Integrated Airbag Cutting Solution - Lectra€¦ · to enable your success 7 Lectra offers the...

Transcript of Integrated Airbag Cutting Solution - Lectra€¦ · to enable your success 7 Lectra offers the...

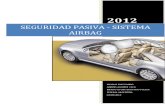

Integrated Airbag Cutting Solution

2

FocusQuantum is a fully integrated laser airbag cutting solution which enables airbag manufacturers to achieve their operational excellence and cost reduction objectives.

The complete FocusQuantum range, covering costing to manufacturing, comprises state-of-the-art laser-cutting equipment for one-piece woven (OPW) and cut-and-sew airbag fabric, a full suite of cut preparation software and value-added Lectra Professional Services.

To remain competitive, you need to:

■ Guarantee quality nearing zero defects

■ Ensure the highest rate of productivity

■ Control costs to increase margins

FocusQuantum enables you to:

■ Drive down cutting cost per bag

■ Maximize productivity at high capability

■ Increase material savings

■ Achieve a high OEE rating

■ Optimize plant productivity per m2

Customer Value Proposition

EXPERTS BASED CLOSE TO YOUR OPERATIONSInternational team of airbag consultants and solutions specialists to support you

FAST RFQ TURNAROUND AND CUT PREPARATIONAirbag software suite to optimize RFQ responses and cutting preparation

SUPPORT AND SERVICES A PHONE CALL AWAYEmbedded sensors and remote services to maximize uptime and performance

RFQs, COSTING CUTTING PREPARATION

ENGINEERING DEPARTMENT

CONSUMABLES & PARTS

PROFESSIONAL SERVICES & CONSULTING

CONTRACTS, WARRANTY & AFTER-SALES SUPPORT

SHOP FLOOR ERP, MES

WORK ORDER AUTOMATED CUTTING LINE

CONNECTIVITY, REPORTING

FocusQuantum Suite FocusQuantum Pilot Connector

Lectra Integrated Offer

3

OPW 3K

FT3K / FT6K

FocusQuantum range common features

■ 2 Rofin laser sources, top-mounted to optimize plant floor space

■ 2-head, 2-beam linear motor cutting system for high productivity, reliability and accuracy

■ Fully protected cutting space, compliant with the most stringent safety regulations

■ More than 200 embedded captors and sensors enabling predictive and preventive maintenance

■ Cutting conveyor with interchangeable ribs to minimize maintenance time and part replacement costs

■ Optimal cutting qualityEmbedded intelligence adjusts the cutting path in real time. Using SmartCutting technology, even distorted materials can yield perfectly cut parts. Dynamic power flow control minimizes flashbacks.

■ Accelerated performance2 Rofin 1.5kW laser cutting heads work in parallel with an optimized material flow.

■ High productivity per m²Built-in lasers ensure maximum compactness.

■ Maximized uptimePredictive and preventive maintenance ensure high availability, thanks to more than 200 built-in sensors connected to Lectra’s international call centers.

■ User-centered interfaceFocusQuantum Pilot and Suite software enable intuitive, process-oriented operations.

■ Enhanced safetyIntegrated fire prevention system and automatically controlled cutting zone locking system minimize risk.

LASER CUTTING SOLUTION FOR ONE-PIECE WOVEN (OPW) AIRBAG FABRIC

LASER CUTTING SOLUTION FOR CUT-AND-SEW AIRBAG FABRIC

Designed for higher productivity, quality and availabilityFocusQuantum

OPW 3KPERFORMANCE

Cutting speed Up to 180m/min

Maximum acceleration 25m/s2

Effective cutting window length Unlimited – continuous cutting

Effective cutting window width 3000mm

SPECIFICATIONS VERSALIS-AU-1H-S

Length 8335mm

Width including peripherals 7000mm

Width excluding peripherals 4915mm

Laser cutting heads 7.5” FOCAL

Number and power of laser sources

2X1500W

Rear table height 980MM

Installed power (maximum) 80KW

Location of machine controls Left

Safety devicesEmergency stops, inbuilt

extinguisher, cutting zone locking system

Waste management Automatic cutting waste cleaner

Temperature 10° to 40°CRelative humidity (at 30°C without condensation)

<85%

*Compatibility *PLX, RS274D, DXF, DWG

Operating system Windows 64-bit

A-weighted emission sound pressure level at workstation (excl. chiller)

<75 dB (A)

Safety standardsCE, conforming to machine

directive 2006/42/CE

OPW 3K

*Provided by the FocusQuantum OPW software suite.

4

FT3K & FT6K

Designed for higher productivity, quality and availability

FocusQuantum FT3KScalable investment

Greater productivity than the previous generation*

FocusQuantum FT6KBest-in-class performance

Up to 2.3x greater productivity* than the previous generation

PERFORMANCE FocusQuantum FT3K-8 FocusQuantum FT6K-8

Cutting speed with 15-30 plies of PA6.6 Up to 30m/min Up to 30m/min

No load speed (max) 180m/min

Maximum acceleration 20m/s2

Effective cutting window length Unlimited, 1200mm conveyor byte

Effective cutting window width 2800mm 3000mm

Number of laser cutting heads 10” Focal x1 x2

Number and power of laser sources 1x3000W 2x3000W

Upgradable into FT6K YES N/A

SPECIFICATIONS 1x3000W

Overall length of cutting machine with spreading and transfer tables (excluding spreading system)

22.06m

Width including peripherals 7000mm

Width excluding peripherals 4915mm

Rear table height 980MM

Installed power 136KW 158KW

Location of machine controls Left

Safety devicesEmergency stops, inbuilt extinguisher, automatic clearing of waste,

auto-controlled cutting zone locking system

Temperature 10°C to 40°C

Relative humidity (at 30°C without condensation) >80%

*Compatibility *PLX, RS274D, DXF, DWG

Operating system WINDOWS 64-bit

A-weighted emission sound pressure level at workstation (excl. chiller)

<75 dB (A)

Safety standards CE, conforming to machine directive 2006/42/CE

* Results in comparison to the previous generation of Focus laser cutting solutions following benchmarks performed by Lectra on a representative sample of bags. Productivity gains may vary.

*Provided by the FocusQuantum software suite.

On-site upgradeIncrease capacity by 65% at a later date with an on-site upgrade

from FocusQuantum FT3K to FT6K.

High productivity per m²Compact plant footprint made possible by lasers installed on platform level.

Optimal cut qualityAccurate power control minimizes flashbacks and fusing.

High capabilityAchieve Ppk greater than 1.67.

Material savingsCut parts with zero buffer through optimized nesting enabled by FocusQuantum Suite software.

Up to 98% availabilityMore than 200 built-in sensors connected to Lectra’s international call centers enable

predictive and preventive maintenance for maximized uptime.

Streamlined user interfaceUser-centered, FocusQuantum Pilot and Suite enable intuitive, process-oriented operations.

Enhanced operator safetyAutomatic waste removal and fire extinguisher minimize the risk of fire.

5

■ Quick RFQ turnaround and new program launch Control cost targets, technical feasibility and production capacity using purpose-built software.

■ Roll width variationsQuickly introduce new production programs with management of final product characteristics and production constraints.

■ Significant material savingsOptimized nesting for cut-and-sew airbags, optimized loom layout with Smartcutting for OPW airbags, powered by FocusQuantum Suite.

■ Continuous improvementImprove performance through regular updates and gap analysis, training, consulting and project management.

■ Real-time adjustment to fabric distortion Benefit from Lectra’s SmartCutting technology to instantaneously adjust the laser cutting path and achieve optimum quality and material savings.

Suite

All-in-one pre-production software suite for FocusQuantum airbag manufacturing covering costing and order programming, as well as management of marker, spreading and cutting parameters.

For OPW

Fully Integrated Pre-Production Software

WELCOME PACK

■ Secure production start with the right consumables

■ Contains all consumables for one month’s usage at an attractive price

MAINTENANCE KIT

■ Contains all parts which must be replaced at the same time

CUTTING SUPPORT

■ Serrated brass plates are designed to dissipate heat and prevent laser flashback

■ Easy to replace only damaged plates

CUTTING AREA REDUCER

■ Adapts cutting area to the material width

OPTICAL PART KIT

■ Contains the highest quality optics for an optimal lifetime

■ Guarantees an optimal beam and more precise focal point

GREASING PACK

■ High quality grease and pump to deliver the right quantity of lubricant to prevent breakage

COOLING FLUID KIT

■ Prevents corrosion and microbiological development

POLYETHYLENE FILM FOR FLAT

■ Facilitates the separation of layers

Genuine Consumables and Parts

6

Online support

Onsite support

Software upgrades

Reporting & My support

Spare PartsCovered only

by Support FullPredictive

Maintenance

Preventive Maintenance

CertificationOnly for Support Pro & Support Essential

Service Support Path

Lectra Services

SUPPORT FULL

Start with Support Full

SUPPORT PRO

Continue with Support Pro

SUPPORT ESSENTIAL

Transition toSupport Essential

Follow the training and certification path to become more autonomous.

Once knowledge and skills to carry out major repairs and maintenance have been acquired, transition to Support Essential (connection of the system is mandatory).

Move toward maintenance autonomy with Lectra’s guidance

Benefits

■ To prevent downtime and maximize your system avaibility

■ To control your system performance

■ To guarantee cutting quality with direct access to 40 years of application expertise

Lectra Professional Services provide the project management skills and know-how required to implement the FocusQuantum integrated offer into your existing manufacturing processes while meeting ROI, cost and performance objectives within deadline. Our teams are available to assist at three critical stages.

Implementation projects

■ Fully managed FocusQuantum installation and implementation

■ Project management approach and problem solving methodology to meet customer objectives

■ Maximize return on investment

Operational excellence projects

■ Optimized quality

■ Reduced cost per bag

■ Increased capacity

■ Improved process capability

SmartCutting® projects for OPW

■ Manage SmartCutting implementation to ensure perfect cutting quality and achieve material savings

Airbag expertise to enable your success

7

Lectra offers the expertise, technology and industry knowledge to support you, starting with the definition of a solution suited to your needs and throughout the life of your cutting room, from implementation to support and process optimization.

Lectra Services

The right partner to take your automotive cutting room to the next level.

32 subsidiaries

5 call centers

3 international advanced technology centers

Nearly 1,700 employees

50 nationalities

Lectra Professional ServicesMeet your ROI,

cost and performance objectives

Implement best practices

and become fully autonomous

Standardize and control

your production processes

Ready your operations to

satisfy production increases

8

About LectraFor forward-looking companies that breathe life into our wardrobes, car interiors, furniture and more, Lectra is committed to crafting the premium technologies that facilitate the digital transformation of their industry. Lectra’s offer empowers brands and manufacturers from design to production, providing them with the market respect and peace of mind they deserve. In the automotive industry, Lectra offers integrated cutting room solutions and expert services dedicated to suppliers of airbags as well as fabric and leather vehicle seating and interior components. Founded in 1973, today Lectra has 32 subsidiaries across the globe, serving customers in over 100 countries. With nearly 1,700 employees, Lectra reported revenues of $313 million in 2017. Lectra is listed on Euronext (LSS).

® FocusQuantum is a registered trademark of Lectra.

The Hive @LectraOfficial

LectraAutomotive