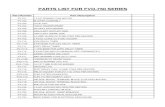

00105000 CT Etech EV 1-3-6-10-15-20-30-45-65-95 50Hz Eng by ...

Fvo Eng 50hz

Transcript of Fvo Eng 50hz

-

8/2/2019 Fvo Eng 50hz

1/8

1

FVOFlows rates up to: 200m 3/hHeads up to: 16mMax. immersion: 10mMax. particle size: 75 and 100 mm*ND of discharge: 80/100 mm*Protection index: IP 68* depending on the model

OPERATING LIMITS

N.T. N 145-17/EN G. - Ed.1/05-05

SUBMERSIBLE PUMPSLifting of polluted water

Commercial use4 pole - 50 Hz

Lifting of polluted water in the collectivehousing, tertiary and industrial sectors.

Lifting of: Wastewater and drainage water Valve water Sludgy water Draining of septic tanks.

0

6

4

110

16

130 200 Qm/h

m APPLICATIONS

BENEFITS The combination of the two materials

Cast iron + 316L Stainless Steelensures protection against corrosionand increased reliability.

Particle size of up to 100mm. Two types of standard installation:

xed ooded sump installation andmobile installation.

Possibility of dry well installation withthe cooling sleeves option.

Possibility of ATEX installation, thanksto the ATEX option and ATEXaccessories.

FVO

SPECIFICATIONS- Cast iron hydraulic part + 316L stainlesssteel motor.

- 10 m detachable cable.- Vortex impeller.- Installation on base elbow with 33/42

guide bars or installation on stainless steellegs for a mobile installation.

- Available in a version with a cooling sleeve.- Available in an anti-deagrating version(ATEX).

-

8/2/2019 Fvo Eng 50hz

2/8

Range codeVORTEX impeller4 pole

ND of discharge (cm)Impeller (cm)P2 (kW)Three-phase400 V

F VO4 08 - 16 / 2.0 T 4

2

FVO

IDENTIFICATION

DESIGN Hydraulic part- Submersible.- Axial suction under casing, horizontal

discharge outlet with anged xing.- Intermediate chamber between the pump

and the motor, lled with oil, isolated by auid side mechanical seal and a motor sidelip seal.

- A single impeller type: VORTEX.- With a particle size of 75mm for the

FVO408s and 100mm for the FVO410s.

Motor- Submersible, direct starting or Y .- Built-in temperature probe protecting the

motor against overheating (WSK tempera-ture probe).

- Direct starting up to 4 kW; star-delta star-ting beyond this level.

- Speed: 1450 rpm- Winding: ~3; 400V- Frequency: 50 Hz- Insulation class: F- Protection index: IP 68- Compliance: CE- Operation:

- Continuous S1- Intermittent S3, 20 start/hr

recommended- Options : ATEX

Cooling sleeve

Model FVO 408 FVO 410Pump body EN GJL 250 EN GJL 250Impeller EN GJL 250 EN GJL 250Shaft AISI 420 AISI 420Mechanical seal SiC/SiC SiC/SiC

Motor side seal NBR NBRMotor frame AISI 316L AISI 316L

STANDARD CONSTRUCTION

HYDRAULIC PERFORMANCES

0

0

4020 60 100 140 18080 120 160 200

4

8

12

16

20

Qm 3 /h

Hm

Imp.gpm

Ql/min

Ql/s

HftFVO 410

0

0

4020 60 80 100 120

4

8

12

16

Qm 3 /h

Hm

Imp.gpm

Ql/min

Ql/s

Hft

FVO 410-25/8.4FVO 410-22/7.2FVO 410-20/5.9

FVO 408-21/3.8FVO 408-19/3.2FVO 408-18/2.7FVO 408-17/2.4FVO 408-16/2.0

FVO 408

10 20 30 40 50 60 70

1000 2000 3000

5040302010

10 20 30 40

1000 2000

302010

-

8/2/2019 Fvo Eng 50hz

3/8

d F

Eek

K a

3 0 0

303.4

1 8 0

b

5 2

6 1 5

( 5 5 0 -

7 5 0 )

J

3 0 0

300 118.5

303.4

1 8 0

105

14

9060

1 5

4 0

A

D1 pump

300

2 pumps325

1 pump650

2 pumps700 x 1200

2 guidebars

ND 11/4

E F

C

BND2

N D 1

12

I

H

min

G

1 pump 12002 pumps 1500

8 5

L M

O

ND2

ND1 N

H 1 G

min

K

3 0 0

8 0

380.5

230.5

1 9 5

T

3

F V O

DIMENSIONS FVO 408

Fixed installation ND 80 Mobile installation ND 80

TECHNICAL DATA

ND1 ND2 A B C D E F G H I J K L M a b c d e k H1 N O T80 80 200 160 19 149 81 228 660 300 70 185 355 180 315 200 170 170 220 14 14 635 85 200 409

Curve Operation Max. P1 P2 I Speed Mains IP Cable Weight Particle Startingnr starts/h kW kW A RPM voltage m kg size

FVO 408-16/2.0T4 1 S1 20 2.7 2.0 6.1 1450 3~400V, 50Hz 68 10 70 75 directFVO 408-17/2.4T4 2 S1 20 3.4 2.4 6.7 1450 3~400V, 50Hz 68 10 70 75 directFVO 408-18/2.7T4 3 S1 20 3.7 2.7 7.0 1450 3~400V, 50Hz 68 10 70 75 direct

FVO 408-19/3.2T4 4 S1 20 4.5 3.2 8.0 1450 3~400V, 50Hz 68 10 70 75 directFVO 408-21/4.0T4 5 S1 20 5.3 4.0 8.9 1450 3~400V, 50Hz 68 10 70 75 direct

-

8/2/2019 Fvo Eng 50hz

4/8

4

FVO

DIMENSIONS FVO 410

TECHNICAL DATA

ND1 ND2 A B C D E F G H I J K L M a b c d e k H1 N O T100 100 220 180 18 169 91 255 825 780 90 195 440 225 400 260 220 220 250 15 20 890 90 250 450

Curver Operation Max. P1 P2 I Speed Mains IP Cable Weight Particle Startingnr starts/hr kW kW A RPM voltage m kg size

FVO 410-20/5.9T4 6 S1 20 7.1 5.9 14.2 1450 3~400V, 50Hz 68 10 96 100 star-deltaFVO 410-22/7.2T4 7 S1 20 8.8 7.2 16.5 1450 3~400V, 50Hz 68 10 96 100 star-deltaFVO 410-25/8.4T4 8 S1 20 10.1 8.4 18.5 1450 3~400V, 50Hz 68 10 96 100 star-delta

d F

Eek

K a

4 0 0

339

1 8 0

b

6 8

6 1 5

( 5 5 0 -

7 5 0 )

J

2 3 8

250 132

1 3 0

110

14

8860

1 5

4 0

A

D1 pump

300

2 pumps325

1 pump650

2 pumps700 x 1200

2 guidebars

ND 11/2

E F

C

BND2

N D 1

12

I

H

min

G

1 pump 1200

2 pumps 1500

8 5

L M

O

ND2

ND1 N

H 1 G

min

K

3 3 7

. 5

9 0

428

260

2 2 0

T

Fixed installation ND 100 Mobile installation ND 100

-

8/2/2019 Fvo Eng 50hz

5/8

1 - Stop valvesStop valve ND 80 2017162Stop valve ND 100 2017163

2 - Check valveBall check valve ND 80 4015761Ball check valve ND 100 4015762

4, 5 and 14 EAPSIPAE with 10 m cable 2519921IPAE with 30 m cable 2519922IPAE with 50 m cable 2519923Cable clip for IPAE 2519927Zener barrier 2521216

7 - Chain5 m chain 201558010 m chain 2015581

10 - Base elbow setBase elbow set ND 80, 2x1'' 1/4 bars 2029052Base elbow set ND 100, 2x1'' 1/2 bars 2029053

5

FVO

ACCESSORIES RECOMMENDED FOR ATEX INSTALLATION

1 : Gate valve

2 : Ball check valve4 : IPAE, electronic air pressure switch5 : Cable clip for IPAE6 : Guide bars ND 327 : Lifting chain9 : Control box for ATEX installation

(YN5000E)Unit must not be placed inside anexplosive zone

10 : Base elbow set11 : Cable (10m)13 : Bleed hole to be created14 : Zener barrier for ATEX installation

Note: ATEX pumps are optional

Yn5000

1

2

6

7

10

13

11

14

4

5

9

9 - Control box 1 pump installation 2 pump installationControl box Reference Control box Reference

FVO 408-16/2.0T4 YN 5110E 2521217 YN 5210E 2512218FVO 408-17/2.4T4 YN 5110E 2521217 YN 5210E 2512218FVO 408-18/2.7T4 YN 5110E 2521217 YN 5210E 2512218FVO 408-19/3.2T4 YN 5110E 2521217 YN 5210E 2512218FVO 408-21/4.0T4 YN 5110E 2521217 YN 5210E 2512218FVO 410-20/5.9T4 YN 5116E 2521223 YN 5216E 2521224FVO 410-22/7.2T4 YN 5120E 2521225 YN 5220E 2521226FVO 410-25/8.4T4 YN 5120E 2521225 YN 5220E 2521226

Yn 5000

AUTO

!

+-

P1

P 2

!RESETMEMO

I

0

295

1 8 0

260

2 4 0

2 4 5

-

8/2/2019 Fvo Eng 50hz

6/8

6

FVO

1 - Gate valvesGate valve ND 80 2017162Gate valve ND 100 2017163

2 - Check valveBall check valve ND 80 4015761Ball check valve ND 100 4015762

3 - FloatNivo 430X1-10 M ECOLO 4027319Nivo 430X1-20 M ECOLO 4027320Cable clip 4013188

7 - Chain5 m chain 201558010 m chain 2015581

10 - Base elbow setBase elbow set ND 80, 2x1 1/4 bars 2029052Base elbow set ND 100, 2x1 1/2 bars 2029053

ACCESSORIES RECOMMENDED FOR FIXED INSTALLATION

1 : Gate valve

2 : Ball check valve3 : Float switch5 : Cable clip6 : Guide bars

11/4 for FVO 40811/2 for FVO 410

7 : Lifting chain8 : Control box YN 4000 or YN 5000E

10 : Base elbow set11 : Cable (10 m)13 : Bleed hole to be created

Yn5000

1

2

6

7

10

13

11

3

5

9

260

2 4 0

2 4 5

295

1 8 0

Yn 5000

AUTO

!

+-

P 1

P 2

!RESETMEMO

I

0

8 - Control box 1 pump installation 2 pump installationControl box Reference Control box Reference

FVO 408-16/2.0T4 YN 4112 4035802 YN 4212 4035804FVO 408-17/2.4T4 YN 4112 4035802 YN 4212 4035804FVO 408-18/2.7T4 YN 4112 4035802 YN 4212 4035804FVO 408-19/3.2T4 YN 4112 4035802 YN 4212 4035804FVO 408-21/4.0T4 YN 4112 4035802 YN 4212 4035804FVO 410-20/5.9T4 YN 5116E 2521223 YN 5216E 2521224FVO 410-22/7.2T4 YN 5120E 2521225 YN 5220E 2521226FVO 410-25/8.4T4 YN 5120E 2521225 YN 5220E 2521226

-

8/2/2019 Fvo Eng 50hz

7/8

7

FVO

1 - Base supportBase support for FVO 408 2017687Base support for FVO 410 2015584

2 - ElbowElbow ND 80 2017698Elbow ND 100 2015597

3 a n d 4 - Quick coupling3) ND 80 182754) ND 80 182693) ND 100 197924) ND 100 18276

5 - Flexible pipe10 m exible pipe ND 80 201769120 m exible pipe ND 80 201769230 m exible pipe ND 80 201769310 m exible pipe ND 100 201558520 m exible pipe ND 100 201558630 m exible pipe ND 100 2015587

6 - Chain5 m chain 201558010 m chain 2015581

ACCESSORIES RECOMMENDED FOR MOBILE INSTALLATION

1 : Mobile installation base support2 : Pipe bend

3 & 4 : Quick coupling5 : Flexible pipe6 : Lifting chain

5

6

4

3

2

1

7 - Control box 1 pump installation 2 pump installationControl box Reference Control box Reference

FVO 408-16/2.0T4 YN 4112 4035802 YN 4212 4035804FVO 408-17/2.4T4 YN 4112 4035802 YN 4212 4035804FVO 408-18/2.7T4 YN 4112 4035802 YN 4212 4035804FVO 408-19/3.2T4 YN 4112 4035802 YN 4212 4035804FVO 408-21/4.0T4 YN 4112 4035802 YN 4212 4035804FVO 410-20/5.9T4 YN 5116E 2521223 YN 5216E 2521224FVO 410-22/7.2T4 YN 5120E 2521225 YN 5220E 2521226FVO 410-25/8.4T4 YN 5120E 2521225 YN 5220E 2521226

Yn 5000

AUTO

!

+-

P1

P2

!RESETMEMO

I

0

3 4

-

8/2/2019 Fvo Eng 50hz

8/8

8

FVO

IPAE

Electronic Air Pressure Switchfor clear and polluted water.- Suitable for operation in an explosiveatmosphere.

- Useable for draining and lling.- Complies with directive 94/9/CE (ATEX):protection against explosive atmospheres.

- Remote control.- Anti-deagrating.- Insensitive to water temperature and foam.- Acid-resistant.- Undisruptable, highly accurate to within2cm and economical.

- Power supply voltage: 220V - 50Hz.- Use with YN 5000E.

For an ATEX installation, use the Zenerbarrier (see IPAE manual for more informa-tion).

FEATURESa) Electrical400V 50 Hz three-phase direct starting forthe FVO 408 model

400V 50 Hz three-phase star-delta startingfor the FVO 410 model

Mandatory thermal protection againstovercurrents via discontactor, circuit breakeror control unit with level regulator.

b) AssemblyPump in a vertical position for xed ormobile installations.Mobile installation: discharge oriceconnected by an elbow to a exible pipe of adiameter greater than that of the pumpsdischarge.Double installation: the pumps may betwinned via manifold.Check valve and valves to preferably betted in the upper part of the dischargeduct.Connection via exible or rigid pipe.

c) PackagingPump supplied on a pallet with electric cableH07RN-F (10 m).Screws and xing for assembling on thebase elbow set supplied with the pump.Accessories packaged separately.

Yn4000 : control and protection box for1 or 2 lifting pumps. Management ofpump(s) in xed ooded sump or dry wellinstallations; level monitoring and protectingof motor(s) against overcurrents, overloadsand dry running.

Control unit order referenceIntensity range Yn4100 Yn4200in A 1 PUMP 2 PUMPS1.6 to 05 (Yn4105)4035801 (Yn4205)40358033.7 to 12 (Yn4112)4035802 (Yn4212)4035804

Probe management card: 44033562 for S400 (I 12A).

YN5000EManagement of one or two pumps by micro-processor in ooded sump or dry well xedinstallations. Level monitoring and protectingof motor(s) against overcurrents, thermaloverloads and dry running.

RECOMMENDED ACCESSORIES

NIVO430Ecological, mercury-free polluted water oatswitch.Useable for draining and lling, withdiscontactor.

Starting intensity rangeREFERENCE AYN 5110E 2521217 0.5 - 10 directYN 5210E 2521218 0.5 - 10 direct

YN 5109E 2521219 6.3 - 9

YYN 5209E 2521220 6.3 - 9 YYN 5111E 2521221 10 - 11 YYN 5211E 2521222 10 - 11 YYN 5116E 2521223 12.5 - 16 YYN 5216E 2521224 12.5 - 16 YYN 5120E 2521225 16 - 20 YYN 5220E 2521226 16 - 20 YYN 5132E 2521227 24 - 32 YYN 5232E 2521228 24 - 32 YYN 5142E 2521229 33.1 - 42 YYN 5242E 2521230 33.1 - 42 YYN 5155E 2521231 42.1 - 55 YYN 5255E 2521232 42.1 - 55 Y

YN 5171E 2521233 71 YYN 5271E 2521234 71 Y

53 bd de la Rpublique - Espace Lumire - Bt. 6 - 78403 Chatou Cedex FRANCETel: +33 (0)1 30 09 82 39 - Fax: +33 (0)1 30 09 82 34 - www.salmson.com