IIE Applied Solutions 2009

-

Upload

jonfournier -

Category

Documents

-

view

658 -

download

0

Transcript of IIE Applied Solutions 2009

Using Value Stream Mapping Using Value Stream Mapping to Drive Simulation Model to Drive Simulation Model

ConstructionConstruction Jon Fournier Jon Fournier CCAT, June 3, CCAT, June 3,

20092009

© Copyright 2009, Connecticut Center for Advanced Technology, Inc. All rights reserved.

• The Connecticut Center for Advanced Technology (CCAT) works to strengthen technology-led competitiveness via collaboration with industry, government, and academia

– Strengthen existing companies– Support a world class work force– Lead innovation and enterprise creation

CCAT

© Copyright 2009, Connecticut Center for Advanced Technology, Inc. All rights reserved.

Helping to Strengthen our Nation

Strengthening Economic

Competitiveness

EducationEducation Economic DevelopmentEconomic Development

TechnologyTechnologyInnovationInnovation

CollaborationCollaboration

E-learning

Project Based

InterdisciplinaryMulticultural

© Copyright 2009, Connecticut Center for Advanced Technology, Inc. All rights reserved.

Laser Application Laboratory

• Experienced Staff• State of the Art Equipment• Focused on:

– Hole Drilling– Marking– Welding– Machining– Cutting– Application Assessment

• In-Process Monitoring

Laser Drilling Work Cell

P50L Coupled to Work Cell

Nutfield Laser Driller

IPG Photonics System

Processing Fibers

10kW Yb:Glass Fiber Laser

Various Workstations

Lasertec DMG 80 Powerdrill ShapeKuka Robot

© Copyright 2009, Connecticut Center for Advanced Technology, Inc. All rights reserved.

3D Product Design/CAD Assembly Sequence Ergonomics

Machining Optimization

Inspection

Factory Simulation

Modeling and Simulation Capabilities

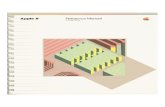

Daily Schedule7-Day

Forecast

Daily Schedule

Daily Priority List

Daily Priority List

Daily Priority List

Receiving

x.xxCycle Time Mins

x.xxLoad Time Mins

x.xxChangeover Time Mins

x.xxOperators Staff

x.xxOperator Name

B20Next Op Tag

x.xxWorkstat ion ID

x.xxProduct Unit

x.xxUptime (%) %

Inspection

21600Cycle Time Secs

x.xxLoad Time Mins

x.xxChangeover Time Mins

x.xxOperators Staff

x.xxOperator Name

B30Next Op Tag

x.xxWorkstation ID

x.xxProduct Unit

x.xxUptime (%) %

Raw Material Storage

x.xxCycle Time Mins

x.xxLoad Time Mins

x.xxChangeover Time Mins

x.xxOperators Staff

x.xxOperator Name

B40Next Op Tag

x.xxWorkstation ID

x.xxProduct Unit

x.xxUptime (%) %

Datum Mori-Seiki 3P

21Cycle Time Mins

x.xxLoad Time Mins

10Changeover Time Mins

1Operators Staff

3P-OpOperator Name

B50Next Op Tag

SH-630,#2Workstation ID

x.xxProduct Unit

70Uptime (%) %

Air Foil Mill SV500 (3)

105Cycle Time Mins

x.xxLoad Time Mins

15Changeover Time Mins

.3Operators Staff

AFOpOperator Name

B60Next Op Tag

SV500,5,7,10Workstat ion ID

x.xxProduct Unit

90Uptime (%) %

Drill Inner

83Cycle Time Mins

x.xxLoad Time Mins

10Changeover Time Mins

1Operators Staff

DrInOpOperator Name

B70Next Op Tag

x.xxWorkstation ID

x.xxProduct Unit

90Uptime (%) %

Drill Outer

64Cycle Time Mins

x.xxLoad Time Mins

10Changeover Time Mins

1Operators Staff

DrOutOpOperator Name

B80Next Op Tag

x.xxWorkstation ID

x.xxProduct Unit

90Uptime (%) %

Horizontal Mill

214Cycle Time Mins

x.xxLoad Time Mins

20Changeover Time Mins

5Operators Staff

x.xxOperator Name

B90Next Op Tag

x.xxWorkstat ion ID

x.xxProduct Unit

95Uptime (%) %

UK Forging

2X/Month

Horizontal Fin. Outer

135Cycle Time Mins

x.xxLoad Time Mins

5Changeover Time Mins

1Operators Staff

x.xxOperator Name

B100Next Op Tag

x.xxWorkstation ID

x.xxProduct Unit

90Uptime (%) %

Horizontal Fin. Inner

90Cycle Time Mins

x.xxLoad Time Mins

5Changeover Time Mins

1Operators Staff

x.xxOperator Name

B110Next Op Tag

x.xxWorkstat ion ID

x.xxProduct Unit

90Uptime (%) %

Polish

108Cycle Time Mins

x.xxLoad Time Mins

x.xxChangeover Time Mins

9Operators Staff

x.xxOperator Name

B120Next Op Tag

x.xxWorkstat ion ID

x.xxProduct Unit

99Uptime (%) %

QA1 Shift

10Cycle Time Mins

x.xxLoad Time Mins

x.xxChangeover Time Mins

1Operators Staff

x.xxOperator Name

C20Next Op Tag

x.xxWorkstation ID

x.xxProduct Unit

99Uptime (%) %

UT Probe (QA)

9Cycle Time Mins

x.xxLoad Time Mins

0Changeover Time Mins

1Operators Staff

x.xxOperator Name

B140Next Op Tag

x.xxWorkstation ID

x.xxProduct Unit

98Uptime (%) %

Wash1 Shift

14Cycle Time Mins

x.xxLoad Time Mins

0Changeover Time Mins

1Operators Staff

x.xxOperator Name

C30Next Op Tag

x.xxWorkstation ID

x.xxProduct Unit

99Uptime (%) %

Clean Beads

8Cycle Time Mins

x.xxLoad Time Mins

0Changeover Time Mins

x.xxOperators Staff

x.xxOperator Name

C40Next Op Tag

x.xxWorkstat ion ID

x.xxProduct Unit

100Uptime (%) %

SubCon Polish1.7 + Days

SubCon NDT3 Days

SubCon Glass Peen5 Days SubCon Paint/Coat

GE

A10

B10 B20 B30 B40 B50 B60 B70 B80 B90 B100 B110 B120 B130 B140 B150

C10 C20 C30 C40

A20

x.xxDist. To Next Feet

x.xxNum. of Elements

Count

x.xxMTTR Mins

x.xxDist. To Next Feet

x.xxNum. of Elements

Count

x.xxMTTR Mins

x.xxDist. To Next Feet

x.xxNum. of Elements

Count

x.xxMTTR Mins

x.xxDist. To Next Feet

x.xxNum. of Elements

Count

x.xxMTTR Mins

x.xxDist . To Next Feet

3Num. of Elements

Count

x.xxMTTR Mins

x.xxDist. To Next Feet

2.5Num . of Elements

Count

x.xxMTTR Mins

x.xxDist. To Next Feet

2.5Num. of Elements

Count

x.xxMTTR Mins

x.xxDist. To Next Feet

6Num. of Elements

Count

x.xxMTTR Mins

x.xxDist. To Next Feet

2Num . of Elements

Count

x.xxMTTR Mins

x.xxDist. To Next Feet

2Num. of Elements

Count

x.xxMTTR Mins

x.xxDist. To Next Feet

x.xxNum. of Elements

Count

x.xxMTTR Mins

x.xxDist. To Next Feet

x.xxNum. of Elements

Count

x.xxMTTR Mins

x.xxDist. To Next Feet

x.xxNum. of Elements

Count

x.xxMTTR Mins

x.xxDist. To Next Feet

x.xxNum. of Elements

Count

x.xxMTTR Mins

x.xxDist . To Next Feet

x.xxNum. of Elements

Count

x.xxMTTR Mins

7.5

Days

Hrs

60.00

Hrs

Mins

60.00

Mins

Secs

60

Name

Unit 43

Name

Unit 0

Name

Unit2160

Name

Unit 49

Name

Unit 16

Name

Unit 27

Name

Unit

3 Shifts, 3 OperatorsScrap 2%

Time Avail – 100%

Frequency 1/5th LotLot Size 42,000#

3 pallets1 Shift

Lot Size 48 + 1Time Avail – 100%

3 Shifts, 1 Operators per shift

Scrap 2%Time Avail – 100%

3 ShiftsScrap 1%

Shared 3 Ops-75,80,90

3 Shifts, 1 Operators per shift

Scrap 2%Time Avail – 100%

3 ShiftsScrap 2%

3 ShiftsScrap 2%

2 Shifts (5 Ops – 1st, 4 Ops – 2nd)Scrap 2%

MRP

ProductionControl

30-Day Firm

Weekly Pull

60-Day Forecast

Weekly Pull

Monthly Forecast

PROCESS: Machine/Coat/PaintDATE: 05/02/08REVISION:CCAT: Susan Coffeyfn/GKN Aeropace 10765 05 01 08.vsd

35

Name

Unit

Value Stream Mapping

Reverse Engineering

Robotics

Other Processes

Composite Processes

© Copyright 2009, Connecticut Center for Advanced Technology, Inc. All rights reserved.

DELMIA QUEST Simulation Tool• Originally developed by Deneb Robotics

– Acquired by Dassault Systemes (makers of CATIA)• Manufacturing-focused Discrete Event Simulation (DES) tool• Supports two scripting languages

– Simulation Control Language (SCL)• Model run-time logics• Macro-scripting language

– Batch Control Language (BCL)• Create/Modify elements within the model

© Copyright 2009, Connecticut Center for Advanced Technology, Inc. All rights reserved.

Value Stream Mapping with eVSM

• Software developed by GumshoeKI• Based in Microsoft Visio

– Utilizes Visual Basic for Applications (VBA) macros• Export VSM data to Excel spreadsheet• Calculate distance traveled with spaghetti charting

eVSM.com

© Copyright 2009, Connecticut Center for Advanced Technology, Inc. All rights reserved.

eVSM Data Import to QUEST

• Process list generated by eVSM

• Needs “next operation” data to provide operation/assembly sequencing

• Save Excel output to plain-text file

© Copyright 2009, Connecticut Center for Advanced Technology, Inc. All rights reserved.

eVSM->QUEST Model Builder – Text Input

• User specifies configuration file for input data– Identifies delimiter in text file– Lists spreadsheet column names for data– Lists SCL logic files to compile before building

• For assigning logics to buffers, machines– Specifies model-wide settings

• Machine/buffer geometry/spacing• Model init/term logic

© Copyright 2009, Connecticut Center for Advanced Technology, Inc. All rights reserved.

eVSM->QUEST Model Builder –Element Building

• Builds part classes– Embeds process sequence in part class

• Builds machines with input/output buffers– Makes connections between workstations– Sets logics on machines, buffers

• Builds processes with requirements & products– Identifies assembly operations and requires

appropriate part classes

© Copyright 2009, Connecticut Center for Advanced Technology, Inc. All rights reserved.

eVSM->QUEST Model Builder – Optional Additions

• Adds QUEST constructs when data is found– Labor requirements– Setup/Changeover times– Load/Unload times– Process scrap– MTBF/MTTR/%Uptime– Source Arrivals

• Transfers unused data to process attributes– Easily transfer data from VSM to QUEST for use in logics

© Copyright 2009, Connecticut Center for Advanced Technology, Inc. All rights reserved.

eVSM/Visio Interface

• Automated export from eVSM, macro execution in QUEST– Form for specifying

model build parameters

• Builds BCL script to execute macro

• Starts QUEST in BCL mode, executes script

© Copyright 2009, Connecticut Center for Advanced Technology, Inc. All rights reserved.

Spaghetti Charting for machine layout

• eVSM has basic “spaghetti charting” capabilities– Generate Visio layout, connect processes– Visualizes part travel

• CCAT developed spaghetti charting tools– Creates “smart” links between charts and VSM’s– Able to pull machine locations into VSM from

layout• QUEST importer uses these coordinates to locate

machines

© Copyright 2009, Connecticut Center for Advanced Technology, Inc. All rights reserved.

Demo

© Copyright 2009, Connecticut Center for Advanced Technology, Inc. All rights reserved.

Electronic assembly modeling project

• Received processes in eVSM format• Built initial importer for eVSM data• Evaluated number of workstations, operators,

and inspectors required to meet projected production rates

© Copyright 2009, Connecticut Center for Advanced Technology, Inc. All rights reserved.

Machining cell evaluation

• Used spread sheet interface to import process data• Evaluated number of stations, people, to meet

projected production rates• Evaluated proposed cell layout• Identified bottleneck for machining time reduction

© Copyright 2009, Connecticut Center for Advanced Technology, Inc. All rights reserved.

Machining Cell Evaluation

• Turbine Blade Manufacturing Cell• Generated electronic Value Stream Map using eVSMTM

• Used eVSM to Generate QUEST model of system• “What If” scenarios were tested in the model

“CCAT has provided access to tools that have helped us better understand how to make our value stream lean. Using their value stream mapping and factory modeling software, we were able to run “what if” scenarios on our future state. Our team was able to see the impact of batch sizes, buffer stock and asset utilization in a virtual environment before implementation. This has given us the validation we needed to move forward on our shared resource value stream. I highly recommend any manufacturing company to tap into the CCAT’s state of the art offerings.”

~Continuous Improvement Manager for client

© Copyright 2009, Connecticut Center for Advanced Technology, Inc. All rights reserved.

Large Fuel Cell Manufacturing

• Imported flow of parts from eVSM• Manually modified element locations• Manually added material handling system

© Copyright 2009, Connecticut Center for Advanced Technology, Inc. All rights reserved.

Machining Value Stream Analysis

• Received data in eVSM format• Modified map with simulation data• Built spaghetti chart for machine locations• Completely automated build (using BCL script)

© Copyright 2009, Connecticut Center for Advanced Technology, Inc. All rights reserved.

Machining Bottleneck Identification

• Received basic VSM• Evaluated future state recommendations

– Evaluated adding shifts to machine feeding bottleneck

– Evaluated splitting processes to different machines• Total modeling and initial analysis time : 4 hrs

© Copyright 2009, Connecticut Center for Advanced Technology, Inc. All rights reserved.

Conclusion• Easy to generate basic QUEST models

– Eliminates much manual, tedious input to QUEST– Works as a spreadsheet-based interface

• eVSM can quickly generate this spreadsheet format• Looking at other simulation packages

– Basic exporter to FlexSim– Basic exporter to Arena– Working on exporter to NIST’s Core Manufacturing

Simulation Data (CMSD) format• Package-independent

© Copyright 2009, Connecticut Center for Advanced Technology, Inc. All rights reserved.

Looking for partner companies

• CCAT is looking for SMM’s to use & test eVSM/QUEST tools– Aerospace/DoD Supply Chain Level Companies

© Copyright 2009, Connecticut Center for Advanced Technology, Inc. All rights reserved.

Questions?

• Jon Fournier• Applications Engineer, CCAT• 222 Pitkin Street, Suite 106• East Hartford, CT

• http://www.ccat.us• [email protected]• http://delmiaquest.blogspot.com

![01577 Datenblatt SS-IIE - RAYLASE · Deflection unit SS-IIE-7 SS-IIE-10 SS-IIE-12 SS-IIE-15 Mirror type SI SI SI QU SI SC Acceleration time [ms] 0.19 0.22 0.25 0.36 0.30 0.24 Writing](https://static.fdocuments.in/doc/165x107/5f47a3d8dce6920e443e62b6/01577-datenblatt-ss-iie-raylase-deflection-unit-ss-iie-7-ss-iie-10-ss-iie-12-ss-iie-15.jpg)