HANGERS & TRUSS BOOTS - Affordable Pergolas · A complete guide to the design, specification and...

Transcript of HANGERS & TRUSS BOOTS - Affordable Pergolas · A complete guide to the design, specification and...

A complete guide to the design, specification and installation of Pryda Hangers and Truss Boots.

HANGERS & TRUSS BOOTS

PRYDA AUSTRALIA

Head Office: 29 Healey Road, Dandenong, Vic 3175

Tel: (03) 9706 5488 Fax: (03) 9706 5499

Offices in Sydney, Brisbane and Perth.

For contact details in your state visit www.pryda.com.au or email [email protected] Division of ITW Australia Pty Ltd

ESSENTIAL NOTES - PRYDA PRODUCT GUIDES

The information in this Product Guide is provided for use in Australia by architects, engineers, building designers, builders and others. It is based upon the following criteria: 1. No Substitution: The products covered by or recommended in

this guide must not be substituted with other products. 2. Design Capacity Basis: See Codes & Standards following 3. Supporting Constructions: Constructions using Pryda

products must be built in accordance with the BCA or an appropriate Australian standard. Note: This includes appropriate corrosion protection- See Corrosion Protection following

4. Correct Installation: Installation of Pryda products must be strictly in accordance with the instructions in this guide

5. Current Guide Version Used: The current version of this guide, including any amendments or additions, must be used. Users are advised to check with Pryda for updates at least every three months by telephone, the web site: www.pryda.com.au or by email to: [email protected].

CODES & STANDARDS Product design capacities in this guide have been derived from: (a) results of laboratory tests carried out by or for Pryda Australia (b) engineering computations in accordance with the relevant

Australian standards, ie: * AS1720.1-1997 Timber Structures. Part 1: Design Methods * AS/NZS1170:2002 Structural Design Principles - or AS1170-

1989 SAA Loading Code * AS4055 -1992 Wind Loads for Housing Reference is also made to AS1684.1-1999 Residential Timber Framed Construction - Part 1: Design Criteria.

Design capacities tabulated in this guide apply directly for joints in houses and on secondary beams in other structures. For joints on primary beams in structures other than houses, reduce the capacity to 75% of the tabulated value. Design capacities are related to the Joint Group of the timber as defined in AS1720 and AS1684. If the joint group of timber members joined together varies, the lower group must be assumed for design, eg: JD5 is lower than JD4. Load Duration Factor for Wind Because AS/NZS1170:2002 reduces the design wind action (aka “load”) in many regions compared to AS1170-1989, Standards Australia has issued a draft amendment to AS1720.1-1997 which proposes a reduction in the duration of load factor for timber strength (k1) which, for fasteners, is from 1.3 to 1.15. This Guide therefore provides dual product design capacities, ie: 1. taking into account this proposed change 2. in accordance with the previous Loading Code and for use with

the wind uplift forces tabulated in AS1684. Users of this guide must, therefore, ascertain the standard used for determining the wind actions (loads) before selecting the appropriate wind load design capacity.

CORROSION PROTECTION Some Pryda structural connectors are hot dip galvanised to Z275 level. Others are hot dip galvanised after manufacture and some are made from Marine Grade (316) stainless steel. The Z275 zinc coating is adequate for Category A uses as defined in the BCA and tabulated below. For Category B uses (as per BCA), these products can be: (a) hot dip galvanised, (b) powder coated, or (c) stainless steel, all supplied to order. For detailed advice, contact a Pryda office. Cat’y Environment Location

A Other - not covered by Cat. B below Internal B Uses subject to high humidity

(eg: swimming pool buildings) Internal

Within 1 km of the coast Internal In heavy industrial area* Internal

* eg: Port Pirie, Newcastle. LIMITED WARRANTY Pryda Australia warrants: * Products in this guide are free from defects in the material or

manufacturing * Design capacities are in accordance with test results or current,

relevant Australian standards and the Building Code of Australia.

* Pryda products are structurally adequate provided they are designed, installed and used completely in accordance with this guide.

This warranty apples only to: * products in this guide * products used in the specified applications and not damaged

after manufacture and supply * joints free from wood splitting, decay or other timber defects

within the joint or within 150 mm of the joint. INSTRUCTIONS FOR INSTALLATION These notes are provided to ensure proper installation. 1. All fasteners used must be manufactured by reputable

companies and be of structural quality. 2. Connectors must not be installed on timber which is split before

or during installation. If the timber is likely to split as fasteners are driven, fastener holes must be pre-drilled.

3. Do not overload the joints- during construction or in service. 4. Bolt hole diameter must be 0.8 mm to 1.5 mm larger than the

bolt diameter and the specified washers must be installed. 5. Use proper safety equipment and due care in installing these

connectors 6. Any gaps in joints between the timber members must not

exceed 3 mm 7. Do not over-tighten screws. DEFINITIONS Special terms used in this guide are as defined in Australian standards, including: Design Capacity: the maximum Limit State Design load (aka “action”) which the product can safely support under the specified load condition, eg: dead + roof live load (1.2G + 1.5Q). Load case “Live” means dead + live load. Joint Group: classification of a timber according to its fastener-holding capacity.

Copyright: © Pryda Australia - A Division of ITW Australia – ABN 63 004 235 063 - 2004

PRYDA HANGERS & TRUSS BOOTS GUIDE – FEBRUARY 2007

3

Pryda Hangers & Truss Boots Guide

INDEX

BEAM HANGERS Heavy brackets for large size beams

4

I-JOIST HANGERS Top mount and face mount hangers for timber I-joists

7

JOIST HANGERS Brackets for beam to beam connections

12

JOIST HANGERS- HEAVY DUTY Brackets for beam to beam or beam to brickwork/concrete connections

15

TRUSS BOOTS- MULTI-FIX- Bolt Fix Option Factory fitted brackets for girder truss support of standard trusses includes Joist Boots - Option for fixing with bolts and nails

16

TRUSS BOOTS - MULTI-FIX Screw Fix Option Factory fitted brackets for girder truss support of standard trusses includes Joist Boots - Option for fixing with screws

18

TRUSS BOOTS – HEAVY DUTY Steel Brackets for Heavy Roof Truss Connections

21

BOLTS KITS FOR TRUSS BOOTS Kits of bolts, nuts and washers for fixing truss boots

22

Product Information Updates Information contained in this product guide is subject to change.

The latest updates are available from www.pryda.com.au.

PRYDA TIMBER CONNECTORS Hangers & Truss Boots Guide

PRYDA HANGERS & TRUSS BOOTS GUIDE –FEBRUARY 2007 4

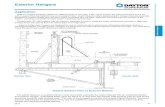

BEAM HANGERSHeavy Brackets for Large Size Beams & I-joists

Beam Hanger for Beams Beam Hanger for I-

Joists Description Pryda Beam Hangers are heavy duty welded hangers for connection of large size beams or I-joists, ranging in thickness from 45 mm to 180 mm, to timber beams or masonry walls. Features Pryda Beam Hangers are: easy to install with a small number of coach screws and/or nails onto timber or with masonry anchors onto masonry or concrete

an economical means of forming these connections ideal for supporting heavily loaded beams on fire rated brick walls, eliminating the need for a girder truss or false wall to support the beams

additional top flange holes on two sizes to allow for easy casting into mortar joints

Hangers for I-joists support double I-joists Supply Beam Hangers are supplied individually. Dimensions Dimensions of Pryda Beam Hangers are shown below.

Hanger Dimensions (mm) Code H W BL1 BL2 BB180 186 77 75 65

BB300 306 77 75 65

BBT140200 200 140 75 65

BBT180240 240 180 75 65

BBT180300 300 180 75 65

BBT180360 360 180 75 65

BBT120400 400 120 75 65

BBT180400 400 180 75 65

The thickness of all Beam Hangers is 3.0 mm.

75

H

200

Coach screwholes are offset

to avoid clashof screws

in beamW

Holes for 3.75 mm nails

Holes for10 mm diam.coach screws

PLAN VIEW

40

Holes on BB45240

& BB75240 for fixing to

masonry

BL1 BL2Weldedjoint

Holes for3.75 mmnails- twoeach legHole for10 mm diam.coach screw,one per leg

Beam Hangers for Beams (BB Series)

W

75

H

250

Holes for fixing to support

PLAN VIEW

75 65

Weldedjoint

Holes eachside for nailfixing tobottom chordof I-joist

Beam Hangers for I-joists (BBT Series)

Installation Fixing to Supports On timber supports, Pryda Beam Hangers can be installed using M10x75 mm coach screws, 75x3.75 mm galvanised flat head nails or a combination of both types of fasteners. Fix 45 mm thick supported beams to the Hanger with M10x50 mm coach screws, 50x3.75 mm nails or with both types of fasteners. On concrete, use M10 Heavy Duty or Chemical Anchors and on masonry use Chemical Anchors. Consult Ramset Australia for types and capacities. The maximum clearance between the end of the supported member and the hanger must be 3 mm.

PRYDA TIMBER CONNECTORS Hangers & Truss Boots Guide

PRYDA HANGERS & TRUSS BOOTS GUIDE –FEBRUARY 2007 5

Supported beam

Supporting beam

Two M10x75 mmcoach screws

2@ 75x3.75mm nails

Pryda Beam Hanger

3 mm max. clearance

Installation on Timber Support Beam

Fixing to Supported Member BB Series Hangers Fix BB series hangers to supported timber beams with one M10x50 mm coach screw each side. If required for additional wind uplift capacity, also drive two 50x3.75 mm flat head nails from each side. BBT Series Hangers Fix BBT series hangers to timber I-joists or trusses with one 35x3.15 mm Pryda Timber Connector Nail each side and one 35x3.15 mm Pryda Timber Connector Nail up into each of the two I-joists or trusses, ie: four nails per hanger. Design Capacities - General The loadbearing capacity of Pryda Beam Hangers depends on the criteria for each load direction as follows: Table D1. Downward Load Capacities

Load Load Design Criteria for: Direct-

ion Case Supporting

Beam/Ledger Supported

Beam

Down Dead load 16.2 kN Not critical

Live + Dead 22.8 kN Not critical

Wind down 31.4 kN Not critical

Up Wind up - Dead load

Withdrawal of fasteners

Shear at fixings

Notes: 1. The down direction loads are for:

(a) supporting member timber of JD5 joint group and SD6 strength group.

(b) Minimum supporting member size of 90x90 mm. 2. For JD4 and SD5 or higher joint/strength group

timber, these capacities can be increased by 25%. 3. For supporting member depths of less than 90 mm,

reduce design capacities in proportion to the depth divided by 90.

For joints on primary beams in structures other than houses, multiply these capacities by 0.75.

For bearing and uplift capacities of concrete or masonry walls, consult a structural engineer. Table D2 Supported Beam Bearing

Beam Strength Group Thickness Capacity Dry Timber

(mm) SD6 SD5 SD4 SD3 SD2 45 14.8 18.5 24.6 28.3 33.2 65 21.3 26.7 35.6 40.9 48.0 70 23.0 28.7 38.3 44.0 51.7 75 24.6 30.8 41.0 47.2 55.4 120 39.4 49.2 65.7 75.5 88.6 140 46.0 57.5 76.6 88.1 103.4 180 59.1 73.9 98.5 113.3 133.0

Notes: 1. For live loads, increase these capacities by 20% for

floors or 35% for roofs. 2. For green timber of equivalent strength group (eg: S6

for SD6), multiply the above bearing capacities by 0.5. 3. Minimum bearing length = 65 mm. Design Capacities: Wind Uplift For Beam Hangers for Beams (not the BBT Series for I-joists), capacities and fixings for wind uplift are as specified in the following tables: Table U1. Supported Beam Fastener Shear k1 = 1.3

Beam Fixing Strength Group Thick. Dry Timber (mm) JD5 JD4 JD3 JD2

45 2/M10x50 mm Coach screws

4.3 7.4 11.5 12.8

4/50x3.75 mm Nails 4.9 5.9 8.2 10.4 Total 9.4 13.3 19.7 23.2

65 Min. 2/M10x75 mm Coach screws

11.1 13.8 16.5 17.5

4/75x3.75 mm Nails 4.9 5.9 8.2 10.4 Total 16.0 19.7 24.7 27.9 Green Timber J4 J3 J2

45 2/M10x50 mm Coach screws

3.4 6.3 9.9

4/50x3.75 mm Nails 4.1 5.9 8.2 Total 7.5 12.2 18.1

65 Min. 2/M10x75 mm Coach screws

7.8 10.7 13.6

4/75x3.75 mm Nails 4.1 5.9 8.2 Total 11.9 16.5 21.8

Note: For use with design actions (loads) determined from AS/NZS1170:2002 , multiply the above capacities by 0.88.

PRYDA TIMBER CONNECTORS Hangers & Truss Boots Guide

PRYDA HANGERS & TRUSS BOOTS GUIDE –FEBRUARY 2007 6

Table U2. Supporting Beam Fastener Withdrawal Fixing: 2 coach screws & 2 nails

Green Timber Dry Timber Load Factor J4 J3 J2 JD5 JD4 JD3 JD2 k1 = 1.3 10.9 15.1 20.1 9.4 12.7 18.4 21.9

k1 = 1.14 9.6 13.2 17.6 8.2 11.1 16.1 19.2 Note: Select the design capacity in accordance with the factor

and, therefore, the code used for the design loads, ie: * 1.14 for AS/NZS1170:2002 * 1.3 for AS1170-1989 or AS1684-1999 Design Examples 1. An unseasoned Douglas fir (Oregon) main floor

beam supports 70 mm thick, dry radiata pine secondary floor beams. Both timbers are strength group SD6

Load Design Design Capacities (kN) Case Loads

kN Supporting

Beam Supported

Beam

Dead load 5.2 16.2 Table D1

23.0 Table D2

Live+ Dead 20.8 22.8 27.6

Wind+/-Dead

No uplift

2. A dry hardwood (JD3) ridge beam supports 65 mm

thick, dry pine (JD4, SD6) rafters.

Design Capacities (kN) Load Case

Design Loads

kN Supporting Beam

Supported Beam

Dead load 2.4 16.2x1.25 = 20.2

21.3

Live+ Dead 5.0 22.8x1.25 = 28.5

25.6

Wind +/-Dead load

9.0 uplift- based on AS1170-

1989

Table U1, JD4 = 19.7

Table U2, JD3 = 18.4

PRYDA TIMBER CONNECTORS Hangers & Truss Boots Guide

PRYDA HANGERS & TRUSS BOOTS GUIDE –FEBRUARY 2007 7

I-JOIST HANGERSTop mount and face mount hangers for timber I-joists

Features Pryda I-Joist Hangers have features as follows:

Ideally suited to support of modern timber I-Joists.

Use of full depth hangers provides torsional restraint to the I-joist.

Dimples ensure correct alignment of nails into bottom flange of the I-joist to prevent squeaking. There is provision for a screw through the hanger into the bottom of the bottom flange to further reduce squeaking.

Description LT and LF types hangers are specifically designed for use with proprietary I-Joists such as Hybeam®, SmartFrame I-joist and Hyne I-Beam. LT type are for top fixing and LF for face fixing. LFVS are variable slope and skew. LFSL and LFSR are 45o degree skewed, left and right respectively. LVSIA type is a variable skew angle. Specification Dimensions are tabulated on the next page. All hangers are manufactured from G250, Z275 galvanised steel in 1.2 mm thickness, except for:

LFSL/SR - 2.0 mm LF220/105, LF300/105, LT240/105 - 1.6 mm LT300/105, LT356/121 - 2.6 mm LVSIA - 5 mm

Packaging All products are packaged in quantities of 25 per carton except some of the largest hangers which are sold 15 per carton and LVSIA at 10 per carton. See the Price List for details. Details of the available range of Pryda I-Joist Hangers are tabulated in the following. ‘Double’ I-Joist Hangers are for support of two I-Joists, side by side or a single 90 or 120 mm wide I-Joist.

Bracket Types Pryda I-Joist Hanger types are illustrated below:

W B

H

D

W B

H

LF Type

Face Mount LT Type #1 Top Mount

LT Type #2 Top Mount

LFVS Type Variable Slope & Skew

LFSL/SRType

45o Skewed Hanger LVSIA Type

Variable Skew Angle Dimensions H, B and W are tabulated in the Dimension tables following. LT Type 2 applies for Hangers: LT240/52, LT300/52, LT356/60, LT302/65, LT356/65, LT356/70, LT240/70, LT302/70, LT240/90, LT245/90, LT300/90, LT356/90. LT Type 1 applies to all other LT hangers.

PRYDA TIMBER CONNECTORS Hangers & Truss Boots Guide

PRYDA HANGERS & TRUSS BOOTS GUIDE –FEBRUARY 2007 8

Dimensions Dimension symbols are shown on previous page (Bracket Types). Dimensions are as follows: Face Mount

Product H W B Face Joist Code Nail Nail/

Screws mm mm mm Holes Holes

LF190/50 190 50 50 8 1 LF235/50 235 51 50 10 1 LF297/50 297 50 50 12 1 LF235/65 235 65 50 10 1 LF340/60 340 60 50 14 1 LF290/65 290 65 50 12 1 LF340/65 340 65 50 14 1 LF190/70 190 70 50 8 1 LF235/70 235 70 50 10 1 LF290/70 290 70 50 12 1 LF350/70 350 70 50 14 1 LF190/90 190 90 50 8 1 LF235/90 235 90 50 10 1 LF290/90 290 90 50 12 1 LF350/90 350 90 50 14 2 LF220/105 220 105 50 10 2 LF300/105 300 105 50 20 2 LF235/120 230 120 50 10 2 LF290/130 290 130 50 12 2 LF190/140 190 140 50 10 2 LF235/180 220 180 50 10 2

Top Mount Product H W B D Face Joist Top Code Nail Nail/

Screw Nail

mm mm mm mm Holes Holes HolesLT300/47 300 47 50 40 2 1 6 LT200/50 200 50 50 40 2 1 6 LT240/50 241 50 50 40 2 1 6 LT240/52 240 54 50 52 2 1 6 LT300/52 302 54 50 52 2 1 6 LT240/65 240 65 50 40 2 1 6 LT356/60 356 60 60 52 2 1 6 LT360/60 360 60 50 40 2 1 6 LT302/65 302 65 60 52 2 1 6 LT360/65 360 65 50 52 2 1 6 LT200/70 200 71 50 40 2 1 6 LT240/70 240 70 50 52 2 1 6 LT245/70 245 77 50 40 2 1 6 LT302/70 302 71 50 52 2 1 6 LT360/70 360 71 50 52 2 1 6 LT240/90 241 90 50 60 2 1 6 LT245/90 245 90 50 60 2 1 6 LT300/90 302 90 50 63 2 1 6 LT360/90 360 90 50 65 2 1 6 LT400/90 400 90 50 40 2 1 6 LT240/105 240 105 50 52 6 2 6 LT300/105 302 106 50 52 8 2 6 LT356/121 356 121 50 52 8 2 6

Variable Slope & Skew, Face Mount

Product H W B Face Joist Code Nail Nail/

Screws mm mm mm Holes Holes

Variable Slope LF190/47VS 190 47 70 10 7 LF224/54VS 224 54 70 10 7 LF224/59VS 224 59 70 10 7 LF224/65VS 224 65 70 14 12 LF190/70VS 190 70 70 10 7 LF224/70VS 224 70 70 14 12 LF224/90VS 224 90 70 14 12

Variable Slope & Skew LF230/54SL 230 54 48 14 10 LF230/54SR 230 54 48 14 10 LF275/60SL 275 60 48 16 10 LF275/60SR 275 60 48 16 10 LF220/70SL 220 70 48 14 10 LF220/70SR 220 70 48 14 10 LF215/90SL 215 90 63 16 10 LF215/90SR 215 90 63 16 10

Notes: 1. LT & LF type I-joist Hangers are specifically designed for use with I

section floor joists such as Hybeam®, Smartframe Joist and Hyne I-beam.

2. LT hangers are top mount and LF are face mount. 3. LVSIA angles are 75x50x5 UA x 150 mm long. Installation - General To achieve the specified design loads, Pryda I-Joist Hangers must be correctly installed as specified in the following: 1. Refer to l-joist manufacturers’ instruction manuals for span

table selection and other details for on-site installation of their systems.

2. Use only galvanised Pryda Timber Connector Nails, Pryda product code OSNIB or OSNIB35. On 35 mm thick supporting members use 35x3.75 mm nails; on thicker members use 40x3.75 mm nails.

3. For screwing the joist to the hanger seat, use 30 x 6 gauge bugle-head or wafer-head wood screws.

4. All nail holes are to be filled with the specified nails in order to achieve hanger capacity.

PRYDA TIMBER CONNECTORS Hangers & Truss Boots Guide

PRYDA HANGERS & TRUSS BOOTS GUIDE –FEBRUARY 2007 9

Installation – Face Mount Hangers 3 mm maximumclearance

Minimum20 mm

I-joistweb

I-joistchord

30x6 gauge bugle-heador wafer-head wood screws

I-joistHanger

Installation Details Note: Use the recommended screw to seat the I-Joist into the hanger properly Installation – Top Mount Hangers

3 mm maximumclearance

Minimum 3 mm, max. 6 mm space

to eliminate contactbetween hanger and steel which

may cause squeaks

I-joistweb

I-joistchord

30x6 gauge bugle-heador wafer-head wood screws

I-joistHanger

Installation Details Notes: 1. The special nail must be used to avoid squeaks from nails

coming in contact with the hanger’s seat. 2. Use the recommended screw to seat the I-Joist into the hanger

properly.

Installation – Common Problems Poor or incorrect installation can lead to serious problems. Common problems are illustrated below: Note: See specified nail.

Nailplate is incorrect due to:1. Top plate is too thin, or2. Wrong length nail is usedTop nails

are missing

Top plateis too wide Incorrect

nailinstallation

If the top plate is too narrow it may cause:1. Hanger deformation2. Nail pull-out or shear3. Supported beam deformation

Joist is not seated properly into the hanger.This may cause nail pullout or shear under load.

Spreading hanger legs will push the joist upwhich may cause uneven floors, squeaky floors

and joist rotation Installation- Variable Skew Angles LVSIA variable skew angles are installed as shown in the following diagram, ie: 1. Notch the I-joist at ends to provide for fitting the LVSIA 2. Locate the angle with the 75 mm leg vertical and its mid-length

at the middle of the required end location of the I-joist. Fix the angle to the supporting beam, waling plate or ledger with 4@ 12g Type 17 screws. Screw length should be not less than that tabulated on the next page for the I-joist span and spacing.

3. Locate the I-joist on the angle and fix it up through the bottom of angle with 1@ 10g x 30 mm countersunk or bugle head screw.

4. Nail the I-joist top chord to the support with 2/75x3.05 mm nails.

Notch bottom chord of I-joists55x5 mm for flush finish

Fix I-joist to LVSIA Anglewith 1@10g x 30 mmType 17, Countersunk screw

I-joist/I-beamBeam or Waling Plate 40 mm min.

thickness

Notch end of I-joist80x10 mm approx.

for LVSIA Angle

Fix LVSIA Angle tosupporting beam or

waling plate with4@ 12g x35 mm

Type 17hex. head, self-drilling screws

Pryda LVSIA Angle75x50x5 UA

x 150 mm long

Fix top chord to supportwith 2/75x3.05 mm nails

LVSIA Installation Detail

PRYDA TIMBER CONNECTORS Hangers & Truss Boots Guide

PRYDA HANGERS & TRUSS BOOTS GUIDE –FEBRUARY 2007 10

Installation – Hanger Size Selection The recommended size of Pryda I-Joist Hangers for support of proprietary I-joists in house floors is as follows:

I-joist Code

I-joist Size (mm)

Face Mount Hanger Code

Top Mount Hanger Code

Variable Slope &

Skew Rafter Hanger Code

Variable Skew

Hanger Left

Code

Variable Skew

Hanger Right Code

Double I-joist

Hanger Code

Face Mount

Double I-joist

Hanger Code

Top Mount Futurebuild Hybeam

HJ200-45 200x45 LF190/50 LT200/50 LF190/47VS* LVSIA LVSIA JH100* NA

HJ240-45 240x45 LF235/50 LT240/50 LF190/47VS* LVSIA LVSIA JH100* NA HJ240-63 240x63 LF235/65 LT240/65 LF224/70VS* LF220/70SL* LF220/70SR* LF190/140* NA HJ240-90 240x90 LF235/90 LT240/90 LF224/90VS* LF215/90SL* LF215/90SR* LF235/180 NA HJ300-45 300x45 LF297/50 LT300/47 LF190/47VS* LF230/54SL* LF230/54SR* LF220/105* NA HJ300-63 300x63 LF290/65 LT302/65 LF224/65VS* LF220/70SL* LF220/70SR* LF290/130 NA HJ300-90 300x90 LF290/90 LT300/90 LF224/90VS* LF215/90SL* LF215/90SR* LF235/180* BBT180300

HJ360-63 360x63 LF340/65 LT360/65 LF224/65VS* LF220/70SL* LF220/70SR* LF290/130* NA

HJ360-90 360x90 LF350/90 LT360/90 LF224/90VS* LF215/90SL* LF215/90SR* LF235/180* BBT180360

HJ400-90 400x90 LF350/90 LT400/90 LF224/90VS* LF215/90SL* LF215/90SR* LF235/180* NA

Hyne I-Beam HI20070 200x70 LF190/70 LT200/70 LF190/70VS* LVSIA LVSIA LF190/140 BBT140200

HI24570 245x70 LF235/70 LT245/70 LF224/70VS* LF220/70SL* LF220/70SR* LF190/140* NA

HI30070 300x70 LF290/70 LT302/70 LF224/70VS* LF220/70SL* LF220/70SR* LF190/140* NA HI36070 360x70 LF350/70 LT360/70 LF224/70VS* LF220/70SL* LF220/70SR* LF190/140* NA HI24088 244x88 LF235/90 LT245/90 LF224/90VS* LF215/90SL* LF215/90SR* LF235/180 BBT180240

HI30088 300x88 LF290/90 LT300/90 LF224/90VS* LF215/90SL* LF215/90SR* LF235/180* BBT180300

Tillings SmartFrame Joist SJ20044 200x44 LF190/50 LT200/50 LF190/47VS* LVSIA LVSIA LF190/90 NA

SJ24051 240x51 LF235/50 LT240/52 LF224/54VS* LF230/54SL* LF230/54SR* LF220/105 LT240/105

SJ30051 300x50 LF297/50 LT300/52 LF224/54VS* LF230/54SL* LF230/54SR* LF220/105* LT300/105

SJ36058 360x58 LF340/60 LT356/60 LF224/59VS* LF275/60SL* LF275/60SR* LF235/120* LT356/121

SJ20068 200x68 LF190/70 LT200/70 LF190/70VS* LVSIA LVSIA LF190/140 BBT140200

SJ24068 240x68 LF235/70 LT240/70 LF224/70VS* LF220/70SL* LF220/70SR* LF190/140* NA

SJ24088 240x88 LF235/90 LT240/90 LF224/90VS* LF215/90SL* LF215/90SR* LF235/180 BBT180240

SJ30088 300x88 LF290/90 LT300/90 LF224/90VS* LF215/90SL* LF215/90SR* LF235/180* BBT180300

SJ36088 360x88 LF350/90 LT360/90* LF224/90VS* LF215/90SL* LF215/90SR* LF235/180* BBT180360

SJ40088 400x88 LF350/90* LT400/90 LF224/90VS* LF215/90SL* LF215/90SR* LF235/180* BBT180400

Notes: 1. For hangers marked *, web stiffeners must be installed in accordance with the I-joist manufacturers’ specification. 2. JH100 are Heavy Duty Joist Hangers. 3. BBT hangers are Beam Hangers.

PRYDA TIMBER CONNECTORS Hangers & Truss Boots Guide

PRYDA HANGERS & TRUSS BOOTS GUIDE –FEBRUARY 2007 11

Design Capacities Tabulated below are design capacities for Pryda I-joist Hangers fixed with the number of nails tabulated. “Face nails” are driven into the face of the supporting beam, “Top nails” into the top of the supporting beams and “Joist nails” into the carried member. General Notes 1. For uses in other than houses, reduce these capacities

by: - commercial/ industrial buildings- 6%, - essential services buildings - 12%.

2. Use only Pryda 40x3.75mm or 35x3.75 mm galvanisedPryda Timber Connector Nails, or equivalent.

3. “Dead” is dead load plus any portion of live loadconsidered to be permanent.

Face Mounted Hangers With a minimum of eight face nails, these hangers can carry the design residential floor loads of (1.5 kPa live) for joists up to 5.9 m span at 600 mm spacing or 7.9 m span at 450 mm spacing, provided that the timber in supporting beams has a joint group of JD4 or better. For other design cases, use the Pryda Connection Designer program.

Hanger Codes Face Nails

Dead + Floor Live Design Capacity, ФNj (kN), for

Supporting Beam with Joint Group: J4 J3 JD5 JD4 JD3

LF190/50 ../90 8 4.4 6.2 5.2 6.2 8.7 LF235/50.. /60../70../90

10 5.5 7.8 6.4 7.8 10.9

LF290/50, /65, /70, /90, /130

LF230/130, LF220/180

12 6.6 9.3 7.7 9.3 13.1

LF340/60, LF350/70, LF350/90

14 7.7 10.9 9.0 10.9 14.2

Note: Where these hangers are fixed to a 35 mm thick supporting member, use the 35x3.75 mm nails and multiply design capacities by 0.88. Top Mounted Hangers The design capacities of top mounted brackets is greater than that required to support the applied residential floor loads (1.5 kPa live) for the I-joist products listed in this file.

Hanger Code

Top Nails Dead + Floor Live Design Capacity, ФNj (kN), for Supporting Beam

with Joint Group: JD5 JD4 JD3

All LT series 6 5.2 5.7 6.1

Note: 4 nail fixing may be used at reduced capacities of 4.3 (JD5), 4.7 (JD4), 5.1 (JD3).

Variable Slope & Skew Hangers Typically used to support I-joists used as roof rafters.

Hanger Code Face Nails

Joist Nails

Design Capacity, ФNj (kN), for Supporting Beam with JD5 or Higher Joint Group for Load

Case: Dead Load

Only Dead +

Roof LiveWind Uplift

LF190/47VS, LF190/70VS LF224/54VS, LF224/59VS

10 7 2.8 4.6 3.2

LF224/65VS, LF224/70VS, LF224/90VS

14 12 4.0 6.4 4.5

Note: Where these hangers are fixed to a 35 mm thick supporting member, use the 35x3.75 mm nails and multiply design capacities by 0.88. Skewed Hangers Typically used to support I-joists used in floors at 45o to the supporting beam.

Hanger Code Face Nails

Joist Nails

Design Capacity, ФNj (kN), for Supporting Beam with JD5 or

Higher Joint Group for Load Case: Dead + Floor Live

LF220/70SL/RLF230/54SL/R

14 10 4.7

LF215/90SL/RLF275/60SL/R

16 10 5.4

Note: Where these hangers are fixed to a 35 mm thick supporting member, use the 35x3.75 mm nails and multiply design capacities by 0.88. Variable Skew Angles Used to support I-joists at an angle other than 90o to the support, LVSIA design capacities are:

Fixing into Supporting

Beam, Waling Plate or

Screw Length Dead + Floor Live Design Capacity,

ФNj (kN), for Supporting Beam with Joint Group:

Ledger (mm) J4 J3 JD5 JD4 JD3

4/12g Type 17 screws

35 3.9 5.5 3.9 5.5 7.8

Note: For uses in other than houses, reduce these capacities by: commercial/ industrial buildings- 6%, essential services buildings - 12%. Minimum Screw Length For Span & Spacing For Houses, Support Member Joint Group = JD4 minimum, With or Without Ceiling Attached, Single Span I-joists

Spacing Min. Screw Length (mm) for Span (m) (mm) 6.0 6.5 7.0 7.5 8.0 8.5 9.0 300 35 35 35 35 35 35 35 400 35 35 35 35 35 35 35 450 35 35 35 35 35 35 40 600 35 35 40 40 45 45 NS

Note: For continuous span I-joists, increase spans above by 33%.

PRYDA TIMBER CONNECTORS Hangers & Truss Boots Guide

PRYDA HANGERS & TRUSS BOOTS GUIDE –FEBRUARY 2007 12

JOIST HANGERS Brackets for Beam to Beam or Beam to Brickwork/Concrete Connections

Joist Hanger for Pergola

Rafter to Beam Joint

Heavy Duty Joist Hanger for Large Sizes, Heavy Loads

General Description Pryda Joist Hangers, Split Joist Hangers and Heavy Duty Joist Hangers have been preferred and used in Australia and overseas for more than 20 years. They are strong, easy to install, cost effective, well designed connectors for many timber beam to beam joints. The wide range of these brackets provides for all common timber sizes and for glued laminated timber beams. These brackets have been designed to achieve high design loads at low cost through incorporating Pryda’s extensive design expertise and taking account of the results of laboratory testing at Monash University in Melbourne. Advantages In addition to being well designed and laboratory tested, Pryda Joist Hangers are: cost effective, eliminating the need for costly on-site skilled labour to make special housing for joints etc.

easily fixed into position with Pryda Timber Connector Nails, M12 bolts or self drilling screws. These hangers have wide flanges for ease of nailing.

Hanger Size Selection To establish a suitable Joist Hanger size, determine: 1. The joint group of the timber to be jointed.

Joint groups are specified in AS1720.1 SAA Timber Structures Code and in Pryda Timber Data. Groups for some timbers commonly used in Australia are:

Timbers Joint Group Dry GreenNorth American Oregon, western Hemlock JD4 J4 Heart-excluded Radiata pine and other softwoods JD4 J4 Pine as above – heart-in JD5 Slash pine JD3 J3 Ash type hardwoods from Victoria, NSW highlands and Tasmania

JD3 J3

Non-Ash type hardwoods from Queensland and NSW JD2 J2 Note: The moisture content of “dry” timber must not exceed 15%. Where beams of different joint groups are to be joined together, apply the lower group to both.

2. Loads to be supported. Applied loads are to be calculated in accordance with appropriate standards. Pryda Roof, Pryda Floor and Pryda Frame software output reaction loads which can be used for support bracket selection.

3. Thickness of beam, truss or joist to be supported and supporting beam thickness. When using JH code hangers (rather than JHS), the hanger’s bearing thickness must be up to 4 mm greater than that of the supported beam.

4. Fixing method: nails or bolts 5. Hanger size from the design load tables in this file based on the

above data.

PRYDA TIMBER CONNECTORS Hangers & Truss Boots Guide

PRYDA HANGERS & TRUSS BOOTS GUIDE –FEBRUARY 2007 13

Description This section covers properties of Pryda Joist Hangers, formerly known as Framing Brackets.

Features Pryda Joist Hangers are suitable for many joints including: - joist to beam - floor truss to beam - jack to TG truss - pergola rafters to fascia - ceiling joist to hanger - beams to masonry Installation Suitable Fasteners are: * Nails: Use only 35 x 3.15 mm, galvanised Pryda

Timber Connector Nails or Senco 50x2.87 mm hardened, roll threaded gun nails (Code: WGF21AZA) driven through the metal- not into the holes

* Bolts: M12 or ½ inch bolts with a nut and a 50x50x3.0 mm square or 55 mm dia.x3.0 mm round washer installed on the supporting beam on the face opposite to the hanger only.

See the Design Capacities table on the following page for the maximum number of nails, bolts or screws for each Joist Hanger. Specification Sizes: As shown above Steel: Zincform G300-Z275, thickness is 1.0 mm for all Hangers except FB38220 and FB50220 – 1.2 mm. Packing Joist Hangers are supplied in cartons as follows:

Product Codes Carton Number

FB: 3860*, 5060*, 3590*, 3890*, 4590*, 5090*, 35120*, 38120*, 45120*, 50120*

45

FB: 35140*, 38140*, 45140*, 50140* 40

FB: 38180, 45180*, 50180* 30

FB: 60130, 65170, 70200, 90200, 72163, 94152 25

FB: 38220, 45220, 50220* 15

Note: * Means also available as an individually barcoded Merchant Pack.

Dimensions

Supporting beam A

Install washeron all bolts on the back surface

Depth ofHanger

Pryda JoistHanger

Thickness

Supported beam B

Bearing:75 mm - most hangers60 mm - FB60130, FB65170 - FB72163, FB94152

Beam Athickness

Code Thick- ness

Depth Code Thick- ness

Depth

FB3860 38 61 FB3590 35 94

FB3890 38 92 FB35120 35 118

FB38120 38 114 FB35140 35 141

FB38140 38 140 FB35180 35 184

FB38180 38 182 FB4590 45 89

FB38220 38 222 FB45120 45 113

FB5060 50 55 FB45140 45 136

FB5090 50 86 FB45180 45 179

FB50120 50 110 FB45220 45 219

FB50140 50 134 FB70200 70 195

FB50180 50 176 FB90200 90 195

FB50220 50 216 FB72163 72 163

FB60130 60 120 FB94152 94 152

FB65170 65 167

Note: FB70200, FB72163, FB90200 and FB94152 are suited to support of Pryda Longreach or Pryda Span floor trusses. Hanger Selection Select the Joist Hanger as follows: * Thickness: equal to or up to 4 mm more than the

supported beam or I-joist thickness * Depth: - not more than beam, truss or I-joist depth

- for beams of up to 50 mm thickness: not less than 60% of beam depth

- for I-joists or floor trusses, sufficient to cover 10 mm of top chord depth minimum

* Design Capacity: as tabulated on the next page or as computed by the Pryda Connector Selector program

PRYDA TIMBER CONNECTORS Hangers & Truss Boots Guide

PRYDA HANGERS & TRUSS BOOTS GUIDE –FEBRUARY 2007 14

Design Capacities per Joist Hanger Hanger Code Floor Live + Dead Load Wind Uplift - Dead Load

Fixing to Beam

A*

Beam A or Truss Thick. Design Capacity φNj (kN) for

Joint Group:

Fixing to

Beam B*

Wind Load Durn. Factor

Design Capacity φNj (kN) for Joint Group:

mm J4 J3 JD5 JD4 JD3 mm J4 J3 JD5 JD4 JD3

FB3860, FB5060 6 Nails 35 min. 2.4 3.4 2.9 3.4 4.8 3 nails k1 = 1.3 2.3 2.9 2.9 2.9 2.9 k1 = 1.14 2.0 2.9 2.9 2.9 2.9

FB3590, FB3890 10 Nails 35 min. 3.6 5.1 4.5 5.4 7.5 5 nails k1 = 1.3 3.4 4.8 4.2 4.8 4.8 FB4590, FB5090 2 Bolts 35 3.1 4.8 3.9 5.4 6.5 k1 = 1.14 3.0 4.8 3.7 4.4 4.8 45 4.0 6.1 5.0 6.5 6.5

FB35120, FB38120 12 Nails 35 min 4.3 6.0 5.3 6.4 8.9 6 nails k1 = 1.3 4.0 5.7 5.0 5.8 5.8 FB45120, FB50120 2 Bolts 35 3.1 4.8 3.9 5.4 6.5 k1 = 1.14 3.5 5.0 4.4 5.2 5.8 45 4.0 6.1 5.0 6.5 6.5

FB35140, FB38140 16 Nails 35 min 5.4 7.7 7.0 8.4 11.8 8 nails k1 = 1.3 5.1 7.2 6.6 7.7 7.7 FB45140, FB50140 2 Bolts 35 3.1 4.8 3.9 5.4 6.5 k1 = 1.14 4.5 6.3 5.8 6.9 7.7 45 4.0 6.1 5.0 6.5 6.5

FB35180, FB38180, 20 Nails 35 min 6.5 9.1 8.6 10.3 14.4 10 nails k1 = 1.3 6.1 8.6 8.1 9.6 9.6 FB45180, FB50180 4 Bolts 35 6.2 9.6 7.8 10.9 13.0 k1 = 1.14 5.3 7.5 7.1 8.5 9.6 45 9.0 14.0 11.4 13.0 13.0

FB38220 26 Nails 35 min 8.3 11.6 11.0 13.1 18.4 13 nails k1 = 1.3 7.8 11.0 10.4 12.4 15.0 FB50220 4 Bolts 35 6.2 9.6 7.8 10.9 13.0 k1 = 1.14 6.8 9.6 9.1 10.8 15.0 FB45220 45 7.9 12.3 10.1 13.0 13.0

FB60130 12 Nails 35 min 4.3 6.0 5.3 6.4 8.9 6 nails k1 = 1.3 2.5 3.6 3.1 3.8 5.2 2 Bolts 35 3.1 4.8 3.9 5.4 6.5 k1 = 1.14 2.2 3.2 2.7 3.3 4.6 45 4.0 6.1 5.0 6.5 6.5 10 nails k1 = 1.3 3.8 5.4 5.1 6.1 8.4 70 5.2 6.5 6.5 6.5 6.5 k1 = 1.14 3.3 4.7 4.5 5.3 7.4

FB65170 18 Nails 35 min 6.0 8.4 7.8 9.3 13.1 6 nails k1 = 1.3 2.5 3.6 3.1 3.8 5.2 4 Bolts 35 6.2 9.6 7.8 10.9 13.0 k1 = 1.14 2.2 3.2 2.7 3.3 4.6 45 7.9 12.3 10.1 13.0 13.0 10 nails k1 = 1.3 3.8 5.4 5.1 6.1 8.4 70 10.4 13.0 13.0 13.0 13.0 k1 = 1.14 3.3 4.7 4.5 5.3 7.4

FB70200 20 Nails 35 6.4 9.2 8.6 10.2 14.4 3 nails k1 = 1.3 2.3 2.9 2.9 2.9 2.9 4 Bolts 35 6.2 9.6 7.8 10.9 13.0 k1 = 1.14 2.0 2.9 2.9 2.9 2.9 45 7.9 12.3 10.1 13.0 13.0 10 nails k1 = 1.3 6.1 8.6 8.1 9.6 9.6 70 10.4 13.0 13.0 13.0 13.0 k1 = 1.14 5.3 7.5 7.1 8.5 9.6

FB72163 18 Nails 35 6.0 8.4 7.8 9.4 13.0 3 nails k1 = 1.3 2.3 2.9 2.9 2.9 2.9 4 Bolts 35 6.2 9.6 7.8 10.9 13.0 k1 = 1.14 2.0 2.9 2.9 2.9 2.9 45 7.9 12.3 10.1 13.0 13.0 10 nails k1 = 1.3 6.1 8.6 8.1 9.6 9.6 70 10.4 13.0 13.0 13.0 13.0 k1 = 1.14 5.3 7.5 7.1 8.5 9.6 FB90200 22 Nails 35 7.1 10.0 9.4 11.2 15.7 3 nails k1 = 1.3 2.3 2.9 2.9 2.9 2.9 4 Bolts 35 6.2 9.6 7.8 10.9 13.0 k1 = 1.14 2.0 2.9 2.9 2.9 2.9 45 7.9 12.3 10.1 13.0 13.0 11 nails k1 = 1.3 6.7 9.4 8.9 10.6 10.6 70 10.4 13.0 13.0 13.0 13.0 k1 = 1.14 5.9 8.2 7.8 9.3 10.6 FB94152 18 Nails 35 6.0 8.4 7.8 9.3 13.1 3 nails k1 = 1.3 2.3 2.9 2.9 2.9 2.9 4 Bolts 35 6.2 9.6 7.8 10.9 13.0 k1 = 1.14 2.0 2.9 2.9 2.9 2.9 45 7.9 12.3 10.1 13.0 13.0 9 nails k1 = 1.3 6.0 8.3 5.8 6.9 8.7 70 10.4 13.0 13.0 13.0 13.0 k1 = 1.14 5.3 7.3 5.1 6.1 8.5

Notes: 1. Beam A = Supporting, Beam B = Supported 2. Select wind uplift capacity according to the factor and, therefore,

the code used for the design loads/actions, ie: * 1.14 for AS/NZS1170:2002, * 1.3 for AS1170-1989 or AS1684-1999 3. Where both bolts and nails are used together, dead or live load

capacity = nails capacity + bolt(s) capacity, maximum: FB70200, FB90200 - 22.6 kN, all other brackets-26.9 kN.

4. These capacities apply directly for joints in houses and on secondary beams in other structures. For joints on primary beams in structures other than houses, multiply the capacity by 0.88.

5. For FB60130 and FB65170 brackets, wind uplift – dead load values have been reduced due to a shorter end distance on the supported beam compared to the other brackets.

6. For FB70200 to FB94152, the wind uplift 3 Nails fixing option allows for fixing to the chords only of I-beams or trusses.

PRYDA TIMBER CONNECTORS Hangers & Truss Boots Guide

PRYDA HANGERS & TRUSS BOOTS GUIDE –FEBRUARY 2007 15

JOIST HANGERS – HEAVY DUTY Heavy Duty Hanger for Large Sizes, Heavy Loads

JH… Hanger

Features Pryda Heavy Duty Joist Hangers are:

designed to support large size timber beams and columns manufactured from heavy duty (2 mm) steel.

Specification Steel: 2.0 mm Zincform® G300-Z275 Packing per carton

10

Sizes: As below:

6550

125

177

JH65 JH75 JH100

187

125

5075

50100

140

213

Design Capacities - per Heavy Duty Hanger:

Load Case

Wind Load

Design Capacities (ΦNj) (kN) for Joint Group:

Factor J4 J3 J2 JD5 JD4 JD3

JH65, JH75 with 26 Nails into Supported and Supporting Beams Dead load 6.8 9.6 13.4 9.0 10.8 15.0 Floor live + dead 8.2 11.6 16.2 11.0 13.0 18.2 Roof live + dead 9.2 13.0 18.0 12.2 14.6 20.4 Wind load +/- dead k1 = 1.3 15.4 21.8 30.6 20.6 24.6 34.4 Wind load +/- dead k1 = 1.14 13.5 19.1 26.8 18.1 21.6 30.2JH100 with 32 Nails into Supported and Supporting Beams Dead load 8.2 11.6 16.2 11.0 13.2 18.4 Floor live + dead 11.0 14.0 19.6 13.2 15.8 22.2 Roof live + dead 11.2 15.6 22.0 14.8 17.8 24.8 Wind load +/- dead k1 = 1.3 18.4 26.4 37.0 25.2 30.0 41.8 Wind load +/- dead k1 = 1.14 16.1 23.2 32.4 22.1 26.3 36.7Notes: 1. For JH hangers, ‘Fixing means’ is the number of nails into the

supporting beam for dead and live loads, and the number of nails into the supported beam for wind uplift load.

2. Re: Load Case: “Floor live”, “Roof live” and “Wind load” mean “…plus or minus dead load.

3. Design capacities apply directly for joints in houses and on secondary beams in other structures. For joints on primary beams in structures other than houses, multiply these capacities by 0.75.

4. Select the design capacity in accordance with the factor and, therefore, the code used for the design loads, ie:

* 1.14 for AS/NZS1170:2002 * 1.3 for AS1170-1989 or AS1684-1999

Installation Correct installation of Pryda Heavy Duty Joist Hangers is essential to achieve the design capacities. Use only 35x3.15 mm galvanised Pryda Timber Connector Nails or 50x2.87 mm Hardened, Coated, Screwshank Nails. Do not nail within 20 mm of the ends of the timber beams. SPLIT JOIST HANGERS Features Pryda Split Joist Hangers are:

suitable for any practical thickness of timber beam. manufactured from heavy duty (2 mm) steel

Specification Steel: 2.0 mm Zincform® G300-Z275 Packing per carton

Supplied in cartons of 10, ie. 5 right hand and 5 left hand.

Code & Size: Product code is JHS. Size is as below Dimensions

For full capacity, 16Timber ConnectorNails per hangerinto supportingbeam

For full capacity, 16Timber Connector Nails per hangerinto supported beamat min. 20 mm from beam end

230

70

55

7015

20 mm min.end distance

for nails

Installation Use only 35 x 3.15 mm galvanised Pryda Timber Connector Nails or 50x2.87 mm hardened, roll threaded machine nails (Code: WGF21AZA) driven though the metal, not through the holes, to fix these connectors. Do not nail within 20 mm of the ends of the timber beams. For each hanger, drive 16 nails into the supporting beam and 16 nails into the supported beam. Design Capacities Limit State Design capacities for two Pryda Split Joist Hangers in houses are:

Load Case Design Capacity φNj (kN) for Timber Joint Group:

J4 J3 J2 JD5 JD4 JD3

Dead Load 8.2 11.6 16.3 11.0 13.1 18.4

Floor live+ dead 10.0 14.0 19.7 13.3 15.9 22.2

Roof live + dead 11.1 15.7 22.6 14.9 17.8 24.8

Wind up- dead k1 = 1.3 9.4 13.2 18.5 10.5 15.0 20.9

Wind up- dead k1 = 1.14 8.2 11.6 16.2 9.2 13.2 18.3

Notes: 1. The above capacities apply where all of the nails specified above in Installation have been driven through each bracket at not less than 20 mm from the end of the beams.

2. Select the wind load design capacity in accordance with the factor and, therefore, the code used for the design loads, ie:

* 1.14 for AS/NZS1170:2002 * 1.3 for AS1170-1989 or AS1684-1999

PRYDA TIMBER CONNECTORS Hangers & Truss Boots Guide

PRYDA HANGERS & TRUSS BOOTS GUIDE –FEBRUARY 2007 16

TRUSS BOOTS- MULTI-FIX- Bolt Fix Option Metal brackets for timber construction

Truss Boot

Application & Features Pryda Multi-Fix Truss Boots comprise: Joist Boots –used for: * End support of joists and beams * Support of lightly loaded trusses from girder trusses

Truss Boots – used for support of standard trusses. The Bolt Fix option (fixing with bolts, nuts and washers, plus nails) provides higher design capacities than Screw-Fix (see page 18). Specification

Type Product Code

Timber Thick.

Bolt Diam.

Application- Support of:

Joist TBS35 35 12 Small components

Boot TBJ35 35 12 eg: at hip ends

TBJ35/T 35 12 Lightly loaded

TBJ45 45 12 trusses

TBJ70 70 12

Truss TB35/12 35 12 Standard

Boot TB35/16 35 16 trusses

TB45/16 45 16

Note: The TBJ35/T has a tongue to tie the supported truss to the girder. Steel TBS – 1.2 mm G300 –Z275 Galvanised

TBJ & TB – 1.6 mm G300 –Z275 Galvanised

Packing 10 per carton

Size See dimensions following

Dimensions Dimensions of Pryda Joist Boots and Truss Boots are:

38/4855

95

7517

38/4855

95

7550

17

TBS35 TBJ35, TBJ35/T, TBJ45

38/4855

95

17 75

115

73

90

969

53

TB35, TB45 TBJ70 Installation Fix Pryda Multi-Fix Truss Boots with bolts and nails as tabulated below:

Boot Type To Girder To Suppd. Truss

TB35/45 2 M12 Bolts, 4 Nails 4 Nails

TBJ35/45, TBJ70 TB35/12

2 M12 Bolts, 8 Nails 1 M12 Bolt, 8 nails

TB35/16, TB45/16 2 M16 Bolts, 8 Nails 2 M12 Bolts, 12 nails

Notes: 1. Bolts are to be M12 or ½ inch diameter with nuts and 55 mm

diameter or 50x50 mm square by 3 mm thick washers, or M16 or 5/8 inch diameter with nuts and 65 mm diameter or 57x57 mm square by 4 mm thick washers. See Pryda Bolt Kits

2. Nails are 35x3.15 mm galvanised Pryda Timber Connector Nails

3. Where the roof is subject to little or no wind uplift, nails alone can be used to fix the supported truss- see Design Capacities next page or the Pryda Connection Designer program.

Pryda Multi-Fix Truss Boots and supported members are to be installed as follows: 1. Fit the Boot flush with the bottom of the girder bottom chord

and hammer nails into all nail holes. Drill the bolt hole and fit the bolt with the nut and washer on the face opposite to the boot.

2. Sit the incoming member into the boot and nail it in place. The clearance between the end of the incoming member and the face of the girder truss chord should not exceed 5 mm, preferably 0 mm. Drill the bolt hole (TBJ and TB types only) and fit the bolt(s) and nut(s).

Install Anti-split Claw nailplates on the girder truss chord on both faces and both sides of the Boot, ie: 4 nailplates of:

Chord width (mm) 90 120,140 170,190 Anti-split Plate Size 3C2 4C2 6C2

PRYDA TIMBER CONNECTORS Hangers & Truss Boots Guide

PRYDA HANGERS & TRUSS BOOTS GUIDE –FEBRUARY 2007 17

Anti-split nailplateson both faces of girder and both sides of boot Truss Boot

Supported truss

35x3.15 mm PrydaTimber Connector nails

4 each side

M12 or M16 boltsas required to meetdesign load

Installation Detail 1 Supported truss

M12 or M16 boltsas required to meetdesign load

35x3.15 mm PrydaProduct nails

Truss Boot

Round or square washer of size required for bolt

size (see Installation)

Installation Detail 2

Design Capacities – Bolt Fix Option The tabulated Limit State Design capacities apply directly to Pryda Truss Boot joints in houses or on secondary trusses or beams in other structures. For joints on primary trusses or beams in structures other than houses, multiply these capacities by 0.75. Girder timber thicknesses are minimums. Supported truss thicknesses are minimums for bolt capacity and maximums (3 mm tolerance for two nailplates) for fitting the timber into the boot. 70 and 90 mm thickness can be made from 2@ 35 mm and 2@ 45 mm respectively, nail or bolt laminated together as specified by the truss designer. Select the wind load design capacity in accordance with the factor and, therefore, the code used for the design loads, ie: * 1.14 for AS/NZS1170:2002 * 1.3 for AS1170-1989 or AS1684-1999 For joint groups other than those in the following tables, the following factors give a capacity which may be conservative. Maximum capacity is 30 kN. Compared Factor for Joint Group:

To: J4 J3 JD5 JD3 JD2 J2 0.40 0.63

JD4 0.72 1.17 1.32 Accurate design capacities for any joint group or structure and member type are given by the Pryda Connection Designer software, included in Pryda Frame, see Main Menu > Extras > Connection Designer.

Design Capacities Girder Truss

Boot Fixing Load Design Capacity ΦNj (kN) - Joint Group: Code Bolts Case J2 JD4

& Nails Minimum Girder Thickness (mm) 35 45 70 35 45 70

Dead 6.3 7.5 7.5 4.5 5.8 7.6 Live + dead 8.5 10.1 10.1 6.1 7.8 10.2

2@ M12bolts only Wind +/- dead 14.3 17.0 17.0 10.2 13.2 17.2

Dead 8.5 9.7 9.7 6.1 7.3 9.1 Live + dead 11.5 13.1 13.1 8.2 9.9 12.3

TBS35 TBJ70 2@ M12

bolts + 4 nails Wind +/- dead 19.3 22.0 22.0 13.8 16.7 20.8

Dead 6.3 7.5 7.5 4.5 5.8 7.5 Live + dead 8.5 10.1 10.1 6.1 7.8 10.2

2@ M12bolts only Wind +/- dead 14.3 17.0 17.0 10.2 13.2 17.2

Dead 10.0 11.2 11.2 7.4 8.7 10.4 Live + dead 13.5 15.1 15.1 10.0 11.7 14.1

TBJ35 TBJ35/TTBJ45

TB35/122@ M12

bolts + 8 nails Wind +/- dead 22.8 25.5 25.5 16.8 19.8 23.8

Dead 8.4 10.8 11.5 6.0 7.7 11.6 Live + dead 11.3 14.6 15.5 8.1 10.4 15.7

2@ M16bolts only Wind +/- dead 19.1 24.6 26.2 13.7 17.6 26.5

Dead 12.1 14.5 15.2 8.9 10.6 14.5 Live + dead 16.3 19.5 20.5 12.0 14.3 19.6

TB35/16TB45/16 2@ M16

bolts + 8 nails Wind +/- dead 27.5 30.0 30.0 20.2 24.1 30.0

Note: Where loads are based on AS/NZS1170:2002, the wind load capacities above must be divided by 1.14. Supported Truss, Beam or Joist

Boot Thick- Fixing Des.Cap. ΦNj (kN) Code ness Bolts &/or Wind Uplift - Dead

Nails k1 = 1.3 k1 = 1.14 (mm) J2 JD4 J2 JD4

TBS35 35 4 nails 1.3 0.9 1.2 0.8 TBJ35 35 8 nails 3.9 3.1 3.4 2.7

TBJ35/T 1@ M12 bolt 7.2 5.1 6.3 4.5 1@ M12 bolt+ 8 nails 13.6 10.2 11.9 8.9

TBJ45 45 8 nails 3.9 3.1 3.4 2.7 1@ M12 bolt 8.5 6.6 7.2 5.8 1@ M12 bolt + 8 nails 15.0 11.6 13.2 10.2

TBJ70 70 8 nails 3.9 3.1 3.4 2.7 1@ M12 bolt 8.5 8.6 7.5 7.5 1@ M12 bolt + 8 nails 15.0 13.7 13.2 12.0

TB35/12 35 12 nails 4.8 5.4 4.2 4.7 TB35/16 2@ M12 bolts 14.4 10.2 12.6 9.0

2@ M12 bolts+ 12 nails 26.2 19.8 23.0 17.4 TB45/16 45 12 nails 4.8 5.4 4.2 4.7

2@ M12 bolts 16.4 13.2 14.4 11.6 2@ M12 bolts+ 12 nails 30.0 22.7 26.3 19.9

Notes: 1. The above supported truss capacities take into account the much greater

flexibility (rotation under load) of nails only joints compared to the stiffer bolted or bolted and nailed joints.

2. For wind uplift, take the lower of the capacities for the supported truss and girder, ie: look up both tables above.

PRYDA TIMBER CONNECTORS Hangers & Truss Boots Guide

PRYDA HANGERS & TRUSS BOOTS GUIDE –FEBRUARY 2007 18

TRUSS BOOTS - MULTI-FIX- Screw Fix Option Metal brackets for timber construction

Truss Boot - Screw Fixed

Application & Features Pryda Multi-Fix Truss Boots comprise: Joist Boots -used for:

* End support of joists and beams * Support of lightly loaded trusses from girder trusses Truss Boots - used for support of standard trusses.

The Screw Fix option (fixing with screws only or nails only into supported member) avoids the need for anti-split plates and washers on bolts. Design capacities are somewhat lower than for Bolt Fix (see page 16). Pryda Truss Boots are designed to support trusses and other components 35-38mm or 45-48mm thick, carried by girders which are at least 35 mm thick. When the girder has multiple laminates, the same screws may be used but the plies must be nail or bolt laminated together as specified on the next page. Specification

Type Product Code

Timber Thick.

Application- Support of

Joist TBS35 35 Small components

Boot TBJ35 35 eg: at hip ends

TBJ35/T 35 Lightly loaded

TBJ45 45 trusses

TBJ70 70

Truss TB35/12 35 Standard

Boot TB35/16 35 trusses

TB45/16 45

Steel TBS - 1.2 mm G300 -Z275 Galvanised TBJ & TB - 1.6 mm G300 -Z275 Galvanised

Packing 10 per carton

Dimensions Dimensions of Pryda Joist Boots and Truss Boots are:

38/4855

95

7517

38/4855

95

7550

17

TBS35 TBJ35, TBJ35/T, TBJ45

38/4855

95

17 75

115

73

90

969

53

TB35, TB45 TBJ70 Note: The inside dimension allows for the thickness of the supported timber plus two nailplates, eg: 38 mm allows for 35 mm timber + 2@ nailplates. Installation Generally, use the smaller holes present in the product and ignore all bolt holes. The Self Drilling wood screw (Code WTF12-35) will widen the hole in the Boot to the appropriate diameter to provide a tight fit. If a nailplate lies underneath the screw hole, the self drilling wood screw may be used if a nailplate hole is partially visible through the nail hole. Alternatively, use a Self Drilling steel screw (code WSF12-35) to drill through any nailplate. Where the roof is subject to little or no wind uplift, 35x3.15 mm galvanised Pryda Timber Connector Nails alone can be used to fix the supported truss- see Design Capacities next page. For screw fixing, Pryda Multi-Fix Truss Boots and supported members are to be installed as follows: 1. Fit the Boot flush with the bottom of the girder bottom

chord and power drive screws into all nail holes, ignoring the bolt holes. Do not over-tighten the screws. Any rubber or neoprene washer on the screw shank may be left in place and the screw is properly tightened when this washer squashes out to the same diameter as the integral metal washer.

2. Sit the incoming members into the Boot and hold in

place with screws, using a power screwdriver and the number of screws specified. Do not over-tighten screws. The clearance between the end of the ..

PRYDA TIMBER CONNECTORS Hangers & Truss Boots Guide

PRYDA HANGERS & TRUSS BOOTS GUIDE –FEBRUARY 2007 19

JOIST BOOTS & TRUSS BOOTS- Screw Fix Option - Continued incoming member and the face of the girder

truss chord should not exceed 5 mm. 3. The screws have been designed to

accommodate the twisting forces that are induced into this type of connection, and further “anti-rotation” devices are not necessary. Studies by Pryda show that anti-split nailplates are not required for these boots with screwed fixing, especially with softwood chords to the girders, but may still be required for other circumstances – refer to Pryda literature.

4. Care must be taken when screwing the boot onto a girder bottom chord. To minimise the risk of injury to the installer if the screwdriver slips, we recommend that an extender be used to provide greater clearance of the hands away from the Boot. This may not be necessary with the TBS types that are much shorter.

Screw numbers are as tabulated below:

Boot Type To Girder To Supported TrussTBS35/45 4 4

TBJ35/45, TBJ70 8 8 TB35/45 8 12

Joist Boot or Truss Boot

Supported truss

Self drilling wood screws, 2 each side - TBS4 each side - TBJ and TB

Installation Detail 1

Supported truss

Self Drilling screws: 2 each face - TBS, 4 each face - TBJ, 6 each face - TB

Joist Boot or Truss Boot

Installation Detail 2

Fixing Details For Double & Triple Girders DOUBLE GIRDERS 2@ 35 Girder Laminations – Preferred Fixing Detail

65 mm Self drilling woodscrews into the girder

Truss Boot

Alternative Fixing Detail

8@ 35 mm Self drilling wood screws+ 10@ 65x2.87 mm nails into girder

Truss Boot

2@ 45 Girder Laminations – Preferred Fixing Detail

65 mm Self drilling wood screws+ 4@ 90x3.33 mm nails into girder

Truss Boot

Alternative Fixing Detail

35 mm Self drilling wood screws+ 8@ 90x3.33 mm nails into girder

Truss Boot

TRIPLE GIRDERS 3@ 35 or 3@ 45 mm Laminations – Preferred Fixing

35 mm Self drilling wood screws+ 2@ M12 bolts with 50x50x3 mm square washers on timber side only

Truss Boot

Alternative Fixing Detail

35 mm Self drilling wood screws+ 18@ 90x3.33 mm nails:(12 to front lamination, 6 to back lamination)

Truss Boot

PRYDA TIMBER CONNECTORS Hangers & Truss Boots Guide

PRYDA HANGERS & TRUSS BOOTS GUIDE –FEBRUARY 2007 20

NOTES For Fixing Details For Double & Triple Girders 1. Nails at the Truss Boot are to be spaced 70mm

(min) apart along the grain and 40mm (min) apart across the grain. They should be as close to the Truss Boot as practical, but not further away than the depth of the member.

2. Use the details for 35mm laminates for timber thickness between 35 and 40 mm, and the 45mm details for timber thickness between 41 and 50 mm.

3. All Self Drilling galv hex head screws are 12g – 11x35 (35mm long) or 12g – 11x65 (65mm long).

4. For all double and triple girder trusses, the chords (top and bottom) and webs are to be nailed at:

Timber Width Nail Rows & Maximum Spacing

Up to 105 mm 2 rows at 500 mm

106 - 210 mm 2 rows (staggered) at 250 mm

211 - 300 mm 3 rows (staggered) at 250 mm

30 - 50 mm

30 - 50 mm

250 mm 250 mm

Nails staggered

500 mm

30 - 50 mm

30 - 50 mm

30 - 50 mm

250 mm 250 mm 250 mm

30 - 50 mm

250 mm 250 mm

101 - 200 mm Chords or Webs

Timber Up to 100 mm Chords or Webs

201 -300 mm Chords or Webs

250 mm 250 mm

250 mm 250 mm

Design Capacities - Screw Fix Option In the following table, load case “Live” means Live + Dead load, “Wind” means Wind down + Dead, “Wind Uplift” means Wind uplift - Dead load. Girder timber and supported truss thicknesses are minimums.

Girder Truss Boot Thick- Screw Design Capacity ΦNj (kN) Code ness No. J2 JD4

(mm) Dead Live Wind k1 = 1.3

Wind k1 = 1.14

Dead Live Wind k1 = 1.3

Wind k1 = 1.14

TBJ70 70 4 5.7 7.7 13.0 11.4 4.1 5.5 9.4 8.2

TBS35 35 8 11.4 15.4 15.8 15.8 8.2 11.1 15.8 15.8 TBJ35 min. TBJ45 TB35.. TB45..

Supported Truss, Beam or Joist

Boot Thick- Fixing DesignCap. ΦNj (kN) Code ness Wind Uplift

(mm) k1 = 1.3 k1 = 1.14 J2 JD4 J2 JD4

TBS35 35 min. 4 nails 1.6 1.1 1.4 1.1

4 screws 3.5 2.5 3.1 2.2

TBJ35, TBJ45 35 min. 8 nails 4.7 3.4 4.1 3.0

or TBJ70 8 screws 10.4 7.5 9.1 6.6

TB35/12, TB35/16, 35 min. 12 nails 7.1 5.6 6.2 4.9

TB45/16 12 screws 15.8 12.5 13.9 11.0

Notes: 1. The tabulated Limit State Design

capacities apply directly to Pryda Truss Boot joints in houses or on secondary trusses or beams in other structures. For joints on primary trusses or beams in structures other than houses, multiply these capacities by 0.75.

2. Select the wind load design capacity in accordance with the factor and, therefore, the code used for the design loads, ie:

* 1.14 for AS/NZS1170:2002 * 1.3 for AS1170-1989 or AS1684-1999 3. Design capacities for other joint groups

can be calculated (possibly conservatively) by applying the factors as follows, with a maximum capacity of 15.8 kN:

Compared Factor for Joint Group To: J4 J3 JD5 JD3 JD2 J2 0.40 0.63

JD4 0.72 1.17 1.32

4. Accurate design capacities for any joint group or structure and member type are given by the Pryda Connection Designer software, included in Pryda Frame, see Main Menu > Extras > Connection Designer.

5. TBJ35/T capacities are as for TBJ35.

PRYDA TIMBER CONNECTORS Hangers & Truss Boots Guide

PRYDA HANGERS & TRUSS BOOTS GUIDE –FEBRUARY 2007 21

TRUSS BOOTS – HEAVY DUTYSteel Brackets for Heavy Roof Truss Connections

Application

Bottom chord ofgirder truss

Anti-split plates arerequired on both facesof the girder truss chord and on both sides of theTruss Boot

Pryda Heavy Duty Truss Boot fixed withM16 or 5/8 inch bolts with 63 mm squarewashers on the back faces only-* girder truss - 4 bolts* supported truss - 2 bolts

Anti-rotation legof Truss Boot

Carried truss

Features The long anti-rotation leg and heavy duty steel of Pryda Heavy Duty Truss Boots, combined with the inherent high stiffness of the carried truss, prevents twisting of the bottom chord of the girder. Consequently, anti-rotation bars are not necessary. Useful variations of this product have: the anti-rotation leg at 45 degrees for hip ends (../45) welded hinges to allow for any angle (TB80V)

Installation Pryda Heavy Duty Truss Boots are installed with 6@ M16 or 5/8 inch bolts and with 63x4 mm square washers on all surfaces where the bolt head or nut bears directly on the timber. Anti-split Claw nailplates are to be installed on both faces of the girder and on both sides of the truss boot (see Application above). Specification Pryda Heavy Duty Truss Boots are made to the following specification: Sizes: See Dimensions following. Steel: 6.0 mm mild steel, hot dipped galvanised Product Codes:

TB80L, TB80R, TB80C, TB80C/45L, TB80C/45R, TB80V L, R and C indicate position of the anti-rotation bar, ie: Left, Right, Centre 45 denotes leg at 45 degrees V denotes variable angle (hinged)

Packing: TB80L, TB80R- 4 per carton TB80C, TB80V: Sold as singles TB80R is made to order only

Dimensions The dimensions of Heavy Duty Truss Boots are :

100

75

90

7525

7525

150

25

225450

285

225350

285

225350

285

225450

225450

Hinge

General Dimensions

TB80C TB80L TB80R

TB80C45/R TB80V

25

PRYDA TIMBER CONNECTORS Hangers & Truss Boots Guide

PRYDA HANGERS & TRUSS BOOTS GUIDE –FEBRUARY 2007 22

Design Capacities Limit State Design capacities for Pryda TB80 Heavy Duty Truss Boots are tabulated below. These apply only where the Truss Boots are installed in accordance with Installation on the previous page. These capacities apply to timber of joint groups as defined in AS1720.1. At Girder (Carrying) Truss: Girder Load Design Capacity φNj (kN) Truss Case For Timber Joint Group: Thick. J4 J3 J2 JD5 JD4 JD3 JD2

35 Dead 6.8 10.5 16.8 8.6 12.0 16.3 21.5 Live + Dead 9.2 14.2 22.6 11.6 16.2 22.0 29.1 Wind + Dead

k1 = 1.3 15.5 24.0 38.2 19.7 27.3 37.1 49.1

Wind + Dead k1 = 1.14

13.6 21.1 21.4 17.2 23.9 32.6 43.1

45 Dead 8.7 13.5 21.5 11.1 15.4 20.9 27.7 Live + Dead 11.8 18.3 29.1 15.0 20.8 28.3 37.4 Wind + Dead

k1 = 1.3 19.9 30.9 49.1 25.3 35.1 47.7 63.2

Wind + Dead k1 = 1.14

17.5 27.1 43.1 22.2 30.8 41.9 55.4

2@35 Dead 13.2 18.1 23.0 17.2 23.3 27.9 29.5 Live + Dead 17.8 24.4 31.0 23.3 31.4 37.7 39.9 Wind + Dead

k1 = 1.3 30.1 41.2 52.4 39.3 53.0 63.6 67.4

Wind + Dead k1 = 1.14

26.4 36.1 46.0 34.5 46.5 55.8 59.1

At Supported (Carried) Truss- Wind Uplift

Supported Design Capacity φNj (kN) Truss For Timber Joint Group: Thick. J4 J3 J2 JD5 JD4 JD3 JD2

Design loads from: AS1170-1989, k1 = 1.3 35 7.8 12.0 19.1 9.8 13.7 18.6 24.6

2@35 14.3 19.9 26.2 16.8 23.4 31.8 33.7Design loads from: AS/NZS1170:2002, k1 = 1.14

35 6.8 10.5 16.7 8.6 12.0 16.3 21.62@35 12.5 17.5 23.0 14.7 20.5 27.9 29.6

Notes: 1. Design capacities apply directly for joints in houses and on

secondary beams in other structures. For joints on primary beams in structures other than houses, multiply these capacities by 0.75.

2. Select the wind load design capacity in accordance with the factor and, therefore, the code used for the design loads, ie:

* 1.14 for AS/NZS1170:2002 * 1.3 for AS1170-1989 or AS1684-1999 3. Load case “Live” above means Live + Dead load and

“Wind” means Wind +/- Dead load. 4. For the TB80V boot, maximum loads are: Dead and live load: 26.4 kN; wind uplift: 17.8 kN 5. The Pryda Connection Designer software (included in

Pryda Frame) provides a quick and convenient means of determining whether a TB80 Truss Boot is suitable for specific design conditions.

Over-Angles & Over-Straps For uses where the wind uplift load exceeds the uplift capacity of the TB80, an over-angle or over-strap can be used. See the TB80 Uplift Reinforcement (next page). BOLT KITS FOR TRUSS BOOTS Hot dipped galvanised Kits of bolts, nuts and washers are available to suit all bolt fixed truss boots. Details are:

Product Code:

OBK312 OBK316 OBK816

To suit: TBS35/45, TBJ35/45/70

TB35/12

TB35/16, TB45/16

TB80

Packed: 80 80 60 Bolts (mm):

2@ 12x65 2@ 12x100

2@ 12x65 2@ 16x110

6@ 16x110

Washers (square):

4@ 55x3 2@ 55x3 2@ 63x5

6@ 63x5

PRYDA TIMBER CONNECTORS Hangers & Truss Boots Guide

PRYDA HANGERS & TRUSS BOOTS GUIDE –FEBRUARY 2007 23

TB80 UPLIFT REINFORCEMENT DET. TIE – DOWN DETAILS UPLIFT CAPACITY (kN) for Timber Joint Group

& Strength Group: No. Loading

Code J4 (S6)

J3 (S4)

J2 (S3)

JD5 (SD7)

JD4 (SD6)

JD3 (SD5)

AS1170-1989 7.8 12.0 19.1 9.8 13.7 18.6

TB80 (WITHOUT REINFORCEMENT)

AS/NZS1170:2002 6.8 10.5 16.7 8.6 12.0 16.3

AS1170-1989 24.5 38.9 48.2 33.9 41.2 48.0

1

150mm long x 10 mm thick steel over-angle to suit (see Note 4)Ensure full bearing on top chord

Pryda TB80 Truss Boot

140 mmmin.

2@12g Type 17 screws to ensure angle remains straight

60

AS/NZS1170:2002 21.5 34.1 42.3 29.7 36.1 42.1

AS1170-1989 15.0 24.0 33.0 18.0 24.0 33.0

SIN

GLE

CA

RR

IED

TR

USS

(35m

m)

2

Pryda TB80 Truss Boot

(Ensure full bearing on top chord)

50 x 3mm steel overstrap

140min.

Note: The boltthrough theover-strap must be installedthrough or above the heel jointnailplates

AS/NZS1170:2002 13.2 21.0 28.9 15.8 21.0 28.9

AS1170-1989 15.1 20.6 26.2 19.7 26.5 31.8

TB80 (WITHOUT REINFORCEMENT)

AS/NZS1170:2002 13.2 18.1 23.0 17.3 23.2 27.9

AS1170-1989 30.2 41.2 48.6 39.3 48.6 48.6

3

175 mm long x 12 mm thick steel over-angle to suit (see Note 4)Ensure full bearing on top chord

Pryda TB80 Truss Boot

140 mmmin.

2@12g Type 17 screws to ensure angle remains straight

60

AS/NZS1170:2002 26.5 36.1 46.0 34.4 46.4 48.6

AS1170-1989 27.0 41.2 50.0 28.0 35.0 50.0

DO

UB

LE C

AR

RIE

D T

RU

SS (2

/35)

4

Pryda TB80 Truss Boot

(Ensure full bearing on top chord)

50 x 3mm steel overstrap

140min.

Note: The boltthrough theover-strap must be installedthrough or above the heel jointnailplates

AS/NZS1170:2002 23.7 36.1 43.8 24.6 30.7 43.8

Notes: 1. The capacities for Detail-1 and Detail–3, with over-angle, are

limited by either top chord crushing against angle or 4/M16 bolts bearing on carrying truss or bending of outstanding leg of angle.

2. Select Uplift Capacity according to the version of the Loading Code used to compute the design wind loads, ie: AS1170-1989 or the version released in July 2002, ie: AS/NZS1170:2002.

3. The capacities for Detail-2 and Detail-4, with overstrap, are limited by either 4@ M16 bolts bearing on carrying truss or based on Details TD-06/TD-07 published by TRADAC (December 2000). For these tabulated capacities (details 2 & 4 only), the bolt through the over-strap must be installed through or above the heel joint nailplates.

4. The bottom chord of carrying truss shall be a minimum of 140 mm deep.

5. For Over-angle reinforcement, (Detail-1 or 3), Angle size is as tabulated below. For top chord pitches and top chord widths outside the scope of the above table, use over-angle size to suit. The minimum longer-leg (i.e bolted leg) dimension of the over-angle is governed by 25mm end distance for bolt, and the maximum dimension is limited by the over-angle being maintained flush to underside of truss bottom chord.

Top Chord Pitch (degs)

Max. Top Chord Width

Most Suitable Over Angle

Thickness & Length

100 100x75 UA 125 125x75 UA Up to 17.5 150 150x90 UA 100 125x75 UA

18.0 to 25.0 125 150x90 UA

25.5 to 35.0 100 150x90 UA

10mm thick x 150mm long

for single carried trusses 12mm thick x 175mm long

for double carried trusses

Equal angles of similar long-leg dimensions may be used as a substitute. Always bolt-fix through the longer-leg.

6. Fix the over-angle or over-strap to the TB80 with the M16 or 5/8 inch H.S bolt and nut used for fixing the TB80 to the carried truss. Install 63x5 mm square washers where the bolt or nut bears directly onto timber.

PRYDA TIMBER CONNECTORS Hangers & Truss Boots Guide

PRYDA HANGERS & TRUSS BOOTS GUIDE –FEBRUARY 2007 24

A Division of ITW Australia

PRYDA AUSTRALIA Head Office: 29 Healey Road, Dandenong, Vic 3175 Tel: (03) 9706 5488 Fax: (03) 9706 5499

Offices in Sydney, Brisbane and Perth For contact details in your state visit www.pryda.com.au or email [email protected]