Maintenance matrices: overview of common refractory...

Transcript of Maintenance matrices: overview of common refractory...

MIL

LEN

NIU

M S

TEEL

201

3

61

Maintenance matrices: overview of common refractory maintenance methods for BOFs and EAFsWhen dealing with refractory maintenance, steel workers face a range of possibilities and approaches. Often discussed controversially and influenced by suppliers promoting their system, it can be difficult to choose the right method. Therefore, RHI has compiled two matrices summarising BOF and EAF maintenance approaches. The rating of each method in relation to the application area, investment costs and operator stress is designed to support and justify selection of the most appropriate solution for a specific maintenance task.

Vessel relining and maintenance strategies play a major role in determining steel plant efficiency. Usually the

decisions when choosing the maintenance method and related equipment depend on the general plant strategy, budget and orders, production process bottlenecks, and any space restrictions on-site.

Typically, steel producers look closely at maintenance to optimise one or more of the following topics:

` Reduction of specific brick consumption` Targeted maintenance of premature wear areas` Decreasing likelihood of breakouts` Increasing lining lifetime` Predictable lining lifetimes

Following on from RHI’s philosophy to consult with steel producers based on extensive global experience and know-how, the maintenance matrices provide an overview of commonly used maintenance methods and their suitability for different pre-wear areas in the vessels. The maintenance matrices provide a fundamental tool to determine the best customer-specific solution.

REFRACTORY MAINTENANCE Often, refractory maintenance costs are rated as a minor economic factor when only the direct refractory costs are evaluated. However, the maintenance method contributes far more to the total cost of ownership estimate if the following issues are also considered in the analysis:

` Manpower and equipment costs for installation` Vessel downtime due to maintenance` Inventory costs` Steel plant logistics

Authors: Gregor Lammer, Christoph Jandl and Karl-Michael Zettl RHI AG

r Fig 1 Manual gunning in a BOF plant

STEELMAKING AND CASTING

a

MIL

LEN

NIU

M S

TEEL

201

3

62

Thereby, the impact of the maintenance method becomes more evident. Minimising human influence during refractory application or reducing the physical stress on operators can also be decisive criteria, for example in the case of manual gunning (see Figure 1).

BOF MAINTENANCEIn converter steel plants various techniques are used for refractory lining maintenance, including standard gunning using a hand lance or manipulator gunning (eg, Shooter (see Figure 2)), the use of self-flowing mixes, as well as the application of conditioned converter slag by, for example, splashing, washing and foaming. In summary, maintenance methods can be assigned to two main categories: Slag maintenance and maintenance using refractory products.

EAF MAINTENANCESteelmakers’ maintenance philosophy in EAF steel plants varies between zero and excessive maintenance, always depending on the conditions on-site (eg, production process bottlenecks, automation level, changeable vessel, available maintenance equipment, target productivity and produced steel grades).

There are two main products used for EAF maintenance: gunning mixes and fettling mixes (see Table 1). The ANKER TWIN machine (see Figure 3) provides the efficient application of both.

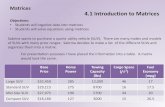

MAINTENANCE MATRICESIn the following maintenance matrices (Tables 2 and 3), the vessels are subdivided into the multiple common wear areas (see also Figures 4 and 5). Each maintenance method focuses on the technical rating for a specific vessel region.

COMMON BOF MAINTENANCE METHODSTypical BOF maintenance methods in use include:

Slag splashing After steel tapping, the remaining slag in the vessel is splashed with a high-pressure nitrogen jet on to different areas of the lining for 2 to 5 minutes.

Slag coating and slag washing After tapping, the vessel is tilted for deslagging and a small amount of liquid slag is retained in the vessel. This slag is enriched with

Method Description PerformanceGunning Targeted spraying of wet and chemically bonded refractory mixes 80–400kg/min to repair worn areas or preventively maintain a furnace damaged by mechanical, thermal, and chemical attack during its lifetime. Fettling Applying dry, non-chemically bonded mixes to repair Up to 800kg/min the wear of hearth and banks.

r Fig 3 ANKERTWIN machine

r Fig 2 RHI shooter

r Table 1 Definition of gunning and fettling

MIL

LEN

NIU

M S

TEEL

201

3

63

STEELMAKING AND CASTING

a

doloma or raw dolomite to cool the slag and increase its adhesive properties. Subsequently, the vessel is rocked several times to apply a thin slag layer.

Hot patching Self-flowing refractory mixes enable precise care of the scrap impact zone, tapping pad and bottom joint. While the repair is longer lasting than the aforementioned slag coating, it requires a longer period to achieve maximum durability.

Manual and manipulator gunning By gunning pre-worn areas with special gunning mixes, an extension of the vessel lining service life is targeted.

Automated gunning By increasing the gunning speed, super gunning requires an automated gunning process to handle mix throughputs of up to 400kg/min. A long mix lifetime, no influence on the gas purging plug availability, and adapted lining concepts can solve the requirement for maximum productivity at the lowest costs.

Slag conditioning Adding fluxes containing MgO to increase the (MgO)-content closer to the saturation point helps to minimise dissolution of <MgO> and reduce refractory wear.

Slag foaming After tapping the heat, carbon is added to the remaining slag causing it to foam and cover the walls. This method is similar to slag splashing but without additional investment and N2 blowing.

EQUIPMENT FOR BOF MAINTENANCEThe following RHI equipment is available to maintain BOF vessels:

` ANKERJET (Type A): A pressure vessel machine used to feed the gunning system with the necessary mixes

` Shooter: A manipulator exclusively designed for the application of gunning material onto refractory bricks in furnaces

` CONREP: An advanced, completely automated gunning system designed for high precision gunning, with a laser interface and minimised human influence for maximum mix performance

COMMON EAF MAINTENANCE METHODS The EAF maintenance methods currently in use and the RHI equipment available for efficient gunning and fettling mix application are summarised below:

Maintenance by shovelling Fettling material is manually thrown into the vessel using a shovel from outside the vessel.

r Fig 5 Common wear areas in an EAF

r Fig 4 Common wear areas in a BOF

MIL

LEN

NIU

M S

TEEL

201

3

64

The application is performed using a hand lance from outside the vessel.

Fettling manipulator – ANKERFRIT The fettling mix is stored in a silo and applied using a 360° rotatable chute. The system is crane operated and very high fettling mix throughputs are possible.

Gunning manipulator ‘basic’ (roof access) – ANKERSINGLE The gunning mix is fed by a pressure vessel based fixed system. The application is performed using a remote controlled manipulator from the centre of the vessel. The system is crane operated and provides targeted maintenance of all wall areas.

Combined fettling and gunning manipulator – ANKERTWIN This system combines a basic fettling

Hot repair with fettling mix in big bag Fettling material contained in a big bag is dropped into the vessel using a crane.

Hand gunning ‘light’ – ANKERGUN and ANKERJET Type M The gunning mix is fed by a small, mobile compressed-air system. The application is performed using a hand lance from outside the vessel.

Dry spin – ANKERROTO (dry) The fettling mix is stored in a silo and applied by a spin wheel below the silo. The system is crane operated.

Wet spin – ANKERROTO (wet) Similar to dry spin, but this method uses gunning mix.

Hand gunning ‘advanced’ – ANKERJET Type A The gunning mix is fed by a pressure vessel based fixed system.

r Table 2 BOF maintenance matrix

Method Machinery Physical RHI’s system solution investment stress on 1 2 3 4 5 6 7 8 9 10 Machinery Refractory cost operator material

Modified None None + + + + + ++ + + Dololime, raw (MgO) magnesite, saturated raw dolomite slagSlag High None + ++ + +++ ++ ++ ++ Dololime, raw splashing magnesite, raw dolomiteSlag None None ++ ++ + ++ ++ + Dololime, raw washing magnesite, raw dolomiteSlag None None + ++ + ++ ++ + + Dololime, raw foaming magnesite, raw dolomite, carbonHand Low High +++ + + + + + + +++ + + ANKERJET ANKERGUN gunning hand lance ANKERJETManipulator Intermediate Intermediate ++ ++ ++ ++ ++ + ++ ++ ++ ++ ANKERJET ANKER GUN gunning Shooter ANKERJETAutomated High Low ++ +++ +++ +++ ++ ++ +++ ++ +++ +++ ANKERJET ANKERJET gunning CONREP ANKERREPHot repair None Low + +++ ++ + +++ ++ + No equipment ANKERREP mix required Patching None Low + +++ ++ + + + No equipment with bricks required

Appropriate (+), good (++), ideal (+++), and the specific area cannot be maintained with the method (blank)

Lip

ring

Upp

er c

one

Char

ge p

ad

Bott

om jo

int

Bott

om w

ith

plug

s

Bott

om w

itho

ut p

lugs

Tap

pad

Taph

ole

repl

acem

ent

Trun

nion

Upp

er c

one

Mai

nten

ance

usi

ng

refr

acto

ry p

rodu

cts

Slag

mai

nten

ance

MIL

LEN

NIU

M S

TEEL

201

3

65

STEELMAKING AND CASTING

CONCLUSIONSIt is a well-established fact that successful, efficient and effective BOF maintenance has to be a combination of slag and refractory maintenance, whilst for EAFs a combination of fettling and gunning mix application is appropriate.

The maintenance matrix approach incorporates more transparency and fact based decision making into selecting the appropriate refractory maintenance methods tailored to the customer’s specific requirements. MS

Gregor Lammer, Christoph Jandl and Karl-Michael Zettl are with RHI AG, Steel Division, Vienna, Austria.

CONTACT: Gregor Lammer, [email protected]

manipulator and gunning manipulator. The system is crane operated and remote controlled.

Gunning manipulator (door access) The mix application is performed using a remote controlled manipulator through the door.

Gunning manipulator ‘advanced’ (roof access) – TERMINATOR S The gunning or fettling mix is fed by a pressure vessel based fixed system and high feeding rates are possible. The application is performed using a remote controlled boom from the centre of the vessel.

Automated gunning robot (roof access) – TERMINATOR XL This is the fully automated version of the TERMINATOR and includes a residual thickness laser measurement system.

r Table 3 EAF maintenance matrix

Method Application Machinery Physical Fettling material Gunning material RHI’s system solution temperature investment stress on cost operator Hot Cold Hearth Bank Cooling Wall Hot Door Slag Equipment Refractory panels spots zone material 1 2 3 4 5 6 7 Maintenance o None High + + + (*) ANKERFRIT, by shovelling PERFRITHot repair o None Middle ++ + ANKERFRIT, using fettling PERFRIT mix in big bag Hand o o Very low High + + + + + ANKERGUN, ANKERJET, gunning ANKERJET ANKERGUN —light TYPE M Dry spin o Low Low ++ ANKERROTO ANKERFRIT, (dry) PERFRITWet spin o o Low Low + + + + ANKERROTO ANKERJET, (wet) ANKERGUNHand o o Low High ++ ++ ++ + ++ ANKERJET ANKERJET gunning TYPE A ANKERGUN —advancedFettling o Low Low ++ +++ ANKERFRIT ANKERFRIT, manipulator PERFRITGunning o o Intermediate Low +++ +++ +++ +++ +++ ANKERSINGLE ANKERJET, manipulator ANKERGUN basic (roof access) Combined o o Intermediate Low ++ +++ +++ +++ +++ +++ +++ ANKERTWIN ANKERFRIT, fettling and PERFRIT, gunning ANKERJET, manipulator ANKERGUNGunning o o High Low + +++ ++ +++ Third party ANKERJET, manipulator equipment ANKERGUN (door access) Gunning o o High Low + +++ +++ +++ ++ +++ TERMINATOR S ANKERJET, manipulator ANKERGUN —advanced (roof access)Automated o o High Low + +++ +++ +++ ++ +++ TERMINATOR XL ANKERJET, gunning ANKERGUN robot (roof access)Appropriate (+), good (++), ideal (+++), option (o), using fettling mix (*), and the specific area cannot be maintained with the method (blank)

![[PPT]Tema 2.- MATRICES - Open Course Ware Moodle 2.5 · Web viewMATRICES PRODUCTO DE MATRICES POTENCIAS NATURALES DE MATRICES CUADRADAS MATRICES SUMA DE MATRICES. PRODUCTO DE UN ESCALAR](https://static.fdocuments.in/doc/165x107/5c17a16c09d3f2c7368c2ad2/ppttema-2-matrices-open-course-ware-moodle-25-web-viewmatrices-producto.jpg)