Jan/Feb 2015 O&MM Fabricator

-

Upload

national-ornamental-miscellaneous-metals-assn -

Category

Documents

-

view

224 -

download

7

description

Transcript of Jan/Feb 2015 O&MM Fabricator

The official publication of the National Ornamental & Miscellaneous Metals Association January / February 2015

$6.00 US

®FabricatorOrnamental and Miscellaneous

Metal

The face of tech school apprenticeship, page 51

Biz TalkWhat fabricators say about 13 estimating apps, page 14

Shop Talk

page 45

13 bending tips, page 30

Shop Talk

See METALfab2015, March 11–14, 2015, program guide after page 34

2014 Top Job Gold Award: Non-forged, exterior railing and fence

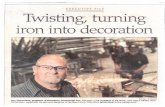

Modifying tools crıtıcal to completing Falling Hammer Productions’ job

Making stainless look forged

Prompt Service. Superior Quality. Competitive Pricing.REQUEST YOUR FREE CATALOG OR SCAN CODE TO DOWNLOAD NOW!

Lewis Brass & Copper Co.69-60 79th Street, Middle Village, NY 11379 USA | phone 718-894-1442 | fax 1-718-326-4032

Visit our new website at www.lewisbrass.com | [email protected] FOR CATALOG

CALL US OR VISIT www.lewisbrass.com TODAY!1-800-221-5579 (US Only) | 1-718-894-1442

BRASS & BRONZE PRODUCTS IN STOCK FOR IMMEDIATE SHIPMENT

The Tubing & Alloy Experts

Over 60 years of providing Tubing, Sheet, Coil, Bar and more, where and when you

want it on both ready-to-order and custom orders.

BRAS

SBR

ONZE

COPP

ER

NIC

KEL-SI

LVER

Celebrating our 57th Year

1957-2014

Heirloom Stair & Iron Inc.Campobello, SC, USA

Forging Your Future | Recognition

* First time members, offer expires March 31, 2015

Membership in the National Ornamental & Miscellaneous Metals Association (NOMMA) offers a unique opportunity to meet and interact with the best and brightest in the ornamental and miscellaneous metalworking industry. The connections you make here will serve you in the future when questions arise, you’ll know what colleagues to call. NOMMA interactions lead to profitable collaborations, new jobs, and lifelong friendships.

NOMMA serves its members and advances the industry through education and the promotion of a positive business environment. By becoming involved in NOMMA, you have a chance to add your voice to the conversations that shape and grow the industry. There is no better way to ensure your business’s needs are part of the discussion than by being at the table with the leaders and technical minds that are shaping the future.

The NOMMA annual Ernest Wiemann Top Job Awards program rec-ognizes excellence in metalwork craftmanship regardless of size or scope. The Mitch Heitler Award for Excellence, which is the highest honor given by NOMMA, is chosen from among the gold winners of the Ernest Wiemann Top Job Awards by a panel of judges. The program has helped innovate and advance the industry by showcasing ideas that push the envelope, overcome challenges, and improve upon existing concepts. All winning projects are showcased in the Fabricator magazine and featured on the website. Press releases are mailed to newspapers in the winning shop’s community. The contest is a great marketing tool to showcase your business!

Visit www.nomma.org today to discover many more compelling reasons to become part of NOMMA family.

National Ornamental & Miscellaneous Metals Association

t: 888.516.8585 f: 888.279.7994 www.nomma.org

Join NOMMA Today and Save $100*

Visit us online at www.nomma.org and enter promo code: DM2-2014

Forging Innovation . Shaping Business . Delivering Profits

As a member you agree to follow NOMMA’s Code of Ethics (viewable on the NOMMA website).

NOMMA Membership Application - Join Us!Membership Category – Check One:

Fabricator MemberMetal fabricating shops, blacksmiths, artists or other firms and individuals in the industry whose products or services are sold directly to the consumer or the consumer’s immediate agent.

q Micro Shop - $350 (annual gross revenues under $250,000)q Medium Shop - $425 (annual gross revenues $251,000–$2,499,999)q Large Shop - $500 (annual gross revenues $2.5 million and higher)

Supplier MemberSupplier members are those members that produce or distribute materials, machinery, and accessories for the industry or provide services that may be used by the industry.

q Nationwide - $595 (operating on a nationwide or international basis)q Regional - $465 (operating within a 500-mile radius)q Local - $375 (operating within a 150-mile radius)

q Affiliate - $310.00 q Teacher q School q Non-profit organizationIndividuals, firms, organizations and schools that do not engage in the fabrication of ornamental or miscellaneous metal products, do not provide products or services to the industry, but have a special interest in the industry.

Company:____________________________________________________________________________________

Primary Contact :______________________________________________________________________________

Address:___________________________________________________________________________________

City:_____________________________________________ State: ________ Zip: _________________________

Country: __________________________________________________________________________________

Phone:__________________________Fax:________________________ Toll Free:_______________________

E-mail: ____________________________________________ Web:_____________________________________

Company Description/Specialty:____________________________________________________________________________________

Payment method: q Check (Payable to NOMMA, in US dollars, drawn on US bank)

q AMEX q Discover q MasterCard q VISA

Card # _________________________________________________ Exp.:________________ CVV: ___________

Print name on card: ___________________________________________________________________________

Signature_____________________________________________________________________________________

Return to: NOMMA, 805 South Glynn St., Ste. 127 # 311, Fayetteville, GA 30214 • Ph: 888-516-8585 • Fax: 888-279-7994 • [email protected] • www.nomma.org

Membership Category – Check One:

q Fabricator - $425 $325 (to pay in four payments, you can enroll in the Quaterly Payment Plan - please see below)Metal fabricating shops, blacksmiths, artists or other firms and individuals in the industry whose products or services are sold directly to the consumer or the consumer’s immediate agent.

SuppliersSupplier members are those members that produce or distribute materials, machinery, and accessories for the industry or provide services that may be used by the industry. q Nationwide - $595 (operating on a nationwide or international basis) q Regional - $465 (operating within a 500-mile radius) q Local - $375 (operating within a 150-mile radius)

q Affiliate - $310.00 qTeacher q School q Non-profit organizationIndividuals, firms, organizations and schools that do not engage in the fabrication of ornamental or miscellaneous metal products, do not provide products or services to the industry, but have a special interest in the industry.

Company:____________________________________________________________________________________

Primary Contact:______________________________________________________________________________

Address:___________________________________________________________________________________

City:_____________________________________________ State: ________ Zip: _________________________

Country: __________________________________________________________________________________

Phone:__________________________Fax:________________________ Toll Free:_______________________

E-mail: ____________________________________________ Web:_____________________________________

Company Description/Specialty:____________________________________________________________________________________

Payment method: q Check (Payable to NOMMA, in US dollars, drawn on US bank)

q AMEX q Discover q MasterCard q VISA

Card # _________________________________________________ Exp.:________________ CVV: ___________

Print name on card: ___________________________________________________________________________

Signature_____________________________________________________________________________________

JOIN BY JUNE 30, 2013 AND RECEIVE A $100 DISCOUNT OFF YOUR FIRST YEAR OF DUES*

Return to: NOMMA, 805 South Glynn St., Ste. 127 # 311, Fayetteville, GA 30214 • Ph: 888-516-8585 • Fax: 888-279-7994 • [email protected] • www.nomma.org

FAX TO: 888-279-7994Join Online: www.nomma.org • By Phone: 888-516-8585, ext. 101

Quarterly Payment Planq Please enroll me in the Quarterly Payment Plan.Payment method: q Please auto charge my credit card. q Please bill me each quarter.

Questions? Contact: Liz Johnson, Member Care & Operations Manager: (888) 516-8585, ext. 101, [email protected]

FAB 201501

January / February 2015 n O&MM Fabricator 5

About the cover Falling Hammer Productions LLC, Wolcott, CT, won the 2014 NOMMA Top Job gold award in the non-forged, exterior railings & fences category for this 125-foot, 304 stainless steel railing for a large residence. See story, page 45.

President’s Letter ............. 7METALfab2015: You’re invited!

Exec. Director’s Letter .... 8Trello helps you organize workflow.

NEF ........................................12Foundation names new leadership team.

Metal Moment .................66Dragon Forge has the passion to do it for television.

News ........................................................59n Demand softens, but outlook of the

Architecture Billings Index remains positive.

n Construction employment increases in 37 states and District of Columbia.

Events......................................................60Plan now for blacksmithing classes

through September.

Media ......................................................61Review of Ironwork Today 4:

Inside and Out.

Products ................................................62

What’s Hot!

NOMMA Supplier Members .........57

New NOMMA Members ..................58

Ad Index .................................................65

Bent offerings .....................................30You can find bending tips in a vari-ety of places, including the NOMMA ListServ. But when O&MM Fabricator magazine wanted to find a few, we spoke directly to the fabricator. Here’s a baker’s dozen worth of ideas.

By Jeff Fogel

Shop Talk

Making stainless look forged ....... 45Stainless steel is harder to bend and more finicky to weld. Find out how Falling Hammer Productions took extra care during design and fabrication of this Top Job gold-winning railing.

By Peter T. Swarz-Burt

Top Job Winner Profile

The current face of technical school apprenticeship ............................51Trade schools depend on advice from local companies to help build their pro-grams. Here’s what Savannah Technical College, Savannah, GA, has learned.

By Steve Hartley and William Burns

Also: 5 ways you can help students get the training they need for you .......... 55

Biz Talk

Inside

n

January / February 2015 Vol. 56, No. 1

The only show exclusively for ornamental & misc. metal fabricators ..........after 34The METALfab2015 program demonstrates the value of peer networking and continuing education: n Education sessions n Exhibits n Awards banquet n Shop tours n Business classes, presented

by Tyler Pare, a consultant with FMI Corporation, Raleigh, NC, will offer a number of how-to tips.

n Keynote speaker, Barry Will-ingham, is the vice president/general manager of Ameristar Perimeter Security USA Inc.

METALfab2015 Guide

Shop Talk

What fabricators say about 13 estimating software programs... 14Whatever tool you use for estimating the costs from job to job, make sure your method is consistent. Software helps you achieve this.

While sometimes tedious to learn, software can also save you time and cut down on mistakes.

Which program works is for you?By Linda Erbele

Knowledge to enlighten the industryMETALfab2015

Gulf Coast members show favorite measuring devices ..........10

NOMMA loses Sam Paresi and Bob Ponsler Jr. .................................... 11

Letter to the Editor ............................ 11Strength of square tubing vs. square solid.

NOMMA Network

Heitler Award

Sell More Jobs:FabCAD JobViewerNow available on the App Store℠, our game-changing selling tool allows you to show the customer exactly how the finished product will look on your iPad® or iPhone®. Using photos of the job site, select gates from our design library or use your own and sell the job on the spot. No drawing required.

Technology partner to great designers, fabricators and business ownerswww.fabcad.com / 1-800-255-9032

Easily input field measurements of your gate, fence, or railing

job and FabCAD Premium draws the job for you in seconds. It

also generates the dimensions and cut list, everything your shop needs to build the job.

Boost your Business:FabCAD Premium

App Store is a service mark of Apple Inc. Autodesk is a registered trademark of Autodesk Inc and/or its subsidiaries and/or affiliates in the USA or other countriesiPad and iPhone are trademarks of Apple Inc., registered in the U.S. and other countries. FabCAD is a registered trademark of FabCAD Inc.

January / February 2015 n O&MM Fabricator 7

n

President’s Letter

METALfab2015: You’re invited!The arrival of a new year means new year resolutions, a fresh start, and most importantly, the time to sign up for METALfab.

This year’s annual confer-ence takes place March 11–14 at the Valley Forge Casino Resort, just outside of Philadelphia.

As NOMMA’s president and convention chair, I’d like to extend an official invitation for you to join us. Our Convention Committee and NOMMA Edu-cation Foundation have spent months planning an outstanding pro-gram that features excellent education, shop tours, exhibits, and social events.

Look for opportunitiesStarting Wednesday morning, our

keynote speaker, Barry Willingham, will discuss how to find opportunities during times of adversity and chal-lenge. Considering the recent reces-sion and the many changes occurring in our industry, I think this presenta-tion will hit home for many members.

Barry, who is vice president and general manager of Ameristar Perim-eter Security USA Inc., is one of our own members and a seasoned speaker.

Ways to manage business betterIn the area of education, I’m partic-

ularly excited about our business class series, which will be led by Tyler Pare of FMI Corp.

His classes will cover improving productivity, connecting actual job costs back to estimating, developing business, managing effectively, han-dling change orders, and learning how to measure business performance.

The knowledge you gain from these classes will more than pay for your METALfab costs.

Other education sessions will cover cash flow, hiring employees, and mea-suring.

I’m delighted to report that the popular video shop tours are back, plus we’ll board buses on Saturday for

some actual shop visits. The video and actual shop tours always provide a wealth of ideas by seeing how other fabricators organize their shops and the equipment they use.

Tools that improve ROIThe exhibits open Thursday

morning; you’ll see your favor-ite vendors from around the world. The METALfab show provides a great opportunity to see the latest industry prod-

ucts and obtain ideas for future jobs. Chances are you’ll see a tool that will save you money.

How the top fabricators did itAs the former Top Job Awards

Contest chair, one of our most useful resources is the Top Job Jamboree, which takes place Friday afternoon.

During the Jamboree, the entries from the awards contest are flashed on a screen and the entrants come for-ward to talk about their work. Often, an interesting conversation ensues with members of the audience. The Jambo-ree is a true goldmine of information.

Benefits of engaging interactionWhile you’ll gain an incredi-

ble amount of knowledge from our stellar education line-up, another great source for learning comes from conversations during class breaks, at social events, and on the bus during shop tours.

We call this interaction the “NOMMA Network,” and it will pro-vide you with tons of benefits.

Finally, we will have an exciting spouse program. I encourage you to bring your better half, and bring your employees as well. Also, be sure to plan time before and after the event for sightseeing.

I look forward to seeing each of you at METALfab2015.

Mark Koenke, Germantown Iron & Steel Corp., is president of NOMMA.

Dedicated to the success of our members and industry.

NOMMA OfficersPresident

Mark Koenke, Germantown Iron & Steel Corp. Jackson, WI

President-ElectAllyn Moseley, Heirloom Stair & Iron, Campobello, SC

Vice President/TreasurerKeith Majka, Majka Railing Co. Inc., Paterson, NJ

Immediate Past PresidentJ.R. Molina, Big D Metalworks, Dallas, TX

fAbricAtOr DirectOrsGreg Bailey, Bailey Metal Fabricators, Mitchell, SD Max Hains, Mofab Inc., Anderson, INMaciej Jankowski, Artistic Iron Works, Norwalk, CTTina Tennikait, Superior Fence & Orn. Iron,

Cottage Hills, IL Cathy Vequist, Pinpoint Solutions, Jupiter, FLHenry Wheeler, Wheeler Ornamental Metals, Dothan, AL

supplier DirectOrsBill Schenke, Ameristar, Tulsa, OKMark Sisson, Mac Metals Inc., Kearny, NJDave White Jr., Locinox USA, Countryside, IL

NOMMA eDucAtiON fOuNDAtiON OfficersChair

Lynn Parquette, Mueller Ornamental Iron Works Inc., Elite Architectural Metal Supply LLC, Elk Grove Village, IL

Vice ChairRob Rolves, Foreman Fabricators Inc., St. Louis, MO

TreasurerMike Boyler, Boyler’s Ornamental Iron Inc., Bettendorf, IA

Nef trusteesHeidi Bischmann, Hartland, WICarl Grainger, Grainger Metal Works, Nichols, SCMark Koenke, Germantown Iron & Steel Corp., Jackson, WI

Christopher Maitner, Christopher Metal Fabricating, Grand Rapids, MI

Greg Terrill, Division 5 Metalworks, Kalamazoo, MI

NOMMA chAptersChesapeake Bay

Patty Koppers, President, Koppers Fabricators Inc.Forestville, MD 301-420-6080

FloridaMarco Vasquez, President, Vasquez Custom Metals Inc., Tampa, FL, 813-248-3348

Gulf CoastRandy LeBlanc, President, Metal Head Inc., Lafayette, LA, 337-232-38383

NortheastKeith Majka, President, Majka Railing Co. Inc., Paterson, NJ, 973-247-7603

Pacific NorthwestGale Schmidt, President, A2 Fabrication Inc., Milwaukie, OR, 503-771-2000

Upper MidwestMark O’Malley, President, O’Malley Welding & Fabricating Inc., Yorkville, IL, 630-553-1604

NOMMA stAffExecutive Director, J. Todd Daniel, CAE Meetings & Exposition Manager; NEF Executive Director, Martha PenningtonMember Care & Operations Manager, Liz HarrisSales Director, Sherry Theien Editor, O&MM Fabricator, Robin Sherman

fAbricAtOr eDitOriAl ADvisOry bOArDterry Barrett, Pinpoint Solutions, Jupiter, FLDoug Bracken, Wiemann Metalcraft, Tulsa, OKBill Coleman, Arc Angels, Dunedin, FLNancy Hayden, Tesko Enterprises, Norridge, ILChris Holt, Steel Welding, Freedom, PARob Rolves, Foreman Fabricators, St. Louis, MO

O&MM Fabricator n January / February 20158

I always look out for organiza-tional software that will increase my efficiency at work. Recently, I stumbled on a useful tool for NOMMA member shops — a web-based project management program called Trello.

Trello, now with report-edly 5 million members, runs from your Internet browser and uses the idea of a whiteboard with sticky notes. Mainly used to track workflow, it has other uses as well.

One use is that rather than see-ing one project board in a conference room, all members of your team can view the board from their computer or mobile device at all times.

Trello’s workflow system can be traced to the famous kanban schedul-ing system that was made famous by Toyota in the 1980s. As your jobs move through the shop, you simply advance the cards from one stage to the next.

You can also list months to make it a calendar or design it as your personal “to do” task manager.

The real power of Trello is what you can do on the back of a card. If it were a real yellow sticky, you’d run out of room quickly. By using the back, you

can attach a file, create a check-list, assign it to a coworker, and color code it. You can write notes on it, too.

Trello has many competi-tors, but I chose it after testing several systems. My runner-ups include Basecamp, 5pm, and Zoho Projects.

Trello is my favorite because of its simplicity, and it’s not

packed with confusing bells and whis-tles that I’ll never use. However, Trello does have some hidden advanced fea-tures you can use as needed, e.g. a cal-endar, card aging, and voting.

The basic Trello is free. You can get more features by purchasing Trello Gold or Trello Business Class, which both cost $45 per year per user. The paid versions allow you to upload huge attachments, which may be handy when sharing design drawings. The free version limits you to attachments no larger than 10 MB.

I’ll conduct a webinar on this soft-ware later. And soon I’ll share another ing online tool called Priority Matrix.

Best of luck with your organizing!

How to reach usOrnamental & Miscellaneous Metal Fabricator (ISSN 0191-5940), is the official publication of the National Ornamental & Miscellaneous Metals Association (NOMMA).

O&MM Fabricator / NOMMA 805 South Glynn St., Ste. 127, #311 Fayetteville, GA 30214

Editorial We love articles! Send story ideas, letters, press releases, and product news to: Fabricator at address above. Ph/Fax: 888-516-8585. E-mail: [email protected].

Advertise Reach 8,000 fabricators For information, call Sherry Theien, Ph: 815-282-6000. Email [email protected]. Ads are due on the first Friday of the month preceding the cover date. Send ads to: Fabricator at address above. Email ads to: [email protected] (max. 5 megs by e-mail). Or upload ads to our website where a downloadable media kit is available: www.nomma.org.

Membership Join NOMMA! Beyond the magazine, enjoy more benefits as a NOMMA member. To join, call 888-516-8585, ext. 101. For a list of benefits, see membership ad in this issue.

Exhibit in METALfab Exhibit at METAL-fab, NOMMA’s annual convention and trade show. For more information, con-tact Martha Pennington at 888-516-8585, ext. 104, or [email protected].

Subscriptions Subscription questions? Call 888-516-8585. Send subscription address changes to: Fabricator Sub-scriptions, 805 South Glynn St., Ste. 127, #311, Fayetteville, GA 30214. Fax: 888-516-8585, or [email protected].

1-year: U.S., Canada, Mexico — $302-year: U.S., Canada, Mexico — $501-year: all other countries — $442-year: all other countries — $78

Payment in U.S. dollars by check drawn on U.S. bank or money order. For NOM-MA members, a year’s subscription is a part of membership dues.

NOMMA Buyer’s Guide Published each December as a separate issue. Deadline for all advertising materials is October 31. Contact Sherry Theien at 815-282-6000 or [email protected].

Opinions expressed in Fabricator are not necessarily those of the editors or NOMMA. Articles appearing in Fabrica-tor may not be reproduced in whole or in part without the express permission of NOMMA.

© 2015 National Ornamental & Miscellaneous

n

Executive Director’s Letter

Trello helps you organize workflow

Todd Daniel is executive director of NOMMA.

Are you a NOMMA Top Job winner? Do you have how-to, step-by-step tips to share? Have you solved an interesting fabrication problem? Write for O&MM Fabricator. Contact Editor Robin Sherman at [email protected].

WE WANT YOUR JOB PROFILES, TIPS

Need to close a gate?We have the solution!All Locinox gate closers feature:

LOCINOX USA - [email protected]: 877-562-4669 FAX: 708-579-0978 Let’s make better fences together

All our gate closers feature:

Adjustable closing speed & pressure

QUICK-FIX Easy mounting with Quick-Fix

L R For left and right opening gates

Adjustable final closing action: snap or smooth

Designed with rustproof materials

Unaffected by temperature changes

A gate closer for every situation:MAMMOTH-180An elegantly designed self-closing hinge that opens smoothly and closes gates up to 330 lbs regardless of the outside temperatures.

SAMSONIndustrial, horizontally mounted gate closer with adjustable speed and force. It is designed with rustproof materials and installed with pre-fitted Quick-Fix mounting hardware.

APPLICATION BY GATE WIDTH Mammoth-180 0 - 330 lbs

Samson-250 0 - 160 lbs

Samson-400 160 - 200 lbs

Verticlose 0 - 150 lbs

APPLICATION BY GATE WEIGHT

VERTICLOSE-STD180° hinge applications!Adjustable, vertical mounted gate closer suited for use with 180° hinges, wall mount applications and gates with arched tops.

VERTICLOSE-RAIL90° hinge applications! Can be installed to push the gate closed or mounted on the secure side of the gate to pull the gate closed.

APPLICATION BY GATE WIDTH

n

The NOMMA Network

O&MM Fabricator n January / February 201510

Gulf Coast members show favorite measuring devicesThe Gulf Coast NOMMA

Network held their fall meeting in Clinton, MS, on November 15, with Iron Innovations Inc. serv-ing as host shop.

The main program for the day was “Show-n-Tell,” where members demonstrated their favorite tools, in this case, a vari-ety of laser measuring devices.

Scott Meckes of Door- king also demonstrated a radio transmitter that tested signal strength. The device ensures that gate operator electronics will have a sufficient signal during the design stage.

For the business session, NOMMA Executive Director Todd Daniel gave a slide show called the “Not So Dirty Dozen.” He showed 12 online informa-tion sources that you can access from either the NOMMA web-site or from related associations.

Scott Colson, who served as host for the day, showed a tele-vision commercial he recently produced and gave a short talk on advertising.

There were the usual favor-ite events, including a shop tour, the famous buck-in-a-bucket raffle, and a delicious barbecue lunch.

During the tour, attendees, saw Iron Innovations’ torch cut-ting system and several jobs in process. Attendees were particu-larly interested in the company’s parts organization rack, which used 5-gallon buckets.

The next meeting is tenta-tively planned for Fort Payne, AL, and time and date will be announced.

The Gulf Coast NOMMA Network enjoyed a nice turnout at their November meeting, with attendees coming from Alabama, Louisiana, and Mississippi.

James Minter Jr., left, shows his favorite laser measuring device to a captivated audience.

During the tour of the Iron Innovations shop,

the parts organization rack, featuring 5-gallon buckets,

was a hit with attendees.

January / February 2015 n O&MM Fabricator 11

Gulf Coast members show favorite measuring devices

In Memoriam

NOMMA loses Sam Paresi, past volunteer

Sam Paresi, 88, a long-time NOMMA volunteer, passed away on December 27, 2014. He was employed with Julius Blum & Co. Inc. for 66 years before his retirement in 2011.

Sam was a reg-ular participant at METALfab conferences and a founder of the National Ornamen-tal Metal Museum

in Memphis, TN. He served on the NOMMA Standards Com-mittee for many years and helped develop standards that are still used to day.

He also helped to create the Metal Rail Manual and NAAMM-NOMMA Finishes Manual.

In 1992 Sam received the Julius Blum Award for outstand-ing service to the industry. In 2010, the NOMMA board voted him as an honorary lifetime member, and he was recognized at a special ceremony during a Northeast Chapter meeting in January 2011.

Sam began his career at Julius Blum in 1944, at age 18, as an errand boy, and then moved up to inside sales, warehouse foreman, and then outside sales. The only time he left Blum was to serve his country in the Korean War.

Sam will always be remem-bered for being kind, friendly to all, and for being passionate about the industry. At NOMMA conferences, he always made a point to say hello to everyone and he had a true concern for the well being of others.

Services were held December 30 in Massapequa Park, NY.

Donations in his memory should go to: Association for the Help of Retarded Children (Nassau).

Strength of square tubing vs. square solid

I’m reading the November/Decem-ber 2014 O&MM Fabricator, and the article on testing railings is quite good.

However, I’d like to point out an inaccuracy. A statement made in the article says that square tubing is stron-ger than square solid. It’s a common misconception and an argument I’ve faced multiple times. This isn’t true when comparing apples to apples.

For instance, people should not assume that a hollow of a same alloy and temper as a solid, will be stronger. The opposite is true.

Where it gets tricky is that steel tubes under 2 inches are manufactured to ASTM 513 and are made from a differ-ent steel composition than standard hot rolled solid bars. They have a minimum yield strength of 72,000 psi and tensile of 87,000 psi with 10 percent elongation, whereas A36 steel has a yield strength of only 36,000 psi and tensile of 58,000 to 80,000 psi with 20 percent elongation.

Now, if someone takes the same grade of material, such as architectural bronze, and compares a 1-inch solid square versus a 1-inch square tube, (no matter what thickness tube) the solid will almost always win.

For details on the actual calculations for this, see http://bit.ly/1tuQSpd

Kendall Shrock Shrock Fabrication

Author, Jeff Fogel, respondsThis tube vs. solid strength is an old

debate. Engineers and physics students fight about it in pubs.

A tube can be at least as strong, if not stronger, than solid stock provided we are talking about similar mass and not similar diameter.

What this means is that hollow tube has a higher strength to mass ratio than solid. But when you’re comparing equal diameters, the solid wins hands down.

Having said that, Kendall Schrock is considered one of the most knowledge-able people in the industry. I’d go with his opinion (which, unlike a physicist, is predicated on real life). I have no problem being corrected by him.

Letter to the Editor

n

In Memoriam

NOMMA loses 41-year member Bob Ponsler Jr.,

Bob Ponsler Jr., 66, of Won-derland Products Inc., Jack-sonville, FL, died suddenly on December 14, 2014.

Bob was a 41-year NOMMA member and served as Florida

Chapter president in 2003 and also as chapter representa-tive to the NOMMA board.

In 2006, he served on the

NOMMA Technical Commit-tee and attended the ICC spring code hearings that year. He also attended many METALfab con-ventions.

His father, Bob Ponsler Sr., was a past NOMMA president and NOMMA legend.

He served in the Florida Army National Guard for many years and retired as a major.

Wonderland Products started out by building playground equipment in the 1950s. From there, the company moved into light industrial blacksmithing and later became known world-wide for its high-end ornamental work.

The company has won numer-ous awards in the Top Job con-test.

One of the things the com-pany is known for is its expertise in working with Monel metal.

Bob is survived by his wife Daysi Melo Ponsler, mother Thelma Ponsler, sister Jeanie Allen, brother David Ponsler and three sons Robert Pons-ler III (Rachael), Joseph Pons-ler (Sarah) and James Ponsler (Tayna) and eight grandchil-dren. Two of his sons — Joe and Jimmy — continue to run the business.

n

NOMMA Education FoundationIn partnership with the National Ornamental & Miscellaneous Metals Association

O&MM Fabricator n January / February 201512

DONATE!

For more information on donating to the NOMMA Education Foundation Contact NEF Executive Director Martha Pennington, 888-516-8585 x104, [email protected].

Foundation names new leadership teamThe NOMMA Education Foundation would like to congratulate its new officers.

Chair, Lynn Parquette, Mueller Orna-mental Iron Works Inc., Elite Architec-tural Metal Supply (pictured, left).

Vice Chair, Rob Rolves, Foreman Fab-ricators Inc. (pictured, center).

Treasurer, Mike Boyler, Boyler’s Ornamental Iron Inc. (pictured, right).

METALfab2015 education highlightsAlong with the outstanding lineup of NOMMA members

presenting at METALfab2015, NEF is providing a very special presenter, Tyler Pare, a consultant with FMI Corporation.

Pare will present a series of classes for the METALfab2015 education program on Wednesday, March 11 and Thursday, March 12.

As a consultant with FMI, Tyler focuses on leveraging his construction experience and his knowledge of business mechanics to help clients mitigate risks and improve produc-tivity. The topics that Tyler will be covering include:

n Leveraging Your Competitive Advantage by Improv-ing Productivity

n Connecting Actual Job Costs Back to Estimating n Key Performance Indicators that Drive Best Practices n Keys to Effective Management n Driving Best Practices in Business Development n How to Avoid Confrontation with Change Orders

Other useful sessionsWhere’s The Cash? Dave Filippi, FabCAD will present a

practical and unconventional look into small business man-agement

Hedging Your Bets on Hiring the Right Employee for You. Roger Carlsen, Ephraim Forge, will lead a discussion on how to design an employee search paradigm, including, but not limited to:

n Where to look for possible candidates. n Some first impressions insights. n Designing the right written test to fit your specific needs.n Thoughts on actual hands on task testing. n Making the final decision.Measuring Made Easy. Mark O’Malley, O’Malley Welding

& Fabricating Inc. and Terry Barrett, Pinpoint Solutions will show attendees the tools, technology, and methodology for

field measuring, shop drawings, and shop and field layout.

History of Metalwork. Eric Cuper, Cuper Studios LLC, will focus on history of metal emphasizing blacksmithing and decorative work, and how technology and modern design have impacted it.

Under 40 — Hammering Out Your Course in Metal-work. Discover how the under-40 group see its future path to success.

Video Shop Tours. This is your chance to see in-person how other fabricators set up shop.

Women in the Business. A roundtable discussion for women about their challenges and successes, and what the future holds.

ListServ Live. Meet the people who participate in the NOMMA ListServ discussions and ask them more questions, in person.

Other classes will be announced; be sure to check the NOMMA website at www.nomma.org.

For more information: See the METALfab2015 Convention Guide included in this issue after page 34.

Special NEF events at METALfab2015Don’t forget to consider making a tax-deductible contribu-

tion for our Live and Silent Auctions set for Thursday, March 12, 2015, during METALfab2015.

The Auction Committee is requesting donations of auc-tion items, which may include, but are not limited to:

n Metal sculpture, a garden gate, hand-forged furniture, books, artwork or antiques;

n Non-metal items such as tools, gift baskets, gift certifi-cates/coupons, jewelry, electronics, clothing, food/wine, presentation drawings, the use of a condo at the beach or air-line tickets;

n Specialized services to create a custom one-of-a-kind item for the winning bidder;

n Or, be creative– the sky’s the limit!Donation forms are available at www.nomma.org under

the education tab. Thank you in advance for your contribu-tion to NEF.

Finally, please join the NEF trustees at the Partners in Education Reception on Friday, March 13.

This event is sponsored by NEF to thank you for your con-tinued support of the foundation.

O&MM Fabricator n January / February 201514

By Linda M. Erbele

Shop Talk

n Whatever tool you use for estimating the costs from job to job, make sure your method is consistent. Software helps you achieve this. While sometimes tedious to learn, software can also save you time and cut down on mistakes. Here’s what fabricators say about 13 programs.

What estimating app works for you?

Editor’s note: For this article, O&MM Fabricator looked at a 13 estimating software programs used by fabricators. We sought to interview at least one fab-ricator for each app and talk to the ven-dor as well. If one of the two sources are not mentioned in a description, it was because we could not reach the source.

Due to the numerous products and features, and space limitations in the magazine, we cannot describe each com-prehensively. Instead, we attempt to give you a “sense” of the product.

Sometimes it’s an RFP for a job. Some-times it’s a customer with a sketch for complicated work. Regardless of the way the job comes in, you create an

estimate for the cost of the work.Estimators likely build a job in their

mind to some degree from start to finish — every weld, pipe and sheet, cutting to finishing. What machines are used for each step? The purchase price for each piece of material, as well as shipping costs, are included.

The labor hours for every process required to turn raw materials into a final job is accounted for. Plus hours for installation. If that requires an over-night at the customer’s location, per diem for the employees might be part of the cost. If a truck is rented, its cost and that of gasoline is factored in.

Thus, an estimate would include all costs for design, field measuring, materials, labor, finishing, installation, travel, machine rental, subcontractors,

overhead, and profit as a percentage. Kevin Hill, administrator with

Owens Welding in Cleveland, GA, says that after the material and labor costs he adds in the costs to run the machines and the use of other consum-ables, such as welding rods and wire, gas, and power. Like most fabricators, he says the shop uses a lot of electricity.

“Basically, an estimate is an educated guess,” says Hill.

Sometimes, experience tells him the cost of a job. Sometimes, it’s a blind bid or a price by the hour.

“When you find that an estimate was too low, you can’t go back to the customer and ask for more money,” he says. “You just eat it and move on. But you learn from it.”

Michael Stone, author of Markup and

Structural Material Manager

For more information:

doorking.com/dcslide

DKS DC Slide Gate Operators are perfect where backup power is critical, as they keep running when AC power has been lost. No power – no problem. In remote locations without power, simply connect our solar panel and large batteries for stand-alone operation.

The DKS Model 9024 provides everything you expect from a gate operator in this class – and more. Power where you need it, when you need it.

The new DKS DC Slide Gate Operator’s powerful DC motor, and full size gearbox, deliver the best gate opening power – and security – in its class.

Full sized gear box moves gates up to 35 ft. and 1000 lbs.

Member: AFA, DASMA, NAA, IDA, NOMMA, NPA, SIA, SSA

Parking Control Access Control Telephone Entry Gate Operators

New DC Slide Gate Operatorwith Backup when power is down, or with Solar when there is no power

See us in booth 539

O&MM Fabricator n January / February 201516

BIG BLU HAMMER MFG. CO.3308 Frank Whisnant Rd., Morganton, NC 28655PHONE: 828-437-5348 • FAX: 828-437-9217

The Big BLU Power Hammer continues to become the workhorse and center of activity in hundreds of shops across the United States and in many foreign countries around the world.

Profit, A Contractor’s Guide Revisited, says you rarely see an estimator who has made the mistake of overestimating. If a mistake has been made, it’s usually the other way around. Maybe you acciden-tally left out an item. Easy to do.

You’ve got to use a systemStone teaches a course on

estimating (see www.mark-upandprofit.com). What is important in a takeoff, he says, is the use of a consistent system.

“Too many people get hung up on how to get the numbers,” he says. “What’s important is using the same system every time. You do the same thing, the same way, every time. That’s how you stop things from falling through the cracks.”

The consistent system must also be a good system. Stone says that two mis-takes people make with estimating are not using a system that covers all the variables, including profit and over-head — and the second is guessing. “It’s very boring and tedious, but it has to be done right or you lose money,” he says.

For some fabricators, creating an

estimate requires a sharp pencil with an eraser, maybe graph paper, or a legal pad — and a long night.

For others, it’s a spreadsheet with fields for quantities of materials, then the labor: hours for cutting, weld-ing, sanding, polishing, yadda, yadda, yadda. . . . Then columns for additional hours of installation.

Using a spreadsheetLike many, Spirit Ironworks in Bay-

port, NY, is a small shop that does a lot

of custom work. Partner Rachel Miller, who does most of the estimating, recently began using an Excel spread-

sheet to track time on a job.“If we get a similar job, I can

occasionally pull labor from (an older job,) but it’s never the same,” she says, because each job is different. A look at older jobs can

at least give her an idea of labor hours per operation.

The advantage to a spreadsheet is it can be as simple as a list of prices or as complex as you can make it. With rows and columns, items of material can be listed and the var-

ious labor functions (cutting, welding, sanding) can be listed beside them. Once set up, a spreadsheet can serve as a checklist of materials and processes.

Because it can calculate, columns can be totaled and the percentages for overhead and profit factored in.

However, spreadsheets are two- dimensional. They can’t make an asso-ciation between much more than the rows and columns. Scrolling through multiple pages of material and other data can be tedious.

Structural Material Manager

January / February 2015 n O&MM Fabricator 17

See more at www.cmrp.com/circular-staircases

Chicago, IL • Kansas City, MO • www.cmrp.com • [email protected] PRODUCTS COMPANY 1-800-644-0674

O&MM Fabricator n January / February 201518

Using softwareEstimating programs typically can

be customized by the user. All the pro-grams we review are Windows-based, but ask the vendor if there is iPhone, iPad, or Mac functionality.

Many fabricators, even small shops, use a software application, which may be available either on-premise — meaning you own it, and the program has been loaded onto your computer; or it is in “the cloud” — meaning the application and sometimes a materials database are accessed on the Internet and live on a provider’s server. Variations can exist, such as the application on your com-puter and the database in the cloud.

Most software vendors offer com-plimentary training when you buy the product, and online help documents for later. Many of the larger software packages have videos online showing how they work. Look for the best train-ing deal after the “new” wears off.

Software is sold typically as “licensed users,” sometimes referred to as “seats” — the number of people at the company

they have an estimating function and can also help you manage other business operations from production to purchas-

ing and accounting. Some can do multing and nesting — combin-ing lengths of the same materi-

als to create the most efficient cuts to reduce overages of materials. This can extend to telling the shop how

to best use the sheet or bar most eco-nomically. Some can even track price breaks by quantity, knowing when buying 50 of something will cost less than buying 46.

Bluebeam Jim Toney, general manager at

Southwest Architectural Metals in Hen-derson, NV, uses Bluebeam.

“We use it in doing takeoffs for a project in preparation for proposals,” he says. “It is primarily used in lieu of paper documents and can be passed electronically to share information. We pass the marked up electronic files between the different divisions of our companies: structural steel, miscella-neous steel, stair structures, and archi-tecturally exposed metals and glass.”

The software is cloud-based and everyone can work in the same file. Southwest Architectural Metals doesn’t use it to produce the final document the customer sees, but if they are success-ful with the bid, the Bluebeam file can be transferred to the operations side so they can understand the project’s scope.

Bluebeam costs $219, and customers can buy a $79 annual training package.

“Bluebeam Revu allows users to perform many types of digital takeoffs; they do not need to own any additional Bluebeam software,” says Steve Jones, senior channel sales specialist. “While Revu is an extremely powerful tool (especially for the price point), it is not a 100% apples-to-apples replacement for dedicated on-screen takeoff solu-tions, which cost substantially more and are more specialized. However, for many of our customers, Revu has all of the features they need to get their job done efficiently.”

He adds that Bluebeam doesn’t have a material or labor cost database.

“Users can add costs [of materials] to their measurement markup tools by using custom columns in the markups list, but this information does need to

authorized to use it. Prices start with the first user, and most go up with each seat. Sales people can sometimes dis-count the cost when more licenses are purchased, so don’t hesitate to negotiate.

Many programs include a database of material items. Depending on the volatility of prices for the particular metal a fabricator uses, a database of costs by sheet or length can be helpful.

Some programs are “enterprise resource planning” (ERP) programs —

Structural Material Manager

Phone: 1-800-467-2464 • 636-745-7757

Upgraded Vise Capacity 3/4” to 2-1/2” Tubing

Adjustable Height Larger V-Block ViseRecommended for pipe notchingModel 400-VSU2ADJ

Double Sided VS Ultimate Tube/Pipe Notcher

MEMBER

Wider Table Allows Vice to Travel Further so Cutting can be Accomplished on both sides of the End Mill. This allows Notching those

otherwise “Impossible Pieces.”

January / February 2015 n O&MM Fabricator 19

ISO 9001QMI-SAI Global

The Cable Connection800-851-2961 • 775-885-2734 faxwww.ultra-tec.comE-mail: [email protected]

• Fittings and cable for 1/8", 3/16", 1/4", 5/16", and 3/8" diameter cable

• Diverse array of fittings adapt to field conditions dictated by the job

• For either indoor or outdoor installation

• Cable runs custom cut and swaged to your specs

• Swageless technology fittings available for 1/8" and 3/16" diameter cable

• Weather-resistant type 316 stainless steel — virtually maintenance-free

• Less labor intensive — easy to install

Top three judged photos receive prizes and you will receive credit for every photo that we use for promotional purposes (ex: Photo courtesy of ABC Metalworks).

See the 2014 winners and get details on submitting your own photos at our home page: www.ultra-tec.com.

2013 NAHB “New American Home”

O&MM Fabricator n January / February 201520

Overview of software programs for estimating cost of jobs

Application Strengths* Weaknesses* Improvements Cost Training coming (basic plan)

Blue Beam Relatively None Spring $219 $79 per year with OST inexpensive identified 2015

E2 Shop Comes in Learning Spring 2015 — $1,995 Free System modules curve metrics

FabMate Customized None Early $3,000 Free by shop 2015

FabSuite Comes in Complexity First quarter $5,000 5 hours free modles 2015

FabTrol Calculates labor Fields a bit Rewrite in $3,500 Free per operation limited, Spring 2015 based on requires to address previous inputs abbreviations field size

Fast Track Low cost None identified None expected soon $295 Free manual

JobBoss Job tracking None Feb $2,750; Free identified 2015 $299/month

MIE Quote-It Adaptable Learning Jan $2,500 w/initial training free; curve 2015 $1,500 + $215 for training

PlanSwift Figures linear Learning Mid-2015 $950 $295 footage on screen curve from PDF, CAD dwg

ProEst Detailed estimates None Spring $1,295 $695 for from on-screen plans identified 2015 online class

Structural Multing, nesting None Spring $1,495 + Free manual Material identified 2015 — $795 estimate Manager metrics module

Visual EstiTrack Cost tracking Complexity New release $3,000 Free issued Dec 2014

WinEst Pro Ability to view None 2015 $3,500 $1,000 and sort data identified

* Strengths and weaknesses are based on interviews with fabricators who use the software.

tion. It compares the actual costs to the estimated costs. People in the shop scan a piece of paper associated with the job (called a job sheet or router) with a bar-code reader to track their hours spent on each part of the job.

In addition, Rolves says, they gen-erate shipping tickets, purchase orders, and invoices with the software. It tracks the bids that turn into orders and allows the estimator to record notes so that someone else can see how the estimator envisioned the product being made.

The E2 Shop system has an optional database of materials that the user can choose from, and can create reports based on customer or product. The user can add prices based on experience and update them as they change.

The program’s calculator helps break

down how much of a sheet or bar each part (or a job) is using, and it can calcu-late quantity price breaks — the change in price if 10, 25, or 50 are purchased.

“You create your own work centers (in the software,)” he says. “If you want to consider coping a pipe to be a differ-ent operation from cutting a pipe, you can set up it that way. We’ve changed the design set up in the software over the years as we’ve learned things.”

For example, he says they initially set up a unit for welding and a separate unit for layout for the welding. But the welders had to stop work to record time for layout before they went on to weld-ing, and so it made sense for the two operations to be combined.

Rolves says he has used the software a number of years, but has had more

be added manually,” Jones says.Training videos are available. Contact www.bluebeam.com

E2 Shop System Rob Rolves of Foreman Fabricators

in St. Louis, MO, uses the E2 Shop Sys-tem by ShopTech.

“No software takes away the art and intrinsic knowledge needed for estimat-ing, but it helps,” he says.

One big time-saver in using software is the ability to quickly search other jobs that are similar.

“If the powder coating on this job is like another one, that speeds up your time to quote,” he adds.

An ERP product, the software can do more than simply create estimates. It tracks inventory and schedules produc-

Ultra-tec® Cable Railing and Wagner Lumenrail®

No Sharp edges on retainersNo long, bulky fittingsNo uneven, hand-crimped shanks

10600 W Brown Deer RdMilwaukee, WI 53224

(888) 243 [email protected]

wagnercompanies.com

MKT KG NOMMA FABRICATOR NOV 14.indd 1 10/8/2014 9:14:05 AM

O&MM Fabricator n January / February 201522

presents THE BESTIN GATE HARDWARE

PHONE: 1-800-888-9768FAX: 616-235-2901www.dacindustries.com

DAC INDUSTRIES, INC.600 ELEVENTH ST. N.W.GRAND RAPIDS, MI 49504

STEALTH COVER STEALTH ROLLER STRONG ARM LATCH

PANIC DOOR HARDWARE AUTO-LATCH BLACK STRONG ARM LATCH

GATE HINGES

SENTRY LATCHSELF-CLOSING HINGES

BEST

IN GATE HARDWARE30

YEARSDACINDUSTRIES

19852015

labor costs in the manner you want to compile them,” he says. “Make sure the program puts the estimate together the

way you want it done. Don’t adjust your operation to the way the software works.”

Miller says he couldn’t find a program that fit those needs, so he hired Michael Babcock of MB Soft-

ware Solutions to create it.“It is basically a compiler. It’s a

very good compiler as opposed to a spreadsheet,” he says. “It does an excellent job of taking our inputs and compiling them in the man-ner we asked him to do. It prepares

a summary sheet, a list of individual items, then a proposal sheet in a very slick fashion.”

Miller says the software has a mate-rial and labor database, that can be cus-tomized by the user to add costs. They have been using the system since 2003.

MB Software Solutions president Mike Babcock says he’s re-writing the software to bring it to current technical standards and expects that re-write to be complete about mid-2015. It creates estimates, and hours collected by the

Higher levels of management are avail-able above that, such as accounting and quality control.

Contact www.shoptech.com/ products/estimating

FabMateBill Miller, president of Ebinger Iron

Works in Schuylkill Haven, PA, believes the most important thing about an esti-mating program is that it works the way your company does business.

“See if it compiles your material and

training several times over the years, and learned more each time.

“Like any software, if you get train-ing on every part of it at the begin-ning, you won’t retain it,” he says.

Paul Ventura, ShopTech’s vice pres-ident marketing says the product is designed so that a small fabricator can purchase just the estimating portion and download to Quick-Books, or buy the accounting part of the software in addition to the estimating portion.

The E2 Shop System is available on- premise or in the cloud. Employees can report their time with a bar code scan-ner or a tablet, where they can also view the drawings or pictures of the job.

“We have a basic (starter) system priced for the smaller guy,” he says.

The starter system costs $1,995 for each license including free three-day classroom and Internet training, both pre-recorded and live.

Ventura says the basic system can create estimates, track the job, and per-form purchasing and shipping func-tions. The next level of the software adds shop floor system management.

MAGNETIC DRILL PILOT LIGHT

MAGNETIC DRILL MAGNETIC DRILL PILOT LIGHTPILOT LIGHT

MAGNETIC DRILL MAGNETIC DRILL

800-426-7818 SERVICE • INTEGRITY • RELIABILITY HOUGEN.COM800-426-7818 SERVICE • INTEGRITY • RELIABILITY HOUGEN.COM

NEWHMD905TWO SPEED

Pat Pending

From low light to no light, never worry about seeing where you are drilling again. The LED Pilot Light is a standard feature on new models of Hougen magnetic drills. Visit www.hougen.com and see first hand the three new models of magnetic drills plus the redesigned HMD904.

• New Models• More Power

• More Speeds• More Features

Hou-719 NOMMA.indd 1 12/15/14 10:06 AM

Structural Material Manager

The Hebo machines are the absolute fastest way to add value to metal. Literally less than the cost of one $10/hr employee, with a useful life over 25 years. The multi-functional Hebo machines can: twist, bend scrolls, endforge, emboss, texture, edge hammer tubing and solid bar, make baskets, and press belly pickets. The machines work with: steel, aluminum, bronze, copper, and brass.

Hebo Machines were started by German Blacksmiths, with you the fabricator in Hebo Machines were started by German Blacksmiths, with you the fabricator in mind. Their mission has been to partner with you, to provide you with a mechanical advantage to speed up your processes, in order to help make you as fast, efficient and profitable as possible.

Phone: Office 503-722-7700 Cell 503-572-6500Email: [email protected] or [email protected]

Websites: www.usahebo.com | www.drivewaygates.com | www.forgedironsupply.com

Email: [email protected] www.heboe.com | Phone ++49 6453 91330 Fax 49 6453 913355 | Hebo Maschinenfabrik, Am Berg 2, 35285 Gemunden-Grusen, Germany

CALL FOR A FREE DVD 503-722-7700OR VISIT WWW.USAHEBO.COM

If you need a machine and don’t buy it, then you will ultimately find that you have paid for it and don’t have it. - Henry Ford

“”

STM MOTOR UNIT Can twist up to 1.25”

HEBO SCROLL MACHINEScroll up to 3/4” square cold

24-TON HYDRAULIC TABLE

O&MM Fabricator n January / February 201524

tion management, purchasing, and inventory control.

FabSuite integrates with modeling systems such as Tekla and SDS/2, as well as AutoCAD-based systems such as Advance Steel. Thus, a CAD design can be imported, and estimates and production control information can be generated. An included web-based interface enables remote access to data as well as recording of shop activities on tablets or smartphones.

Issler says a detailed inventory sys-tem allows the user to add the costs of materials. Fabricators can maintain that database as their pricing changes.

Contact www.fabsuite.com/ estimating

FabTrolDavid York of York Metal Fabri-

cators, Oklahoma City, OK, has used FabTrol since it was a DOS program, pre-Windows.

“Inside Fabtrol, there are abilities to build pre-fabricated units and calculate how many inches of weld go on a piece of metal,” York says.

The software offers a field to put in the material, with an associated field (or more) for the labor that will be required. For a railing, for example, he puts in the welds, the core drills, brackets, and pick-ets, each with the associated labor.

“When I’m done, it tells me how many hours I have per post,” York says. “If we sell the job, then I give it a job number. When engineering details the job, it gives them a bill of material. Then they hit a button that says ‘optimize.’ It tells purchasing they will need to order 376 pieces of pipe.”

York says that once it goes to the shop, the program tracks the labor for the project, which can then be compared

to the estimate. Brian Williams, FabTrol’s

general manager, says the pro-gram allows the fabricator to build a model of the shop operations within the software. “We have the ability to set up for-

mulas to derive time based on the length, the type of material, the weight of materials, or the perim-eter of a plate,” he says. “As you’re doing your material takeoff, we have automation that determines

what types of operations needs to hap-pen for certain types of material, then how long those steps should take.”

Williams estimated that it could take a fabricator new to the software an entire day to create a model of the shop within the software. But a person just using it for its estimating capabilities could get going with little training in just a few hours.

He says that the software will cal-culate buyouts and sub-outs, freight, markups, overhead, and profit. FabTrol comes in three levels, FabTrol Shop, for small shops, FabTrol MRP for more management, and FabTrol Pro.

FabTrol Pro maintains a material cost database that is updated automat-ically for users who also use the pur-chasing system. Users have full con-trol over material pricing. The latest pricing for a given bid can be saved and re-used, and/or each job can have custom pricing. FabTrol tracks labor, for those using the production module, and can provide feedback about man-hours per assembly type.

Williams adds that FabTrol Pro was re-written and released in the fall of 2014, and the estimating module is being re-written with an expected Spring 2015 release date.

A common complaint about FabTrol has been the limited field size, and Wil-liams says a re-write will address that.

Contact www.fabtrol.com/software/ fabtrol-pro-enterprise/ estimating.html

Fast Track EstimatingFast Track Estimating was created by

Michael Stone, who teaches classes on

shop foreman can be input manually to be compared against the estimate.

“The beauty of this software is it’s as simple or as complex as you choose to make it,” Babcock says. “What I’ve heard from my customers is that the other softwares do all this whiz-bang stuff, and they only use 20% of it. FabMate provides a simple, clear way for consistent estimat-ing, taking the routine out of one’s head and tracking it in a database, so that knowledge is preserved and able to be re-applied for future estimates.”

It has a materials database, and the ability to factor in labor and installation costs, such as a hotel stay.

“You shouldn’t need a manual for this software,” he says, although a 52-page book comes with it. “You should be able to pick it up, just common sense.”

The price begins at $3,000, and the current version has no additional cost for other users, at this point.

“It’s all you can eat,” Babcock says. He offers a 30-day money-back

guarantee and says he’s happy to discuss customization of the product.

“I’m a small company that started 10 years ago. I’m willing to listen and put something together that will help you work smarter not harder,” he says.

Contact www.mbsoftwaresolutions. com

FabSuiteBrad Landry, division manager with

Grunau Metals in Oak Creek, WI, uses FabSuite for estimating, project man-agement, and production control.

“It puts together a material list, con-nects to Outlook, and sends (the list) to vendors,” he says. “You can send a spreadsheet out for them to fill out so you don’t have to do any keypunching.”

The software has multing and nest-ing functions to minimize overages and suggest the best cut from sheet material.

“They have a very open minded development team that listens to cus-tomers and implements things when we ask,” Landry says. “They listen to us fabricators and have made some really good changes.”

Bill Issler, FabSuite president, says fabricators can purchase just a module to create estimates or larger modules that do project management, produc-

Structural Material Manager

The choice is yours...internally or externally mounted.

• Hydraulic closer & hinge all in one small, powerful package!

• Dual bearing glide system for consistent superior performance

• High strength aluminum — tested to 500,000 cycles

• ADA compliant

• Multiple adjust options — closing speed and final snap action

• Powerful hydraulics

• Visibly small footprint

• Highly tamper resistant

• Maintenance free – no messy grease

P: (800) 716-0888 E: [email protected] www.ddtechglobal.com

Hydraulic Gate Closer and Hinge

O&MM Fabricator n January / February 201526

up, but the MIE support people have always been quick to fix it.

MIE Quote It is the quoting and estimating software part of MIE Trak Pro, created by MIE Solu-tions. It integrates with Quick-

Books as an on-premise software. It does not contain prices for mate-rial, but users can add them to

the database.MIE Quote It prices start at

$2,500 for the first seat with training included, or $1,500 with training priced separately. Additional seats are $1,500 each. MIE Trak Pro costs $5,995 for the first seat and $2,995

for additional seats.It is available on-premise for both

the application and database, or on-premise applications with cloud-based database at $50 per month or both in the cloud.

Contact www.mie-solutions.com

PlanSwiftSRS, in Metuchen, NJ, has been

using PlanSwift for about two years to do takeoffs for railings. The software imports drawings from PDF, JPG, or CAD formats.

One feature of the app is that the user can click on the beginning of a line that indicates a rail or wall, for exam-ple, then click on the other end, and the software estimates linear footage or square footage, even gallons of paint for an area.

It also imports data from a spread-sheet, so if you had, for example, foot-age of various pieces of metal, it can add that in as you direct it, says Lou Anelli, PlanSwift’s vice president mar-keting. The software can figure labor based on the data you give it.

“It integrates fully with Excel and a variety of accounting software applica-tions,” he adds.

SRS lead estimator Lin Huang says she can import the drawings from a job and create the takeoffs by clicking on the beginning and the end of the rail-ings to develop the linear footage.

“It’s very convenient to separate the types of railings,” she says.

In the past, she had to keep track of the footages on each page of a job manually. PlanSwift can show her a summary of the pages on one side of the screen and on the other, a totaled

garbage out,” he says. “People will punch in the wrong job number, or forget to punch out so it looks like they had 90 hours on one job in a week.”

JobBOSS is available in the cloud or on-premise. Marketing director Mike Stadelman says an on-premise seat license is $2,750 or the Internet subscrip-tion is $299 per month for the first user and $19 per month for the next user.

On-line training guides are available for free and regional training sessions available at a cost. The cloud version comes with 30-days of free consultation training.

A material cost database is available and can be updated by the user.

Currently, shop hours can be tracked with a smartphone or tablet in the online version and that will be avail-able in the future with the on-premise version.

Contact www.jobboss. exactamerica.com

MIE TrakJoe Skelton owner, of Nemesis Met-

als in Fond Du Lac, WI, uses MIE Trak software, another ERP system.

“It quotes our projects, and breaks down material costs,” he says. “It (defines the order of) all the opera-tions when they hit the floor. We tell it dimensions, and it does the math on that piece of material. The system’s pretty adaptable.”

The app helps with the repetitive parts of estimating and keeps track of materials and labor, he says. Shop workers can track their time by scan-ning a job sheet or tapping it in on a tablet. He adds that occasionally an issue with the software has come

profitable estimating. His simple esti-mating software is $295. It breaks down parts of the job as “assemblies” (a group of labor and material steps to perform a single unit of work) and allows the fab-ricator to enter materials, labor, and subcontractor costs. Then the percentage for overhead and profit is applied to create the final price.

Stone says that the “assem-blies” can be adjusted to match the needs of the shop, and some are already built in that are applicable to fabricators.

“It’s a small, bare-bones, get-the-job-done type program,” he says. “Our tar-get market is the smaller company.”

The software includes a database of materials, labor, and assemblies that are easily customized, Stone says. The esti-mator enters the quantity of each assem-bly; material, labor hours, and other costs can be adjusted for each project as needed.

They can also easily create new assemblies by cloning an existing assem-bly and adjusting. The software then cre-ates an estimate document.

Stone says it is so simple that a train-ing class isn’t really necessary, but he’s personally available to help anyone get started.

“I always take support calls, and they usually last about two minutes,” he says.

Contact www.markupandprofit. com/products/ estimating-software

JobBOSSTony Martinez, production coordi-

nator with Big D Metalworks in Dallas, TX, has a mantra about the fabrication business: You can’t manage it if you don’t measure it.

“How do you know you made money on it if you don’t track the hours?” he says.

He uses JobBOSS by Exact America for purchasing, job tracking, and cost analysis.

The program also has estimating and scheduling functions. Big D doesn’t use those functions because the company has spreadsheet processes they have used for years, he says.

He has advice about any software though.

“With any program, you’ve got to factor in human errors. Garbage in,

Structural Material Manager

January / February 2015 n O&MM Fabricator 27

list of footages, by page. “That saves a lot of time,” she says. She says the software has other functions that she has

yet to explore. Currently, SRS uses an internally generated spreadsheet to add the labor and material costs to the mate-rial list that is generated by PlanSwift, then the spreadsheet adds in overhead and profit.

The software itself does not come with a material cost database, but users can add the prices and update them as necessary.

“It has a lot functions, and PlanSwift has a good team to develop other functions,” she adds.

User licenses are $950 for PlanSwift, and the company offers a 14-day free trial download. A $200 annual support plan includes all upgrades. The first hour of training is free and the company offers a $295 training package in addition that includes personalized webinars.

Contact www.planswift.com

ProEstAt press time, Gale Schmidt with A2 Fabricators,

Milwau kie, OR, had just begun working with ProEst con-struction estimating software to customize a database.

“Seems like most software out there having to do with steel focuses on structural members. ProEst is more univer-sal and they seem willing to customize for miscellaneous metals,” she says.

ProEst president Jeff Gerardi says the ProEst database is easy to maintain and fabricators can add their costs to the materials in the database.

“The ProEst software is very easy to use and operate,” he says. “It automatically calculates the total pounds and labor necessary to install and fabricate any type of metal.”

ProEst comes in three levels of annual subscription (standard, professional and enterprise) starting at $1,295 per year.

Training requires an additional fee. The company offers three types: Web-based, classroom, and on-site.

Contact www.proest.com

Structural Material Manager Custom Fabrication builds a lot of steel tanks, and

co-owner and president Roger Rhoades says he has the esti-mates from jobs the company built 15 years ago stored in his files in the Structural Material Manager software. That saves a lot of time for him.

“Hardly any of our stuff is the same, but a lot of it is sim-ilar,” he says. “You may get four or five hours to bid a job.”

But even estimates from scratch are easy to create with the software.

“If you type in something in wrong, it will tell you and you go back figure out what you did wrong,” he says. “There is a place in the program you can put in hours (to create the estimate.) Then you can go in the program to print the materials to a [Microsoft] Word document and send it out as a inquiry for material to the vendor.”

Another feature Rhoades likes is that it reports the square footage inside and out, which tells him costs for painting and finishing.

O&MM Fabricator n January / February 201528

12080 SW Myslony St. Tualatin, OR 97062 Toll-Free: (866) 252-4628

-Stringers, Staircases & Handrails- Decorative Gates, Fences & Signage

www.albinaco.com

SPIRAL, CIRCULAR & HELICAL BENDINGPipe, Tube, Plate & Structural Members

-Handrail Kits Available: Bent and trimmed per drawing, mid-rails trimmed and coped, assemblies supplied as individual parts or fabricated complete!

CELEBRATING

YEARS!75

Est. 1939

For Custom Fabrication’s type of work, Rhodes says an estimating program must know the weights of materials precisely to generate accurate prices. In addition, the pro-gram has a nesting and multing capability, so it tells the shop how to cut.

“It will add up all your cuts and give you the best size to buy to cut your pieces of it,” Rhodes says. “If you’re buying 60-foot beams, it will tell you how to cut all your pieces to cut waste.”

Structural Material Manager is not full-blown ERP soft-ware, says Edward Easterday, software sales and support with EJE Industries.

“That is actually what so many people find attractive about the product, is that it does not strive to be all things to all people or to handle every conceivable task,” he says. “Instead, it focuses on a few areas and does them extremely well (such as nesting and multing.)”

Another difference from generalized ERP is that Struc-tural Material Manager “speaks” steel.

“By that I mean that an angle can be entered as L 2 x 2 x ¼ x 10’-6, exactly as a fabricator is accustomed to writing it by hand,” Easterday adds. “We don’t require the item to be given some strange part number but, rather, accept it in industry-standard nomenclature. In keeping with the above statement, simplicity is our claim to fame in the steel soft-ware industry. Our customers are expected to be literate in fabrication-related matters rather than computer-ori-ented ones.”

The software comes with a materials cost database that must be updated by the fabricator.

The software is on-premise and costs $1,495 for the main system plus an additional $795 for the estimating module. Easterday says there is no training cost because the manual is “very complete” and training videos are on the website.

Contact www.ejeindustries.com

Visual EstiTrackAs an ERP shop management software, Visual EstiTrack

by Henning Software not only creates estimates but also tracks and manages jobs.

Tom Zuzik Jr., vice president of sales and design with Artistic Railings in Garfield, NJ, has been using EstiTrack for shop management for nine years.

“We’ve built our materials and labor into the software,” he says. “It produces a list of our costs, then we are able to compare the estimate against the actual. It’s fabulous for tracking costs.”

The material office enters material purchased into the software, and employees in the shop scan their time on a work order sheet the software prints per job.

He’s happy with the software, but when asked about weaknesses, he says that it is not a simple system.

“For people who have never used a system, it’s not a small jump,” he added. “As with any of the larger software pack-ages, it takes someone in the company to manage it. Some-one has to do the input and the checks. The biggest thing with time and material tracking is — it’s only as good as your input.”

The software does not come with a material cost database.

January / February 2015 n O&MM Fabricator 29

says the company uses it and an exist-ing spreadsheet to create estimates. They input raw materials to the com-pany spreadsheet, which they adjust on a per-job basis, to get prices by pound or foot, then add that information to WinEst to calculate the labor. WinEst can track materials as well.

“We plug in our numbers and it builds our percentages” to create the final estimate, he says.

He added that the company’s owner uses it to review costs.

Billie Henning, vice president with Henning Software, says the software is an on-premise purchase. It will down-load to QuickBooks or a customer can buy the Visual Books accounting sys-tem. Time spent on the job can be tracked with bar code scanners in the shop or a smartphone.

The first user license starts at $3,000.

Contact www. henningsoftware.com/ products/ visual-estitrack/overview

WinEst Pro

WinEst Pro comes with a starter construction database and will work with most other databases. It works with most accounting, scheduling/project management, and CAD soft-wares. The user can build a template of standard questions that go with every estimate (Travel time? Over-head? Machine rental?) and use it as a checklist.

Robert Aquilera, drafting manager at JSR Incorporated in Schertz, TX,

Structural Material Manager

For your information

About the authorLinda Erbele, an Atlan-ta-based writer with 15 years of journalism expe-rience, specializes in busi-ness and travel writing.

“WinEst sells the RS Means Con-struction Cost Data in a WinEst data-base format,” says Steve Watt, segment

manager for the General Con-tractor/Construction Manager Division of Trimble Buildings.

(WinEst was recently acquired by Trimble.) “A customer can choose to subscribe to annual price updates,

which would include updated material prices.”

The first user license starts at $3,500. Training is in addition and can be done on-line for $1,000.

Contact http://buildings.trimble. com/products/winest

n

O&MM Fabricator n January / February 201530

Shop Talk

Bent

n You can find bending tips in a variety of places, including the NOMMA ListServ. But when O&MM Fabricator wanted to find a few, we spoke directly to the fabricators. Here’s a baker’s dozen of ideas.

OFFERINGS

Chapala Iron Company’s home-made scroll bender receives multiple custom dies and is adjustable for larger scrolls. It was built based on information gleaned from O&MM Fabricator articles. See Tip 13.

In the world of bending, two types of people do this work: Those who bend for fabricators and those fabricators who bend for themselves. So to speak.

Whereas the first category may not be willing to share what is essentially their trade secrets, the second group has no such restrictions.

Because bending is part of so many fabrication jobs, one thing is for sure: Fabricators have plenty of experience and are just fine with sharing it.

Read on for 13 ideas.

By Jeff Fogel

January / February 2015 n O&MM Fabricator 31

1 Bend first, cut later

Cutting the right length can be a Sisy-phean task owing to the material nature of a bend.

The outside of the bend has a tendency to stretch while the inside of the bend is com-pressed. This results in a distortion of the overall length of the piece.

Worse, it’s not always uniform so the bend can wind up somewhere other than you planned.