Lubrication oil, grease and others

-

Upload

pioneer-group -

Category

Education

-

view

220 -

download

1

Transcript of Lubrication oil, grease and others

Bangladesh University of Business and Technology(BUBT)

TXE-411 Assignment

Submitted By: Date: 07.01.2016

Name: ID. Intake:

Md. Khairul Bashar 12131107011 7th

Title: Lubrication Oil, Grease and others (11)Lubrication:

prevention of metal-to-metal contact by means of an intervening layer of fluid.The principle of supporting a sliding load on a friction-reducing film is known as lubrication.

These lubricants are used to a large extent in the lubrication of aircraft internal combustion engines& moving parts.

Industrial Requirement

– Improving productivity & Minimizing waste .

– Reducing costs of Operation .

Classification of Lubricants• Animal• Vegetable• Mineral• SyntheticThese are highly stable at normal temperatures.Animal lubricants may not be used for internal combustion because they produce fatty acids.Examples of vegetable lubricants are:Castor oilOlive oilCottonseed oilAnimal and vegetable oils have a lower coefficient of friction than most mineral oils but they rapidly wear away steel.

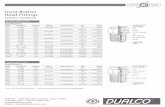

Components of Lubrication Systems• Plumbing for Lubrication Systems• Temperature Regulator (Oil Cooler)• Oil Viscosity Valve• Oil Pressure Relief Valves• Oil Separator• Oil Pressure • Oil Pressure Pumps• Scavenge Pumps• Oil Dilution System

(03)Lubricating oilsLubricants

All liquids will provide lubrication of a sort, but some do it a great deal better than others.

Oil Requirement :– Provide high quality products, supported by successful field experience.–Work to lower maintenance.-Work to Lower cost of operation through value added services– Provide products to help Machine for long operation.The advantages of a lubricating oil: • are improved heat dissipation from the friction point

• its excellent penetrating and wetting properties.

Main disadvantage

Complex design is required to keep the oil at the friction point and prevent the danger of leakage.

Fig: Oils are used in Chains

• Lubricating oils consist of a base oil and additives which determine their performance characteristics. The additives, however, determine its actual performance by influencing the base oil’s.

The additives to• oxidation stability.• anticorrosion properties.• wear protection.• emergency lubrication properties.• wetting behavior.• emulsibility.• stick-slip behavior.• viscosity-temperature behavior.Main tasks, remain lubrication and protection against friction and wear.

Oil Lubrication Methods

Liquid lubrication

Boundary Hydrodynamic Elastohydrodynamic

Mineral & synthetic Oil

Synthetic oil Engine oil Transmission fluid. Refrigeration oil. Compressor oils. Metalworking fluids and oils. Laminating oils. Industrial hydraulic fluid. Copper and aluminum wire drawing solution. Electrical insulating oil. Industrial process oils. Oils used as buoyants.

This list does not include all types of used oil.Oil Lubriaction

Purpose of Oils

Oil reduces friction between moving parts

Lubrication –slippery surface between moving parts

-Seal –Between piston rings and cylinder surface

-Cool-Especially bearings(disspate heat)

-Clean-Contaminates held in suspension(wear particles)

Change oil before winter lay-up so contaminates are removed and do not damage the machine during storage.

Different lubricants show different behavior regarding these requirements.

(23)Lubricating Greases

• Lubricating greases consist of a lubricating oil, a thickening agents and one or more additives.

The function of grease is to remain in contact with and lubricate moving surfaces without leaking out under gravity or centrifugal action, or be squeezed out under pressure.

Today’s new-generation greases are expected to do much more than lubricate. They must meet a wide range of demanding performance requirements.• Long, trouble-free service life, even at high temperatures• Rust and corrosion prevention• Dependable, low-temperature start-up• Resistance sling and water wash.

• Lubricating greases consist of a lubricating oil, a thickener and one or more additives.• The thickener is responsible for the characteristics of the grease.

Complex greases generally have a higher drop point. More resistant to oxidation. Synthetic thickeners are most resistant to temperature.Extensive testing is done to verify properties.

The advantage of a lubricating grease over an oil is that it Remains at the friction point for a longer time.less effort is required in terms of design.Its disadvantage is that grease neither dissipates heat nor removes wear particles from the friction point.

Lubricating Greases - Uses(1)Machinery that runs intermittently or is in storage for an extended period of time.(2) Machinery that is not easily accessible for frequent lubrication.(3) Machinery operating under extreme conditions such as high temperatures and pressures, shock loads, or slow speed under heavy load.(4) Worn components. Grease maintains thicker films in clearances enlarged by wear and can extend the life of worn parts that were previously oil lubricated.

Grease Characteristics-viscosity-Bleeding, migrationis-penetration-Contaminants.-Corrosion- and rust-resistance-Dropping point-Evaporation-Oxidation stability

(34)Synthetic Lubricants

• Because of the high operating temperatures of gas-turbine engines, it became necessary to develop lubricants which would retain their characteristics at temperatures that cause petroleum lubricants to evaporate and break down. Synthetic lubricants do not break down easily and do not produce coke or other deposits.

Gears Lubrication• Proper Lubrication with timely addition / replacement plays vital role in maintaining the gear boxes withefficiency and increasing its working life.• Oil level should be checked in all the gear boxes oil indicators / dip sticks.• Oil level should be in between the minimum and maximum limits of the dip stick (or indicator).• Testing of the lubricating oils used to be carried out periodically. The following tests are to be done…1. Dirt contamination2. Moisture3. Volatile materials (Benzene, kerosene, spirit etc,)4. Viscosity5. Acidity6. Alkalinity due to soda (Na2 Co3) etc.,

LUBRICATION

Right lubricant is appliedto the right place,

on the right machine,in the right amount,

at the right time.

Refference:

1.http://www.slideshare.net/mamdouhsm/principles-of-lubrication-new

2.https://lubricantspecialist.files.wordpress.com/2011/10/basic-of-lubricants-lubrication.ppt

3.MJLBL_Prospectus