iLumTech development of lighting on inquiry street lighting

-

Upload

zuzana-masarova -

Category

Documents

-

view

219 -

download

3

description

Transcript of iLumTech development of lighting on inquiry street lighting

• Full new street LED luminaires

• Parts of the new luminaire (a new design, optical solution, thermal solution etc)

• The upgrade of an existing luminaire

SUPPORT OF ILUMTECH WITH THE DEVELOPMENT

LED luminaires are generally equipped with aluminium heatsinks due to the high thermal conductivity and low weight of the material. However, it is possible to minimise the use of aluminium and achieve improved heat transfer performance in larger luminaires by using plastic heatsinks embedded with an aluminium heat spreader. The used plastic, such as polycarbonate (PC), high density polyethylene (HDPE) or polypropylene copolymer (PPCO), may not be enough to cool the luminaire necessitating the use of a heat spreader under the heat source to increase heat dissipation. The use of injection moulded plastics opens up flexibility in terms of the geometric structure of the heatsinks, which can be easily optimised for convection heat transfer. Plastic is also approximately 40 % lighter than aluminium, which ensures better resistance to shock and vibration, in addition to having no antenna effect resulting in reduction of EMI. The result of these factors is increased heat transfer performance, weight reduction, cost saving and ease of manufacture.

Housing material Heat Spreader Total weight Numerical results, °C

IEC 60598-2-3*, °C Flux

kg TC Driver Housing TC TJ Driver Housing lm

PC Al6061 3.76 123.7 86.6 95.9 113.7 119.6 76.6 85.9 13,900

PC Al6061 2.90 125.5 83.1 97.3 115.5 121.4 73.1 87.3 13,900

HDPE Al6061 2.45 118.9 82.5 102.1 108.9 114.8 72.5 92.1 14,200

PPCO Al6061 2.37 114.9 81.2 102.6 103.9 109.8 71.2 92.6 14,300

Simulation results*10°C shall be deducted from the temperatures measured on the luminary in the test enclosure to allow for the effects of natural air movement which occur in the working environment of luminary.

www.ilumtech.eu [email protected]

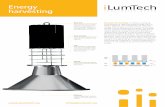

Hybrid Streetlight

THE DEVELOPMENT OF THE STREET LUMINAIRE• Concept and design – form, shape definition

• Optical design – optical solution, measurements, evaluation

• Thermal design – thermal simulation and evaluation

• Electronic design – component selection, electrical schematic

• Mechanical engineering – mechanical design and prototyping

• Tooling production

• Internal measurements and testing

• Self declaration and external certification on request

• Full documentation preparation (technical, product, marketing)

• Update and upgrade, technical support

THE RIGHT DESIGN

From a design point of view, a street luminarie should feature:

• A functional design that supports the best possible performance

• An aesthetic ideal for the selected enviroment

• The potential for fututre upgrade/customisation

• Design customisation potential – corporate identity colour, pattern

THE MOST SUITABLE OPTICAL SOLUTIONThe development of LED street lighting optics can be approached in two ways:

a) Standard solution – by using standard optics available on the market (lenses, reflectors)

b) Optimised solution – the optical system can be optimised according to application and customer requirement:

- Street lighting configurator – thanks to this tool we can combine existing lenses on the market to create the requested LIDC

- Design of a new optical system (lenses or reflector)

Standard solutions Customer solutions

STANDARD SOLUTIONS FOR DIFFERENT ROAD CLASSES (EN 13201-2)Distribution curves based on a multilens system made of PMMA

STANDARD SOLUTIONS FOR DIFFERENT ROAD CLASSES (EN 13201-2)Distribution curves based on a multilens system made of PMMA

STANDARD SOLUTIONS FOR DIFFERENT LIGHT DISTRIBUTION (IESNA)Distribution curves based on a single lens system for COB made from silicon

STREET LIGHTING CONFIGURATOR

The Street Lighting Configurator is a tool which combines existing lenses on the market to create the requested LIDC.

the configurator uses 4 different lenses with different intensity curves and calculates

256 combinations with rotation steps 90°

it is possible to insert the LDT of any lens into the configurator

it is possible to modify the rotation step

the configurator can be extended to work with more LID curves

the configurator can be used to mix different luminous intensity curves

DEVELOPMENT OF OPTICS ON REQUEST

I 4746 I

Refractor and diffuser selection It is difficult to understand the advan-tages and disadvantages of each type of refractive or non-refractive diffuser, especially in terms of its application in a specific setting. Our optical engineers are experienced in making these choices and can help customer understand which best suits their needs.

Refractor optimisation It is possible to modify a refractive ma-terial in order to achieve a desired LIDC; however, this is an incredibly difficult task that requires a high level of expertise. To help us with this process we have devel-oped our own LIDC Optimiser software, which helps us determine the precise LIDC needed for each application and provides calculations we can use as a base for opti-cal optimisation.

Refractor design There are a variety of refractive optics used in illumination systems. In this group we can find lenses, arrays, prisms, pillow optics and also protective covers. The abil-ity of these opitcal parts to directly control the light is due to the law of refraction. Based on this great flexibility, we are able to creat any refractor design according to customer needs.

Lens optimisation Lenses are used in LED luminaires and are commonly positioned directly on the LED. There are many lens shapes to choose from. Only experienced and knowledge-able optical engineers know how to de-termine the best lens for each product, with the possibility of combining various lenses within one optical system in order to achieve the desired result. For highly demanding street lighting luminaires we have developed our own optimisation software, the Street Light Configurator, which allows us to combine up to four dif-ferent lenses at various angles in order to provide the needed LIDC.

Lens design Lenses are standard parts in optical design. Illumination designs use internal reflection and the law of refraction to cap-ture the light emitted by a light source. In most cases we use free form lenses. This will be an area of focus in ourfuture de-signs, as such lenses are incredibly flexible and can be used in variety of applications.

Product development & engineering services / Optical design / Refractor, diffuser & lens design services Refractor, diffuser & lens design services / Optical design / Product development & engineering services

Optical parts

Reflector & parabolic

louvre design

Refractor, diffuser & lens

design

Spectral & luminance

analysis

Laboratory

Refractor, diffuser & lens design

Optical parts Refractor, diffuser & lens design Spectral & luminance analysis LaboratoryReflector & parabolic louvre design

PROPER THERMAL MANAGEMENT

In order to guarantee suitable thermal management it is important to provide:

• Thermal evaluation, simulation (Solidworks, modules: Flow Simulation, Electronic cooling, HVAC)

• Thermal design and optimisation

• Thermal characterisation of LEDs, driver(s), lenses, etc.

• Thermal measurements (test chamber WT 450/70, TK2M, infrared camera, thermometer...)

THERMAL EVALUATION

PCBs + Lenses

GlassDriver

HousingITEM VALUE

Ambient temperature 40 °CNo. of LEDs 52LED model OSRAM OSLON SquareMaximum TC of LED 110 °C (@ 700mA, L70/B10, >60,000 hours)Forward current per LED 700 mAWall plug efficiency 20 %Total electrical power 111 WTotal thermal power 89 W

THERMAL EVALUATION

ITEM VALUE

Ambient temperature 40 °CNo. of LEDs 1LED model Citizen CLL042Maximum TC of LED 60 °CForward current per LED 700 mAWall plug efficiency 20 %Total electrical power 36 WTotal thermal power 29 W

Housing

LEDDriver

Lens

THERMAL SIMULATION ANALYSIS

Cross-sectional view TC of LEDs Air velocity

Driver temperature Housing temperature

THERMAL SIMULATION INPUTS & OUTPUTSINPUTS FROM CUSTOMER• Ambient temperature• Type of PCB• 3D models of luminary and PCB• Driver model no.• LED model no.• Forward current per LED• Material of components• Lifetime requirement (e.g. L70/B50, L80/B20)

OUTPUTS FROM ILUMTECH• Maximum TC of LED• Maximum driver temperature• Housing temperature• Air flow velocity• Temperature profile

THERMAL SIMULATION ANALYSIS

Cross-sectional view TC of LEDs Air velocity

Driver temperature Housing temperature Temperature of lenses

MEASUREMENTS, EVALUATION / OPTIMIZATION • Thermal measurements and evaluation – thermal test - life time prediction, thermal characteristics of the luminaire, max. lm output evaluation

• Optical measurements and evaluation (LDT, IES files)

• Electronic measurements and evaluation (electrical safety test, EMC test)

MEGIN M – light distribution options

The Company reserves the right to change any product specifications without prior notification.

C0.0-C180.0 C90.0-C270.0

9090

75

60

45

30 15 0 15 30

45

60

75200

300

500

MEGIN ML02 12650 lm 4500 K

LOR = 100%lower flux fraction 100%upper flux fraction 0%

MEGIN M (L02) power consumption

(W)

26 35 44 62 97 115Net lumen output* (lm) 2900 3900 4900 6800 10700 12650

Luminous flux tolerance +/- 10%

* at Ta = 25 °C

C0.0-C180.0 C90.0-C270.0

9090

75

60

45

30 15 0 15 30

45

60

75

750

600

450

MEGIN ML03 12400 lm 4500 K

LOR = 100%lower flux fraction 100%upper flux fraction 0%

MEGIN M (L03) power consumption

(W)

26 35 44 62 97 115Net lumen output* (lm) 2850 3800 4800 6700 10500 12400

Luminous flux tolerance +/- 10%

* at Ta = 25 °C

C0.0-C180.0 C90.0-C270.0

9090

75

60

45

30 15 0 15 30

45

60

75

200

400

MEGIN ML04 12450 lm 4500 K

LOR = 100%lower flux fraction 100%upper flux fraction 0%

MEGIN M (L04) power consumption

(W)

26 35 44 62 97 115Net lumen output* (lm) 2850 3850 4800 6700 10550 12450

Luminous flux tolerance +/- 10%

* at Ta = 25 °C

C0.0-C180.0 C90.0-C270.0

9090

75

60

45

30 15 0 15 30

45

60

75200

300

500

MEGIN ML05 12350 lm 4500 K

LOR = 100%lower flux fraction 100%upper flux fraction 0%

MEGIN M (L05) power consumption

(W)

26 35 44 62 97 115Net lumen output* (lm) 2850 3800 4800 6650 10450 12350

Luminous flux tolerance +/- 10%

* at Ta = 25 °C

C0.0-C180.0 C90.0-C270.0

9090

75

60

45

30 15 0 15 30

45

60

75

400500600

200

MEGIN ML06 12200 lm 4500 K

LOR = 100%lower flux fraction 100%upper flux fraction 0%

MEGIN M (L06) power consumption

(W)

26 35 44 62 97 115Net lumen output* (lm) 2800 3750 4700 6600 10350 12200

Luminous flux tolerance +/- 10%

* at Ta = 25 °C

C0.0-C180.0 C90.0-C270.0

9090

75

60

45

30 15 0 15 30

45

60

75

300

MEGIN ML07 12300 lm 4500 K

LOR = 100%lower flux fraction 100%upper flux fraction 0%

MEGIN M (L07) power consumption

(W)

26 35 44 62 97 115Net lumen output* (lm) 2850 3800 4750 6650 10450 12300

Luminous flux tolerance +/- 10%

* at Ta = 25 °C

C0.0-C180.0 C90.0-C270.0

9090

75

60

45

30 15 0 15 30

45

60

75

300

400

MEGIN ML08 12550 lm 4500 K

LOR = 100%lower flux fraction 100%upper flux fraction 0%

MEGIN M (L08) power consumption

(W)

26 35 44 62 97 115Net lumen output* (lm) 2900 3850 4850 6750 10650 12550

Luminous flux tolerance +/- 10%

* at Ta = 25 °C

MEGIN M

The Company reserves the right to change any product specifications without prior notification.

ø 60

345 673

568

56

202

Features

• Low power consumption and high system efficacy up to 114 lm/W

• Dimming possibilities: intelligent dimming (fully programable driver) /

step dimming (bi-power output)

• 8 different light distribution curves (lenses types L01 standard, L02–L08

on request)

• Tiltable spigot (135° in 5° steps)

• Up to 150 W sodium lamp replacement

Areas of application

• Streets, sidewalks, parks, industrial areas

Mounting Pole top installation Pole side entry installation

Light source LED

Optical system Lenses

Light distribution Direct

Wiring Electronic control gearOn request: intelligent dimming /step dimming (bi-level output)

Materials Housing: die cast aluminiumCover: polycarbonate

Surface finish Housing: grey, other colours on request

Lifetime 100 000 hrs / L80

Ambient temp. From -25 °C to +40 °C

C0.0-C180.0 C90.0-C270.0

9090

75

60

45

30 15 0 15 30

45

60

75

400

200

MEGIN ML01 12800 lm 4500 K

LOR = 100%lower flux fraction 100%upper flux fraction 0%

STANDARD ON REQUEST

Luminaire type(lenses type)

net lumen output

(at Ta = 25 °C)

power consumption

colour rendering

index

correlated colour

temperature

windage area(m2)

road class

recomended mounting height

(m)

replacement of standard

weight

(lm) (W) CRI (Ra) CCT (K) (kg)

MEGIN M (L01) 2950 26 70 4500 0.026 ME6 5-8 HPS 70 W 9.7MEGIN M (L01) 3950 35 70 4500 0.026 ME6 5-8 HPS 70 W 9.7MEGIN M (L01) 4950 44 70 4500 0.026 ME6 7-10 HPS 70 W 9.7MEGIN M (L01) 6900 62 70 4500 0.026 ME5 7-10 HPS 100 W 9.7MEGIN M (L01) 10850 97 70 4500 0.026 ME4 8-12 HPS 150 W 9.7MEGIN M (L01) 12800 115 70 4500 0.026 ME4 8-12 HPS 150 W 9.7

Luminous flux tolerance +/- 10%

43 %

ENERGYSAVING

70Raco lour rendering in

dex

system eff icacy

114lm / W

up to

12,800lmnet lumen outp

ut

up to

Name of luminaire TRITON 150 W MEGIN M

Light source ME LEDLuminous flux of installed light sources (lm) 15,000 10,850LOR (%) 72 100Net lumen output (at Ta = 25 °C) 10,800 10,850Power consumption (W) 169 97System efficacy of luminaire (lm/W) 63,9 111,9

MEGIN M

FINAL PRODUCT