IC Engine Flow Simulation using KIVA code and A Modified ... · Nanda, S. I.C. Engine Flow...

Transcript of IC Engine Flow Simulation using KIVA code and A Modified ... · Nanda, S. I.C. Engine Flow...

1

IC Engine Flow Simulation using KIVA code and A Modified Reynolds Stress Turbulence Model

Satpreet Nanda and S.L. Yang

Mechanical Engineering-Engineering Mechanics Department

Michigan Technological University Houghton, Michigan 49931

Abstract

The flow processes inside an engine are very complex and to simulate the highly anisotropic turbulent engine flows, second moment models (Reynolds stress models) are used. The KIVA code has been modified to include the Reynolds stress turbulence model (RSTM) for this purpose. In this study the existing RSTM in the KIVA code [1] has been modified to resolve the flow better in the engine. The flow inside the engine has high bulk velocities in the vertical plane and the flow in the horizontal plane is slow and influenced by shear and pressure effects. In the modified RSTM the dissipation equation has been modified to be more sensitive to shear effects and irrotational strains. The modified RSTM is used to simulate the flow inside a four-valve engine cylinder and the results are compared with the Standard k-ε model, the original RSTM in the KIVA code and the experimental results. The comparisons are made for the intake and compression strokes. The modified RSTM shows better results and is able to resolve the flow characteristics better than the original RSTM in the KIVA code.

Introduction

The in-cylinder fluid dynamics in engines has been shown to play an important role during the combustion process. In particular, in-cylinder fluid flows contribute to fuel air mixing which is important to the fuel-burning rate.

Turbulence generated in an I.C. engine is anisotropic. During the Intake process, the flow passing the valve separates and results in a highly unsteady motion. This flow contains both large-scale and small-scale turbulence. Since turbulence has a major effect on combustion, flow-mixing and on heat-transfer in an engine, to model the flow inside an engine a proper turbulence model should be used. Most industrial computations of engine flows use the two-equation models based on the Boussinesq approximation. Using this assumption the Reynolds stress tensor is directly proportional to the strain rate, which implies that the Reynolds stress is directly in phase with the strain rate, which is not the case in real complex flows. The second moment model (from now on referred as Reynolds stress turbulence model, RSTM) has the potential to resolve complex flow-fields and it has been shown that it is able to resolve engine flow better than other models [2 & 3]. The models based on the Boussinesq approximation suffer from many shortcomings, which are overcome in the RSTM. A modified model of the RSTM has been developed to improve the dissipation equation and better resolve the flow in the engine. First, the original RSTM in the KIVA code is ∗ To whom the correspondence should be made

2

shown followed by the modifications and there effects on the model. In the end the results obtained from different models are compared with experimental results. Modifications to original RSTM

The original RSTM was modified by adding three extra terms to the dissipation rate equation and modifying a term in the Reynolds stress transport equations

The modification in the Reynolds stress transport equation is in the dissipation term that has been taken to be anisotropic. Generally for high Reynolds number models the dissipation expression used in the Reynolds transport equation is modeled

as ijij εδρε3

2= , here the viscous effects are neglected. As the fluid approaches a solid

wall the energy containing and dissipation range of motions overlap and the dissipation

rate is then commonly expressed [3] as

+−= sji

ijsij fk

uuf

32

)1(3

2’’

δερε .

The dissipation equation used in this research with the modifications is as follows:

( )

∂∂

∂∂+

∂∂

−−=

∂∂+

∂∂

k

t

ki

i

k

i

xxx

UCC

x

U

t

εσµερερερ

εεε 313

2

( ) ( ) Gl SSSCk

PCk

+++−+−+ Ωεερερ εε 21 (1)

The last three terms are the ones that are added to the original dissipation equation.

ΩS is the vorticity term, this term may be interpreted as emphasizing the role of irrotational deformations in promoting energy transfer across the spectrum or, equivalently, of augmenting the influence of normal strains. iikfCS ΩΩ−= ΩΩΩ ρ (2)

where 1.0=ΩC and k

jijki x

U

∂∂

=∈Ω is the mean vorticity vector, ΩS sensitizes the

production of ε (in fact, the spectral energy transfer) to both the sign and intensity of the irrotational straining and is beneficial for modeling the evolution of ε in flows with strong acceleration and deceleration (compression and expansion as in engine flows).

lS is added to compensate for excessive growth of the length scale l, this was originally

introduced by Hanjalic and Jakirilic [4] into the transport equation for ε. This term

increases ε locally in the zone where the turbulence length scale ε

23

k becomes excessive.

3

Another termlk

i

ji

i

xx

U

xx

UkCS

∂∂∂

∂∂∂

=Ω

22

3 ερε , modeling the gradient of production of

dissipation is added, this term was introduced first by Jones and Launder [5], and is designed to resolve the production of dissipation in viscous regions. Experimental Set-up and Grid Generation

The experimental results were obtained from Michigan State University’s [MSU] Engine Research Laboratory. The experimental measurements were made using Molecular Tagging Velocimetry (MTV) [6], a method developed at MSU’s Engine Research Laboratory to study the engine in-cylinder processes. Two planes were chosen for collection of MTV data. The first one is the vertical plane between the two intake valves, in the center of the cylinder, which will be referred to as the tumble plane. Due to the limited access, approximately only the top half of this plane is measured. The second plane of data was taken at a horizontal slice 2.4 cm below head face.

The computational grid for the engine geometry was made using GRIDGEN® [7] and a modified version of the K3prep. A three dimensional multi-block mesh was constructed using GRIDGEN®, where it first reads the engine geometry (wire-frame) in PLOT-3D format. To ensure the simulation result is convergent, a grid dependency study was performed. The medium grid, which is used to show the results, has around one hundred and thirty thousand cells and one forty three thousand vertices when the piston is at the bottom dead centre, the top view is shown in Figure 1 and the front view is shown in Figure 2. The test was only performed in non-reacting flow conditions for the intake and compression strokes. The terms added were first linearized and then added to the respective differential equation. The terms added to the dissipation equation were linearized using Taylor series and the term added to the Reynolds stress transport equation was linearized using “max” and “min” functions [8]. The differential expressions introduced in the equations are then discretized using the finite-volume approach. The differential expressions within the volume integral were approximated using finite-difference approximations. Using the relation between physical and computational space relations was obtained to approximate the expressions. The details of the method can be found in Nanda [9]. Results and Conclusions

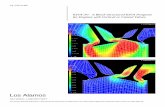

The velocity contour and vector plots for different models have been compared

with the experimental result. Comparison of results are presented in both XY and XZ planes, i.e., at Z=8.85 cm (horizontal plane) and Y=0.0 cm (plane between the two intake valves, this plane will be referred to as the tumble plane) as shown in Figure 3(a) & (b). Since the engine geometry is symmetric along the Y=0.0 cm axis, the flow should be symmetric, which can be seen in the numerical results, but the results from the MTV data are not symmetric. This could be due to the hand-built inlet manifolds (might have some minor imperfections) used in the experiment [10].

4

It can be seen from the results that the modified model is able to resolve the flow better than the original RSTM. This is because the modified model is more sensitive to irrotational/normal strains which are quite dominant in engine flows. Also the modified model is able to predict the intensity better than the other models. A better result for recirculation zones, velocity magnitude and vectors is shown by the modified RSTM. Acknowledgements

The author would like to thank Professor H. J. Schock and Mr. Mark Novak of Michigan State University, Automotive Research Experiment Station, for providing us with the experimental data and information about the experimental setup. The author will also like to thank the MEEM department at Michigan Technological University for providing financial assistance during this research. References:

1. Yang, S. L., Peschke, B. D. and Hanjalic, K. Second-Moment Closure Model for IC Engine Flow Simulation Using KIVA code. J. Engineering for Gas and Turbine Power, vol. 122, April 2000.

2. Yang, S. L. Siow, Y. K. and Peschke, B. D. Numerical study of non-reacting gas turbine combustor swirl flow using Reynolds Stress Model. J. Engineering for Gas and Turbine Power, vol. 25, October 2003 (To be published).

3. Yang, S. L. Siow, Y. K., Teo, C. Y. Numerical Study of LDI Combustor with Discrete jet swirlers using Reynolds stress Model. J. Engineering for Gas and Turbine Power, July 2003.

4. Hanjalic, K. and Launder, B. E. Contribution towards a Reynolds-Stress closure for low-Reynolds-number turbulence. J. Fluid Mechanics, vol. 74, pp593-610, 1976.

5. Hanjalic, K. and Jakirlic, S. Contribution towards the second moment closure modeling of separating turbulent flow. Computers & Fluids, vol. 27, No. 2, pp. 137-156, 1998.

6. Jones, W. P. and Launder, B. E. The predictions of Laminarisation with a two-equation model of turbulence. Int. J. Heat and Mass Transfer, vol 15, 301, 1972.

7. Gendrich, C. P., Koochesfahani, M. M. and Nocera, D. G. Molecular Tagging Velocimetry and Other Novel Applications of a New Phosphorescent Supramolecule. Experiments in Fluids 23(5) 361-372, 1997.

8. GRIDGEN®, Grid Generation and Pre-Processing for CFD, V.14.1, Pointwise Inc., 213 S. Jennings Ave., Fort Worth, TX 76104-1107, USA, 2003

9. Nanda, S. I.C. Engine Flow Simulation Using KIVA Code and a Modified Reynolds Stress Turbulence Model. Masters Thesis, Michigan Technological University, 2003

10. Fedewa, A. M. Private Conversation, Graduate Student at Michigan State University, Engine Research Laboratory, 2003.

5

Y= 0.0 cm

Figure 1 Bottom View

Z X

Y

Figure 2 Isometric View

YX

Z

2.4 cm Z=8.85 cm

11.25 cm

Figure 3 (a) Front view of engine wire-frame

Inlet Runner

Figure 3 (b) Top view of engine wire-frame

Exhaust Runner

6

10 m/s

10 m/s 10 m/s 10 m/s

1750

1537

1324

1111

898

685

470

260

47

-165

-378

-590

-804

-1017

-1230

10 m/s

(a) Standard k- model (b) original RSTM (c) modified RSTM (d) MTV data

Figure 4 X component velocity contour and UV vector plots at Z=8.85 cm plane for 4500 C.A.

10 m/s 10 m/s 10 m/s

19001100500220

-930-1635-2342-3050-3760-4460-5170-5880-7300-8000

10 m/s

(a) Standard k- model (b) original RSTM (c) modified RSTM (d) MTV data

Figure 5 Z component velocity contour and UW vector plots at Y=0.0 cm plane for 4500 C.A.

(b) original RSTM (c) modified RSTM (d) MTV data

Figure 6 X component velocity contour and UV vector plots at Z=8.85 cm plane for 5000 C.A.

1300

1150

994

840

688

535

380

230

77

-75

-230

-380

-530

-687

-850

10 m/s10 m/s 10 m/s

(a) Standard k- model

10 m/s 10 m/s

720

650

570

500

425

350

280

205

130

60

-15

-90

-160

-236

-310

10 m/s

(a) Standard k- model (b) original RSTM (c) modified RSTM (d) MTV data

Figure 7 Y component velocity contour and UV vector plots at Z=8.85 cm plane for 5400 C.A.

10 m/s