Header & Piping Sizing

-

Upload

antonio-ortega-rodenas -

Category

Documents

-

view

14 -

download

4

Transcript of Header & Piping Sizing

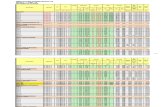

M/S DALMIA CEMENT (BHARAT) LTD1X120 TPH CFBC BOILER

HEADER THICKNESS CALCULATION

PREPARED BY:JRY

APPROVED BY:JRK

Header & Piping Thickness Calculation

Description Material

CONVECTION CAGE

1 323.9 38.1 1 122 354 393 SA 106 Gr B 952.00 27.85 33.34 0.6500 19.70 5.49

2 Front Intermediate HDR(CG) 273 31.75 1 122 354 393 SA 106 Gr B 952.00 23.67 27.78 0.6500 17.36 4.11

3 Interconnecting HDR(CG) 168.3 21.95 4 122 354 393 SA 106 Gr.B 952.00 14.37 19.21 0.6500 33.69 4.84

4 FRONT BOTTOM HDR(CG) 273 31.75 1 122 354 393 SA 106 Gr.B 952.00 23.67 27.78 0.6500 17.36 4.11

5 273 31.75 1 122 354 393 SA 106 Gr.B 952.00 23.67 27.78 0.6500 17.36 4.11

6 219.1 28.58 2 122 354 393 SA 106 Gr.B 952.00 22.12 25.01 0.5500 13.07 2.89

7 219.1 28.58 2 122 354 393 SA 106 Gr.B 952.00 18.47 25.01 0.6500 35.38 6.54

SUPERHEATER 739.4

8 PSH outlet header 323.9 34.93 1.00 122 460.00 SA 335 P11 978.00 27.73 30.56 0.6500 10.23 2.84

9 wing wall I/L HDR 273 38.1 2.00 122 420.00 SA 335 P11 1019.00 27.53 33.34 0.5000 21.10 5.81

10 wing wall 0/L HDR 273 41.28 2.00 122 492.00 SA 335 P11 850.00 32.68 36.12 0.5000 10.54 3.44

11 SSH inlet header 323.9 31.75 1.00 122 465.00 SA 335 P11 973.00 22.09 27.78 0.8280 25.74 5.69

12 SSH outlet header 323.9 34.93 1.00 122 582.00 SA 335 P 91 830.00 25.51 30.56 0.8280 19.82 5.06

CROSS OVER DUCT

13 COD FRONT header 273 25.4 2.00 122 318 357 SA 106 Gr.B 1150.00 20.51 22.22 0.6500 8.38 1.72

14 COD REAR header 273 25.4 2.00 122 318 357 SA 106 Gr.B 1150.00 20.51 22.22 0.6500 8.38 1.72

15 COD SIDE header 273 28.58 4.00 122 318 357 SA 106 Gr.B 1150.00 23.80 25.01 0.5500 5.07 1.21

ECONOMISER

16 ECO inlet header 273.1 31.75 1.00 118 230 241 SA 106 Gr.B 1202.28 19.33 27.78 0.6030 43.71 8.45

17 ECO outlet header 219.1 20.62 2.00 118 276 287 SA 106 Gr.B 1202.28 12.39 18.04 0.8000 45.68 5.66

18 HANGER OUTLET HDR 219.1 20.62 2.00 118 289 300 SA 106 Gr B 1202.28 12.39 18.04 0.8000 45.68 5.66

BOILER FEED PUMP

36 feed water suction hdr 457.2 11.13 1 6.5 160 160 SA 106 Gr B 1202.2 2.00 9.74 0.95 386.15 7.74

37 feed water discharge hdr 323.9 28.58 1 155 160 160 SA 106 Gr B 1202.2 20.18 25.01 0.95 23.92 4.83

38 Feed water header 323.9 33.32 1 155 210 210 SA 106 Gr B 1202 23.31 29.16 0.8 25.06

39 Auxiliary steam header 323.9 10.31 1 6 250 250 SA 106 Gr B 1202 1.85 9.02 0.7 388.37

40 Auxiliary steam header 114.3 8.56 1 21 300 300 SA 106 Gr B 1202 1.99 7.49 0.7 276.37

Sl. No

Outside diameter

(mm)

Thickness (mm)

No of headers

Design Pressure (kg/cm^2)

max working

temp deg.C

Design Temp Deg. C

Allowable Stress (kg/m^2)

Minimum thickness required

(mm)

Min. thick available

(mm)

Ligament Efficiency

(%)

% Margin Available

Allowance mm

FRONT/REAR ROOF HDR(CG)

REAR WALL BOTTOM HDR(CG)

SIDE WALL(L&R)Bottom HDR (CG)

SIDE WALL(L&R)TOP HDR (CG)

M/S DALMIA CEMENT LTD1X120 TPH CFBC BOILER

HEADER SIZING CALCULATION

PREPARED BY :JRA

APRROVED BY:JRK

Header Sizing Description

CONVECTION CAGE

1 323.9 38.1

0.24770 133900 107.5 354 Err:511 Err:511 Err:511 0.1200

2 273 31.75

0.2095 133900 107.5 354 Err:511 Err:511 Err:511 0.1200

3 Interconnecting HDR(CG) 168.3 21.950.1244 33475 107.5 354 Err:511 Err:511 Err:511 0.1200

4 273 31.750.2095 133900 107.5 354 Err:511 Err:511 Err:511 0.1200

5 273 31.750.2095 133900 107.5 354 Err:511 Err:511 Err:511 0.1200

6 219.1 28.58

0.16194 66950 107.5 354 Err:511 Err:511 Err:511 0.1500

7 219.1 28.580.16194 66950 107.5 354 Err:511 Err:511 Err:511 0.1200

SUPERHEATER

8 PSH outlet header 323.9 34.930.25404 140000 105 421.00 Err:511 Err:511 Err:511 0.1200

9 wing wall I/L HDR 273 38.1 0.1968 70000 103.5 395.00 Err:511 Err:511 Err:511 0.1500

10 wing wall 0/L HDR 273 41.280.19044 70000 100.00 454.00 Err:511 Err:511 Err:511 0.1200

11 SSH inlet header 323.9 31.75 0.2604 140000 99.00 440.00 Err:511 Err:511 Err:511 0.1500

12 SSH outlet header 323.9 34.93 0.25404 140000 96.00 545 Err:511 Err:511 Err:511 0.1200

Sl. No.

Outside dia ( mm)

Header thk.

(mm)

Inside dia m

Fluid flow (kg/hr)

Operating pressure (ksc(a))

Operating temp.

(deg. C)

Specific volume (m3/kg)

Actual velocity

(m/s)

Velocity m/s/mmID

Velocity m/s/mmID(max limit)

FRONT/REAR ROOF HDR(CG)

Front Intermediate HDR(CG)

FRONT BOTTOM HDR(CG)

REAR WALL BOTTOM HDR(CG)

SIDE WALL(L&R)Bottom HDR (CG)

SIDE WALL(L&R)TOP HDR (CG)

M/S DALMIA CEMENT LTD1X120 TPH CFBC BOILER

HEADER SIZING CALCULATION

PREPARED BY :JRA

APRROVED BY:JRK

CROSS OVER DUCT

13 COD FRONT header 273 25.40.2222 70000 111 318 Err:511 Err:511 Err:511 0.1200

14 COD REAR header 273 25.40.2222 70000 111 318 Err:511 Err:511 Err:511 0.1200

15 COD SIDE header 273 25.40.2222 70000 111 318 Err:511 Err:511 Err:511 0.1200

ECONOMISER

16 ECO inlet header 273.1 31.75 0.2096 140000 116 230 Err:511 Err:511 Err:511 2m/s

17 ECO outlet header 219.1 20.62 0.17786 70000 116 276 Err:511 Err:511 Err:511 2m/s

18 HANGER OUTLET HDR 219.1 20.62 0.17786 70000 116 289 Err:511 Err:511 Err:511 2m/s

M/S DALMIA CEMENT LTD1X120 TPH CFBC BOILER

HEADER SIZING CALCULATION

PREPARED BY :JRA

APRROVED BY:JRK

BOILER FEED PUMP

36 feed water suction hdr 457.2 11.13 0.43494 280000 6.5 160 Err:511 Err:511 Err:511 0.6-0.9

37 feed water discharge hdr 323.9 28.58 0.26674 280000 162 160 Err:511 Err:511 Err:511 1.5-2.4

38 Feed water header 323.9 33.32 0.25726 280000 162 230 Err:511 Err:511 Err:511 1.5-2.439 Auxiliary steam header 323.9 10.31 0.30328 15000 6 250 Err:511 Err:511 Err:511 1.5-2.6

Auxiliary steam header 114.3 8.56 0.09718 3000 21 300 Err:511 Err:511 Err:511 1.5-2.7

M/S BALASORE ALLOYS LTD2 X 140 TPH CFBC BOILER

HEADER THICKNESS CALCULATION

Piping Thickness Calculation

Sl.No Description Material

1406.4 9.53 1 6.4 160

SA 106 Gr B 1202.00 1.83 8.34 355.90

2

273 9.27 1 6.4 160

SA 106 Gr B 1202.00 1.47 8.11 449.97

3219.1 20.62 1 160 160

SA 106 Gr B 1202.00 14.42 18.04 25.10

4

273.1 25.4 1 160 160

SA 106 Gr B 1202.00 17.79 22.22 24.91

5219.1 15.09 1 160 160

SA 106 Gr B 1202.00 14.42 13.20 -8.45

6 Spray Piping to boiler attemperator-142.2 4.85 1 160 160

SA 106 Gr B 1202.00 3.38 4.24 25.43

7steam line from CSDH to PRDS - 1

114.3 13.49 1 96 540SA 335 P 22 520.50 10.40 11.80 13.49

8

355.6 9.53 1 7.00 250

SA 106 Gr B 1202.00 1.78 8.34 367.83

9 Feed water piping from eco to drum219.1 15.09 1 117.00 277

SA 106 Gr.B 1202.00 10.92 13.20 20.93

10 Drum to COD 219.1 15.09 1 122 318 SA 106 Gr.B 1202.00 11.33 13.20 16.52

11 COD to cage 219.1 15.09 1 122 325 SA 106 Gr.B 1202.00 11.33 13.20 16.52

12 PSH to DSH-1 273 21.44 1 122 421 SA 355 P11 1018.00 16.18 18.76 15.92

13 DSH-1 to WWSH SH 273 21.44 1 122 395 SA 355 P11 1043.00 15.83 18.76 18.48

14 WWSH to Final SH 323.9 25.4 1 122 454 SA 355 P11 984.00 19.66 22.22 13.06

18 Main steam pipe upto MSSV 323.9 25.4 1 122 555 SA 355 P91 1045.00 18.61 22.22 19.40

Main steam from MSSV to CSDH 406.4 50.8 1 105.5 540 SA 355 P22 520.50 38.15 44.45 16.52

Outside diameter

(mm)

Thickness (mm)

No of headers

per boiler

Design Pressure (kg/cm^2)

Design Temp Deg. C

Allowable Stress (kg/m^2)

Minimum thickness required

(mm)

Min. thick available

(mm)

% Margin Available

Feed water piping from deaerator to BFP suction

Feed water piping from BFP header to BFP

Feed water piping from BFP to BFP header

Feed water piping from BFP outlet to HP heater-I

Feed water piping from HP heater-I to economiser

steam line from PRDS-1 to ejector/gland sealing

M/S BALASORE ALLOYS LTD2 X 140 TPH CFBC BOILER

HEADER THICKNESS CALCULATION

CSDH 558.8 88.9 1 105.5 540 SA 355 P22 520.50 71.42 77.79 8.91

19Steam piping from CSDH to PRDS-II

60.3 8.74 1 97 540SA 355 P22 520.50 5.89 7.65 29.84

20114.3 6.08 1 21 250

SA106 Gr B 1202.00 1.74 5.32 205.78Steam piping from PRDS-II to termial

point

M/s DALMIA CEMENT (BHARAT) LTD.

Piping Sizing

Sl. No. Description

1 406.4 9.53 1 280000 6.4 160 Err:511 Err:511 0.6-0.9 0.6-0.9

2 273 9.27 1 140000 6.4 160 Err:511 Err:511 0.6-0.9 1.8-2.4

3 219.1 20.62 1 140000 160 160 Err:511 Err:511 1.5-2.4 1.8-2.4

4 273.1 25.4 1 280000 160 160 Err:511 Err:511 1.5-2.4 1.8-2.4

5 219.1 15.09 1 140000 160 160 Err:511 Err:511 3.00

6 42.2 4.85 1 7000 160 160 Err:511 Err:511 3.00

7 114.3 13.49 1 15000 96 540 Err:511 Err:511 35-50

8 355.6 9.53 1 15000 6.00 250 Err:511 Err:511 28-43

9 219.1 15.09 1 140000 116.00 277 Err:511 Err:511 2-3

10 Drum to COD 219.1 15.09 1 70000 111.5 318 0.01737 12.1 30-50 20-35

11 COD to cage 219.1 15.09 1 70000 109.5 325 Err:511 Err:511 50.00 20-35

12 PSH to DSH-1 273 21.44 1 140000 105 421 Err:511 Err:511 50.00 35-61

Outside dia

( mm)

Pipe thk.

(mm)

No of Lines

Fluid flow

(kg/hr)

Operating

pressure ksc(a)

Operating temp.

(deg. C)

Specific volume (m3/kg)

Actual velocity

(m/s)

Allowable Velocity

m/s

Allowable Velocity

m/s(AS PER Tender)

Feed water piping from deaerator to BFP suction

Feed water piping from BFP header to BFP

Feed water piping from BFP to BFP header

Feed water piping from BFP outlet to HP heater-I

Feed water piping from HP heater-I to economiser

Spray Piping to boiler attemperator-1

steam line from CSDH to PRDS - 1

steam line from PRDS-1 to ejector/gland sealing

Feed water piping from eco to drum

M/s DALMIA CEMENT (BHARAT) LTD.

13 DSH-1 to WWSH SH 273 21.44 1 140000 104.5 395 Err:511 Err:511 50.00 50-76

14 WWSH to Final SH 323.9 25.4 1 140000 100 454 Err:511 Err:511 50.00 50-76

18 Main steam pipe upto MSSV 323.9 25.4 1 140000 97 540.00 Err:511 Err:511 50 50-76

0 406.4 50.8 1 280000 97 540.00 Err:511 Err:511 50 50-77

0 CSDH 558.8 88.9 1 280000 97 540.00 Err:511 Err:511 50 50-78

Main steam from MSSV to CSDH

M/s DALMIA CEMENT (BHARAT) LTD.

19 60.3 8.74 1 3000 96 540 Err:511 Err:511 35-50 35-61

20 114.3 6.08 1 3000 21 250 Err:511 Err:511 50 20-30 25-40 30-50

Steam piping from CSDH to PRDS-II

Steam piping from PRDS-II to termial point