FOUNDATIONDRILLINGFebruary2009 - A.H. Beck 2009.pdf · Eng-ChewAng,Geotechnical Engineer and...

Transcript of FOUNDATIONDRILLINGFebruary2009 - A.H. Beck 2009.pdf · Eng-ChewAng,Geotechnical Engineer and...

FOUNDATION DRILLING February 2009Page 2

CREATIVE USE OFDRILLED SHAFTS FORSLOPE STABILIZATIONat the Lowman PowerPlant, Leroy, Alabamaby Steven “Keith” Anderson

Vice President of OperationsA.H. Beck Foundation Co., Inc., andMark Petersen, P.E., G.E.Geotechnical Section Supervisor,Black & Veatch

Introduction

When PowerSouth Energy Cooperative,formerly Alabama Electric Cooperative

(AEC) devised a plan to design new airquality control (AQC) improvements for

the Charles R. Lowman Power Plant inLeroy, Alabama, its research indicated thatthe new AQC facilities should be con-structed adjacent to the Tombigbee River.However, the unstable riverbank at thechosen location — near a coal unloaderfacility — had moved more than four feetlaterally toward the river over the last 16years.Because of the large amount being spent

on the AQC improvements – nearly

$250,000,000 – everyone involved withthe project knew it was critical to stabilizethe riverbank prior to construction of thenew addition and to protect the existingpower plant area. (Relocating the struc-tures away from the river was consideredtoo cost-prohibitive, so was not consid-ered as an option.)

Geotechnical Investigations

Black & Veatch Corporation (B&V) ofOverland Park, Kansas, a global engineer-ing, consulting and construction compa-ny, was selected as the project’s construc-tion manager/engineer. It hired Geotech-nical Engineering-Testing, Inc. of Mobile,Alabama, to oversee soils explorations andgeotechnical engineering evaluations atthe site. From soils explorations per-formed for this study and previous stud-ies, Black & Veatch engineers could seethat the soil along the riverbank generallyconsisted of layers of soft to stiff consis-tency clays and loose to firm sands toabout elevations -45 feet within the plantarea and -20 feet near the river. These lay-ers were underlain with a layer of stiff clayto about elevation -60 feet, where a rela-tively thick limestone formation existed.They determined that the stiff clay had arelatively high undrained shear strength,but a relatively low residual (drained)

COVER FEATURE

(continued on page 3)

However, the unstable river-bank at the chosen location— near a coal unloaderfacility — had moved morethan four feet laterallytoward the river over thelast 16 years.

Overview of Plant and Slope Stabilization Project.

BECK manufactured crane mounted extended drill attachment.

FOUNDATION DRILLING February 2009 Page 3

shear strength.The engineers also measured artesian

groundwater levels during the period ofMarch to September 2005 and found thatthe elevation varied from +26 feet to +42feet. Geotechnical Engineering-Testing,Inc. performed a study taken nine yearsearlier that measured water elevations inthe limestone at +35 feet at the coalunloader cell area and +42 feet at the AECsouth transmission power line river cross-ing. Inclinometer casings placed withincertain boreholes in both the 2005 and1996 studies showed lateral movementwithin the stiff clay layer at distances of1.5 feet to 4 feet above the top of the lime-stone formation.The location of lateral movement plus

the relatively low residual shear strengthof the stiff clay led Black & Veatch engi-neers to theorize that the riverbank’smovements were caused, in part, by arte-sian water pressures in a limestone forma-tion pushing upwards on a stiff, imperme-able clay layer at about elevation -60.They noted that these movements gener-ally occurred when there had been recentdredging of the coal barge unloading areacoupled with extreme low water levels inthe Tombigbee River.One of the solutions discussed was to

reduce the artesian groundwater pressures

acting on the clays located near the top ofthe limestone formation. It was theorizedthat the reduced pressure should improvethe stability of the riverbank and cause thelateral movement to cease. The artesianpressure would be relieved by installing aseries of wells to pump water from thelimestone layer, thus lowering the artesianpressures.

Concerns with the Final Design

Geotechnical Engineering-Testing, Inc.(GET) hired Dan Brown and Associates,LLC (DBA)* of Sequatchie, Tennessee, aconsulting engineering firm specializing

in slope stability, to perform direct resid-ual shear tests on the stiff clay and to per-form stability analyses. Working closelywith the Owner, the team of B&V, GET,and DBA evaluated stabilization measures,including active drawdown wells, passivedrains, stabilizing berms, and tiebackanchors, among others. Burns &McDonnell (B&M) provided consultingoversight on behalf of Alabama ElectricCooperative (AEC). The team ultimatelydeveloped a final design consisting of one

SHAFTS Contd.

(continued on page 4)

The team ultimately devel-oped a final design consist-ing of one hundred 54-inchdiameter soil dowels (drilledshafts) that averaged 112feet in length. The teamdesigned the shafts to pene-trate down through the stiffclay and into the underlyinglimestone 20 feet.

Shaft access safety platforms used by BECK for the excavation, rebar installationand concrete placement.

56 Inch O.D. x 90 feet long permanent casing being installed.

FOUNDATION DRILLING February 2009Page 4

hundred 54-inch diameter soil dowels(drilled shafts) that averaged 112 feet inlength. The team designed the shafts topenetrate down through the stiff clay andinto the underlying limestone 20 feet. Tomaximize the effectiveness of the drilledshaft stabilization system, the team de-signed the shafts to be placed out in theriver approximately 100 feet from the topof the riverbank slope.The location of the stabilizing shafts

elicited several constructability concerns:

1) It would be extremely difficult forthe contractor to access the shafts fromthe river due to continuous coal deliveriesthat arrived by barge.2) Construction activities and their

added construction loads could cause ariverbank failure.3) The Tombigbee River fluctuates 30

feet in elevation.4) Artesian water percolates up to the

ground surface elevation on top of theriverbank, which makes installing drilledshafts difficult.To address these constructability con-

cerns, B&V contacted ADSC ContractorMember, A. H. Beck Foundation Co., Inc.(Beck) of San Antonio, Texas, to reviewthe site and provide its recommendations.Beck was chosen because of the company’sexperience with installing long-reachdrilled shaft foundations and its ability todesign and build its own equipment.Beck recommended installing the shafts

from the land on a series of access trestlesso that the stabilizing shafts could be con-structed in the required locations withoutapplying any construction loads to theexisting riverbank. Beck suggested build-ing a ground access trestle that wouldstretch 500 feet north and south along theriverbank, as well as a series of seven 75-foot-long finger trestles extending out tothe drill shaft locations. Beck also recom-mended that the trestles be installed at anelevation that would not be affected by theriver fluctuation and that the ownerinstall a deep well system to lower theartesian water head down to an elevationthat would allow for a positive head ofdrilling fluid inside the drilled shafts dur-ing installation.

Beck’s plan called for the access trestleto be built running north and southbetween piers 3 and 30, with 6 of the fin-ger bridges branching off in an east/westdirection, allowing access to install thedrilled piers. Beck would construct theseventh finger bridge at the south end ofthe site and the seventh finger bridgewould not be attached to the access tres-tle. Once Beck had installed all of thedrilled piers and the 28-day concrete com-pressive strength from the shafts hadexceeded or achieved design strength, theplan called for Beck to remove the accesstrestle and finger bridges from the site.B&V incorporated Beck’s recommenda-

tions into the project specifications andput the project out for competitive bid.Due to the tight schedule requirements atbid time, and also recognizing that thetrestle and drilled shaft operations wouldhave to be conducted simultaneously inorder to finish on time, Beck contactedJordan Pile Driving of Mobile, Alabama, tomake a joint bid for the trestle portion ofthe work. Upon completion of the bid

(continued on page 5)

SHAFTS Contd.

Conceptual Plan of Pinning Shafts and Trestle System provided to engineers by BECK.

FOUNDATION DRILLING February 2009 Page 5

process, the Jordan/Beck partnership wasselected for the project.Jordan/Beck began installation of the

drilled shaft foundations in June 2006.First, the owner placed three dewateringwells to draw down and maintain the arte-sian head a minimum of 10 feet below thetop of the shaft elevations.Next, Jordan installed 500 feet of

ground trestle parallel to the river alongwith the corresponding finger bridges thatextended out into the river. This allowedBeck to utilize a 225-ton, American cranewith a special Beck-built drill attachmentthat reached out another 60 feet to accessthe furthest shaft locations.To maintain pier stability, all 100 drill

shafts had a 56 inch outside diameter(O.D.) permanent casing driven to the tipelevation of -60.00 feet or to refusal priorto the excavation of the shaft. The 56 inchO.D. casings had a 0.500 wall thicknessand were an overall length of 90 feet withbands at the top. If Jordan achievedrefusal prior to reaching the elevation ofthe limestone the casings were cut off atelevation +30.00 feet. Beck maintained apositive head of water in the excavation toensure the pier stability below the perma-nent casing.

Pier Excavation Methods

Jordan constructed a template for the 56inch O.D. casing to ensure that the casingswere driven at the correct location. Thetemplate held six casings at a time. AfterJordan set the template and the surveyorchecked the location, Jordan set six cas-

ings into the template. Prior to the pierexcavation, Jordan drove a 56 inch O.D.casing to a tip elevation of -60.00 feet orrefusal, whichever was achieved first.When the permanent casings were inplace, Jordan set a personnel work plat-form into position. Once secured, thedrilling operation began. Beck removedthe material inside the permanent casingand instructed workers to flood the shaftwith water from the storage tank immedi-ately after excavation started to offset theartesian water pressures. Once the work-ers flooded the shaft, Beck resumed theexcavation with the use of a slurry auger.Beck drilled the pier into the limestone

strata, utilizing rock augers, to a tip eleva-tion of -80 feet. After Beck excavated thepier to the design tip elevation, theycleaned the shaft with a flat bottom clean-out bucket. Beck placed a hole cover ontop of the shaft when it was complete.Jordan hauled all spoils to the AEC land-fill, located approximately 4 miles fromthe work site.Because there was very limited working

area on the trestle, Beck had to fabricate thereinforcing steel cages with Cross HoleSonic Logging (CSL) tubes at another loca-tion and trailered down the trestle to be setby the drilling rig. The reinforcement cages

(continued on page 6)

SHAFTS Contd.

Jordan proceeding with trestle work while BECK installs drilled shafts.

BECK working off of trestle to install 54 inch diameter drilled shafts 112 feetdeep.

FOUNDATION DRILLING February 2009Page 6

had a set of horizontal and vertical stiffen-ers tied inside the cage on 15 feet centers

to help support the cage during fabrica-tion. In between each set of stiffeners,Beck wrapped a single no. 4 bar aroundthe outside of the cage to prevent it fromracking. Beck hoisted the cage into thehole by using four pick points. Due to thestresses at the clay limestone interface, thedesign called for additional reinforcingbars in this lower section of the rebarcage. The extra steel made the cage stiffon the bottom and limber on the top, cre-ating a difficult installation environment.

As Beck loweredthe rebar cageinto the pier,workers re-moved the verti-cal and horizon-tal stiffeners.Workers alsoadded the rebarcentralizers tothe cage as itwas loweredinto place.

Tight SpaceRequiresCreativeThinking

The next step involved pumping con-crete out onto the trestle and down intothe shaft – not an easy feat because Beckcould not use a conventional boom pumpand tremie within the limited work area.Beck’s innovative solution was to design

a special 10 inch x 120-foot-long tremie

pipe that allowed the pump line to attachdirectly to the tremie in 10-foot intervals.Workers placed a 10 inch X 10 inch foamsponge in the bottom of the tremie to actas a barrier between the concrete and thefluid in the excavation. Beck workersplaced the tremie approximately 12 inches

SHAFTS Contd.

Because there was very lim-ited working area on thetrestle, Beck had to fabricatethe reinforcing steel cageswith Cross Hole SonicLogging (CSL) tubes atanother location and trail-ered down the trestle to beset by the drilling rig.

Installing instrumentation on reinforcing steel cage.

(continued on page 7)

FOUNDATION DRILLING February 2009 Page 7

off the bottom of the pier and pumpedconcrete to it through a 5 inch line from aconcrete pump 200 feet away. During con-creting, the tremie pipe remained sub-merged a minimum of 10 feet into theconcrete at all times. As the water in the

excavation was displaced by the concrete,Beck pumped it off the top of the shaft andsent it to the coal pile runoff pond. Onceworkers had poured the shaft up, they leftthe top with a smooth finish.Through this unique system, Beck was

able to provide a continuous flow of con-crete into the excavation, which greatlyreduced placement time and the possibili-ty of tremie breaches or concrete lockups,thus providing the owner with a betterquality foundation.

Summary

Jordan/Beck completed construction inDecember 2006. The design team exten-sively instrumented the shafts and sur-rounding ground with standpipe andfiber-optic piezometers to monitor porewater pressures within the relevant strata,slope inclinometers within 10 of the 100installed drilled shafts and the surround-ing ground to monitor lateral movementsof the shafts and surrounding soil, andfiber-optic strain gages placed withinselected shafts to monitor load transferinto the drilled shafts from the movingsoil.Instrument readings taken prior to and

during construction indicated that thesystem is performing as intended withlimited soil movement occurring in orderto mobilize resistance in the drilled shafts,but with the shafts maintaining sufficientexcess capacity to maintain an acceptablemargin of safety against future move-ments. A year after completion of the con-struction, instrument readings still showthat all is functioning properly.

Conclusions

The success of this project can beattributed to the cooperation betweenthe design engineering firms and the spe-cialty foundation contractor. Workingtogether to share ideas and resources,Beck and the design team came up witha cost-effective solution for the owner.The trestle, customized long-reach

drilling equipment, and concrete tremiepipe system ingeniously addressed all fourof the constructability concerns by mak-ing shafts accessible away from the river-bank, minimizing the possibility of river-bank failure, managing river fluctuations,

and drawing down the artesian waterhead. The project succeeded on time andwithin budget – and despite less-than-ideal physical conditions.

Acknowledgments

The authors would like to thankPowerSouth Energy Cooperative (former-ly Alabama Electric Cooperative) for theopportunity to support their plant addi-tions and to add value to their portfolio ofpower generation. In particular, theauthors would like to thank Robert Meyerfor his support and encouragementthroughout the project.�

Beck’s innovative solutionwas to design a special 10inch x 120-foot-long tremiepipe that allowed the pumpline to attach directly to thetremie in 10-foot intervals.

PROJECT TEAM

Owner: PowerSouth Energy CooperativeRobert Meyer

Designer &Construction Manager: Black & Veatch

Eng-Chew Ang, Geotechnical Engineerand Resident Engineer

Bidjan Ghahreman, P.E., Project Geotechnical Engineerand Resident Engineer

Jeff Kurtz, Project ManagerGary Micheel, P.E., Civil/Structural Project EngineerMark Petersen, P.E., G.E., Geotechnical Section SupervisorMitch Post, P.E., Assistant Project Manager

Owner’s ConsultingGeotechnical Engineer: Geotechnical Engineering and Testing (GET)*

Lynn Doyle, P.E., Principal EngineerCurt Doyle. P.E., Project Engineer

Subcontractor to GET: Dan Brown and Associates, LLC*Erik Loehr, PhD, P.E., Consultant*

Owner’s Engineer: Burns & McDonnellCraig Buhr, P.E., Geotechnical EngineerTony Cordes, Project ManagerDave Stous, Hydrogeologist

Specialty Contractor: A. H. Beck Foundation Co., Inc.*Nathan Leyendecker,

Project ManagerGary Phillips, Superintendent

Trestle Contractor: Jordan Pile Driving Inc.Curtis Johnson, Vice PresidentChris Baehr, Project Manager

*Indicates ADSC Members.

SHAFTS Contd.

From building thefirst mechanized steam

powered drilling rig to ourhigh torque hydraulicdrilling rigs of today.

BECK is the nameyou can trust to providesolutions for all of yourdeep foundation needs.

With BECK’s people,equipment, design-build

capabilities, andexperience on your

project, you have thecomfort of knowingall your foundation

problems have solutions.

www.ahbeck.com

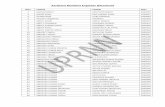

Alabama Electr ic Cooperat iveLowman Power PlantSlope Stabi l izat ion Project

Contact Us At:

Corporate Office5123 Blanco Road

San Antonio, TX 78216210-342-5261

210-342-4965 Fax

Branch Office13650 Hycohen

Houston, TX 77047713-413-3800

713-413-3811 Fax

Branch Office907 South I-45Ferris, TX 75125972-846-2097

972-846-2107 Fax

Branch Office101 Ave. Conquistadores(Casco Sales Facilities)

Cataño, Puerto Rico 00962787-622-4815

787-622-4814 Fax