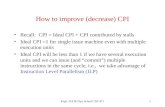

Factors contributing to k-factor optimization with eco mate ® blown foams CPI Orlando 2007

description

Transcript of Factors contributing to k-factor optimization with eco mate ® blown foams CPI Orlando 2007

Factors contributing to k-factor optimization with ecomate® blown foams

CPI Orlando 2007

2

How does ecomate compare?

ecomate 141b 245fa 365mf

c365/2

27 93 / 7

n-C5 cC5

Mol wt 60 117 134 148 149,6 72 70

Bpt, C 31,5 32 15,3 40,2 30 36 49

Sp Gr 0,982 1,24 1,32 1,25 1,28 0,62 0,75

Lambda 10,7 10 12,2 10,6 10,7 14* 11*

LEL/UEL 5,0 – 23,0

7,6 – 17,7 n/a 3,5 – 9,0 3,8 –

13,31,4 – 17,8 1,4 – 8,0

3

How does ecomate comparein Foams ? Handmix Pours Comparison

Molar Substitution - in same formulation Same Index Same Surfactant amount Same Catalyst amount Same molar BA content

4

BA Molar Substitution2” thick sample, 75 ºF

0.18

0.185

0.19

0.195

0.2

0.205k-factor

141b 245fa ecomate

Handmix Data ONLY

Results are Relative

ECOMATE ~ same as 245fa

k NOT SOLELY dependant on MW

0.2040.2020.187

5

Thermal Conductivity Not dependant solely on:

Molecular Wt Gas λ K-Factor at standard conditions

Depends on many additional factors, including: Temperature Processing Formulation Configuration Protection

6

Temperature / k-factor Dependencek-factor change w Temperature

0.100

0.110

0.120

0.130

0.140

0.150

0.160

-40 -20 0 20 40 60 80

TEMP, F

K FA

CTO

R

7

Examine Processing Effects

Hand Mix Factorial Design Examine

Mix Time Mix Speed Pour Size Surfactant Concentration

8

PROCESSING EFFECTS:HAND MIX FACTORIAL

DESIGNMIX TIME, sec

Low 5Mid 7.5High 10

9

PROCESSING EFFECTS:HAND MIX FACTORIAL

DESIGNMIX TIME, sec

MIX SPEED,

rpm

Low 5 1000Mid 7.5 2000High 10 3000

10

PROCESSING EFFECTS:HAND MIX FACTORIAL

DESIGNMIX TIME, sec

MIX SPEED,

rpm

POUR SIZE,

gm

Low 5 1000 150Mid 7.5 2000 225High 10 3000 300

11

PROCESSING EFFECTS:HAND MIX FACTORIAL

DESIGNMIX TIME, sec

MIX SPEED,

rpm

POUR SIZE,

gm

SURF CONC,

pct

Low 5 1000 150 1Mid 7.5 2000 225 1.5High 10 3000 300 2

12

PROCESSING EFFECTS:Handmix Results Summary

Mix Time Mix Speed Pour Size Surf. Concentration

Not significant Faster = lower λ (less BA loss) Larger = lower λ (less surface

area) More = lower λ (less BA loss)

1.00 1.25 1.50 1.75 2.00

28

29

30

C: SURF CONC

lam

bda

One Factor Plot

1000 2000 3000

28

29

30

A: MIX SPEED

lam

bda

One Factor Plot

150 200 250 300

28

29

30

B: SIZE POUR

lam

bda

One Factor Plot

13

Handmix v MachineSame ecomate Formulations

0.14

0.15

0.16

0.17

0.18

0.19

0.2

J91-5 J91-6 J91-8

HANDMACHINE

Machine ALWAYS Superior !

14

Examine Formulation Effects Polyol

Type and Amount Catalyst Surfactant

Type and Amount Blowing agent

Temp Effect Loss / Diffusion Blends

15

Examine Polyol Effects In a Hand Mix Factorial Design

Vary POLYOL BLEND Hold Constant

Catalyst Surfactant Blowing Agent INDEX = 120

16

POLYOL BLEND Design

DESIGN Func. Eq. Wt. Visc. LO – HI LEVELS

Sucrose Glycerin

7 152 30K 25-75

EDA 4 70 17K 0-25

Ester 2.3 212 12K 0-50

17

Polyol Effect: DENSITYDESIGN-EXPERT Plot

DENSITYDesign Points

X1 = A: SUC-GLYX2 = B: ESTERX3 = C: EDA

A: SUC-GLY100.00

B: ESTER75.00

C: EDA75.00

0.00 0.00

25.00

DENSITY

1.6

1.65

1.7

1.75

1.8

1.85

• EDA faster,- Captures more BA- Thus Lower Density

25 – 75%0 – 50%0 – 25%

18

Polyol Effect: THERMAL Props

DESIGN-EXPERT Plot

THERMALDesign Points

X1 = A: SUC-GLYX2 = B: ESTERX3 = C: EDA

A: SUC-GLY100.00

B: ESTER75.00

C: EDA75.00

0.00 0.00

25.00

THERMAL

27

28 2930

31EDA worse !Strong affinity for BALess in vapor space

19

Polyol Results Choice of Polyol Critical -

Not only affects Physicals Faster reactivity captures more BA Polyol Type can also affect k-factor, λ

20

Examine Catalyst Effects Speed of reaction Cell Orientation

Blow v Gel Cats Gel / Rise Ratio

21

Gel Time EffectsFaster = Lower k

0.130

0.132

0.134

0.136

0.138

0.140

0.142

0.144

20 30 40 50 60

Gel Time (s)

Ther

mal

Con

duct

ivity

18.718.919.119.319.519.719.920.120.320.520.7

LAM

BDA

PU Expo2002, pg 459, fig 12

22

Cat Effects:

STRETCHED

SMALL, _|_ RISE BEST

23

Catalyst Effects Results Speed of reaction Cell Orientation Gel / Rise Ratio

Faster is betterSmaller, rounder

betterGel at Rise best

24

Surfactant Effects AFFECTS

Cell formation Polyol / ISO compatibility Strut / window thickness Cell Windows open / closed Fineness of Cells Density

TYPE – Critical ! Mol Wt Siloxane content Degree of modification See Degussa Paper [ref 4]

AMOUNT – very important Optimize for each formulation

25

Examine BA Effects Molecular WeightInfluential, not

critical

26

Examine BA Effects Molecular Weight Gas λ Value

Influential, not critical

Influential, not critical

27

Examine BA Effects Molecular Weight Gas λ Value Solubility = Viscosity

Influential, not critical

Influential, not critical

Very Important on Flow

28

Examine BA Effects Molecular Weight Gas λ Value Solubility = Viscosity Flow = Cell Orientation

Influential, not critical

Influential, not critical

Very Important on Flow

Critical to Thermal Properties

29

Examine BA Effects Molecular Weight Gas λ Value Solubility = Viscosity Flow = Cell Orientation Vapor pressure

Influential, not critical

Influential, not critical

Very Important on Flow

Critical to Thermal Properties

Very Important

30

Examine BA Effects Molecular Weight Gas λ Value Solubility = Viscosity Flow = Cell Orientation Vapor pressure Liquid v Gas

Influential, not critical

Influential, not critical

Very Important on Flow

Critical to Thermal Properties

Very ImportantMeasure k at Use

Temp

31

Liquid v Gaseous BACondensation Effect

k-factor change w Temperature

0.100

0.110

0.120

0.1300.140

0.150

0.160

-40 -20 0 20 40 60 80

TEMP, F

K FA

CTO

R

32

Liquid v Gaseous BA GAS

Advantage of potential lower thermal properties

Lost because of higher Vapor Pressure More Gas escapes during foaming

33

Caveat Moisture

Very poor insulator Very small molecule [MW=18],

Smaller than N2 [MW=28, 78%], Smaller than O2 [MW=32, 21%]

Ubiquitous Penetrates foams readily Plays havoc with K-factor

34

Diffusion Gases want to reach equilibrium

35

DiffusionIF POROUS

Graham’s LawRate1

Rate2

M2

M1=

M2 M1 134 18

Gas245f

a H2O

Rate1 / Rate2 = 2.73 Rigid Foams NOT Porous !Fick’s Law: Solubility Factors

Water 3X greater Diffusion !

36

Blowing Agent LossAHAM Study

Negligible!

Amount of CFC-11 Blowing Agent in Sampled RefrigeratorsSample When Produced,

Pre-1993At End of Life, Prior to Shredding,

2004

A-1 15.2 % 15.4 %A-2 14.1 % 13.0 %

B-1 15.9 % 16.0 %B-2 16.7 % 15.2 %

C-1 16.0 %* 16.0 %C-2 13.0 – 14.0 % * 13.8 %

D-1 14.0 – 16.0 % * 15.7 %D-2 14.0 – 16.0 % * 14.3 %

37

REAL LIFE EXAMPLES BEST EVALUATIONS

Run side-by-side Use Actual CABINETS Use Actual Conditions Measure

Energy used Ice melt over time Compressor cycles, or Temperature change w time

38

Ice Melt TestsDrink Dispenser Tests

Ice Melt @ 75 FIdentical results !

0

1000

2000

3000

4000

0 1000 2000 3000

minutes

ice

rem

aini

ng (g

)

134a

ecomate

39

CONTROL 18% more energy

20% more energy

BTU LOAD TEST – Refrigerated Display case, Maintain 40F

ecomate, 245fa nearly same

40

40 F CHILLER

40 F CHILLER

%Time ON for 95 F: %Time ON for 95 F:

DUTY CYCLE – 39” VENDOR CABINETS5-100 watt bulbs to keep 95F

36.8% 37.4%

ecomate, 245fa nearly same !

41

BLENDING BAs Ecomate very compatible

Why spend extra money?Ecomate / 245fa Blends

PAT APP 20060160911Exp-1 Exp-2 Exp-3 Exp-4

Ecomate, mol% 90 75 50 25

HFC 245fa, mol% 10 25 50 75

K-factor, init 0.165 0.161 0.158 0.153

CS// , psi 31 25 33 24

Dim Stab Cold, [28d,-29C, V%] 2 3 5 9

42

Handmix v MachineSame ecomate Formulations

0.14

0.15

0.16

0.17

0.18

0.19

0.2

J91-5 J91-6 J91-8

HANDMACHINE

Machine ALWAYS Superior !

Ecomate machine k values respectable

43

Thermal Conductivity Not dependant solely on:

MW Gas λ K-Factor at standard conditions

Depends on many additional factors, including: Formulation Processing Configuration Protection

44

Conclusions Thermal Improvements available

Thru formulation Thru processing

Protect foams from Moisture Ecomate nearly equals 245fa

in Hand mix data in Side-by-side Performance Tests

Compare for Yourself!

Compare for Yourself !