Introduction to CATIA -GSC-AIO SESION Ed4

-

Upload

mohamedalamine -

Category

Documents

-

view

26 -

download

1

description

Transcript of Introduction to CATIA -GSC-AIO SESION Ed4

-

1MODULE 8: Engineering - Tool CAD/CAMAuthor: Fermn S. Rodrguez LagunaESI AIRBUS MILITARY

2011/2012

ESI - AIRBUS MILITARY

SESSION: Introduction to CATIA. CAD/CAM

MasterGSC&AIOGLOBALSUPPLYCHAIN&AERONAUTICALINDUSTRIALOPERATIONS

Module8:Engineering

Module: Engineering- Herramienta CAD/CAMAuthor: Fermn S. Rodrguez LagunaCompany: INALSYS Ingeniera y Anlisis de Sistemas

2011/2012

INDEX1.TolerancesChain2.ManufacturingSystembasedonCAD/CAM3.ToolCAD/CAMCATIAV.54.VirtualManufacturing TRAINING

4.1ApplicationCNC4.2ApplicationComposites4 3 Application Riveting4.3ApplicationRiveting4.4ToolingManufacturing

MasterGSC&AIOGLOBALSUPPLYCHAIN&AERONAUTICALINDUSTRIALOPERATIONS

Module8:Engineering

-

2REFERENCE:

Diseo de Mquinas, A.S. Hall , A.R. Hollowenco H.G. Laughlin McGraw-Hill Anlisis estadstico de tolerancias, Jos M Gurruchaga Vzquez Di e i e T le ci Ge t ic A P i iti Re e Dimensiones y Tolerancias Geomtricas, A. Primitivo Reyes Tolerancias Dimensionales y Geomtricas-TGyD, Guillermo Navarrete

Herrera Comunicacin: Acotando el PDM. Aplicaciones Comerciales, D. Jenaro

Fernndez Martnez Expresin Grfina en la Ingeniera. OCW-UPM, Javier Prez lvarez Jos

Luis Prez Benedito Santiago Poveda Martnez Sistemas de Fabricacin AIRBUS Dassault Aviation and Dassault Falcon Jet Corp., 2011 Dassault Aviation and Dassault Falcon Jet Corp., 2011 Airbus S.A.S 2011 Curso de CATIA v.5 ESI FAG Documentacin Tcnica, ALU-Stock S.A.

MasterGSC&AIOGLOBALSUPPLYCHAIN&AERONAUTICALINDUSTRIALOPERATIONS

Module8:Engineering

1. CHAIN OF TOLERANCE

1.1 Chain of tolerances in Aeronautics1.2 Process of Analysis. Reference Systems1.3 Metrology - Measurement Systems

MasterGSC&AIOGLOBALSUPPLYCHAIN&AERONAUTICALINDUSTRIALOPERATIONS

Module8:Engineering

-

31.1 CHAIN OF TOLERANCES IN AERONAUTICS

Manufacturing tolerances:

The manufacturing processes introduced in the dimensions of the partserrors or deviations from established measures at the definition of them.

These deviations are due to:

- Games of the tools or machine tools used in the manufacture- Errors of measuring instruments or measuring operators- Errors of measuring instruments or measuring operators.- Dilation of the parts of bodies as a result of temperatures thatacquire parts to make them.- Deformations produced by the internal tensions of the pieces.

MasterGSC&AIOGLOBALSUPPLYCHAIN&AERONAUTICALINDUSTRIALOPERATIONS

Module8:Engineering

What is the chain of tolerances for parts that are sets?

Likewise, in the aircraft industry where product complexity does not allow themanufacture of all components that make up an aircraft by a single manufacturer it ismanufacture of all components that make up an aircraft by a single manufacturer, it isnecessary a chain of companies that provide all the necessary elements for inclusionin the final product .

This can multiply the effects of manufacturing tolerances of each supplier.

Excellence in industrial products associated with the assembly of a product, it canbecome prohibitively expensive when offered a high precision, and often due to poortreatment tolerance.treatment tolerance.

It is necessary to offer a compromise between accuracy and dimensional tolerances.

MasterGSC&AIOGLOBALSUPPLYCHAIN&AERONAUTICALINDUSTRIALOPERATIONS

Module8:Engineering

-

4FAL A400M

Airbus Militarys A400M multi-role transport aircraft has completed a series of tests to validate the lowest speed at which it can take off. (24 March 2011) March 2011 Airbus S.A.S 2011

Global Supply Chain A400MIntegration of more than 100,000 components

Proveedor SYSTEMSPOWER PLANT. ENGINE AND PROPELLER

Proveedor AvinicaProveedor Estruct.1

CENTRAL BOXProveedor Estruct.2

CONTROL SURFACEENGINE AND PROPELLER

Proveedor Estruct.3NOSE-PROA Proveedor SYSTEMS

Airbus Militarys A400M multi-role transport aircraft has completed a series of tests to validate the lowest speed at which it can take off. (24 March 2011) March 2011 Airbus S.A.S 2011

Proveedor TrenProveedor Estruct.4

GNDOLAS

NOSE PROA

Proveedor Estruct.5 Fuselaje

Proveedor SYSTEMS

-

5Global Supply Chain A400MIntegration of more than 100,000 components

Proveedor SYSTEMSPOWER PLANT. ENGINE AND PROPELLER

Proveedor AvinicaProveedor Estruct.1

CENTRAL BOXProveedor Estruct.2

CONTROL SURFACE

Proveedor P1

Proveedor P1Proveedor A1 Proveedor A2

Proveedor CS1

Proveedor CS2

Proveedor CB1 Proveedor CB2

ENGINE AND PROPELLER

Proveedor Estruct.3NOSE-PROA Proveedor SYSTEMS

Proveedor P1

Proveedor 3NP1

Proveedor 3NP2Proveedor S1

Airbus Militarys A400M multi-role transport aircraft has completed a series of tests to validate the lowest speed at which it can take off. (24 March 2011) March 2011 Airbus S.A.S 2011

Proveedor TrenProveedor Estruct.4

GNDOLAS

NOSE PROA

Proveedor Estruct.5 Fuselaje

Proveedor SYSTEMS

Proveedor T1 Proveedor T2

Proveedor F1 Proveedor F2

Proveedor S2

Proveedor S3

Proveedor 3NP3

Proveedor G1 Proveedor G2

Global Supply Chain A400MPossible Existing Tolerances

Proveedor SYSTEMSPOWER PLANT. ENGINE AND PROPELLER

Proveedor AvinicaProveedor Estruct.1

CENTRAL BOXProveedor Estruct.2

CONTROL SURFACE

Proveedor P1

Proveedor P1Proveedor A1 Proveedor A2

Proveedor CS1

Proveedor CS2

Proveedor CB1 Proveedor CB2didi di di

di di

didi

ENGINE AND PROPELLER

Proveedor Estruct.3NOSE-PROA Proveedor SYSTEMS

Proveedor P1

Proveedor 3NP1

Proveedor 3NP2Proveedor S1

Tol. i

dididi

di didi

didi

didid

did

di

d

Airbus Militarys A400M multi-role transport aircraft has completed a series of tests to validate the lowest speed at which it can take off. (24 March 2011) March 2011 Airbus S.A.S 2011

Proveedor TrenProveedor Estruct.4

GNDOLAS

NOSE PROA

Proveedor Estruct.5 Fuselaje

Proveedor SYSTEMS

Proveedor T1 Proveedor T2

Proveedor F1 Proveedor F2

Proveedor S2

Proveedor S3

Proveedor 3NP3

Proveedor G1 Proveedor G2

didi

didi

di di di di

di

di

di

didi

-

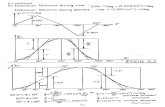

6Standards of Representation

By the standards we define and describe the tolerances of the lineardimensions for use in technical drawings.g

Tolerances indication of a method of representation does not involve theuse of a particular manufacturing method, measurement or control.

Standards:EN 20286 Sistema ISO de tolerancias

UNE 1129 T l i d t li lUNE 1129 Tolerancias de cotas linealesUNE 1122 Acotacin tolerancias conosUNE 1149 Principios de tolerancias fundamentales

MasterGSC&AIOGLOBALSUPPLYCHAIN&AERONAUTICALINDUSTRIALOPERATIONS

Module8:Engineering

ISO System of Tolerance

Tolerances allo s stems establish criteria for conj gating the Tolerances allow systems establish criteria for conjugating thefunctional conditions of the errors of manufacturing processes,keeping the interchangeability.

Currently the most widely accepted is the ISO standard containedin the UNE 4-040 040-81, with variations of single-axis systems

i l h lor single hole.

MasterGSC&AIOGLOBALSUPPLYCHAIN&AERONAUTICALINDUSTRIALOPERATIONS

Module8:Engineering

-

7MasterGSC&AIOGLOBALSUPPLYCHAIN&AERONAUTICALINDUSTRIALOPERATIONS

Module8:Engineering

Characterization: Sample Rules EXTERNAL DIMENSIONAL FIGURE (axis) is at MMC when in its upper limit of size. INNER DIMENSIONAL FIGURE (hole) is to LMC when its set reference is sized greater than o.INNER DIMENSIONAL FIGURE (hole) is to LMC when its set reference is sized greater than o.

MasterGSC&AIOGLOBALSUPPLYCHAIN&AERONAUTICALINDUSTRIALOPERATIONS

Module8:Engineering

-

81.2 REVIEW PROCESS. REFERENCE SYSTEMS

Analysis of Tolerances:Analysis of Tolerances:There will be based on standards and criteria and a system ofdimensional and geometric tolerances for the identification,evaluation, measurement and correction.

Reference Systems:C ll b t th t l i l i ti f th d tCollaborate on the metrological inspection of the productmanufactured and will be a function of the measurement methodadopted

MasterGSC&AIOGLOBALSUPPLYCHAIN&AERONAUTICALINDUSTRIALOPERATIONS

Module8:Engineering

Dimensional and Geometric TolerancesGD&T: It is an internationally accepted language to specify areas ofparts tolerances on engineering drawings. Through this technicalparts tolerances on engineering drawings. Through this technicalsystem communicate to perform the design-Manufacturing-Inspectionof parts.

They should provide:- Communication between technical- The manufacture of the parts- The manufacture of the parts- Interchangeability of components

MasterGSC&AIOGLOBALSUPPLYCHAIN&AERONAUTICALINDUSTRIALOPERATIONS

Module8:Engineering

-

9Reference Systems - Coordinates :Reference Systems must be based on a homogeneous

f C t i t Th RS h ld t b f dreference Cartesian system. The RS should not be confused.

Among the features that will need to define the different points of references are:

AccessiblePermanentReliables

MasterGSC&AIOGLOBALSUPPLYCHAIN&AERONAUTICALINDUSTRIALOPERATIONS

Module8:Engineering

PROBLEMS OF TOLERANCEREJECTION!

MasterGSC&AIOGLOBALSUPPLYCHAIN&AERONAUTICALINDUSTRIALOPERATIONS

Module8:Engineering

-

10

CYCLE ASSESSMENT OF TOLERANCE

PLANNING AND DESIGN

MANUFACTURINGCORRECTION

PROCESS

MEASUREMENTMETROLOGY

MasterGSC&AIOGLOBALSUPPLYCHAIN&AERONAUTICALINDUSTRIALOPERATIONS

Module8:Engineering

In CAD designs start from dimensionally accurate parts.The product has dimensional changes in its geometry.Beware TGyD geometric figures that appear to be and they are not!Beware TGyD geometric figures that appear to be and they are not!

MasterGSC&AIOGLOBALSUPPLYCHAIN&AERONAUTICALINDUSTRIALOPERATIONS

Module8:Engineering

-

11

MasterGSC&AIOGLOBALSUPPLYCHAIN&AERONAUTICALINDUSTRIALOPERATIONS

Module8:Engineering

Dimensional control of manufactured parts.

1.3 METROLOGY MEASURING SYSTEMS

CMM (Coordinate measuring machines)(PC-DMIS CMM software )Laser TrackerMeasuring ArmsMeasuring MicroscopesPhotometryPhotometryProbes

1. Radio-frecuency2. Software

MasterGSC&AIOGLOBALSUPPLYCHAIN&AERONAUTICALINDUSTRIALOPERATIONS

Module8:Engineering

-

12

SYSTEM MMC CONVENTIONAL FIXTURE

Some comparative Measurement Systems :

INFORMATION High Basic RegularACCURACY Very Good Good NA

VELOCITY Good Low ExcelentINVESTMENT Highest Media LowTRAINEDPEOPLE

High Good Basic

MasterGSC&AIOGLOBALSUPPLYCHAIN&AERONAUTICALINDUSTRIALOPERATIONS

Module8:Engineering

The need to avoid high values in the chain of manufacturingtolerances search sometimes leads to specialized laboratories :

Properly applied the concepts of TDyG, Have proper instrumentation for measurement, Have proper facilities for measurement,, Accredited / certified by a third party organization. Have the technology to provide an appropriate balance between:

CORRECTNESSTIME COST

MasterGSC&AIOGLOBALSUPPLYCHAIN&AERONAUTICALINDUSTRIALOPERATIONS

Module8:Engineering

-

13

The problems of interpretation of dimensional tolerances generate: Conflicts provider vs. customer, both rely heavily on IM, but the case takes them to others. Use tools that do not meet the measurement capability sufficient to specified tolerances,(c 0.005mm / 1 m2)

CONSEQUENCES OF FAILURE CHAIN OF TOLERANCE: Stopping the production line.Lot cessation product or to its effective verification.P lt / i f t f i t ti i ll f t iPenalty / suspension for arrest of integration in all manufacturing

MasterGSC&AIOGLOBALSUPPLYCHAIN&AERONAUTICALINDUSTRIALOPERATIONS

Module8:Engineering

Hamburg, Germany

Global Supply Chain A380

Broughton, Great Britain

Toulouse

Cdiz,Spain

MasterGSC&AIOGLOBALSUPPLYCHAIN&AERONAUTICALINDUSTRIALOPERATIONS

Module8:Engineering

-

14

Global Supply Chain A380

MasterGSC&AIOGLOBALSUPPLYCHAIN&AERONAUTICALINDUSTRIALOPERATIONS

Module8:Engineering

Chain integration tolerances in structural elements:

MasterGSC&AIOGLOBALSUPPLYCHAIN&AERONAUTICALINDUSTRIALOPERATIONS

Module8:Engineering

-

15

MasterGSC&AIOGLOBALSUPPLYCHAIN&AERONAUTICALINDUSTRIALOPERATIONS

Module8:Engineering

Product Data Management (PDM)System management and production planning based on data management

2. Manufacturing system based on CAD/CAM

y g p p g gsupported by computer systems.

These systems are based on:

MAIN FEATURES PDM:Storage system and data and document managementProcess management and workflow(Workflow Management)Management structure of the productGrading and StandardizationgManaging the programmingPlanning, monitoring and control of activities and resources.(Work History Management)

Traditionally, each company has developed his "own"

MasterGSC&AIOGLOBALSUPPLYCHAIN&AERONAUTICALINDUSTRIALOPERATIONS

Module8:Engineering

-

16

CAD and PDM systems whose relationship is directCompany CAD PDM Company

SDRC I-DEAS Metaphase SDRC p

SAP PDM SAP

MatrixOne MatrixOne

PTC Pro/Engineer Windchill PTC

EDS-UGS UNIGRAPHICS iMAN EDS-UGS

Dassault-IBM CATIA IBM-PLM Dassault-IBM

I t h I t h Intergraph Intergraph

Ariba(Agile) Agile Software-Ariba

Axalant Eigner + Partner

SmarTeam Smart Solutions MasterGSC&AIO

GLOBALSUPPLYCHAIN&AERONAUTICALINDUSTRIALOPERATIONSModule8:Engineering

This baseline lies the high weight that is assigned in the selectiong g gprocess to the relationship between the PDM system and the systemused CAD .

Here we must consider that although PDM systems have interfaceswith many CAD systems, the ideal situation suggests that PDMsystem should be the owner of the data and be CAD systems whichy ymade the connections, bridges, with the PDM system .

MasterGSC&AIOGLOBALSUPPLYCHAIN&AERONAUTICALINDUSTRIALOPERATIONS

Module8:Engineering

-

17

The data are owned by the CAD system that produces them, being inthe role of PDM management system of references to documents.

Access to document data is possible only through the interface thatallows CAD program.

MasterGSC&AIOGLOBALSUPPLYCHAIN&AERONAUTICALINDUSTRIALOPERATIONS

Module8:Engineering

CAD/CAM

SystemVirtual Manufacturing

PDM

MasterGSC&AIOGLOBALSUPPLYCHAIN&AERONAUTICALINDUSTRIALOPERATIONS

Module8:Engineering

-

18

Evolution CATIA V.6 A PDM system to be considered as such, must develop the

capabilities attributed to him, but also must respect the structure thatis presupposed, otherwise some of the advantages of using thesep pp g gsystems can be depleted in the medium term.

Ownership of the data, the information model is to store them, mustrest with the PDM system and ultimately the owner-user PDMsystem. The possibility of modifying the model designed is anintrinsic feature of PDM system.

CATIA V.6PDM MODEL CAD/CAM

MasterGSC&AIOGLOBALSUPPLYCHAIN&AERONAUTICALINDUSTRIALOPERATIONS

Module8:Engineering

INFRASTRUCTURE INTEGRATIONPRODUCTIONParts under virtual model

Management System - CAD / CAM Integrated

Infrastructure CAD/CAM

Manufacturing Management System (Material Resources)

Tooling design / manufacturing workbenches

Junction System(r)

Manufacturing Management System (Human Resources)

Specialists / Assemblers

OUTSOURCING

Parts under virtual model

y ( )

VirtualManufacturing

Tooling requirements

Materials integration

Infrastructure and auxiliary

MasterGSC&AIOGLOBALSUPPLYCHAIN&AERONAUTICALINDUSTRIALOPERATIONS

Module8:Engineering

-

19

INFRASTRUCTURE INTEGRATIONPRODUCTIONParts under REAL model

Management System - MANUFACTURING

Infrastructure CAD/CAM

Manufacturing Management System (Material Resources)

Tooling design / manufacturing workbenches

Junction System(r)

Manufacturing Management System (Human Resources)

Specialists / Assemblers

OUTSOURCING

Parts under REAL model

y ( )

VirtualManufacturing

Tooling requirements

Materials integration

Infrastructure and auxiliary

MasterGSC&AIOGLOBALSUPPLYCHAIN&AERONAUTICALINDUSTRIALOPERATIONS

Module8:Engineering

Dassault Falcon 7XAUTONOMY:. 5,950 nm (10.260 km)SPEED: To Mach .90 Maximum Operating Speed (MMO)SEATS 10 17SEATS:10-17

Passengers: 8Crew: 3 pilots, 1 flight attendant

MasterGSC&AIOGLOBALSUPPLYCHAIN&AERONAUTICALINDUSTRIALOPERATIONS

Module8:Engineering

-

20

3. Tool CAD/CAM: CATIA V.5

CATIA (computer-aided three dimensional interactive application)It is an application CAD / CAM integrated with PDM support for thedesign, manufacturing and computer-aided engineering.

The program is developed to provide support from concept design toproduction and product analysis.production and product analysis.

MasterGSC&AIOGLOBALSUPPLYCHAIN&AERONAUTICALINDUSTRIALOPERATIONS

Module8:Engineering

CATIA ,Organized in different application modules, each of which fulfills specific functions.

Given its breadth in terms of operational possibilities, CATIA is provided to you in p p p ydifferent configurations.

The most commonly corresponds to the one called Hybrid Design which comprises the following modules CATIA:

- SKETCHER: Generation from 2D sketches which generates the 3D.- PART DESIGN: Implementation of solid created based on the sketcher.- ASSEMBLY DESIGN: Assemblies of parts made individuallyp y- WIREFRAME AND SURFACE DESIGN: Generation of base areas- GENERATIVE SHAPE DESIGN: Advanced Surface Generation- DRAFTING: Creating implementation plans based on 3D

MasterGSC&AIOGLOBALSUPPLYCHAIN&AERONAUTICALINDUSTRIALOPERATIONS

Module8:Engineering

-

21

APPLICATIONS CATIA V.5

Virtual Manufacturing PDM

Manufacturing Management

Tooling design Industrial Design

Machine Tools

oo g des g

...

Master GSC & AIOGLOBAL SUPPLY CHAIN & AERONAUTICAL INDUSTRIAL OPERATIONS

Module 8: Engineering

2

3

1

DEFINITION OF THE MOUSE IN CATIA

BUTTON SYMBOL EFFECT 2 PULSADO MUEVE EN PLANO PANTALLA

1

2 + UNA VEZ 1 (Y NO SUELTO 2) ZOOM

2 + 1 (FIJNDOLOS) GIRO en 3 D

MasterGSC&AIOGLOBALSUPPLYCHAIN&AERONAUTICALINDUSTRIALOPERATIONS

Module8:Engineering

-

22

Ability to design and ergonomicanalysis of elements of the controli t t ti i ti linstrumentation in operationalposts.

MasterGSC&AIOGLOBALSUPPLYCHAIN&AERONAUTICALINDUSTRIALOPERATIONS

Module8:Engineering

MasterGSC&AIOGLOBALSUPPLYCHAIN&AERONAUTICALINDUSTRIALOPERATIONS

Module8:Engineering

-

23

Implementation capacity of complete items of equipment and systems.

MasterGSC&AIOGLOBALSUPPLYCHAIN&AERONAUTICALINDUSTRIALOPERATIONS

Module8:Engineering

Application to automotive

MasterGSC&AIOGLOBALSUPPLYCHAIN&AERONAUTICALINDUSTRIALOPERATIONS

Module8:Engineering

-

24

Application for industrial manufacture as the production of metal profiles

MasterGSC&AIOGLOBALSUPPLYCHAIN&AERONAUTICALINDUSTRIALOPERATIONS

Module8:Engineering

-

25

MasterGSC&AIOGLOBALSUPPLYCHAIN&AERONAUTICALINDUSTRIALOPERATIONS

Module8:Engineering

-

26

Application to the design of aeronautical structures and implementation of numerical control applications

MasterGSC&AIOGLOBALSUPPLYCHAIN&AERONAUTICALINDUSTRIALOPERATIONS

Module8:Engineering

CATIA implementation of structural elements of the frames for the NC machining

-

27

ThefirstoffiveA380sforChinaSouthernAi li t h d i H b GAirlinestouchesdowninHamburg,Germany,completingitssuccessfulmaidenflight(3March2011)

March2011AirbusS.A.S.2011

MasterGSC&AIOGLOBALSUPPLYCHAIN&AERONAUTICALINDUSTRIALOPERATIONS

Module8:Engineering

Manufacture of a fuselage 22% A380

-

28

Sending structural elements for final assembly line (FAL)

Application to the processing of all operational phases in the aircraft industry: Design- Manufacture and production (Lay-Out, desarrollo de utillaje,...) - FAL

All based on implementation of 3D digital models

MasterGSC&AIOGLOBALSUPPLYCHAIN&AERONAUTICALINDUSTRIALOPERATIONS

Module8:Engineering

-

29

Component library 100% integrated with all major modules of CATIA V5

MasterGSC&AIOGLOBALSUPPLYCHAIN&AERONAUTICALINDUSTRIALOPERATIONS

Module8:Engineering

-

30

TRAINING: 4.1 MANUFACTURING CNC

MasterGSC&AIOGLOBALSUPPLYCHAIN&AERONAUTICALINDUSTRIALOPERATIONS

Module8:Engineering

-

31

-

32

TRAINING: 4.2 COMPOSITES MANUFACTURING

MasterGSC&AIOGLOBALSUPPLYCHAIN&AERONAUTICALINDUSTRIALOPERATIONS

Module8:Engineering

INVAR structure with components used in the manufacture of tooling forforming processes composite material.

Invar also called Nivarox FeNi36 or is an iron alloy (64%) and nickelInvar, also called Nivarox FeNi36 or is an iron alloy (64%) and nickel(36%) with minor proportions of carbon and chromium.

Because of its small thermal expansion coefficient has a low coefficientof thermal expansion which enables parts processes either by dry or wetobtain very good tolerances.

H it i t i t d t l tHowever, its use is restricted to platessmall thickness on steel or aluminum basesdue to its high cost and weight.

MasterGSC&AIOGLOBALSUPPLYCHAIN&AERONAUTICALINDUSTRIALOPERATIONS

Module8:Engineering

-

33

The A350 XWB programme reached a new industrial milestone with the successful curing of this new-generation jetliners largest composite fuselage panel, which was completed by Airbus partner Premium AEROTEC (18 March 2011). March 2011 Airbus S.A.S 2011 MasterGSC&AIO

GLOBALSUPPLYCHAIN&AERONAUTICALINDUSTRIALOPERATIONSModule8:Engineering

Due to strong market demand, Airbus will increase the production rate for its A330 Family of jetliners to ten aircraft per month (3 February 2011)February 2011 MasterGSC&AIO

GLOBALSUPPLYCHAIN&AERONAUTICALINDUSTRIALOPERATIONSModule8:Engineering

-

34

MasterGSC&AIOGLOBALSUPPLYCHAIN&AERONAUTICALINDUSTRIALOPERATIONS

Module8:Engineering

-

35

TRAINING: 4.3 MANUFACTURING RIVETING

MasterGSC&AIOGLOBALSUPPLYCHAIN&AERONAUTICALINDUSTRIALOPERATIONS

Module8:Engineering

-

36

Integration componentsFixings:

Riveted joints - HilokjAbility to use nuts for torque controlManufacturing cost less than other piping systemsAvailable in a wide range of sizes

MasterGSC&AIOGLOBALSUPPLYCHAIN&AERONAUTICALINDUSTRIALOPERATIONS

Module8:Engineering

load

MasterGSC&AIOGLOBALSUPPLYCHAIN&AERONAUTICALINDUSTRIALOPERATIONS

Module8:Engineering

-

37

MasterGSC&AIOGLOBALSUPPLYCHAIN&AERONAUTICALINDUSTRIALOPERATIONS

Module8:Engineering

TRAINING: 4.4 MANUFACTURING EQUIPMENT

MasterGSC&AIOGLOBALSUPPLYCHAIN&AERONAUTICALINDUSTRIALOPERATIONS

Module8:Engineering

-

38

MasterGSC&AIOGLOBALSUPPLYCHAIN&AERONAUTICALINDUSTRIALOPERATIONS

Module8:Engineering

Designing a useful setting for transport by ship manufacturing nose of aircraft. Use reference crane and coupling assembly mounted to the structural assembly.

MasterGSC&AIOGLOBALSUPPLYCHAIN&AERONAUTICALINDUSTRIALOPERATIONS

Module8:Engineering

-

39

MasterGSC&AIOGLOBALSUPPLYCHAIN&AERONAUTICALINDUSTRIALOPERATIONS

Module8:Engineering

1. Lift truck2. Support beam3. Lifting gear and hook4 and 5. Support rail / guide (front ends) and Motor translation bridge6. Keypad / Remote7. Supply box bridge

3

pp y g8 and 9. Carriage guide support beam connection10. Supply cable support structure / control car11. Cable car guide12. Cable car supply

MasterGSC&AIOGLOBALSUPPLYCHAIN&AERONAUTICALINDUSTRIALOPERATIONS

Module8:Engineering

-

40

BRIDGE CRANE AT AIRBUS FACILITY GETAFE (MADRID)

MasterGSC&AIOGLOBALSUPPLYCHAIN&AERONAUTICALINDUSTRIALOPERATIONS

Module8:Engineering

-

41

-

42

MasterGSC&AIOGLOBALSUPPLYCHAIN&AERONAUTICALINDUSTRIALOPERATIONS

Module8:Engineering

-

43

" "

Aristteles (384 AC-322 AC); Greek philosopher.

Questions

MasterGSC&AIOGLOBALSUPPLYCHAIN&AERONAUTICALINDUSTRIALOPERATIONS

Module8:Engineering