enVerid Data Sheet HLR 1000E-R · The HLR 1000E-R is an all-inclusive solution that contains...

Transcript of enVerid Data Sheet HLR 1000E-R · The HLR 1000E-R is an all-inclusive solution that contains...

www.enverid.com

HVAC Load Reduction® (HLR®) Technology

HLR technology represents a vital addition to conventional HVAC systems to reduce the heating and cooling load of outside air. enVerid’s molecular air cleaning technology removes previously hard-to-capture contaminants from indoor air, thereby decreasing the required volume of outside air ventilation and providing more control over air quality.

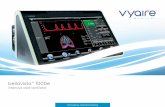

HLR® 1000E-RenVerid Data Sheet

Procedure for Ventilation and HealthThe HLR 1000E-R is fully compliant with ASHRAE 62.1 Indoor Air Quality Procedure (IAQP), the preferred approach to achieve energy efficiency and indoor air quality (IAQ). Introduced in 1981, IAQP is a performance-based design procedure that determines outdoor air intake rates based on an analysis of contaminant sources and air cleaning capacity to stay below recommended contaminant concentration limits.

Heater raises the internal temperature to initiate release of captured contaminants during Regeneration Mode

Sorbent Cartridge Bank houses 12 polypropylene cartridges that contain sorbents used to capture contaminants

Sensors measure CO2, TVOC, temperature, humidity, and pressure levels

Actuators automatically control damper positions

Double-walled, insulated construction, certified for 1000-hr salt-spray

Controller Board intelligently determines when to idle, clean air, or regenerate the sorbents, based on sensor data and advanced machine-learning algorithms

Wireless Cellular Antenna provides the Internet-of-Things (IoT) connection to the enVerid Cloud

Fans control airflow through the HLR 1000E during Adsorption and Regeneration Modes

The ASHRAE 62.1 guide recognizes that “The IAQP may allow for a more cost-effective solution to providing good air quality.” Additionally, “The IAQP may also be used to achieve better air quality than VRP

(lower contaminant levels and/or higher perceived acceptability).”

What’s InsideThe HLR 1000E-R is an all-inclusive solution that contains replaceable sorbent cartridges, along with embedded web-accessible controls and sensors. The system is designed to be scalable to building size. Individual or multiple HLR modules can be used in new construction, or easily retrofit to an existing HVAC infrastructure. The HLR 1000E-R is designed for outdoor use, typically on a rooftop. Indoor models for mechanical rooms are also available.

The HLR 1000E-R is designed for rooftop installation.

1

www.enverid.com

enVerid Data Sheet – HLR® 1000E-R

How it WorksThe diagrams below compare HVAC operations using ventilation only (outside airflow based on ASHRAE 62.1 Ventilation Rate Procedure, or VRP) with HLR 1000E-R scrubbing and ventilation (outside airflow decreased using ASHRAE Standard 62.1 IAQP1 calculations and maintaining positive building pressure).

HLR 1000E-R modules have four integrated capabilities:

Indoor Air Scrubbing (Adsorption Mode)

A fraction of the return air stream (700-800 CFM) is directed through the HLR 1000E-R module to remove contaminants of concern. Sorbents in the HLR modules feature selective chemistry which removes 250+ volatile organic compounds (VOCs) along with carbon dioxide (CO2), carbon monoxide (CO), ozone, aldehydes and particulate matter (PM2.5) resulting in cleaned air that is blown back into the building’s indoor circulations.

Automatic Self-Cleaning (Regeneration Mode)

Sensors monitor sorbents in the HLR 1000E-R for saturation, and then initiate a regeneration process to clean the sorbents of captured contaminants, which are then purged outside of the building. Regeneration is scheduled and managed for optimal performance and minimal energy use.

Outside Air Intake Management

Electromechanical control of the HVAC system’s outside air damper reduces the amount of outside air ventilation, automatically adjusting for optimal energy savings, air quality targets, building air pressure, and HVAC economizer modes. The HLR module can have direct 2-10 VDC control of the outside air damper, or use BACnet to coordinate with the Building Management Software (BMS) which can over-ride control of the outside air damper when required.

Monitoring and Reporting

HLR software communicates continuously with the onboard sensors to record, report and optimize all aspects of HLR 1000E-R operation. HLR modules provide secure, real-time reporting of IAQ and operating parameters to the enVerid Cloud.

1 The mass balance analysis is performed per contaminant and per zone to ensure all contaminants are properly below their established limits. These “per zone” outside air CFMs are summed to yield the total ventilation required for the building. enVerid’s IAQP calculator makes it easy.

Vot = Ventilation Rate N = Pollutant Emission Rate QHLR = Scrubbed Air Ef = HLR Air Cleaning Efficiency Cbz = Indoor Concentration at Breathing Level Ez = Ventilation Distribution Effectiveness Co = Outdoor Concentration

Supply Air DuctSupply Air Duct

Outside Air

Return Air Duct or Plenum

Exhaust Regeneration

Outside Air

Return Air Duct or Plenum

Outside AirMinimized

Trea

ted

Air

AHU AHUSupply Air DuctSupply Air Duct

Outside Air

Return Air Duct or Plenum

Exhaust Regeneration

Outside Air

Return Air Duct or Plenum

Outside AirReduced

Trea

ted

Air

AHU AHU

Ventilation Only Ventilation and Scrubbing

2

www.enverid.com

enVerid Data Sheet – HLR® 1000E-R

HLR ModesThe diagrams below depict the “under-the-hood” view of HLR 1000E operation during the Adsorption and Regeneration Modes.

The enVerid Cloud enables users to monitor and manage HLR modules and building IAQ

enVerid CloudEach HLR 1000E-R module supports the IoT and is connected to the enVerid Cloud using a secure wireless broadband connection. End-to-end encryption and system hardening provide additional layers of security. With a secure login to the enVerid Cloud, facility managers and engineers have 24/7 access to IAQ measurements and HLR system configuration and monitoring.

• Anytime, anywhere access from any Internet-connected device (PC, tablet, smartphone)

• Secure login with username and password over encrypted HTTPS connection

• Different user types with different access levels

• Real-time and historical views of IAQ (CO2, TVOC), comfort (temperature, relative humidity), outside air controls, energy savings and other measurement data.

• HLR system configuration and settings

• HLR system monitoring and performance

Adsorption Mode Regeneration Mode

Captures • CO2, CO, Aldehydes, VOCs, ozone, PM2.5

Step 2: Vent Contaminants Outside • Regeneration dampers opened

Step 1: Closed Loop Heating • All dampers closed • Air heated to 130-150 ˚F

UnitOverview

Dashboard

Air sampling interval 1 min.

10 %

15 %

100 %

15 %

0 %

1 min.

80 ratio

600 ppm

1000 ppm

500 μg/m3

120 min.

90 min.

30 min.

Outside Air Inlet Minimal Setting

Outside Air Inlet Conventional Setting

Outside Air Inlet Maximum Setting

Outside Air Inlet Default Setting

Outside Air Inlet Emergency Setting

Time interval for reading IAQ in HLR

Maximum allowed CO2 passage befroe regeneration

CO2 Low Target

CO2 High Target

VOC High Target

Min time left befroe end-of-day for mid-day regeneration

Min cumalative scrubbing time before mid-day regeneration

Min cumalative scrubbing time before after hours regeneration

Edit Load from Unit Upload To Unit

Achive

Energy Savings

Export Data

Events

Alarms

Commands

Licenses

User Regeneration Profiles

Installation

Operational Parameters

Operational Parameters

Outside AirIndoor Air (from return duct or plenum)

Clean Air (to AHU or plenum)

Inside cartridge bank

Exhaust Air

Air Flow

3

enVerid Systems, Inc. is committed to improving energy efficiency and indoor air quality in buildings worldwide through its innovative HVAC Load Reduction® (HLR®) solutions. Awarded the prestigious 2016 R&D 100 Award, enVerid is the only solution that helps commercial, education and government buildings remove carbon dioxide (CO2), aldehydes, volatile organic compounds (VOCs) and particulate matter (PM2.5) from indoor air, reducing the outside air intake required for ventilation. enVerid’s HLR technology is ASHRAE-compliant and has been recognized by the U.S. Department of Energy, the U.S. General Services Administration’s Green Proving Ground Program, and the U.S. Green Building Council. For more information, please visit www.enverid.com.

© Copyright 2017 enVerid Systems, Inc. All rights reserved. HLR and Load Reduction are registered trademarks of enVerid Systems, Inc. Third-party trademarks mentioned are the property of their respective owners. | 11.17

www.enverid.com [email protected]

enVerid Data Sheet – HLR® 1000E-R

SpecificationsModel Name HLR 1000E-ROutdoor Installation Installed on curb or equipment supportsConstruction Weather-tight, double-wall, insulated,

powder-coated galvanized steel, 1000-hr salt spraySorbent Cartridges 12Unit Cabinet Weight 600 lbs / 272 kgUnit with Cartridge Set 800 lbs / 363 kgMaximum airflow 800 CFMStatic pressure added to AHU fan NegligibleMaximum allowed external static pressure 0.2 inches of water (50 Pascal)Maintenance 1x per yearOperating Life 20+ years when scheduled maintenance is performedDimensions Unit with DampersHeight (allow additional 48” clearance for service) 36.6 in / 930 mm

Length (allow 15” clearance for duct elbow) 91.10 in / 2314 mmWidth (allow additional 36” clearance on front & back for service with hoods, addtl 48” front & back without hoods)

With damper hoods: 69.1 in / 1755 mm With damper covers (no hoods): 55.6 in / 1412 mm

Ducts (diameter) 14 in / 355.6 mmVoltage (VAC) Frequency (Hz) MCA MOCP

208 – 277 50/60 Hz 32 Amp 35 AmpPower Consumption Min Typical Max

Adsorption Mode 144W 288W 330WRegeneration Mode N/A 5,000W 6,800WIdle Mode N/A <1W N/ACommunicationsCellular Link 2.5G / 3G / 4GBACnet over MSTP

Air Flow ComponentsFans 24VDC / 120W max (each x2)Heater with PID Control (2 heater options) 277VAC / 6.5kW

208VAC / 5.5kW

Required Control ConnectionsOutside Air Damper Control Output from HLR Module: 2-10 VDC or via BACnetOutside Air Damper Position Monitoring Input to HLR Module: 2-10 VDC or via BACnetFire Signal Dry Contact Output Input to HLR ModuleAHU Mode Dry Contact Input Input to HLR Module or via BACnetAdditional Control ConnectionsAHU Fan Speed Input Direct wired Input to HLR Module or via BACnetEnergy Meter Dry Contact Input Input to HLR ModuleAvailable 24V Relay Output Output from HLR Module 24V/1AAvailable Dry Contact Output Output from HLR Module 1A (max)Available Dry Contact Input Input to HLR ModuleSensors Location MeasurementMulti Sensor: measure incoming air HLR Module Interior T, RH, CO2, TVOCMulti Sensor: measure outgoing air HLR Module Interior T, RH, C02

Pressure Sensor HLR Module Interior PSorbent Temperature HLR Module Interior TOptional TRH Sensors to calculate energy use Supply Air Duct T, RH

Outside Air Duct T, RH

![Customer Programming Software RG-1000e (CPS RG-1000e) User ...support.smartptt.com/hc/en-us/article_attachments/360026136773/CPS_RG... · 192.168.200.1[51130] 192.168.100.1[30010]](https://static.fdocuments.in/doc/165x107/5e819e496d283477b76cdd83/customer-programming-software-rg-1000e-cps-rg-1000e-user-192168200151130.jpg)