliculi and lacunae for vascularization, innervation and osteocyte communication [61]. The

cancellous structure provides a network of rods and cones for mechanical support and a

network for cell attachment. The porosity of cortical bone is generally less than 5% [27], while

for cancellous bone is between 50 to 90% [62]

The stress-strain curve of cortical bone exhibits a linear elastic region followed by a plastic

deformation region at approximately 0.8% strain [61]. Strain rate observations of bone

mechanics show the viscoelastic properties of bone; low strain rates exhibit bones tough

behaviour and ability to endure large strain, while high strain rates show the brittle behaviour

[63]. This can be observed in Figure 2-9.

Figure 2-9: Tensile stress-strain curve of cortical bone with multiple strain rates [63]

Chapter 2: Literature review

© 2015 Nikola Ristovski Page 19

Cancellous bone is a highly dynamic system; its density and porosity vary greatly between

individuals. The mechanical properties of cancellous bone are highly dependent on the

porosity, which remodels itself based on mechanical cues. This system is known as Wolff’s

law [64]. Figure 2-10 shows a cross sectional view of a femoral head with stress lines marked

on adjacent images showing the lines of bone remodelling against stress.

Figure 2-10: An image illustrating Wolff’s law of bone, demonstrating he cancellous bone remodels

itself to the stress lines via mechano-transduction

2.1.2.4 Scaffold Architecture

The role of biomimetics in tissue engineering has become increasingly clear. The complexities

of human physiology and anatomy result in interactions between various subsystems which

are not well understood. By imitating the body’s natural structure, we are able to provide those

systems with substitutes, removing a layer of complexity involved in the understanding of

subfields. For scaffold construction in bone tissue engineering, the porosity and

interconnectivity, flow properties and surface structure are the main areas of study. Therefore,

it is essential to this field to characterise natural bone and bone formation [65].

The ultimate aim when adjusting the porosity of a scaffold is to imitate the mechanical

properties of human bone while providing an environment which is conducive to cell

proliferation. A number of studies have modified the architecture of scaffolds to imitate the

mechanical properties found in long bone. Shimko et al. [66], investigated the modification of

the porosity of a tantalum scaffolds to match the mechanical properties of human cancellous

bone. Additionally, Fu et al. [67] used porous nickel-titanium scaffolds to imitate the

mechanical properties of cortical bone. As bone contains a hierarchy of structures, it is difficult

to imitate all mechanical and viscoelastic properties without compromising the structures

cellular composition.

Chapter 2: Literature review

© 2015 Nikola Ristovski Page 20

The structure bone pores significantly affect the mechanical characteristics [68], imitating its

effect in scaffolds may result in similar properties. Increasing the porosity of the scaffold

increases its permeability, but inversely decreases the strength of the scaffold. Altering the

pore structure of a scaffold will also increase permeability while, theoretically, maintaining

similar mechanical properties. It is established that the size and orientation of pores within a

scaffold affect the mechanical properties like the Young’s modulus, tensile strength and

compressive yield strength [69], [70].

It is necessary to have both the mechanical properties as well as a porous structure for bone to

grow. Kuboki et al. [71] showed that on hydroxyapatite structures used for BMP-2 delivery,

no bone formation was seen on solid particles, however, porous scaffolds showed signs of

osteogenesis. Numerous finding show increases in cellular activity for porous and it is now

seen as a prerequisite for bone tissue engineered scaffolds. Melt electrospinning is capable of

producing highly porous structures with controlled inner topology, hence it is an ideal

candidate for the production of scaffolds for bone replacement therapy.

2.2 MELT ELECTROSPINNING

Electrospinning is defined as the process of drawing out a liquid polymer fibre from an

extruder via a large electrical potential. The liquefaction of the polymer is occurs in one of two

ways, by a solvent/polymer solution or via a melt. The process of solution electrospinning was

a patent technology dating back to 1938 [72] and has since been used extensively as a

production method for nano-fibrous mats [73].

The process begins at the liquefaction of the polymer where a solution of polymer and solvent

make a low viscosity liquid inside a needle tip. The electrostatic potential increases the charge

of the liquid until the force produced by the electric field is strong enough to pull the polymer

out of the needle tip. These forces change the shape of the polymer, producing what is known

as the Taylor cone [74]. The electrostatic forces will concentrate at the tip of the Taylor cone,

ejecting out a fluid jet. Charge is left in this fluid jet, which is then drawn through the electric

field and attracted to the collector plate.

Melt electrospinning is a similar process, although the polymer is liquefied by melting it. This

can vastly increase the viscosity of the polymer and removes the evaporation of solvent during

fibre formation, which has implications in jet stability and fibre thickness. As a result of melt

electrospinning’s lack of solvents, it holds promise for cell compatibility studies.

Chapter 2: Literature review

© 2015 Nikola Ristovski Page 21

Figure 2-11: Schematic of an electrospinning apparatus. [75]

2.2.1 The Physics of Electrospinning

As described above, the process of melt electrospinning begins at the liquefaction of the

polymer using a solvent (for solution), and using heat (for melt). The polymer is pulled from

the needle tip onto a collector plate, which is the basic outline of the electrospinning process.

Two phases exist during the spinning process, the stable region and the whipping region [15].

The stable region is dominant during the melt electrospinning process and is relevant to my

study.

The process of solution electrospinning has been thoroughly mathematically analysed, with

papers dating back to 1976 [76]. Work on the stable jet region has been completed by a number

of groups including a 1D model using a power law fluid [77], a Newtonian fluid model [78]

and a model accounting for viscoelastic behaviour of polymer melts [79], [80]. The later

model, reported by Feng et al., solved a number of issues and was revisited again by Joo et

al., who reported an in-depth experimental comparison with the model. However, these models

are targeted towards solution electrospinning which must be modified to account for the

isothermal properties of fibres in melt electrospinning. A study by Zhmayev et al. applied the

Carrol and Joo models to the case of non-isothermal jets [15]. The lack of polymer-solvent

interactions greatly simplified the model. However other complication associated with charge

transport and viscoelasticity arose.

2.2.1.1 Polymer Melts, Viscosity and Viscoelastic Properties

A polymer is melted in an extruder and accelerated through an electric field. The first stage in

the melt electrospinning process is liquefying the polymer. The temperature and molecular

Chapter 2: Literature review

© 2015 Nikola Ristovski Page 22

weight of the polymer affect the viscoelastic properties, which as we have stated previously,

is essential in modelling the behaviour of a melt electrospun jet. To describe the effect that the

molecular weight has on the viscoelastic properties, we first need to visualise how a polymer

chain exists inside a plastic matrix.

Plastics are composed of entangled polymer chains, which gives polymers their viscoelastic

properties. It is easier for larger chains to become entangled than shorter ones, hence their

shear viscosity is related to their molecular weight. The Tube model was developed in 1967

by Edwards et al. [81] to describe the entanglement of polymer networks. The Tube model

was applied to determine the melt viscosity dependence on molecular weight [82], it was

determined that two phases exist. The first phase is attributed to the short chain regime, where

molecules are not long enough to entangle. The second phase is the long chain regime, which

occurs when chains are long enough to entangle with each other. Figure 2-12 illustrates the

difference between the two regimes:

𝜼𝒎 = 𝑲𝑳(𝑫𝑷)𝟏

Short Chain

(2-1)

𝜼𝒎 = 𝑲𝑯(𝑫𝑷)𝟑.𝟒

Long Chain (2-2)

Figure 2-12: The dependence of melt viscosity on molecular weight for a number of common polymer

substances. [82]

It is generally believed that the dependency of temperature and time of viscoelastic properties

are analogous. The creep and stress relaxation are time depended viscoelastic properties.

Chapter 2: Literature review

© 2015 Nikola Ristovski Page 23

Briefly, creep is dynamic deformation under a constant load, and stress relaxation is the

constant deformation under a dynamic load, as shown in Figure 2-13.

Figure 2-13: Diagram showing the effect of creep and stress relaxation.

This system can be modelled using a series of analogous resistive and capacitive loads, making

the viscoelastic model known as the Williams-Landel-Ferry (WLF) equation. This equation

states that the effect of temperature is an exponent and proportional to the difference between

the temperature and the glass transition temperature.

𝑳𝒐𝒈(𝒂𝑻) =−𝑪𝟏∗(𝑻−𝑻𝒔)

𝑪𝟐+(𝑻−𝑻𝒔) 𝑻𝒈 > 𝑻 < ~(𝑻𝒈 + 𝟏𝟎𝟎 °𝑪)

(2-3)

Where C1 and C2 are constants dependent on each polymer. Ts is the reference temperature, Tg

is the glass transition temperature and aT is the horizontal shift factor in an empirically fit

compliance data plot (all temperatures are expressed in kelvin) [83]. As stated previously, one

of the main factors effecting the jet thinning is the viscosity of the polymer melt [15].

Manipulation of this parameter results in dynamic control over the fibre thickness and is

essential in understanding the processes of electrospinning.

The extensional viscosity of the polymeric liquid and the maximal difference in elongation

will control the thinning process in a melt electrospun fibre [84]. When the system reaches a

steady state, the elongation viscosity (�̅�) will increase or decrease, dictating the extension

thinning or thickening [79]. A fluid leaves the tip having a certain strain history; it then

experiences a uniaxial extension with a time dependent strain rate. Hence, it would be simpler

to investigate viscous and elastic aspects separately.

Creep Stress

Relaxation