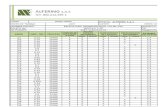

Florens Insp Repair Guideline Download

-

Upload

oscar-gabriel-pineda -

Category

Documents

-

view

224 -

download

0

Transcript of Florens Insp Repair Guideline Download

-

7/28/2019 Florens Insp Repair Guideline Download

1/96

GuidelinesWeb Publication

Florens Container

Services

September 2006

1

Acceptable and Unacceptable Repairs

Acceptable nonconforming repair at off-hire:

An improper repair not in compliance with existing IICL and Florens standards may beconsidered acceptable during off-hire inspection only when all of the following conditionsare met. (Repairs by Florens depot must comply with current IICL andFlorens repair standards).

1) Repair must be sound and be wind and water tight2) A reasonable attempt to perform proper repair must be have been made

3) Repair should not violate any regulation

4) Repair and unit should be fully operational for intended use.

5) Paint color on the repair should be the same. DIFFERENT SHADES(LIGHTER/DARKER) OF THE ORIGINAL COLOR IS ACCEPTABLE.

6) Unpainted minor straightening marks are acceptable at off-hire.

7) Common sense approach to classify acceptable/unacceptable repair is a must.

8) Repair must not compromise the safety or functionality of the equipment.

9) Material used in the repair should be capable and functional as the original.

Following improper repairs may be considered as acceptable if all of the above

criteria are met:

-

7/28/2019 Florens Insp Repair Guideline Download

2/96

GuidelinesWeb Publication

Florens Container

Services

September 2006

2

Acceptable and Unacceptable Repairs

Unacceptable, Non ConformingIICL Repairs

Repair not conforming to IICL standard and Florens' acceptable improper repair criterionshould be considered as unacceptable repair and rectified. When a repair is estimated asimproper, lessee bears the responsibility of proving that the repair was not performed whileon lease or the improper repair was present before lease out. An improper repair can beconsidered as unacceptable if any one of the following criterion is met:

Repair lacks structural integrity Repair may cause safety hazard or cargo damage Material used in the repair does not meet the strength requirement of the original material.

Note: If the repair cost to rectify an unacceptable improper repair is not to lessee's accountand the cost is above $50.00, detailed photos of the improper repair should be taken and sentto local Florens office for special approval. In addition to the photographs, a detaileddescription of the damage is also required.

The illustrations that follow should be used only as a guideline when making a decision on anonconforming repair. Each improper repair should be reviewed separately withconsideration given to the above criteria. If there is any doubt in classifying a repair asacceptable/unacceptable, please contact your local Florens office with photographs forfurther clarification.

-

7/28/2019 Florens Insp Repair Guideline Download

3/96

GuidelinesWeb Publication

Florens Container

Services

September 2006

1

Acceptable and Unacceptable Repairs

Panels:

1) Non conforming straightening2) Non conforming insert or section

3) Dissimilar panel profiles

4) Previous repairs with paint deterioration (rust)5) Repair with same color shade

Example: An acceptable fill welded repair at off-hire.Action:No rectification is required at off-hire inspection.

Pre-existing filler weld repair

Repair is not required

-

7/28/2019 Florens Insp Repair Guideline Download

4/96

GuidelinesWeb Publication

Florens Container

Services

September 2006

2

Acceptable and Unacceptable Repairs

Example: Acceptable weld repair before and after painting.Action: Repair is not required.

Example: A large damaged area that should have been patched.However, plug weld is an acceptable improper repair at off-hire or

if pre-existing. This repair is unacceptable if performed by Florensdepot.

Action: Repair is not required.

Pre-existing filler weld repair

Repair is not required

Pre-existing plug weld repair

Repair is not required

-

7/28/2019 Florens Insp Repair Guideline Download

5/96

GuidelinesWeb Publication

Florens Container

Services

September 2006

3

Acceptable and Unacceptable Repairs

Example: Pre-existing hammer marks. This repair is howeverunacceptable if performed by Florens' depot. Acorrugation dolly and good surface preparation methods

should be used to straighten dented panels.

Action: Repair is not required.

Example: Poor straightening, however meets all of Florensacceptable improper criteria at off-hire.

Action: Repair is not required if the illustrated type of repair ispresent at off-hire.

Note: This repair is unacceptable if performed by Florens depot.

Pre-existing hammer marks

Repair is not required

Poor straightening

Repair is not required

-

7/28/2019 Florens Insp Repair Guideline Download

6/96

GuidelinesWeb Publication

Florens Container

Services

September 2006

4

Acceptable and Unacceptable Repairs

Example: Poor straightening.Action:No repair is necessary.

Example: Minor hammer marks without paint.

Action: Repair is not required.

Straightening marks

Repair is not required

Minor straightening marks

Repair is not required

-

7/28/2019 Florens Insp Repair Guideline Download

7/96

GuidelinesWeb Publication

Florens Container

Services

September 2006

5

Acceptable and Unacceptable Repairs

Example: Minor straightening marks. Florens depot shoulduse backing plate to avoid multiple hammer marks.

Action: Repair is not required.

Example: Hammer marks indicate that backing plate wasnot used. Florens depot must use backing plate to straightenthese types of dents.

Action: This is an acceptable improper repair at off-hire.

Minor straightening marks

Repair is not required

Minor straightening marksRepair is not required

-

7/28/2019 Florens Insp Repair Guideline Download

8/96

GuidelinesWeb Publication

Florens Container

Services

September 2006

6

Acceptable and Unacceptable Repairs

Example: Areas where the interior paint is peeling due tonon repair-worthy impact damages

Action: Repair is not required.Note: Multiple peeling paint areas may be the resultof corrosive Cargo which may be considered damage.

Example: Surface paint failure and evidence of rust on anold repair.

Action:No action is required.

Spot rust on minor dents

Repair is not required

Surface rust on existing patch

Repair is not required

-

7/28/2019 Florens Insp Repair Guideline Download

9/96

GuidelinesWeb Publication

Florens Container

Services

September 2006

7

Acceptable and Unacceptable Repairs

Example: An old repair with advanced stages of corrosion.Action: Repair is not required.

Example: Bleeding rust from an old repair.Action: Repair is not required.

Surface rust on existing patch

Repair is not required

Bleeding surface rust

Repair is not required

-

7/28/2019 Florens Insp Repair Guideline Download

10/96

GuidelinesWeb Publication

Florens Container

Services

September 2006

8

Acceptable and Unacceptable Repairs

Example: Poor welding and surface preparation has causedpremature bleeding and rust.

Action: Repair is not required.

Example: Overlapping exterior patch.Action: Acceptable repair. No action is Required.

Poor surface preparationpre-mature rust

Repair is not required

Overlapping patch

Repair is not required

-

7/28/2019 Florens Insp Repair Guideline Download

11/96

GuidelinesWeb Publication

Florens Container

Services

September 2006

9

Acceptable and Unacceptable Repairs

Floors: Acceptable repairs

*Properly secured dowel repairs that are 25.4 mm (1") or less in diameter.

*Hardened, well adhering hard putty "bondo", floor filler can beconsidered acceptable as long as the filler does not exceed IICL

gouge criteria. Filler should be in flush with the floor andthe filled area must not pass through the floorboard.

*Floor sections with cuts into adjacent boards without light leak.

Example: Well adhering "bondo" repairs not exceeding IICLgouge criterion

Action: Requires no rectification.

Adhering bondo

Repair is not required

-

7/28/2019 Florens Insp Repair Guideline Download

12/96

GuidelinesWeb Publication

Florens Container

Services

September 2006

10

Acceptable and Unacceptable Repairs

Floors: Acceptable repairs

*Properly secured dowel repairs that are 25.4 mm (1") or less in diameter.

*Hardened, well adhering hard putty "bondo", floor filler can beconsidered acceptable as long as the filler does not exceed IICL

gouge criteria. Filler should be in flush with the floor andthe filled area must not pass through the floorboard.

*Floor sections with cuts into adjacent boards without light leak.

Example: Well adhering "bondo" repairs not exceeding IICLgouge criterion

Action: Requires no rectification.

Adhering bondo

Repair is not required

-

7/28/2019 Florens Insp Repair Guideline Download

13/96

-

7/28/2019 Florens Insp Repair Guideline Download

14/96

GuidelinesWeb Publication

Florens Container

Services

September 2006

12

Acceptable and Unacceptable Repairs

Example: Extremely poor workmanship. Repair lacksstructural integrity and material used is inferior and not painted.

Action: Repair is required.

Example: Heat deformation has caused the top rail to bow.Action: Repair is required.

Lacks structural

integrity-

Requires repair

Heat deformation on top

Rail-

Requires repair

-

7/28/2019 Florens Insp Repair Guideline Download

15/96

GuidelinesWeb Publication

Florens Container

Services

September 2006

13

Acceptable and Unacceptable Repairs

Example: Partial profile of the postover-heated and welded.

Action: Rectification is required.

Example: Capped top rail.Action: Repair required.

Over heated post-

Requires repair

Capped top rail

Requires repair

-

7/28/2019 Florens Insp Repair Guideline Download

16/96

GuidelinesWeb Publication

Florens Container

Services

September 2006

14

Acceptable and Unacceptable Repairs

Example: Lashing rod welded to corner post. The lashing rodintrudes into cargo space.

Action: This is a customer damage and should be repaired.(Please note: As previously illustrated, no repair isrequired, if the lashing bar did not interfere with the

cargo space).

Example: Poor surface preparation and lack of paint application.Action: This is an unacceptable improper repair. Correct repairprocedure would be to clean and paint the damaged area.

Intrusion into cargo space-

Requires repair

Poor surface preparation

Requires repair

-

7/28/2019 Florens Insp Repair Guideline Download

17/96

GuidelinesWeb Publication

Florens Container

Services

September 2006

15

Acceptable and Unacceptable Repairs

Example: Very poor straightening repair. This repair isunacceptable because reasonable attempt was not

made.

Action: The correct repair procedure would be to patch andpaint the damaged area.

Example: Unacceptable straightening. Original profile of thepanel is lost.

Action: Rework on the panel is required

No reasonable attempt to

repair the damage-

Repair required

Unacceptable straightening-Repair required

-

7/28/2019 Florens Insp Repair Guideline Download

18/96

GuidelinesWeb Publication

Florens Container

Services

September 2006

16

Acceptable and Unacceptable Repairs

Example: Original profile restoration and welding is unacceptable.Action: Rework is required.

Example: Greater portion of the original profile is not restored.Action: Unacceptable improper repair. Re-work is required.

Unacceptable weld and

straightening-

Repair Required

Unacceptable straightening-Repair Required

-

7/28/2019 Florens Insp Repair Guideline Download

19/96

GuidelinesWeb Publication

Florens Container

Services

September 2006

1

Acceptable and Unacceptable Repairs

Floors: Acceptable repairs

*Properly secured dowel repairs that are 25.4 mm (1") or less in diameter. Therepairs however should not be done in such a way. Florens depots are required to re-

pair according to IICL criteria.

*Hardened, well adhering hard putty "bondo", floor filler can beconsidered acceptable as long as the filler does not exceed IICL

gouge criteria. Filler should be in flush with the floor andthe filled area must not pass through the floorboard.

*Floor sections with cuts into adjacent boards without light leak.

Example: Well adhering "bondo" repairs not exceeding IICLgouge criterion

Action: Requires no rectification.

Adhering bondo

Repair is not required

-

7/28/2019 Florens Insp Repair Guideline Download

20/96

GuidelinesWeb Publication

Florens Container

Services

September 2006

2

Acceptable and Unacceptable Repairs

Example: Hard putty repair gouge that does not exceed IICLcriterion, and the filler is well adhering and does not pass through

the floor board.Action: Repair is not required.

Hard putty not exceeding IICL

gouge criterion

Repair is not required

-

7/28/2019 Florens Insp Repair Guideline Download

21/96

Web Publication

Florens Container Services

September 2006

1

Acceptable and Unacceptable Repairs

Decals

Florens does not require renewal or any type of repair on any horizontal, vertical or square Florenslogos on side panels or doors.

Note: If the horizontal decal is damaged even by more than 50%, no repair replacement or action is

required.

Prior to Gate-Out, all units must be inspected to ensure that Florens' ACEP decal is af-

fixed to CSC plate.

The following missing or damaged decals are acceptable. No rectification is required:

i) Empty lift decalii) UIC decal

iii) Corten steel decal

iv) TIR decalv) Classification decal

vi) Manufacturer's plate or decalvii) Side panel or door logos

viii)Only mismatched colors on numbers and letter markings. (prefix, unit #, weight markings)

-

7/28/2019 Florens Insp Repair Guideline Download

22/96

Web Publication

Florens Container Services

September 2006

2

Acceptable and Unacceptable Repairs

Example: Decal is less than 50% damaged.

Action:No action is required.

Example: More than 50% of the decal is damaged.

Action: Repair is not required.

Decal that is damaged by less than 50%

Repair is not required

Decal that is damaged by more

than 50%

Repair is not required

-

7/28/2019 Florens Insp Repair Guideline Download

23/96

Web Publication

Florens Container Services

September 2006

3

Acceptable and Unacceptable Repairs

Example of a square decal on side panel. No Action is required for damaged logos

Do not replace or

Repair exterior logos

-

7/28/2019 Florens Insp Repair Guideline Download

24/96

Web Publication

Florens Container Services

September 2006

4

Chevron/Height Decal

Example of Scratched / defaced Chevron (height marking) on top side rail.

Action: No rectification is required as 50% of the sign is still visible. Repair

only when marking is not entirely visible. When replacing chevron, the replacementdecal must be placed on the side panel right below the top rail. See yellow mark

on the photo below.

Locatio

nwher

enew

chevro

nisto

bepla

ced

-

7/28/2019 Florens Insp Repair Guideline Download

25/96

Web Publication

Florens Container Services

September 2006

5

Acceptable and Unacceptable Repairs

Example: All digits are legible despite having different colors.

Action: Repair is not required.

Example: Digits are damaged but still legible.

Action: Repair is not required.

Different colors on legible digits

Repair is not required

Damaged digits which are still legibleRepair is not required

-

7/28/2019 Florens Insp Repair Guideline Download

26/96

GuidelinesWeb Publication

Florens Container

Services

September 2006

1

Acceptable and Unacceptable Repairs

Paint Color

Repairs with the same paint color from the original color, but having different

shades in the interior or exterior of the container is acceptable improper repair at

off-hire. Extreme digressions in the color, such as brown on green, yellow or red needrectification of the paint at lessee's account.

Florens depot must use:

Interior color - RAL 7035 (gray) and have DFT of 80 microns.

Exterior color - BS445 (red brown) and have DFT of 125 microns.

Example: Different paint color in the interior of the container isUnacceptable improper repair at off-hire

Action: Different color requires correction.

Note: Florens depot must use Florens' interior color RAL 7035 (gray) andhave DFT of at least 80 microns.

Different paint color

Repair is required

-

7/28/2019 Florens Insp Repair Guideline Download

27/96

GuidelinesWeb Publication

Florens Container

Services

September 2006

2

Acceptable and Unacceptable Repairs

A - Different paint color on the exterior side panels should beconsidered as damage and repaired.

B- Minor variations of the paint shade on the exterior side panelsis acceptable improper repair. No action is required.

Florens depot must use BS445 (red brown) and

have DFT of 125 microns for the exterior panels.

Example:Minor variation from the original paint color.

Action:No repair is required.

A B

Unaccep

tablecolor

Repairis

required

Acceptablec

olor

Repairisnotrequired

Minor variation in paint color

Repair is not required

-

7/28/2019 Florens Insp Repair Guideline Download

28/96

GuidelinesWeb Publication

Florens Container

Services

September 2006

3

Acceptable and Unacceptable Repairs

Example: Lashing rod welded on the front corner post.

Action: Removal of the rod is not required. However,the repair should be cleaned and painted with same shade oforiginal panel color.

Example: Lashing bar welded on the corner casting and top rail.

Action: No action is required.

Welded rod does not protrude into cargo spaceRemoval is not requiredClean &Paint the repair

Welded bar from the casting to top rail.

No action is required.

-

7/28/2019 Florens Insp Repair Guideline Download

29/96

GuidelinesWeb Publication

Florens Container

Services

September 2006

1

Acceptable and Unacceptable Repairs

Door and Door Hardware

In addition to the current IICL criteria, the following guidelines should be applied for the

door and the door hardware:

a) If a patch is required under the CSC plate, the original plate must be refitted. If the CSC

plate is lost or destroyed, it must be replaced. Contact your local Florens office to obtainthe CSC details for the container.

b) Door panel sections at the gasket area should always be butt welded and be flush with

the original panel. Note: Existing patches that overlap should not be replaced, as this isan acceptable improper repair.

c) When a full width insert or section is performed around the hinge blade, the hinge blade

should be removed from the door panel. Do not cut around the hinge blade.Note: Preexisting door repairs with a good quality weld is an acceptable improper repair.

d) Damaged or cracked hinge blades or pins require repair. The repair cost should be in the

account of lessee. Welded hinge blades are unacceptable and should be repaired in allcases.

e) Damaged or missing bushing in a locking bar guide or bracket requires no repair if thedoor operations are not interfered. However, if a guide or bracket is replaced, the repairshould include the installation of the new bushing.

f) Bent or distorted locking bar brackets require repair only if the door operationis hampered.

g) Missing or damaged door tiebacks do not require repair or replacement.

Note: If local conditions require tie backs to be present, replace tie backs on

Florens account.

h) Corroded gasket retainers do not need to be replaced or sectioned as long as it isefficiently securing the gasket in place.

i) The basic principle to apply to determine the repair worthiness of the gasket is lightleakage. If the gasket is light tight, no repair is required.

-

7/28/2019 Florens Insp Repair Guideline Download

30/96

GuidelinesWeb Publication

Florens Container

Services

September 2006

2

Acceptable and Unacceptable Repairs

Door and Door Hardware

Example: Insert not flush with the door panel, causing thedoor bracket to sit unevenly. Correct repair would be flushfitting butt welded insert.

Action:No corrective action is required at off-hire.

Example: The bracket was removed to facilitate repairs.Florens depot must reapply galvanized or stainless steelhardware to the bracket.

Action: This is an acceptable improper repair at off-hire.

Welded bracket

Repair is not required

Locking bar is still functional

Repair is not required

-

7/28/2019 Florens Insp Repair Guideline Download

31/96

GuidelinesWeb Publication

Florens Container

Services

September 2006

3

Acceptable and Unacceptable Repairs

Door and Door Hardware

Example: Welded door hardware. Florens depot shouldreattach using galvanized or stainless steel fasteners.

Action: Properly welded hardware is acceptable improper repair.Repair is not required.

Example: Damaged or missing bushing in a locking bar guideor bracket.

Action: This damage requires no repair if the door operations arenot interfered. However, if a guide or bracket is replaced, the repairshould include the installation of the new bushing.

Bushing missing in locking bar

guide or bracket

Repair is not required

-

7/28/2019 Florens Insp Repair Guideline Download

32/96

GuidelinesWeb Publication

Florens Container

Services

September 2006

4

Door and Door Hardware

Example: : Distorted and bent locking bar bracketsAction: Require repair only if the door operation is affected.

Example: A full width insert or section is around the hinge

Blade. The hinge blade should be removed from the doorpanel. Do not cut around the hinge blade.

Action: Preexisting door repairs with a good quality weld isan acceptable improper repair.

Distorted locking bar bracket

Repair is not required

if door is functional

Good quality weld around the

hinge blade

Repair is not required

-

7/28/2019 Florens Insp Repair Guideline Download

33/96

GuidelinesWeb Publication

Florens Container

Services

September 2006

5

Door and Door Hardware

Example: Weld on hinge blade has questionable structuralintegrity.

Action: Rectification is required.

Example: Repair worthiness of a damaged gasket mustbe determined by checking for light leak. Mere cut

on the gasket, as illustrated, does not warrant repair.

Action: If the cut on the gasket does not leak light, no

repair is required.Note: When a piece of gasket material is missing, an insertis required, otherwise, a more economical repair method

such as bonding the cut area together is preferred.

Poor weld

Repair is required

If the cut does not leak light

Repair is not required

-

7/28/2019 Florens Insp Repair Guideline Download

34/96

GuidelinesWeb Publication

Florens Container

Services

September 2006

6

Door and Door Hardware

Example: The gasket in the illustration does not leak light.Action: No repair is required.

Example: Minor cuts on the gasket which does not leak light.

Action:No repair is required.

Minor cut on the gasketdoes not leak light

Repair is not required

Gasket does not leak lightRepair is not required

-

7/28/2019 Florens Insp Repair Guideline Download

35/96

GuidelinesWeb Publication

Florens Container

Services

September 2006

1

Vents

Minor hairline crack on the vent does not warrant repair or replacement. The air vents must

be replaced only when more than two attachment points are cracked through the edge ofthe vent. In addition, missing, loose or failing sealant does not require repair.

Cracks can be sealed using Sikaflex 221 or equivalent.

Example: Minor hairline crack on the vent does not require repairor replacement. The air vents can only be replaced when morethan two attachment points are cracked through the edge of the vent.

Action:No repair is required.

Example: Missing, loose or failing sealant on the air ventAction: Does not require repair.

Less than two hairline crack

Repair is not required

Loose sealant on the vent

Repair is not required

-

7/28/2019 Florens Insp Repair Guideline Download

36/96

GuidelinesWeb Publication

Florens Container

Services

September 2006

1

Preventive Maintenance / Reconditioning

Florens does not endorse cosmetic repairs on components that result from normal wear

and tear. Only a few and very limited items should be considered as maintenance whichcan be charged to Florens account. As a general rule, maintenance may be required only

when heavy corrosion may compromise the functionality and can lead to structural failure ofthe component. A typical example would be a loose door gasket resulting from

non-damage corrosion of the retaining strip. In addition, a corroded component should onlybe replaced when 50% or more of the entire component is affected, otherwise sectioning or

inserting must be considered, as this type or repair is more economical.

Example: Corroded gasket retainer. However,the functionality of the retainer to securethe gasket is intact.

Action:No repair is required.

Superficial rust on

gasket

Repair is not

required

-

7/28/2019 Florens Insp Repair Guideline Download

37/96

GuidelinesWeb Publication

Florens Container

Services

September 2006

2

Preventive Maintenance / Reconditioning

Example: Superficial rust on the door panel. The area is structurallysound, and water & light tight.

Action:No repair is required.

Example: Heavy door bottom corrosion. Door operation howeveris not compromised and the gasket is still functional.

Action:No maintenance repair is required.

Surface rust on door

panel-

Repair is not required

Gasket and door are functional

Repair is not required

-

7/28/2019 Florens Insp Repair Guideline Download

38/96

GuidelinesWeb Publication

Florens Container

Services

September 2006

3

Preventive Maintenance / Reconditioning

Example: Blunt chipping hammer has led to metal loss in thecorroded area.

Action: Maintenance repair is required.

Example: Superficial rust on the header. Door is functional.

Action: Repair is not required.

Corroded door panel with holes

Repair is required

Superficial rust

Repair is not required

-

7/28/2019 Florens Insp Repair Guideline Download

39/96

GuidelinesWeb Publication

Florens Container

Services

September 2006

4

Preventive Maintenance / Reconditioning

Example: Heavy corrosion on the cross-member flanges, howeverthe functionality of the component is not compromised.

Action:No repair is required.

Example: High degree of localized rust on the front panel. No repair

is required if there are no holes and the container is wind and water tight.Careful use of a blunt chipping hammer to test the loss of parent materialis advisable when severe rust spot is noticed.

Action: Repair is required only when loss of material is evident.

Corroded, but metal intact

Repair is not required

Heavy corrosion, but no pin holes

Repair is not required

-

7/28/2019 Florens Insp Repair Guideline Download

40/96

GuidelinesWeb Publication

Florens Container

Services

September 2006

1

Open tops

Technical criteria to be applied to open top containers are the same as any other Florens'

equipment, i.e. prevailing IICL standard and Florens' depot procedure. Componentsrequiring special attention are:

Roof bows:Roof bows that are cut, broken or do not fit properly should be repaired or replaced.

As dictated by IICL standard, the replacement bow material has to be "like for like" or

of higher quality. The surface of the roof bow should be smooth, snag free and withoutrough drip lines. The dimensions (camber/bow) must conform to ISO standards and allow

for proper water drainage. Florens' typical specification for roof bow is:

Material: STKR41 H.D.G (75 microns)Size: 34mmx3.0mm

Example: Replaced roof bow is of different geometry. It does not have roughdrip lines or jagged edges.

Action: Roof bow should not be replaced or repaired. This is anacceptable repair.

Different profile

Repair is not required

-

7/28/2019 Florens Insp Repair Guideline Download

41/96

GuidelinesWeb Publication

Florens Container

Services

September 2006

2

Open tops

Example: Roof bow with jagged edges will tear the tarpaulin or causepinholes.

Action: This is an unacceptable repair. Roof bow should be replaced.Replacement should be on lessee's account.

Grommets/eyelets:Any missing, damaged, loose or misaligned grommet should be repaired/replaced when itimpairs the tarpaulin to secure properly or it hinders from being weather proof. Surface rust

on the eyelets does not warrant repairs.

The replacement grommets should have a minimum specification of:

Material: SS41 H.D.G (40 microns)Size: circular, inside 40mm, overall 60mm

Note: Florens accepts brass, zinc and hard plastic eyelets at the regular cost of

carbon steel grommets.

Sharp profile

Repair is required

-

7/28/2019 Florens Insp Repair Guideline Download

42/96

GuidelinesWeb Publication

Florens Container

Services

September 2006

3

Open tops

Example: Rust on the eyelets. AnEyelet should be repaired only whenloose, misaligned, missing, or damaged and it impairs tarpaulin to secureproperly.

Action: Repair is not required.

Example: Illustration shows various degree of rust on the eyelets. First

eyelet from the left is still intact and functional. Other eyelets have surface

rust. Action: No action is required on any of the eyelets.

Rusted eyelet

Repair is not required

Rusted eyelets

Repair is not required

-

7/28/2019 Florens Insp Repair Guideline Download

43/96

GuidelinesWeb Publication

Florens Container

Services

September 2006

4

Open tops

A - Grommet A is corroded, but serviceable and functional

No repair is required.

B - Grommet B is cracked due to rust. Broken eyelets due to rust should

be replaced on Florens' account. Replacement is required.

Example: Broken eyelet. An eyelet should be repaired onlywhen it is loose, misaligned, missing, or damaged and it impairs

tarpaulin to secure properly.

Action: Illustrated eyelet should be replacedfor the account of Florens as normal wear and tear.

B

A

Cracked eyelet

Repair is required

Cracked eyelet

Repair is required

-

7/28/2019 Florens Insp Repair Guideline Download

44/96

GuidelinesWeb Publication

Florens Container

Services

September 2006

5

Open tops

TIR cord:Cuts on the plastic cover are acceptable provided the galvanized steel strands are not cut orfraying. Cables not having proper length must be replaced for the lessee's account.

In addition, missing or damaged "metal end piece"/securing points should be repaired for

the lessee's account. Specifications for the replacement cord are:

6mm - 8mm, one piece steel cable with provisions for TIR seals coveredwith clear PVC sheathing

Example: Strands on the cable are frayed and cut.Action: Replacement on lessee Account is required.

Note: Cuts only on the plastic cover of the cable does not require repair.

Cut CableRepair is required

Cut only on plastic cover

Repair is not required

-

7/28/2019 Florens Insp Repair Guideline Download

45/96

Web Publication

Florens Container Services

September 2006

1

Open tops

Rear Header:As a movable part, the rear header should be in good working order and not interfere withdoor operations. Header and pins should be lubricated during normal repair process at no

charge to Florens. At on-hire, as with any other equipment, rear header should be inspected

and an operational test performed to make sure that the header swings freely.

As with any movable part, header and pins should be lubricated

during normal repair process at no cost to Florens.At on-hire, an operational test must be performed to ensure

that headers swing freely.

-

7/28/2019 Florens Insp Repair Guideline Download

46/96

GuidelinesWeb Publication

Florens Container

Services

September 2006

1

Open tops

Drip Pan:Cracked drip pans should be re-welded. All other criteria should be followed as statedin IICL standard.

Corner Gaskets:Damaged or missing corner gaskets should be repaired under lessee's account.

Painting instructions for top rails:Following instructionsshould be followedto paint top rails of the open tops.

Chloronated rubber topcoat should never be applied on open top rails.

Acceptable paint system

1) Amerlock 400 or 350 (varnish of at least 25Microns)2) Three coat system consisting of:

Exterior (DFT) Interior (DFT)

a) zinc rich primer 30 to 35 30b) epoxy primer 40c) polyester resin enamel top coat 55 to 60 80

-

7/28/2019 Florens Insp Repair Guideline Download

47/96

GuidelinesWeb Publication

Florens Container

Services

September 2006

1

Open tops

Tarpaulin:Repair estimates on tarpaulins should be in accordance with TIR standards.

A) At off-hire, when a tarp is missing or is not installed or partially installed on theopen top, depots should note this on the interchange and the estimate. Depots shouldalso obtain confirming signature from the delivering carrier. In addition, weatheringdamage on the floor should be noted. Protect the floor by stacking another container on top.

B) Following is the minimum specification for the replacement tarp: Weight: 18oz/500gms/sq.m Color: blue/BS445 Material: polyester, PVC coated

Grommets: carbon steel, galvanized to 40 microns.(bras, zinc and hard plastic grommets are acceptable)

Reinforcement at roof bow: none Reinforcement at side rails: none Markings: none

Note: Florens depots must replace tarp according to Florens' specifications. Different tarpcolor is acceptable only if all other specifications are met and Florens' customer makes

the replacement during lease.

Example: Tarpaulin color that is different than Florens' blue (BS445).Action: Different color is acceptable only if all other specifications are metand the tarpaulin is replaced during lease. Florens depot must replace tarpaulinaccording to Florens' specifications.

-

7/28/2019 Florens Insp Repair Guideline Download

48/96

GuidelinesWeb Publication

Florens Container

Services

September 2006

2

Open tops

Replacement cost allocation: When it is more economical to replace the tarpaulinthan to repair, depots must replace tarpaulin.

Florens does not advocate lease period or age as factors to allocate repair costs betweendamage and normal wear and tear. Allocation for tarpaulin replacement that has damageand normal wear and tear above the economic value of the repair must comply with the

following steps. The cost should include labor + material.

1) Calculate total cost of repair (damage plus normal wear and tear. Include labor and material),for example, the total cost = $1000.

2) Calculate the percentage of damage cost. For example, the damage cost = $900, or900/1000 = 90%

3) Calculate the percentage of NWT cost.For example, the NWT cost = $100, or 100/1000 = 10%

Apply each individual percentage to allocate the replacement cost of the tarpaulin.For the above example, to replace a 40' tarpaulin at $400, the lessee allocationshould be $360, and NWT allocation should be $40.

Tarpaulin replacement versus repair: When the repair cost of the tarpaulin is 90% ofthe replacement cost, the tarpaulin should be replaced and not repaired. The additional costof replacement should be allocated as NWT to Florens' account. The additional cost shouldbe noted as a separate line item on the estimate.

-

7/28/2019 Florens Insp Repair Guideline Download

49/96

GuidelinesWeb Publication

Florens Container

Services

September 2006

3

Open tops

Pinholes: Pinholes that are less than 5 mm (.20) in diameter can be repaired by usingone component polyurethane caulk (Sikaflex) or "donut" patches. Pinholes that are between5 mm (.20) and 10 mm (.40), must be repaired with a donut patch or a standard patch.In addition, no more than 4 pinhole repairs using caulking or "donut" within a 4"(10 CM)diameter is allowed, otherwise a standard patch must be applied.

Cuts and holes greater than 10 mm (.40): Cuts and holes that are greater than10 mm (.40) require a standard patch which should overlap by at least 15 mm (6) fromall the edges of the damage being repaired.

Patches greater than 100mm (4.0) X 100 mm (4.0): Patches greater than100mm (4.0) X 100 mm (4.0) must have TIR tape applied to the perimeter of the patch.

Existing intact patch without TIR tape is an acceptable repair during off-hire

inspection - no rectification is required.

Example: Caulked tarpaulin repair.Action:No repair is required.Note: Pinhole measuring less than 5 mm in diameter can be repaired

using one component polyurethane caulk.

Note: All repairs are permitted within an existing patch that is properly fitting to

the original tarpaulin. However, Florens does not recommend repair methods that

overlap over the seams of the pre-existing patch.

Caulked RepairRepair is not required

-

7/28/2019 Florens Insp Repair Guideline Download

50/96

GuidelinesWeb Publication

Florens Container

Services

September 2006

4

Open tops

Example: Proper pinhole caulk repair.Action: Repair is not required.Note: Tarpaulin surface must be cleaned with thinner beforeany repair is performed.

Example: Pinhole area measures less than 5mm.Action: This is an acceptable caulk repair.

Caulked RepairRepair is not required

Caulked RepairRepair is not required

-

7/28/2019 Florens Insp Repair Guideline Download

51/96

GuidelinesWeb Publication

Florens Container

Services

September 2006

5

Open tops

Example: Large tear caulked over.Action: Unacceptable repair. Rectification is required.

Example: More than 4 pinhole repairs using caulk or "donuts" within100 mm (4).

Action: Repair is required.Note:No more than 4 donuts are allowed within 100 mm (4") diameter.

Larger area CaulkedRepair is required

More than 4 donuts within100 mm diameter.Repair is required

-

7/28/2019 Florens Insp Repair Guideline Download

52/96

GuidelinesWeb Publication

Florens Container

Services

September 2006

6

Open tops

Example: Pinhole measuring between 5mm and 10mm must berepaired with a "donut" patch or a standard patch.Action:No repair is required.

Example: Patches greater than 100mmX100mm (3.9X3.9) musthave TIR tape applied to the perimeter of the patch as shown in theillustration.Action:No repair is required.

Note: If the TIR tape is missing, but the patch is intact (completely adhering) at off-hire

inspection, no rectification is required.

Donut repair required for pinholes be-tween 5 mm and 10 mm.

No Repair is required

Patches greater than 100mm X100mm

must have TIR tape (see note below)Repair is not required

-

7/28/2019 Florens Insp Repair Guideline Download

53/96

GuidelinesWeb Publication

Florens Container

Services

September 2006

7

Open tops

Example: Pinhole measuring between 5mm and 10mm must berepaired with a "donut" patch or a standard patch.Action:No repair is required.

Example: Patches greater than 100mmX100mm (3.9X3.9) musthave TIR tape applied to the perimeter of the patch as shown in theillustration.Action:No repair is required.

Note: If the TIR tape is missing, but the patch is intact (completely adhering) at off-hire

inspection, no rectification is required.

Donut repair required for pinholes be-tween 5 mm and 10 mm.

No Repair is required

Patches greater than 100mm X100mm

must have TIR tape (see note below)Repair is not required

-

7/28/2019 Florens Insp Repair Guideline Download

54/96

GuidelinesWeb Publication

Florens Container

Services

September 2006

1

Refrigerated Containers

Technical criteria to be applied to refrigerated containers are the same as any otherFlorens equipment, i.e. prevailing IICL standard and Florens depot procedure. Componentsrequiring special attention are:

Machinery

Pre / Post Trip Inspection

The cost for performing the Post Trip Inspection must be priced on the repair estimate.

Please consult with your local Florens Operations representative before assigning cost responsibility

to Lessor or Lessee.

A Florens Pre / Post Trip Inspection Schedule form must be completed at the time of

Pre or Post Trip (Depots are required to use the Florens form or an alternative form that includes

all the elements of the Florens form. Please see Florens Pre / Post Trip InspectionSchedule attachment A). The completed form is to be retained by the depot as a

permanent record. The content of the information on the form should be same or more than theForm in attachment A.

Temperature Recorder

Missing or damaged Winding Keys are not to be replaced.

Example: Missing Partlow key and string requires no rectification.

Action: Do not replace.

-

7/28/2019 Florens Insp Repair Guideline Download

55/96

GuidelinesWeb Publication

Florens Container

Services

September 2006

2

Repairs on Partlow

Florens may decide not to repair some components of the Partlow device in the reefer machinery hav-ing Microlink 2ii and above models with data logger.

When Florens elects not to repair such components, the depots will be notified. In these instances,

please follow the procedure outlined below and place a non-operational partlow decal (supplied byFlorens) on the door of the partlow box.

NOTE: IN ALL INSTANCES PARTLOW DOOR MUST BE FUNCTIONAL AND WATER-

TIGHT.

Depots should continue to estimate partlow repairs as usual regardless of the damage re-

sponsibility (User, DPP or NWT).

Place non operational partlow decal on the door of the partlow box uponinstructions from Florens that the partlow should not be repaired.

Note: IN ALL INSTANCES PARTLOW DOOR MUST BE FUNCTIONAL AND WATERTIGHT.

Place non operational partlowdecal when Florens notifies

that partlow will not be re-

paired.

-

7/28/2019 Florens Insp Repair Guideline Download

56/96

GuidelinesWeb Publication

Florens Container

Services

September 2006

3

Repairs on Partlow

Place the above non-operational decal supplied by Florens on the partlow door

when Florens instruction states that partlow must not be repaired.

-

7/28/2019 Florens Insp Repair Guideline Download

57/96

GuidelinesWeb Publication

Florens Container

Services

September 2006

4

Refrigerated Containers

Machinery

Cables / Plugs

Missing 230 volt plugs are not to be replaced (230 volt cable must meet IICL requirements).

Replacement or installation of (1) cable voltage indicator sleeve is necessary if both

cables are the same color and both indicator sleeves are missing or illegible.

A maximum of 2 proper splices per cable is permitted.

Damaged Cable Stowage doors, door hinges and latches are not to be repaired/replaced.

If the functionality is compromised, remove the door.

Example: Damaged Cable stowage door, door hinges, or door latch.

Action: Remove door on lessee account. No other repair is required.

Damaged door, hinges, or latch

Remove door

-

7/28/2019 Florens Insp Repair Guideline Download

58/96

GuidelinesWeb Publication

Florens Container

Services

September 2006

5

Refrigerated Containers

Example: 230 volt cable is damaged.

Action: replace/repair cable

Note: when 230 volt plug is missing, no replacement is required.

Example: Missing cable indicator sleeve.

Action: If 430 volt and 230 volt cables are of different colors,

do not install sleeve.

Damaged 230V cable

Repair is required

Missing cable indicator

sleeveRepair is not required if

cables are of different

colors

-

7/28/2019 Florens Insp Repair Guideline Download

59/96

GuidelinesWeb Publication

Florens Container

Services

September 2006

6

Refrigerated Containers

Microprocessor

Damaged Battery Pack housings are to be replaced on lessee account.

Discharged batteries are to be replaced at Florens account. Missing batteries are to be replaced onlessee account.

Disconnect the ground wire when welding on the machine or container

(This cost is included in the Post Trip inspection fee and is not to be billed separately).

Component Refurbishment

Compressor refurbishment is to be estimated when surface corrosion affects 75% or

more of the component.

Valve and coil housings are not to be refurbished if they are operational and functional.

Example: Surface corrosion on less than 75% of the component.

Action: Refurbishment is not required.

Surface corrosion less than 75%Repair is not required

-

7/28/2019 Florens Insp Repair Guideline Download

60/96

GuidelinesWeb Publication

Florens Container

Services

September 2006

7

Refrigerated Containers

Example: Corrosion on more than 75% of the component.

Action: Refurbishment: is required.

Example: Less than 75% of surface corrosion on the component.

Action: Do not refurbish.

More than 75% corroded

Refurbishment is required

Surface corrosion less than 75% of

the component

Repair is not required

-

7/28/2019 Florens Insp Repair Guideline Download

61/96

GuidelinesWeb Publication

Florens Container

Services

September 2006

8

Procedure for abrasive cleaning and paintingcorroded compressor

Compressor must exhibit approximately 75% surface rust/corrosion before abrasive cleaning

and painting repair is done on it. Please refer to the Florens Technical and Operations Man-ual, section 8 pages 4 and 5 for guidance in selecting a candidate for this type of repair.

Preferred method of cleaning is to use the needle gun to abrasive clean the

surface rust and flaking paint. Other mechanical method of cleaning, such as

wire brushing is acceptable as long as the surface rust is removed properly.

DO NOT REMOVE THE COMPRESSOR FROM THE UNIT. Cleanand paint as much of the surface area as possible without removing the com-

pressor.

-

7/28/2019 Florens Insp Repair Guideline Download

62/96

GuidelinesWeb Publication

Florens Container

Services

September 2006

9

Procedure for abrasive cleaning and painting

corroded compressor

Use hand tool to clean crevices, and wire brush the entire compres-

sor to obtain correct surface preparation for paint application.

.

As a final step before paint application, using the blower, air clean the

entire compressor. No dust or paint flakes should remain on thecompressor.

-

7/28/2019 Florens Insp Repair Guideline Download

63/96

GuidelinesWeb Publication

Florens Container

Services

September 2006

10

Procedure for abrasive cleaning and painting

corroded compressor

Before applying the paint, mask all the adjacent areas including hoses,

valve cap, sight glass and compressor ID plate. In accordance with thepaint manufactures recommendations:

1) Apply the Prime Coat (Hempadur 15570 WFT 200 DFT 100)

2) Apply the Intermediate Coat (Hempadur 45142 WFT 250 DFT 150)3) Apply the Top Coat (Hempathane 55210 WFT 100 DFT 50

After following the paint suppliers recommendation for the paint

curing time, remove the masking tapes.

-

7/28/2019 Florens Insp Repair Guideline Download

64/96

GuidelinesWeb Publication

Florens Container

Services

September 2006

11

Refrigerated Containers

Example: Valve coil with surface corrosion.

Action: If it is functional, do not refurbish.

Use of Remanufactured Components

The use of certain remanufactured electrical and mechanical components is allowed and

often encouraged by Florens. Contact your local Florens Operations representative for

details relating to specific remanufactured components and approved dealers.

Valvecoilwithsurfacecorrosion

Norepair

isrequirediffunctional

-

7/28/2019 Florens Insp Repair Guideline Download

65/96

GuidelinesWeb Publication

Florens Container

Services

September 2006

12

Refrigerated Containers

Example: Valve coil with surface corrosion.

Action: If it is functional, do not refurbish.

Use of Remanufactured Components

The use of certain remanufactured electrical and mechanical components is allowed and

often encouraged by Florens. Contact your local Florens Operations representative for

details relating to specific remanufactured components and approved dealers.

Valvecoilwithsurfacecorrosion

Norepair

isrequirediffunctional

-

7/28/2019 Florens Insp Repair Guideline Download

66/96

GuidelinesWeb Publication

Florens Container

Services

September 2006

13

Machine Handles

Missing or damaged handle assembly on the machine do not require repair or replacement.

Handle assembly on reefer machinery.

Example: Missing handle on the machinery.

Action: Do not replace the handle.

-

7/28/2019 Florens Insp Repair Guideline Download

67/96

GuidelinesWeb Publication

Florens Container

Services

September 2006

14

Refrigerated Containers Addendum June 2004

Battery Replacement for Carrier Machinery

Battery Replacement for USDA equipment.

Standard Carrier machinery specification for Florens reefers do not have USDA equipment.The battery powering USDA30-00407-02SV should be removed (if present) and is not to be

repaired/replaced when the USDA is not installed in the reefer container. In addition, thejumper cables from the battery to the board must be removed at the time of post trip inspection.

In some cases, when USDA equipment is present, the batteries must emit power and be oper-

able. At off-hire, if the battery is missing or damaged, the repair should be under lessee's ac-count. Discharged batteries should be for Florens account.

Florens

reefer fleet does not have USDA as a standard equipment.

-

7/28/2019 Florens Insp Repair Guideline Download

68/96

GuidelinesWeb Publication

Florens Container

Services

September 2006

15

Refrigerated Containers Addendum June 2004

Battery Replacement for Carrier Machinery

Battery Replacement for USDA equipment.

Example: Carrier battery pack30-0047-02SV is requiredonly if USDA equipment is present in the reefer container.

Action:Remove the battery pack and the jumper cable ifUSDA equipment is not present in the container. In addition,

no replacement is required.

Example: Jumper cable for Carrier battery pack30-0047-02SV

Action:Remove the battery pack and the jumper cable ifUSDA equipment is not present in the container. In addition,no replacement is required.

-

7/28/2019 Florens Insp Repair Guideline Download

69/96

GuidelinesWeb Publication

Florens Container

Services

September 2006

16

Refrigerated Containers Addendum June 2004

Battery Replacement for Carrier Machinery

RTC Battery located in the Controller.

Battery 09-00369-00SV, located in the controller should be functional and not missing. If the

battery is discharged, replace the battery on Florens account and if it is missing, replace it onlessees account

Alarms 86 and 87 during pre/post trip identify the problems with the battery.

Example: Battery 09-00369-00SV in the controller box must be

functional and tested at pre/post trip.

Action: Discharged battery should be replaced on Florens account.Missing or damaged battery should be replaced on lessee account.

Battery Pack

-

7/28/2019 Florens Insp Repair Guideline Download

70/96

-

7/28/2019 Florens Insp Repair Guideline Download

71/96

GuidelinesWeb Publication

Florens Container

Services

September 2006

18

Reefer Condenser Coils

Condition: Condenser fin corrosion

Action: The extent of corrosion shown in the example above does not re-quire replacement.

Condition: Condenser fin corroded and the internal tubing is exposed.

Action: Measure discharge pressure when the container passes thru therating temp. If the discharge pressure is within the tolerance, no action

is required.

-

7/28/2019 Florens Insp Repair Guideline Download

72/96

GuidelinesWeb Publication

Florens Container

Services

September 2006

19

Reefer Condenser Coils

Condition: Obstructed and blocked coil fins. There is saltcollection and the protective coating is failing. The fins

bend easily but do not break.

Action: Water wash under standard tap water pressure underFlorens account.

Condition: Thedegree of the corrosion of the coil fin abovedoes not require replacement. The fins are scrapped and bent dueto physical corrosion testing. Visual testing is Preferred.

Action:No action is required.

-

7/28/2019 Florens Insp Repair Guideline Download

73/96

GuidelinesWeb Publication

Florens Container

Services

September 2006

20

Reefer Condenser Coils

Condition: Blocked condenser coil fins. No tubing is exposed.

Action: Aftervisual inspection, water wash using standard tap pressure onFlorens account.

Condition: Damage to the fins.

Action:No repair is required on minor fin damage as illustrated above.Excessive damage that restricts airflow or reduce cooling capacity maybe repaired using fin combs.

Note: Damage to the tubing is not to be repaired by sectioning. If a tubeis dented by more than 45%, replace the coil on lessee account.

-

7/28/2019 Florens Insp Repair Guideline Download

74/96

GuidelinesWeb Publication

Florens Container

Services

September 2006

21

Reefer Condenser Coils

Condition: Exposed tubing and corroded condenser fins.

Action: Replace condenser coil on Florens account.

Condition: Deeply corroded condenser fins. A slight scrapping or waterwash will expose the tubing.

Action: Replace condenser coil.

-

7/28/2019 Florens Insp Repair Guideline Download

75/96

GuidelinesWeb Publication

Florens Container

Services

September 2006

22

Refrigerated Containers

Pre / Post Trip Inspection Form (AttachmentA)

SPECIAL INSTRUCTIONS

Temperature specified: Other: (Fresh Air Setting)

Plug Type:

Voltage:

COMPONENT code COMMENTS CRITERIA

1.0 Container

1.1 Panels/Walls see structural criteria

1.2 Roof Panel no condensation

1.3 Cleanliness dry1.4 Doors fully operational

2.0 Cabinets/Hatch (REMOVE FAN HATCHES)

2.1 Doors/Windows/Hinges

water tight; clear glass;

gasket

2.2 Partlow cabinet clean & dry; gasket

condition

2.3 Controller cabinet clean & dry; gasket

condition2.4 Hatchesevap. &

heater

airtight; all fasteners

present

2.5 Interior bulkheads secured; no holes

2.6 Air baffle plate hinges

2.7 Fresh air exchange

vent

air tight

Unit Number Mechanic Name

Model # Cooling Unit Ambient Temperature

Serial # Cooling Unit Date and Time:

Serial # Micro:

Serial # Compressor:

Voltage type:200VAC 400VAC Dual Water Cooled condenser: Yes No

Location/Depot: Voltage Supply:

-

7/28/2019 Florens Insp Repair Guideline Download

76/96

GuidelinesWeb Publication

Florens Container

Services

September 2006

23

Refrigerated Containers

Pre / Post Trip Inspection Form

UNIT ID NUMBER: DATE:

3.0 Electrical

3.1 Main Cable 10/4 type length

splices

min length R40=60ft

(18M)

3.2 Main Cable 8/4 type length

splices

min length R20=50ft

(15M)

3.3 Plug 200 VAC model optional

3.4 Plug 400 VAC model required

3.5 400 v. Circuit Breaker general condition; clean

3.6 200 v. Circuit Breaker general condition; clean

3.7 Terminals/Connections tight & well insulated

3.8 Wiring/Insulation routing and condition

3.9 Contactors/Points replace only if points

missing

point material

3.1

0

Control transformer clean; no corrosion

COMPONENT code COMMENTS CRITERIA

4.0 Frame

4.1 Mount Bolts present; torque

5.0 Compressor/Condens

er

5.1 Condenser Coil/Fins clean, free of debris

5.2 Drier no rust.

restriction=replace

5.3 Service valve caps present with O ring; tight

5.4 Solenoid valve coils light rust only

5.5 Mod/SSV light rust only5.6 Compressor mounts no cracks; correct torque

5.7 Guards complete and secured

-

7/28/2019 Florens Insp Repair Guideline Download

77/96

GuidelinesWeb Publication

Florens Container

Services

September 2006

24

Refrigerated Containers

Pre / Post Trip Inspection Form

UNIT ID NUMBER: DATE:6.0 Controller

6.1 Printed circuit boards clean; no cracks (analogunits only; N/Amicroprocessors)

6.2 Control relays clean

6.3 Indicator lights correct colored lens

6.4 Remote monitor;cap/chain

mark if not present_______

6.5 Temperature display all segments display6.6 Temperature set station legible

7.0 Evaporator

7.1 Heaters/Mounts intact; secured

7.2 Sensorcontrol clean; properly mounted

7.3 Sensorrecorder properly mounted

7.4 Defrost termination clean; properly mounted

7.5 TXV insulated sensing bulb

7.6 Drip pan/Drains clean; free

7.7 Coil clean; free of obstruction

7.8 Fan blades/Boss no cracks; alignment;surface rust

7.9 Motor mounts no cracks; torqued

7.10

Venturi / Fan deck no contact with fan; deckclean

7.11

Bearing noise / Freeplay

drag with noise = replace

7.12

Terminal boxes, evapsec

Daikin only water tight; no corrosion

8.0 TemperatureRecorder

8.1 CompartmentHardware

Seals properly

8.2 Chart backing plate present; not distorted8.3 Chart knob present on leash

8.4 Chart (2) present

8.5 Clock operates

8.6 Lifting mechanism operates

8.7 Sympsom lead connection

8.8 Pen operates

-

7/28/2019 Florens Insp Repair Guideline Download

78/96

GuidelinesWeb Publication

Florens Container

Services

September 2006

25

Refrigerated Containers

Pre / Post Trip Inspection Form

UNIT ID NUMBER: DATE:TESTING PROCEDURE (Door closed and Floor Drain Plugs installed)

1. Record VOLTAGE SUPPLY (220 VAC run required 440test)

L1:_______ L2:_______L3:_______

2. Check the resistance on all solenoid valve coils (disconnect leads)

Carrier type = 6 Modulationsuction_______ohm

Suction (SSV) ______ ohm 6

Quench: _______ ohm 6

Daikin type = 18

Hot gasbypass ________ohm

Liquid line #1 ______ ohm9

Liquid line #2 ________ohm 9

3. Check and record the following: (megohm minimum: motor = 1.5; heater = 1.0)

Component Megoh

m

Amp Amp Amp

Evaporator motor (curbleft) L1 L2 L3

Evaporator motor (roadright) L1 L2 L3

Heater (strip back 1 wire lead if needed) L1 L2 L3

Compressor motor L1 L2 L3

Condenser motor L1 L2 L3

Condenser motor (#2) L1 L2 L3

Condenser motor (#3) L1 L2 L3

TURN UNIT ON; SET TEMPERATURE TO 0 F. TO COMPLETE AMP CHECK ABOVE

AND ITEMS #4 THROUGH #12 BELOW.

4. Record the time Unit is started. ____________ am pm

5. Temperature recorder set to record in Degrees F. Check Switch F to C function.Good Bad

6. Close fresh air vent.

7. Set defrost to 6 hour interval.

8. Check Condenser Fan(s) rotation. Carrier air flow direction is up coil and out. Daikin isdown coil.

9. Check Evaporator air flow by physical touch. Flow present at T floor.10. After 10 minutes check compressor oil level. ____________ siteglass (1/4 1/2 level)

11. Moisture indicator color: ________________ Condition: Wet Dry

12. Check that all indicator lights are energized.

Cool / Compressor__________

Inrange ___________ Defrost ___________

-

7/28/2019 Florens Insp Repair Guideline Download

79/96

GuidelinesWeb Publication

Florens Container

Services

September 2006

26

Refrigerated Containers

Pre / Post Trip Inspection Form

UNIT ID NUMBER: DATE:

CHANGE SET TEMPERATURE FROM 0 F. TO 32 F.(TURN CHART INCH)

13. Record the time unit reaches 32 F. ______________ am pm

14. Operate at 32 F. for one hour.

15. Check and record voltage supply to the modulation valve. __________ vac.

16. Suction Pressure Modulation Valve energized ________PSIG. Modulation Valve De-energized ________PSIG.

17. Record highest and lowest point of temperature swing from set point. (If total difference

over 5 F., determine cause.) Lowest temp. ______ Deg. F. (subtract) Highest temp.______ Deg. F. = Total temp. difference ______ Deg. F.

TURN RECORDING CHART INCH; SET TEMPERATURE TO MINUS 10F.

18. Record time when unit reaches set point of minus 10 F. ___________ am pm(Operate unit at minus 10 F. for one hour.)

19. Inspect the container body, exterior surfaces, and panels for frost indicating poorinsulation.

20. Temperature and calibration check at minus 10 F.Temperature on Partlow ______ Deg. F.Temperature controller digital read ______ Deg. F.

Thermometer temperature ______ Deg. F.

21. Leak check. Use electronic leak detector set at 2 oz./year.

Service valves(with caps off)

Drier/WCCconnections

High pressurerelief safetyvalve

TKshaft seal Daikin mod.valve

22. At 0 F. record: Discharge: ___________PSIG Suction: ___________PSIG

TURN TEMPERATURE RECORDING CHART BY HAND INCH.

23. Energize manual defrost.

Time into defrost ______am pm

Time out of defrost ______am pm

Temperature of termination____F.

24. Turn unit OFF and remove the temperature recording chart used for thePTIto be

attached to the invoice. Install 2 new charts with the pressure sensitive face facing the wrongdirection (towards the plate, not the pen). These will be used later by the customer.

25. Install your companys pretrip decal showing the date of thePTI.

-

7/28/2019 Florens Insp Repair Guideline Download

80/96

GuidelinesWeb Publication

Florens Container

Services

September 2006

1

Refrigerated Containers

Structure

Panels

For interior stainless steel panels depots are required to repair (patch) using stainless steel

rivets. Welded patches will be accepted at termination, provided that the Florens general

condition of accepting improper repairs is meet.

For exterior stainless steel panels, depots are required to repair (patch) using welded patches.

Riveted patches will be accepted at termination, provided that Florens general condition ofaccepting improper repairs is met and the repair is not located on the roof.Roof patches must be welded.

Note: Aluminum patches are not permitted on Stainless Steel Cladding and visa-versa.

Interior side-wall dents are not to be repaired unless cut.

Depots must differentiate when estimating patches that require foaming and those

that do not.

Bare aluminum or stainless steel patches affixed to pre-painted white aluminumcladding are to be estimated for painting.

Patches that are smaller than the minimum required size will be accepted at termination,

provided that Florens general condition of accepting improper repairs is met. The patch must

be watertight and able to accommodate a minimum of 4 fasteners.(Depots are required to use patches with a minimum dimension of 6X6).

The use of steel rivets in aluminum cladding or patches is not permitted.

The rivet pattern on patch repairs requires a minimum distance between rivets of 2(50mm)

on center. (Depots are required to conform to the stated IICL criteria of 1(25mm) on center.)

-

7/28/2019 Florens Insp Repair Guideline Download

81/96

GuidelinesWeb Publication

Florens Container

Services

September 2006

2

Refrigerated Containers

Structure

Example: Bare Aluminum patch affixed to painted whitealuminum cladding.

Action: Repair required paint the patch white.

Example: Steel fasteners used on aluminum patch.

Action: Rectification Required. Replace fasteners and/or patch.

Patch not painted

Repair is required

Aluminum patch with steel fastenersRepair is required

-

7/28/2019 Florens Insp Repair Guideline Download

82/96

GuidelinesWeb Publication

Florens Container

Services

September 2006

3

Refrigerated Containers

Structure

Example: Proper stainless steel patch welded to stainless steelcladding. Note: Exterior roof patches on the steel cladded unitsmust be welded.

Action:No action is required.

Example: Sheared rivets resultingfrom damage. The damage is for lesseeaccount.

Action: Rivets should be refastened andsealed.

Sheared rivetsRepair on lessee account

-

7/28/2019 Florens Insp Repair Guideline Download

83/96

GuidelinesWeb Publication

Florens Container

Services

September 2006

4

Refrigerated Containers

Structure

Example: Dented interior side wall.

Action:No action is required if cut is not present.

Dented but not torn panel

Repair is not required

-

7/28/2019 Florens Insp Repair Guideline Download

84/96

GuidelinesWeb Publication

Florens Container

Services

September 2006

5

Refrigerated Containers

Rails

Aluminum Top and Bottom Rail sections that are less than the minimum required by

IICL (Must extend at least one meter from the corner casting) criteria may be considered

acceptable at termination. To be considered acceptable, the section must end midwaybetween the first and second side post and meet Florens general conditions of accepting

improper. (Depot repairs must be in accordance with IICL criteria).

Welding of aluminum top and bottom rails is not permitted. The only circumstance wherewelding may be accepted at termination, is when the weld is located at the splice joint and

a proper splice plate has been used. In addition, Florens general condition for acceptingimproper repairs must be met. (Depot repairs must be in accordance with IICL criteria)

Example: Welded aluminum top rail splice without splice plates.

Action: Rectification is required.

Note: At off-hire, welded rail may be acceptable improperrepair only when the weld is located at the splice joint and a propersplice plate has been used. In addition, Florens general condition of

accepting improper repairs must been met.(Depot repairs must be in accordance with IICL criteria)

Spliced repair with plate

Repair is required

-

7/28/2019 Florens Insp Repair Guideline Download

85/96

GuidelinesWeb Publication

Florens Container

Services

September 2006

6

Refrigerated Containers

Roof Sheet Flange

Example: Damage to roof sheet flange in the area adjacent to the header extension plate.

Action: If not cracked or rivets are not missing, no action. Separated roof sheets requireno action beyond sealing to prevent water ingress.

-

7/28/2019 Florens Insp Repair Guideline Download

86/96

GuidelinesWeb Publication

Florens Container

Services

September 2006

7

Refrigerated Containers

Rails

Example: Welded aluminum rail.

Action: Rectification is required.

Example: Damaged aluminum bottom rail below the rivet line.

Action: Repair by smoothing and caulking the damaged area.

Welded aluminum railRepair is required

-

7/28/2019 Florens Insp Repair Guideline Download

87/96

GuidelinesWeb Publication

Florens Container

Services

September 2006

8

Refrigerated Containers

Rails

Example: Cut aluminum bottom rail upper flange.

Action: Damage meets requirement to stopdrill anddoubler plate reinforcement.

Cleaning

Unless directed otherwise by Florens (certain reposition moves), all off-hired reefers require

interior steam cleaning. On customer account

-

7/28/2019 Florens Insp Repair Guideline Download

88/96

GuidelinesWeb Publication

Florens Container

Services

September 2006

9

Refrigerated Containers Addendum January 2004

RailsLower Web and Flange Damage Criteria on Bottom Rail:

Cuts, gouges, bends or breakage in the lower web and flange of the bottom rail may berepaired by installing doubler plate over the damaged area. The doubler plate must be

installed after first straightening the damaged rail without heat, and then drilling stop holes

at both ends of the crack. This repair method may only be used under the following conditions:

The area of damage may not extend above the lower edge of the rail by more

than 80 mm (3-1/8 in).

The area of damage must not exceed 600 mm (24 in) in length.

All other provisions shown on the current IICL manual continue to apply.

Example: Damaged rail is repaired by Example: The Rail is holed behind T-Clip.doubler plate. Action:No action is required if the above

Action:Noaction is required if the damage: criteria is met. If this type of repair exists Does not extend above the lower edge by at off hire, it is acceptable repair.

more than 80 mm (3-1/8 in)

Area does not exceed 600 mm (24 in) inlength.

.

-

7/28/2019 Florens Insp Repair Guideline Download

89/96

-

7/28/2019 Florens Insp Repair Guideline Download

90/96

GuidelinesWeb Publication

Florens Container

Services

September 2006

11

Refrigerated Containers

Miscellaneous

Example: Missing drain tube and kazoo.

Action: Replace on lessee account.

Example: Missing interior drain plug and chains.

Action:No action is required.

Missing plug and chain

Repair is not required

-

7/28/2019 Florens Insp Repair Guideline Download

91/96

GuidelinesWeb Publication

Florens Container

Services

September 2006

12

Refrigerated Containers Miscellaneous

Repairs on corrugated sub-floor

Example of a typical Steel floor

.

Example: Sub-floor cut, torn or cracked (damage not shown)

Action: Repair using overlay riveted patches

-

7/28/2019 Florens Insp Repair Guideline Download

92/96

GuidelinesWeb Publication

Florens Container

Services

September 2006

13

Refrigerated Containers Miscellaneous

Repairs on corrugated sub-floor

.

Example: Dent on the sub-floor.

Action: Dents do not require repair if not resulting in cut, tear or crack Fordamages requiring repair of the sub-floor, repair by overlapping a riveted patch.

Welded patches are acceptable at off hire.Note: Cut, torn, or cracked sub-floor require repair

-

7/28/2019 Florens Insp Repair Guideline Download

93/96

GuidelinesWeb Publication

Florens Container

Services

September 2006

14

Panel Delamination in Refrigerated Containers (Reefers)

Panel delamination on any area of the reefer container is defined as a separation of the insula-

tion core from inner lining of the metal cladding. It can be caused by impact damage or dueto defects in the manufacturing process. It is important to distinguish the cause of delamina-

tion as this will allow correct allocation to responsible party when rectifying this damage.

As a general guide, delamination due to damage results from foam insulation being sheared

behind the bond line, leaving residue of the insulation on the cladding which is exposed topremature aging. This damage requires repair. While delamination due to defects, results in

the insulation skin being separated from the metal cladding. The insulation skin remainsintact, therefore does not cause premature aging. Depending on the location, size of the de-

laminated area, and the design of the container, delamination bolts should be used. Thesebolts should be used in a Sandwich Construction where insulated panels contribute a signifi-

cant portion of panel strength without embedded posts or stringers.

Regardless of the cause of delamination, repair is not required on the following areas of

the container:

Roof Exterior Panel (exterior cladding)

Side wall exterior sheet and post design. (sheet riveted to side posts)

Sub floor

T floor

Door exterior

Delamination that is not a result of impact damage must be repaired under the following

criteria:

Exterior Side wall: Over 40% of the total panel area is delaminated. Panel with no posts orpanel glued to side posts at 1250 mm centers. Delamination bolts must be used.

Interior Side wall: Use delamination bolts in all cases where the delamination is over 40%of the area of the panel.

Interior Roof: Repair is required when 30% of the panel area is delaminated. Use rivetswhen the stringer glued centers are at 1050mm.

Interior Door: Repair is required when one area exceeds 50% of the lining area. Use delami-nation bolts to repair interior door delamination.

NOTE: INJECTION OF ADHESIVE FOR DELAMINATION REPAIR IS NOT AL-

LOWED.

-

7/28/2019 Florens Insp Repair Guideline Download

94/96

GuidelinesWeb Publication

Florens Container

Services