Heavy Lifts in Deep Water Subsea 7 Experience in NW Australiamcedd.com/wp-content/uploads/Subsea 7 -...

Transcript of Heavy Lifts in Deep Water Subsea 7 Experience in NW Australiamcedd.com/wp-content/uploads/Subsea 7 -...

Heavy Lifts in Deep Water Subsea 7 Experience

in NW Australia

9th April 2014

Ryan Epstein, Marin Abélanet

(Paul van Amsterdam)

2Page 10.12.10

Engineering & Operation from Subsea7 Perth – Australia:

1. Gorgon Project (focus on heavy lifting)

2. HLV Sapura 30003. Deepwater Lowering System DLS4. Passive Heave Compensation5. Lift Rigging6. Installation Method Example

Agenda

10.12.10 3Page

Jansz Heavy Lifts:• 6 structures to 1060 t• 5 spools 30” to 180 t

Gorgon Heavy Lifts:• 14 structures to 860 t• 10 spools 34” to 230 t

(85 x 35 m)

Tie-ins:• 47 small dia, spools• 57 flying leads• infield umbilicals

Further:• metrology• leak testing• pre-commissioning• 3rd party vessel

Gorgon Project - Overview

JANSZ Field• WD 1300 m• 130 km• 3 Structures

GORGON Field• WD 130m – 220 m• 65 km• 7 Structures

10.12.10 4Page

Project : Gorgon Heavy-Lift & Tie-ins

Operator : Chevron Australia (47.3%) Joint Venture : ExxonMobil (25 %t), Shell (25%),

Osaka Gas (1.25%), Tokyo Gas (1%)and Chubu Electric Power (0.417 %)

Field Location : Australian North West Shelf Water Depth : 130-1350m

Contract Award : July 2011 Installation : January 2014 - now

Vessels : Rockwater 2: Sapura 3000: Skandi Acergy: 3rd Party Vessel

Gorgon Project – Overview

10.12.10 5Page

Gorgon - Heavy Lift Structures

Foundations to be installed:• Mudmat type

- up to 938 t- up to 41 m x 32 m

• Suction pile type- up to 474 t- Up to 27 m x 19 m

Manifold / PTS modules to be installed:• Manifold modules

- up to 637 t- up to 19 m x 23 m x 6.5 m

• PTS modules- up to 1186 t- up to 25 m x 25 m x 8 m

Weight in air, incl. rigging (spreaders)

Challenge:- Big, heavy, and deep.- How to install to depth ?

10.12.10 6Page

HLV Heavy Lift Vessel - Sapura 3000

• Sapura 3000 (SapuraAcergy)

• DP 2

• Main Crane (Huisman HLMC)

Main (3000 Sht)– SWL 1600 t @ 37 m, Hs = 1,5 m– Main block does not go subsea– No heave compensation

Aux. (800 Sht)– 725 t @ 53 m, Hs = 1,5 m– 526 t @ 53 m, Hs = 2 m– Down to 250 m waterdepth

Whip– 115 t @ up to 83 m, Hs = 2 m

• 2 x 40 t Deck Crane

• 2 x WROVs

10.12.10 7Page

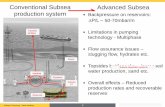

Lowering Systems Considered

Analysed:

• Lift-off from CB by crane main hoist

and next:

• Outrigger with 27 pennants @ 50 m

• Combine aux. hoist and A&R winch (2500 m - 370 t)

• External winch routed via mast crane

• External overboarding winches DLS

10.12.10 8Page

DLS Deepwater Lowering System - Handover

Arrangement:

• 2 storage winches e.a. 6000 m, c/w level wind• 2 traction winches, e.a. 190 t• sheaves• 1 Deepwater Lowering Beam

• each winch in 4-falls• low rotating wire 78 mm

Deepwater Lowering System (DLS)

10.12.10 9Page

DLS Capacity

DLS on board Sapura 3000 DLS lowering beam and connector

Caley Oceans - Glasgow - at 1350 m waterdepth: 1300 t capacityin Bintang installed on starboard side - speed 5 m/min (6 hrs. lowering)

10.12.10 10Page

Passive Heave Compensator – Crane Master

Used for:• Lift-off from CB• Splash zone• Landing

Particularity:• Used for all 20 lifts: 150 t – 1200 t• Stiffness can be modified:

automatic at 750 m WT, or by ROV

Single Unit:• SWL: 700 t• stroke 4.5 m (pin to pin 6.38 m)• Weight: 40 t (incl. shackles)

Double Unit: (made-up from 2 singles)• SWL: 1400 t• Weight: 100 t (incl. plates, swivel, etc.)

10.12.10 11Page

Upper Rigging:• Steel wire ropes• DLS Connector • Crane Master

Lift Rigging

Connected to lowering beamvia Connector

Lower Rigging:• synthetic slings (for easy

handling and protection) • spreader bars• craddle supports

10.12.10 12Page

Heavy Lift Structure - Installation Criteria

Installation parameters: Operations:

• Positioning accuracy: Heading +/- 1.5° better than 1.0° Position tolerance 2.5 m radius better than 1.0 m

• Max landing velocity: 0.2 to 0.3 m/s observed ‘zero’ movements

10.12.10 15Page

Installation Method – Heavy, Big and Deep

Landing

Methods to orientate structure:

• ROV connected to structure• Steered by clump weight

(suspended from vessel crane)