Manufacturing Context & Technology Physics · ANSI Standard Limits and Fits (ANSI B4.1-1967,R1974)....

Transcript of Manufacturing Context & Technology Physics · ANSI Standard Limits and Fits (ANSI B4.1-1967,R1974)....

© Copyright 2019 HP Development Company, L.P. The information contained herein is subject to change without notice.

Manufacturing Context & Technology PhysicsEd DavisStrategy DirectorOffice of the CTO

Dustin Kloempken Applications Engineer

© Copyright 2019 HP Development Company, L.P. The information contained herein is subject to change without notice.

© Copyright 2019 HP Development Company, L.P. The information contained herein is subject to change without notice.

OVERVIEW

1. Why it is paramount to know and understand manufacturing terminology? Why should you care?

2. How do part manufacturers talk about standards?• Dimensioning• Tolerancing• CpK• IT Scale

3. How do you differentiate between various manufacturing methods?• How do various additive technologies fit in?• How do various additive technologies compare to one another?• Where are the spots of confusion?

4. Where does HP Multi Jet Fusion (HP MJF) technology fit in?• Where is the technology today?• Where is it going?• How can existing manufacturing standards work with HP MJF technology?

© Copyright 2019 HP Development Company, L.P. The information contained herein is subject to change without notice.

POLL

1. What is your job function?

a) I run or support a internal/external service bureau

b) Product Marketing

c) Customer Service

d) Sales

© Copyright 2019 HP Development Company, L.P. The information contained herein is subject to change without notice.

POLL

2. Roughly how many parts a week is your organization printing?

a) None right now

b) 1-100

c) 100-250

d) 250-500

e) 500+

© Copyright 2019 HP Development Company, L.P. The information contained herein is subject to change without notice.

3D Prototypers transitioning to Production

Changing materials and re-calibrating machines frequently

Constantly troubleshooting machine, model, or file related issues

Possibly printing multiple times before you get a “good” model

Processing small batches of parts

Non-consistent maintenance schedules

Problems you might be faced with today:

© Copyright 2019 HP Development Company, L.P. The information contained herein is subject to change without notice.

3D Prototypers transitioning to Production

Changing materials and re-calibrating machines frequently

Constantly troubleshooting machine, model, or file related issues

Possibly printing multiple times before you get a “good” model

Processing small batches of parts

Non-consistent maintenance schedules

Problems you might be faced with today:

Do you have time to always change materials and recalibrate when you are printing 100s of parts a day?

How are you able to maintain a production schedule if problems keep occurring?

A part processing line must be established to get repeatable, consistent, and high quality outputs.

If your part yield is low, it becomes very challenging to remain profitable.

Unplanned downtime is a production and costing timeline killer.

These problems prevent your business from scaling

© Copyright 2019 HP Development Company, L.P. The information contained herein is subject to change without notice.

3D Prototypers transitioning to ProductionTerminology repackaging

“How quickly can I get a prototype in my hands”

“What is the service number to troubleshoot this issue?”

“ Too much stepping or shrink? Print it again in a different orientation so that we can get a better looking part”

“ Oh we ran out of post processing supplies again, go get another one from the store”

“ Well, since our machine went down again we might as well do the PMs since they are due soon”

“What will it take to get 5000 parts in the next month under $5/part?”

“What is our backup plan to maintain production schedules if a failed build were to occur?

“What does our production ramp up schedule look like to verify that we are getting the yield of parts that we desire?”

“How many pounds of supplies and what tools will we need to adequately process 1000 parts a week for 6 weeks?”

“At what interval and how much time will we be down for preventative maintenance? Do we have all of the necessary tools and supplies ready?”

Current thought process Change in mindset

Throughput

Timelines

Quality

Preparation

Maintenance

© Copyright 2019 HP Development Company, L.P. The information contained herein is subject to change without notice.

3D Prototypers transitioning to Production

Whatever can get you a result fastest

Small number of parts within spec.

Measurement process to validate part dimensions

100% inspection rate

Process tuned to part design

Choosing the process that gets you part(s) the fastest

Selecting a process which meets your standard/ process capability

Many parts within spec.

Statistical process to validate dimensional success rates

SPC & Audit dimensions

Part design tuned to manufacturing process & process tuned to the part

Choosing the process that is the least expensive, meets your design requirements, and timetables.

MOVE FROM REACTIVE TO PROACTIVE

© Copyright 2019 HP Development Company, L.P. The information contained herein is subject to change without notice.

DEVELOPMENT ASSEMBLY & SUPPORT

Demand Side Supply Side

PRODUCT PARTS PROCESS PARTS PRODUCT

PART PRODUCTIONDESIGN

PRODUCT DEVELOPMENT LIFECYCLE

© Copyright 2019 HP Development Company, L.P. The information contained herein is subject to change without notice.

PRODUCT DEVELOPMENT LIFECYCLE: WHAT YOU WILL HEAR TODAY

DEVELOPMENT ASSEMBLY & SUPPORT

Demand Side Supply Side

PRODUCT PARTS PROCESS PARTS PRODUCT

PART PRODUCTIONDESIGN

HP MJF HANDBOOKHP 3D PROCESS

CONTROL SW

HP JET FUSION5200 SERIES 3D PRINTING

SOLUTION

HP 3D CENTRE SW

© Copyright 2019 HP Development Company, L.P. The information contained herein is subject to change without notice.

DEVELOPMENT ASSEMBLY & SUPPORT

Demand Side Supply Side

PRODUCT

PARTS Req

Assembly PROCESS & Tools

PARTS

PRODUCT

PART PRODUCTION

DESIGN

PRODUCT DEVELOPMENT LIFECYCLE

Part PROCESS & Tools

LAURASupply chain

Engineer/Manager

PETERProcess Engineer

PATRICKProduction manager

LISAMechanical

Engineer

Assembly Reqs

CHRISProgram/Product Manager

JorgeManufacturing

Engineer

JeffPart Quality

Engineer

AlexManufacturing

Quality EngineerMaria

Manufacturing Manager

RICHARDTechnical Sales

JAMESBusiness Owner

© Copyright 2019 HP Development Company, L.P. The information contained herein is subject to change without notice.

END PART PROCESS AND MATERIAL SELECTION PROCESSYou need to meet cost and quality requirements to get on Laura’s list of possible processes

LAURASUPPLY CHAIN ENGINEER / MANAGER

For a given production volume

Pick the least expensive combination of process and material

That meets your design requirements:

Dimensional tolerance consistency

Material properties consistencyLISA

MECHANICAL ENGINEER

© Copyright 2019 HP Development Company, L.P. The information contained herein is subject to change without notice.

END PART PROCESS AND MATERIAL SELECTION PROCESSYou need to meet cost and quality requirements to get on Laura’s list of possible processes

LAURASUPPLY CHAIN ENGINEER / MANAGER

For a given production volume

Pick the least expensive combination of process and material

That meets your design requirements:

Dimensional tolerance consistency

Material properties consistencyLISA

MECHANICAL ENGINEER

© Copyright 2019 HP Development Company, L.P. The information contained herein is subject to change without notice.

Dimensional Requirement: which tolerances necessary for mechanisms to fit, or function. This is very dependent on the application and specific mechanism

3 ELEMENTS OF PART DIMENSIONSAll are necessary

LISAMECHANICAL ENGINEER

A. Fit requirements: there are standards for press fits, and clearance fits, and other “hole and shaft” fitting. ANSI Standard Limits and Fits (ANSI B4.1-1967,R1974). Whether a press or clearance fit is needed is dependent on the functional calculations for a specific mechanism.

B. Functional requirements: But generally, there are more functional tolerances than fit tolerances on a part. Developing the relationship between part tolerances and subsystem function is a large part of the mechanical engineers work in the development phase. This is very application dependent.

1

Geometric Dimensioning & Tolerancing or drawing standards: or how to communicate your dimensional requirements on a drawing. This is called Geometric Dimensioning and Tolerancing or GD&T. If mechanical engineers didn’t follow the same drawing rules, then nobody could understand anybody else’s drawing. ASME Y14.5 or ISO/TC213

2

Dimensional Tolerance standard: this is the standard that allows a comparison between process capabilities. ISO 286/ANSI B4.2-1978 International Tolerance Grade3

© Copyright 2019 HP Development Company, L.P. The information contained herein is subject to change without notice.

LISAMechanical Engineer

Example of standards for hole to shaft types of fits (ANSI B4.1-1967,R1974)

1. Dimensional Part Requirements for General Fit

© Copyright 2019 HP Development Company, L.P. The information contained herein is subject to change without notice.

LISAMechanical Engineer

Most dimensional requirements are about subassembly functioning. Tolerance stacking or worst case analysis for functionality is a large part of the mechanical engineer’s work in the Development Phase

1. Dimensional Part Requirements

© Copyright 2019 HP Development Company, L.P. The information contained herein is subject to change without notice.

LISAMechanical Engineer

Examples of how to communicate your requirements in a drawing

2. Geometric Dimensioning and Tolerancing

Dimension Types

1. Functionally critical dimensions: these are explicitly given a tolerance range of +N/-N2 on the dimension itself

2. Process control dimensions: these are generally dimensions which are easy to measure and which indicate whether a process is drifting or not. They may also imply that the functional dimensions are beginning to vary

3. General dimensions: the tolerance range is not explicitly stated but referred to the signature box on the drawing

Signature Box in accordance with ASME Y14.5 or ISO/TC213

Some ASME Y14.5 or ISO/TC213 symbols

© Copyright 2019 HP Development Company, L.P. The information contained herein is subject to change without notice.

LISAMECHANICAL ENGINEER

3. REMEMBER: A RELEVANT DIMENSIONAL TOLERANCE STANDARD

SINGLE TOLERANCE RANGE, E.G. ± 0.2mm

A PERCENTAGE, E.G. 2%

TOLERANCE RANGE VS. DIMENSION LENGTH

© Copyright 2019 HP Development Company, L.P. The information contained herein is subject to change without notice.

MANUFACTURING PREDICTABILITY 3. Dimensional tolerance standard

Measuring Tools

IT Grade 01 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

Material

International Tolerance Grades defined in ISO 286/ANSI B4.2-1978 , which provide a standardized reference for typical manufacturing process capability in terms of dimensional tolerance for a given dimension

Fits Large Manufacturing Tolerances

Better

© Copyright 2019 HP Development Company, L.P. The information contained herein is subject to change without notice.

The larger the specified dimension, the larger the tolerance range for accuracy

MANUFACTURING PREDICTABILITY 3. Dimensional tolerance standard

Measuring Tools

IT Grade 01 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

Material

Fits Large Manufacturing TolerancesBetter

Tolerances mmµm

Dimension (mm) Standard tolerance gradesIT12) IT22) ) IT32) ) IT42) IT52) IT6 IT7 IT8 IT9 IT10 IT11 IT12 IT13 IT143) IT153)

-

3

6

10

18

30

50

80

120

180

250

315

400

500

3

6

10

18

30

50

80

120

180

250

315

400

500

6302)

Above Up to and including

0,8

1

1

1,2

1,5

2

2,5

3,5

4,5

6

7

8

9

1,5

1,2

1,5

1,5

2

2,5

3

4

5

7

8

9

10

11

2,5

2

2,5

2,5

3

4

4

6

8

10

12

13

15

16

4

3

4

4

5

6

8

10

12

14

16

18

20

22

7

4

5

6

8

9

13

15

18

22

23

25

27

32

11

6

8

9

11

13

19

22

25

29

32

36

40

44

16

10

12

15

18

21

30

35

40

46

52

57

63

70

25

14

18

22

27

33

46

54

63

72

81

89

97

100

39

25

30

36

43

52

74

87

100

115

130

140

155

175

62

0,1

0,12

0,15

0,18

0,21

0,3

0,35

0,4

0,46

0,52

0,57

0,63

0,7

0,25

60

75

90

110

130

190

220

250

290

320

360

400

440

160

40

48

58

70

84

120

140

160

185

210

230

250

280

100

0,14

0,18

0,22

0,27

0,33

0,46

0,54

0,63

0,72

0,81

0,57

0,97

1,1

0,39

0,25

0,3

0,36

0,43

0,52

0,74

0,87

1

1,15

1,3

1,4

1,55

1,75

0,62

0,4

0,48

0,58

0,7

0,84

1,2

1,4

1,6

1,85

2,1

2,3

2,5

2,8

1

© Copyright 2019 HP Development Company, L.P. The information contained herein is subject to change without notice.

MANUFACTURING PREDICTABILITY3. Dimensional tolerance standard

Tolerance Range vs. Dimension Length

2.5

2

1.5

1

0.5

0

50 100 150 200 250 300 350 400

Tole

ran

ceR

ang

e[m

m]

IT15

IT14

IT13

IT12

IT11

Nominal dimension [mm]

The larger the specified dimension, the larger the tolerance range for that dimension

© Copyright 2019 HP Development Company, L.P. The information contained herein is subject to change without notice.

TO COMPARE BETWEEN PROCESSESBoth a process agnostic tolerance specification and the processes capability need to be specified

How well your process can meet that standard or process capability

Tolerance range vs. dimensional length

Plus

© Copyright 2019 HP Development Company, L.P. The information contained herein is subject to change without notice.

TO COMPARE BETWEEN PROCESSESBoth a process agnostic tolerance specification and the processes capability need to be specified

How well your process can meet that standard or process capability

Tolerance range vs. dimensional length

Plus

© Copyright 2019 HP Development Company, L.P. The information contained herein is subject to change without notice.P Confidential for HP internal and HP Channel under NDA use ONLY. Not for customer-facing use

1 CpK = Precision + Accuracy(Cp) + (low bias)

2Process Capability ≠Results from one machine

3Single Dimension SuccesRate ≠ Part Yield

REMEMBER: !

© Copyright 2019 HP Development Company, L.P. The information contained herein is subject to change without notice.

PROCESS CAPABILITY OR CPK is the statistical probability of a process meeting a specFor a process to be capable, it needs to be both repeatable (precise) and centered

• ACCURACY = how close a measurement value is to the specified nominal (also called bias)

• PRECISION = how close multiple measurements are to each other (statistically measured as Cp)

• CAPABILITY = the statistical probability of a dimension being within its tolerance range

• CAPABILITY = Cpk = Cp *(1-(bias/0.5)) = has a statistical equivalent “sigma”

LOW BIAS AND GOOD CP SO CPK IS GOOD

BOTH, accurate and precise

GOOD BIAS (LOW)BUT HIGH VARIABILITY

ACCURATE, but not precise

GOOD CP (LOW VARIABILITY) BUT HIGH BIAS

PRECISE, but not accurate

© Copyright 2019 HP Development Company, L.P. The information contained herein is subject to change without notice.

MANUFACTURING PREDICTABILITYSigma or Cpk is a dimensional success rate. Part yield is different

NOTES:

• Cpk and sigma are metrics for a

specific dimension being good

• For a part to be good, all the specified

dimensions need to be good

• Yield is a part metric and could be

calculated as the statistical sum of

probable dimensional tolerance

failures + some estimation for

cosmetic failures or other.

~Part Yield fora part with

10 dimensions

Dimensions permillion outside

of spec

Dimensions persuccess rate

(%)Sigma Cpk

68.27000

95.45000

98.00000

99.73000

99.99370

99.99966

99.99997

317,300

45500

20000

2700

63

3.4

0.6

0.33

0.67

0.79

1.00

1.33

1.50

1.67

2.20%

62.77%

81.71%

97.33%

99.94%

100.00%

1

2

3

4

5

6

Sigma or Cpk is equivalent to statistical probability of a percentage of population of one specific dimension being good

© Copyright 2019 HP Development Company, L.P. The information contained herein is subject to change without notice.

MANUFACTURING PREDICTABILITY Low Cpk/low yield have high quality control costs

To validate parts are within specified tolerances, 100% inspection is needed for low Cpk processes

~Part Yield fora part with

10 dimensions

Dimensions permillion outside

of spec

Dimensions persuccess rate

(%)Sigma Cpk

68.27000

95.45000

98.00000

99.73000

99.99370

99.99966

99.99997

317,300

45500

20000

2700

63

3.4

0.6

0.33

0.67

0.79

1.00

1.33

1.50

1.67

2.20%

62.77%

81.71%

97.33%

99.94%

100.00%

1

2

3

4

5

6

AssociatedManufacturingQuality Control

Method

100% Inspection

SPC & Audit

dimensions

© Copyright 2019 HP Development Company, L.P. The information contained herein is subject to change without notice.

GENERAL DIMENSION PROCESS CAPABILITY COMPARISON at Cpk=1.33

Measuring Tools

IT Grade 01 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

Material

Fits Large Manufacturing Tolerances

17 18

Typical 3D Processes

Programmedmachining

Precision molding andcritical dimensions

Hard Steel

General PlasticMolding

Soft Steel

Prototype moldingTypically

Aluminum

© Copyright 2019 HP Development Company, L.P. The information contained herein is subject to change without notice.

Part Quality =

PART QUALITY RELATIONSHIP FOR ALL THERMOPLASTIC PROCESSESFor optimum part quality, the part needs to be tuned to the process and the process needs to be tuned to the part

f(thermal history of the part) = f(part geometry, process settings)

Dimensional Error =

f(thermal history of the part) = f(thermal stress in the part) = f(part geometry, process settings)

MJF Dimensional Error =

f(thermal history of the part) = f(thermal stress in the part) = f(part geometry, batch geometry, printing settings, post process settings)

© Copyright 2019 HP Development Company, L.P. The information contained herein is subject to change without notice.

PLASTIC PART MANUFACTURING TECHNOLOGY SPACEFor a manufacturing volume, choose the least expensive material and process that meets your design requirements

# of parts produced /year

CNCCo

mp

lexity+

-

Aluminum Molds

Man

ual

CNC Hybrid

Soft Steel Molds

Hard steel Molds

Acc

ura

cy

-

+

© Copyright 2019 HP Development Company, L.P. The information contained herein is subject to change without notice.

PLASTIC PART MANUFACTURING TECHNOLOGY SPACEFor a manufacturing volume, choose the least expensive material and process that meets your design requirements

# of parts produced /year

CNCCo

mp

lexity+

-

Aluminum Molds

Man

ual

CNC Hybrid

Soft Steel Molds

Hard steel Molds

Acc

ura

cy

-

+

Mold begins to wear and quality drops

Low Thermal Mass = inconsistent temperatures and thermal stress

© Copyright 2019 HP Development Company, L.P. The information contained herein is subject to change without notice.

PLASTIC PART MANUFACTURING TECHNOLOGY SPACEFor a manufacturing volume, choose the least expensive material and process that meets your design requirements

# of parts produced /year

CNCCo

mp

lexity+

-

Aluminum Molds

Man

ual

CNC Hybrid

Soft Steel Molds

Hard steel Molds

Acc

ura

cy

-

+

Features wear and steel hardening causes non-uniformity & thermal stress

Time consuming & expensive qualification

Fine features wear

© Copyright 2019 HP Development Company, L.P. The information contained herein is subject to change without notice.

Total Time = 2-4 weeks• Remove the mold• Machine in changes from

serious deviations of critical dimensions

• Assemble Mold• Install mold into molding

machine• Run while tuning time and

pressure until you get reasonable variability

• Run quantity of parts• Measure• Ship • Sometimes very critical

dimensions are reworked/machined

Iteration 3a,b,c: Dimension by dimension machining of bias, Window study

PLASTIC INJECTION MOLDING DEVELOPMENT PHASE WORKFLOW: TUNING THE PROCESSAssume soft steel molds tuned to IT13 or better with ~10 critical dimensions

Total Time = ~8 weeks• Design Mold• Fabricate Mold• Assemble Mold• Install mold into molding

machine• Run• Measure all dimensions once

and all critical dimension statistically

Total Time = ~ 4 weeks• Remove the mold• Machine in changes to design &

critical dimension bias• Assemble Mold• Install mold into molding machine• Run• Measure• Sometimes, iterate for very fine

dimensions• Complete window study to

determine best pressures, time and temperature

• Run quantity of parts• Measure• Ship

R&D: Test, re-design, release

Manufacturing:Assemble Product

Iteration 2: Reduce Variability/parameter tuning

Iteration 1: First Article: General diimensions

FirstRelease

© Copyright 2019 HP Development Company, L.P. The information contained herein is subject to change without notice.

Iteration 3: Dimension by dimension machining of bias, Window study

GENERAL CAPABILITY: INJECTION MOLDING WORKFLOW WITH SOFT STEEL MOLDTime consuming and costly iterations

Total Time = ~8 weeks

Iteration 2: Reduce Variability / parameter tuning

Total Time = ~4 weeks

Iteration 1First Article: General diimensions

Molding machine installation calibrations

PartRelease

Molding machine factory calibrations

Total Time = 2-4 weeks

Cpk = ~0.3 to 0.6IT13

Cpk = ~1IT13

Or IT 13-14 with Cpk 1.33

Cpk = ~1.33IT13

© Copyright 2019 HP Development Company, L.P. The information contained herein is subject to change without notice.

PLASTIC PART MANUFACTURING TECHNOLOGY SPACEFor a manufacturing volume, choose the least expensive material and process that meets your design requirements

# of parts produced /year

CNCCo

mp

lexity+

-

Aluminum Molds

Man

ual

CNC Hybrid

Soft Steel Molds

Hard steel Molds

Acc

ura

cy

-

+

Features wear and steel hardening causes non-uniformity & thermal stress

Time consuming & expensive qualification

Fine features wear

© Copyright 2019 HP Development Company, L.P. The information contained herein is subject to change without notice.

PLASTIC PART MANUFACTURING TECHNOLOGY SPACEFor a manufacturing volume, choose the least expensive material and process that meets your design requirements

# of parts produced /year

CNCCo

mp

lexity+

-

Aluminum Molds

Man

ual

CNC Hybrid

Soft Steel Molds

Hard steel Molds

Acc

ura

cy

-

+

© Copyright 2019 HP Development Company, L.P. The information contained herein is subject to change without notice.

PLASTIC PART MANUFACTURING TECHNOLOGY SPACEFor a manufacturing volume, choose the least expensive material and process that meets your design requirements

# of parts produced /year

CNCCo

mp

lexity+

-

Aluminum Molds

Man

ual

CNC Hybrid

Soft Steel Molds

Hard steel Molds

Acc

ura

cy

-

+

© Copyright 2019 HP Development Company, L.P. The information contained herein is subject to change without notice.

PLASTIC PART MANUFACTURING TECHNOLOGY SPACEFor a manufacturing volume, choose the least expensive material and process that meets your design requirements

# of parts produced /year

CNCCo

mp

lexity+

-

Aluminum Molds

Man

ual

CNC Hybrid

Soft Steel Molds

Hard steel Molds

Acc

ura

cy

-

+

Limited geometries to parts which allow the mold to open

Time consuming & expensive qualification

© Copyright 2019 HP Development Company, L.P. The information contained herein is subject to change without notice.

PLASTIC PART MANUFACTURING TECHNOLOGY SPACEFor a manufacturing volume, choose the least expensive material and process that meets your design requirements

# of parts produced /year

CNCCo

mp

lexity+

-

Aluminum Molds

Man

ual

CNC Hybrid

Soft Steel Molds

Hard steel Molds

Acc

ura

cy

-

+

Human error

Labor intensive

© Copyright 2019 HP Development Company, L.P. The information contained herein is subject to change without notice.

PLASTIC PART MANUFACTURING TECHNOLOGY SPACEFor a manufacturing volume, choose the least expensive material and process that meets your design requirements

# of parts produced /year

CNCCo

mp

lexity+

-

Aluminum Molds

Man

ual

CNC Hybrid

Soft Steel Molds

Hard steel Molds

Acc

ura

cy

-

+

Limited productivity for complex geometries forces hybrid model

© Copyright 2019 HP Development Company, L.P. The information contained herein is subject to change without notice.

PLASTIC PART MANUFACTURING TECHNOLOGY SPACEFor a manufacturing volume, choose the least expensive material and process that meets your design requirements

# of parts produced /year

CNCCo

mp

lexity+

-

Aluminum Molds

Man

ual

CNC Hybrid

Soft Steel Molds

Hard steel Molds

Acc

ura

cy

-

+

SLS &Extrusion

DLP

© Copyright 2019 HP Development Company, L.P. The information contained herein is subject to change without notice.

PLASTIC PART MANUFACTURING TECHNOLOGY SPACEFor a manufacturing volume, choose the least expensive material and process that meets your design requirements

# of parts produced /year

CNCCo

mp

lexity+

-

Aluminum Molds

Man

ual

CNC Hybrid

Soft Steel Molds

Hard steel Molds

Acc

ura

cy

-

+

DLP

© Copyright 2019 HP Development Company, L.P. The information contained herein is subject to change without notice.

PLASTIC PART MANUFACTURING TECHNOLOGY SPACEFor a manufacturing volume, choose the least expensive material and process that meets your design requirements

# of parts produced /year

CNCCo

mp

lexity+

-

Aluminum Molds

Man

ual

CNC Hybrid

Soft Steel Molds

Hard steel Molds

Acc

ura

cy

-

+

DLP

Shrinkage during curing

Single part productivity

Limited geometry & materials do not emulate other processes

© Copyright 2019 HP Development Company, L.P. The information contained herein is subject to change without notice.

PLASTIC PART MANUFACTURING TECHNOLOGY SPACEFor a manufacturing volume, choose the least expensive material and process that meets your design requirements

# of parts produced /year

CNCCo

mp

lexity+

-

Aluminum Molds

Man

ual

CNC Hybrid

Soft Steel Molds

Hard steel Molds

Acc

ura

cy

-

+

SLS &Extrusion

DLP

© Copyright 2019 HP Development Company, L.P. The information contained herein is subject to change without notice.

PLASTIC PART MANUFACTURING TECHNOLOGY SPACEFor a manufacturing volume, choose the least expensive material and process that meets your design requirements

# of parts produced /year

CNCCo

mp

lexity+

-

Aluminum Molds

Man

ual

CNC Hybrid

Soft Steel Molds

Hard steel Molds

Acc

ura

cy

-

+

SLS &Extrusion

DLPExtruder Resolution vs. time to part & z-property tradeoff

Point process & Poor ratio of Productivity / Acquisition Cost

© Copyright 2019 HP Development Company, L.P. The information contained herein is subject to change without notice.

PLASTIC PART MANUFACTURING TECHNOLOGY SPACEFor a manufacturing volume, choose the least expensive material and process that meets your design requirements

# of parts produced /year

CNCCo

mp

lexity+

-

Aluminum Molds

Man

ual

CNC Hybrid

Soft Steel Molds

Hard steel Molds

Acc

ura

cy

-

+

SLS &Extrusion

DLP“On-Off Energy” means accuracy vs. z-property tradeoff

Point process & Poor ratio of Productivity / Acquisition Cost

© Copyright 2019 HP Development Company, L.P. The information contained herein is subject to change without notice.

PLASTIC PART MANUFACTURING TECHNOLOGY SPACEFor a manufacturing volume, choose the least expensive material and process that meets your design requirements

# of parts produced /year

CNCCo

mp

lexity+

-

Aluminum Molds

Man

ual

CNC Hybrid

Soft Steel Molds

Hard steel Molds

Acc

ura

cy

-

+

HP MJF

SLS &Extrusion

DLP

CNC +HP MJF

© Copyright 2019 HP Development Company, L.P. The information contained herein is subject to change without notice.

PLASTIC PART MANUFACTURING TECHNOLOGY SPACEFor a manufacturing volume, choose the least expensive material and process that meets your design requirements

# of parts produced /year

CNCCo

mp

lexity+

-

Aluminum Molds

Man

ual

CNC Hybrid

Soft Steel Molds

Hard steel Molds

Acc

ura

cy

-

+

HP MJF + HP MJF Complexity Parts

SLS &Extrusion

DLP

CNC +HP MJF

© Copyright 2019 HP Development Company, L.P. The information contained herein is subject to change without notice.

HP 3D Process Control SoftwareEnabling better part tolerancing

© Copyright 2019 HP Development Company, L.P. The information contained herein is subject to change without notice.

PLASTIC PART MANUFACTURING TECHNOLOGY SPACEFor a manufacturing volume, choose the least expensive material and process that meets your design requirements

# of parts produced /year

CNCCo

mp

lexity+

-

Aluminum Molds

Man

ual

CNC Hybrid

Soft Steel Molds

Hard steel Molds

Acc

ura

cy

-

+

HP MJF + HP MJF Complexity Parts

SLS &Extrusion

DLP

CNC +HP MJF

Difficult or impossible to mold

© Copyright 2019 HP Development Company, L.P. The information contained herein is subject to change without notice.

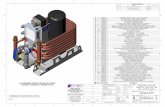

1 part

Traditional Design & Mfg 3D printed integrated design

Fan ventilator lower side

3D printed part

EPDM adhesive seal right

EPDM adhesive seal left

Screw 13x Sealing O-ringFan ventilator upper side

EPDM adhesive seal left

COMBINED PARTS IN FLUID MANAGEMENT: COST COMPETITIVE

6 parts + 13 screws + Assy & testingPart combination results in lower cost and Better

quality/performance

© Copyright 2019 HP Development Company, L.P. The information contained herein is subject to change without notice.

PART QUALITY & COST: HP MJF HANDBOOKFor optimum part quality, the part needs to be tuned to the process and the process needs to be tuned to the part

www.hp.com/go/MJFHandbook

Want to talk to someone about your design specifically?https://enable.hp.com/us-en-3d-prints-plastics-cwu

1-877-468-8369

Summary

3D Printing is entering an era where it can compete up to reasonable production volumes against injection molding and this requires the printing device to have a good ratio of Productivity/Acquisition Cost

A development phase cannot be skipped with any process, but digital process development can be much shorter and much less expensive

The chosen part fabrication process must meet the design requirements for accuracy, and the design will always need to be optimized to the chosen part fabrication process

3D Printing can disrupt product development cycles and the Return on Investment of new products•Designing for and fabricating with 3D Printing, with its shorter development cycles, can open more flexible product development processes, that include such concepts as bridge manufacturing. •Additional functionality or product differentiation can also be considered.

© Copyright 2019 HP Development Company, L.P. The information contained herein is subject to change without notice.