Internal Energy of Molecules Ejected Due to Energetic C60 Bombardment

For your future! - RAUCHrauch.de/cms/upload/downloads/Prospekte/Umweltnorm/20030616Flye… ·...

Transcript of For your future! - RAUCHrauch.de/cms/upload/downloads/Prospekte/Umweltnorm/20030616Flye… ·...

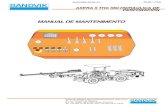

TELIMAT boundary spreading or AXERA H -No fertiliser is ejected overfield edges.

MDS disc spreading vanes orfertiliser output point adjustment -The RAUCH unit can be very easily andaccurately adjusted.

Calibration checks -Calibration equipment isincluded on the implement andensures simple but reliablemonitoring of metering rates.With weigh load or electronicmetering control technology,manual calibration is notneeded.

Open/close shutter slides -A visual indication of the slide position isshown to avoid unintentional spreading.

Quick purging -Fertiliser can be purged andreused.

DFC scale -For accurate stepless adjustmentof metering flow rates.

Spread pattern -The coefficient of variation usingspreading chart data is below 10 %.

Metering accuracy -A smooth gentle agitatorand special meteringshutter slides achieve aperfectly constantapplication rate. User-friendly and, above all,highly accurate applicationrates are possible usingQUANTRON M orQUANTRON P technology.

Late top dressing -By simply shorting the toplink, all the original settingaccuracy is maintained, evenwhen late top dressing atfield edges.

For your future!Environmental fertilising technology is essential to protect tomorrow'senvironment. The RAUCH fertiliser spreader range incorporatingboundary spreading equipment already fulfils all criteria of the European EN 13739-1 standards.

1

2

3

4 5

6

7

8

9

EU standard EN 13739-1 demands Responses from

Boundary spreading: Every machine must be able to operateon field boundaries without fertiliser being ejected beyondthe field edge. This is deemed as accomplished when nomore than 3‰ of the amount spread per hectare is ejectedover a 100m border length and the spread pattern coefficientof variation in the first two tramlines remains below 25%,while the applied amount of fertiliser within a 5m strip fromthe field edge does not exceed 20% of the applied amount inthe rest of the field.

Telimat boundary spreading shield for spreading direct-ly from the tramline.GSE boundary spreading device for spreading directlyat field edges.Rotating speed and fertiliser output point adjustmentfor AXERA H and AXERA H EMC for boundary spreadingdirectly from the tramline.

Metering accuracyThe maximum permitted output flow variation must notexceed 15 % for 25 kg/min., 10 % for 25 to 150 kg/min., and7.5 % for more than 150 kg/min.

Efficient gentle agitator, proportional DfC scales, simple calibration check.Electronic fertiliser metering.

Calibration checksThe application rate must be adjustable by calibration (calibration kit) or by a self-regulating automatic system.Necessary tools to accomplish adjustments must be carriedon the machine.

Simple calibration check procedures with a calibration ramp incorporated on the spreader,spreading charts, proportional DfC scale, weigh loadspreaders, electronic metering control EMC.

Hopper purgingPurging of the hopper must be accomplished withoutspreading and without allowing fertiliser to trickle onto theground. Necessary tools to accomplish this must be carriedon the machine.

Easy removing of the spreading discs, stainless steelwrench and calibration/purging ramp included asstandard equipment on the spreader. With AXERA nocalibration ramp is necessary.

Open/close shutter slidesThe control items (levers/switches, etc) governing the shutterslides must incorporate an on/off indicator clearly visible tothe operator. When closed no fertiliser must trickle onto theground.

Mechanical visual position indicator or QUANTRON M/P/L digital display.

AdjustmentIt must be possible to adjust the machine to another workingwidth and a border spreading mode, even when the hopper iscompletely full.

Adjustable disc vanes with the MDS system.Adjustable fertiliser output point with the AXERAsystem.Disc rotation speed adjustment with both AXERA H andAXERA H EMC.Telimat border spreading, GSE andAXERA H.

Spread patternThe coefficient of variation must not be above 15%. Thisrequirement is applicable for all working modes except borderspreading, irrespective of working width, fertiliser type, etc.

Coefficient of variation lies under 10% using spreadingchart settings in test hall conditions. High fertiliserejection speed from the spreading discs, minimumsplash loss, double disc vanes and automatic correctionof the output point, minimises crowding effect.

Late top dressingCoefficient of variation must not exceed 15 %. By simple machine angle adjustment the original coef-

ficient of variation is maintained whether spreading in"In-field" mode or "Boundary spreading" mode.

Clogging protectionThere must be minimum danger of fertiliser clogging thataffects flow rates or spread pattern.

Large area hopper sieve and slow rotating agitatorminimises clogging.

Hopper volumeThe basic hopper must be equipped with a scale that indica-tes litre levels so that the operator can ascertain fertilisercapacity at all times.

Hopper equipped with litre scales. In addition, withweigh load technology or electronic metering control,the amount of fertiliser remaining at any givenmoment is visually displayed on the screen.

RAUCH Landmaschinenfabrik GmbH �Postfach 1162 �76547 Sinzheim �Tel. 07221-985-0 �www.rauch.de

1

2

5

2

5

3

4

6

7

9

Um

wel

tnor

m-G

B 10

.200

3 PN