Enclosure Catalog

-

Upload

mirceadanila20053264 -

Category

Documents

-

view

265 -

download

7

Transcript of Enclosure Catalog

WELCOME TO HAWKE INTERNATIONAL – INTERACTIVE CATALOGUEThis interactive catalogue has been designed with ease of use in mind.The pages are interactive and contain links or 'hotspots'that can be clicked to take the user to the relevant information or page.

INSTRUCTIONS FOR USEIt is recommended that you print out these instructions for reference.

LINKSA link is signalled when the mouse pointer changes from a hand to a pointing finger. For example where a page number isreferenced .

FIT TO SCREENThe default for each page is fit to screen, which allows a full view of the page without the need to scroll.

TO ENLARGE THE PAGE1. Select the magnifying glass icon from the toolbar and click on the page until the required size is reached.2. To enlarge a particular section of the page, click and hold down the left mouse button, drag the bounding box over the

section you wish to enlarge and release the mouse button.

STEP THROUGH EACH PAGE IN SEQUENCEUse the and buttons, usually found on the toolbar at the top of the screen, to move backwards and forwards throughthe pages. There is a page counter at the bottom left of the screen that indicates where you are in the sequence.You can alsomove to other pages by highlighting the page numbers and typing in a number.

RETURN TO PREVIOUS VIEWClicking the button found in the toolbar at the top of the screen will return you to the previous view i.e. whatever wasdisplayed previously on the screen.This would shrink the page if you had enlarged it, or return you to a previous page if youhad just left it.

Hawke International is committed to providing you, the end user, with software products that are easy to use, that provide you with the information you are seeking in a quick and efficient manner and are of benefit to you. If you have any comments/suggestions about our software products please do not hesitate to contact Hawke International

CLICK HERETO CONTINUE

Start menu 25/10/01 3:20 pm Page 1

All copyright reserved-Hawke Cable Glands Ltd 2002. This document and all copyright therein is the property of Hawke International a trading name of HawkeCable Glands Ltd (A member of the Hubbell Gr oup of Companies). CopyrightCondition:This document shall be used onl y for the purpose for which it is providedand no reproduction or publication of the document may be made and no ar ticlemay be manufactured or assembled in accordance with information contained inthe document without prior written consent of the o wner.

To the best of our knowlage the information contained in this brochure, is accurateat the time of going to print and the company reserves the right to improve ormodify any product illustrated without notification. The company is unable toaccept liability for any inaccuracies, errors or omissions that may exist. It is the customer’s responsibility to ensure that the product is suitable for their application.

HWK05 March ‘02

Visit us at www.ehawke.com

Agent/Distributor

HA

WK

E IN

TE

RN

AT

ION

AL

EE

xeA

ND

EE

xdE

NC

LO

SU

RE

S F

OR

WO

RL

DW

IDE

AP

PL

ICA

TIO

NS

HW

K05 M

arch ‘02

Exe Enclosuresfor WorldwideApplications

Smarter productswww.ehawke.com

Intr

oduc

tion

To the best of our knowledge the information contained in this leaflet, is accurate at the time of going to print and the company reserves the right to improve or modify any product illustrated without notification. The company is unable to accept liability for any inaccuracies, errors or omissions that may exist. It is the customer's responsibility to ensure that the product is suitable for their application.

All copyright reserved-Hubbell Ltd. This document and all copyright thereinis the property of: Hawke International a division of Hubbell Ltd. (A member of the Hubbell Group of Companies). Copyright Condition: This document shall be used only for the purpose for which it is provided and no reproduction or publication of the document may be made and no article may be manufactured or assembled in accordance with information contained in the document without prior written consent of the owner.

Introduction

For those who demand quality, reliability and above all, safety, Hawke products are the obvious choice.

Smarter ProductsHawke International is a member of the worldwide Hubbell Group of Companies and is a well established leading manufacturer of electrical equipment for Hazardous (Classified) locations and hostile environments,with an innovative range of cable connection, termination and barrierproducts.

WorldwideLocated in Manchester, UK, Hawke International has subsidiary companies in Houston, USA and Singapore, along with direct representation in Brazil, the Middle East and Canada. Hawke International is supported worldwide by the Hubbell Group as well as by a network of agents and distributors.

Product DevelopmentA commitment to the development of innovative features which improvethe safety, versatility, reliability and ease of use of our products.

First ChoiceUsed on Offshore and Onshore oil and gas exploration and production facilities. Hawke's products are the 'First Choice' for the world's major oil and gas companies.

A Quality CompanyHawke International's products are designed and manufactured under a quality system not only complying with ISO 9001 but also with the latest international standards. Rigorous and regular in-house testing ensures that every product manufactured meets the highest quality standards.

Hawke International"Leading the way in the design of Smarter Products"

A QUALITY COMPANY ALWAYS DEMANDS THE BEST

HWK05 Mar '02International

Increased Safety Exe

Haw

ke E

nclo

sure

s C

onte

nts

Hawke Enclosures Contents

6 - 15PL6 Series EnclosuresPage No.

PL6 Series FeaturesPL612 Enclosure Technical Data PL615 Enclosure Technical DataPL620 Enclosure Technical DataPL626 Enclosure Technical DataPL630 Enclosure Technical Data PL612 and PL615 Cable Entry PositionsPL620 and PL630 Cable Entry PositionsPL6 Series Technical Information

789101112131415

PL7 Series Enclosures 16 - 21PL7 Series FeaturesPL712 Enclosure Technical DataPL722 Enclosure Technical DataPL712 and PL722 Cable Entry PositionsPL7 Series Technical Information

1718192021

22 - 36

37 - 40

S Series EnclosuresS Series Stainless Steel FeaturesStainless Steel Size 1 Enclosure Technical DataStainless Steel Size 2 Enclosure Technical DataStainless Steel Size 3 Enclosure Technical DataStainless Steel Size 4 Enclosure Technical DataStainless Steel Size 5 Enclosure Technical DataStainless Steel Size 6 Enclosure Technical DataStainless Steel Size 7 Enclosure Technical DataStainless Steel Size 8 Enclosure Technical DataStainless Steel Size 9 Enclosure Technical DataSize 1, Size 2 and Size 3 Cable Gland Entry PositionsSize 3 and Size 4 Cable Gland Entry PositionsSize 5 to Size 9 Cable Gland Entry PositionsStainless Steel Size 1 to Size 9 Technical Information

2324252627282930313233343536

EZE Series EnclosuresEZE 22 Enclosure Technical DataEZE 42 Enclosure Technical DataEZE 62 Enclosure Technical Data

373839

InternationalConnection Solutionswww.ehawke.comUPD 11 02 09

To the best of our knowledge the information contained in this leaflet, is accurate at the time of going to print and the company reserves the right to improve or modify any product illustrated without notification. The company is unable to accept liability for any inaccuracies, errors or omissions that may exist. It is the customer's responsibility to ensure that the product is suitable for their application.

All copyright reserved-Hubbell Ltd 2008. This document and all copyrighttherein is the property of: Hawke International a trading name of Hubbell Ltd(A member of the Hubbell Inc Group of Companies). Copyright Condition: This document shall be used only for the purpose for which it is provided and no reproduction or publication of the document may be made and no article may be manufactured or assembled in accordance with information contained in the document without prior written consent of the owner.

Page No.

50 - 73Technical Data

Increased Safety Exe

Haw

ke E

nclo

sure

s C

onte

nts

5151

51 - 5555 - 5657 - 59

606161

62 - 6263

63 - 6868 - 7070 - 73

1.0 Potentially Explosive Atmospheres2.0 Area Classification (Classification of Locations)3.0 CENELEC and IEC4.0 ATEX 94/9/EC Directive5.0 Extract from EN 60079-14 : 1997/IEC 60079-14 : 1996 Installation in Hazardous Areas6.0 Apparatus Marking - IEC and CENELEC (Group II)7.0 CE Marking8.0 Certification/Listing9.0 CENELEC and IEC Degree of Protection, IP Code10.0 IECEx Scheme11.0 North American Hazardous (Classified) Locations12.0 Wiring Systems13.0 Abbreviations, Acronyms and Definitions

Hawke Enclosures Contents

464747

Stopping Plug Types 375 and 387Internal/External Earth StudHTB6/PET5 Breather Drain

74Smarter Products

45 - 48Accessories

4142

43 - 4444

Dissipated Wattage FactorCombined Terminal Resistance 'F'Maximum Physical Quantity of TerminalsTable of Earths

40 - 44Technical Calculations

InternationalConnection Solutionswww.ehawke.comUPD 11 02 09

To the best of our knowledge the information contained in this leaflet, is accurate at the time of going to print and the company reserves the right to improve or modify any product illustrated without notification. The company is unable to accept liability for any inaccuracies, errors or omissions that may exist. It is the customer's responsibility to ensure that the product is suitable for their application.

All copyright reserved-Hubbell Ltd 2008. This document and all copyrighttherein is the property of: Hawke International a trading name of Hubbell Ltd(A member of the Hubbell Inc Group of Companies). Copyright Condition: This document shall be used only for the purpose for which it is provided and no reproduction or publication of the document may be made and no article may be manufactured or assembled in accordance with information contained in the document without prior written consent of the owner.

PL6

PL6

Ser

ies

se r ies

Features

Corrosion Resistant Stainless Steel Lid Fixing Screws with Nylon Retaining Washers

External Mounting Feet

Anti-Static Properties

The Ultimate in Robust GRP Construction

One Piece Durable Captive Moulded Silicone Gasket

Designed to withstand impact resistance up to 20Nm.GRP Construction provides a high degree of resistance to corrosive atmospheres.

Removes the risk of ignition sources through static induced sparking resistivity.

Eliminates the need to remove the lid when mounting the enclosure on the wall.

Prevents loss of screws during assembly and maintenance.

Provides Ingress Protection to IP66 and IP67. Optimum performance at low and high temperature extremes.

DTS01 deluge protection witnessed by EECS.

Stainless Steel Rating Label Highly durable and corrosion resistant.

Insulation Resistance in accordance with EN 50014 : 1998, which does not exceed 1 G Ω.

InternationalHWK05 Mar '02

Smarter productswww.ehawke.com

PL6

Ser

ies

Encl

osur

es

To the best of our knowledge the information contained in this leaflet, is accurate at the time of going to print and the company reserves the right to improve or modify any product illustrated without notification. The company is unable to accept liability for any inaccuracies, errors or omissions that may exist. It is the customer's responsibility to ensure that the product is suitable for their application.

Copyright Condition: This document shall be used only for the purpose for which it is provided and no reproduction or publication of the document may be made and no article may be manufactured or assembled in accordance with information contained in the document without prior written consent of the owner.

Increased Safety ExePL6 Series Enclosures

Glass Reinforced Polyester

All copyright reserved-Hubbell Ltd. This document and all copyright thereinis the property of: Hawke International a division of Hubbell Ltd. (A member of the Hubbell Group of Companies).

Notes: For Junction Box Wattage Factor & Combined Terminal Resistance see pages 37 - 39.An earth terminal equal to that of the largest power terminal will be fitted.

Increased Safety Exe. II 2 GD Exe II, ExtD. PL612 BASEEFA Certificate No. BAS 01 ATEX 2107X. Baseefa 06ATEX0117X.

IECEx Bas 06.0027U. Suitable for use in Zone 1, Zone 2, Zone 21 & Zone 22.

IP66 and IP67 ingress protection to IEC 60529 and EN 60529. DTS01 deluge protection witnessed by EECS. Operating temperature range -60°C to +75°C. Temperature Class and Ambient T6 40°C. Optional T5 with ambients up to 65°C. Assembly instruction data sheet No. A.I. 273. For PL612.

Construction and test standards IEC 60079-0, IEC 60079-7, IEC 61241-0 andIEC 61241-1. EN 60079-0, EN 60079-7, EN61241-0 andEN 61241-1.

IECEx BAS 06.0028X.ZPL612 BASEEFA Certificate No. BAS 01 ATEX 2101U. Baseefa 06ATEX0116U.

Note: For Cable Entry Positions see page 11.# Not possible with an earth continuity plate.* Shroud not possible with earth continuity plate option.

Alternative Certification Options Available.

For full Technical Specification see page 13.

InternationalConnection Solutionswww.ehawke.com

Amps Amps

Max. PhysicalTerminal Content

Reduced Terminal Contentat Max. Terminal Amps

MAXIMUM QUANTITY OF ENTRIES PER FACE

TerminalType

Conductor Size (mm²)

Min. Max.

Max.Volts

Max. PerPillar:

2 x 10mm²3 x 6mm²4 x 4mm²

4 x 0.5mm² MIN

TerminalQuantity

TerminalQuantity

TERMINAL CAPACITY DATA

WDU 2.5WDU 4WDU 6WDU 10

MK6/6

HTB6

BK6

WDU 2.5N 0.5

0.5 550

ConductorSize mm²

Max AmpsPer Pillar

2.5 420

420

0.50.50.5

2.546

46

1.5 10

550690550550275

1210976

16 1010975

N/AN/A

N/AN/A

N/A N/A

1717222940

11

11

1

172229392126

0.50.75

11.52.54610

1181015212637

Thread Size

Quantity

M16/M20

2 * 1

M25 M32

1#

PL6

Seri

es G

RP

Encl

osur

es

To the best of our knowledge the information contained in this leaflet, is accurate at the time of going to print and the company reserves the right to improve or modify any product illustrated without notification. The company is unable to accept liability for any inaccuracies, errors or omissions that may exist. It is the customer's responsibility to ensure that the product is suitable for their application.

All copyright reserved-Hubbell Ltd 2008. This document and all copyrighttherein is the property of: Hawke International a trading name of Hubbell Ltd(A member of the Hubbell Inc Group of Companies). Copyright Condition: This document shall be used only for the purpose for which it is provided and no reproduction or publication of the document may be made and no article may be manufactured or assembled in accordance with information contained in the document without prior written consent of the owner.

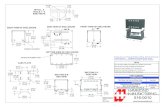

4 off 7mm Dia. Mounting Holes

Approx. weight : 0.8kg

4 off M5 Stainless Steel SocketHead Cap Screws, Key Size-4mm

102mm sq. CRS

120mm sq. 73.5mm

8.5mm

Face A

Face C

Face

B

Face

DIncreased Safety Exe

Glass Reinforced Polyester PL612 Enclosure Type

AExe II/Exe II.Exe II.

Technical Data

HWK79 July '08

Note: For Cable Entry Positions see page 11.

Notes: For Junction Box Wattage Factor & Combined Terminal Resistance see pages 37 - 39. An earth terminal equal to that of the largest power terminal will be fitted.

Increased Safety Exe. II 2 GD Exe II, ExtD. PL615 BASEEFA Certificate No. BAS 01 ATEX 2107X. Baseefa 06ATEX0117X.

IECEx Bas 06.0027U. Suitable for use in Zone 1, Zone 2, Zone 21 & Zone 22.

IP66 and IP67 ingress protection to IEC 60529 and EN 60529. DTS01 deluge protection witnessed by EECS. Operating temperature range -60°C to +75°C. Temperature Class and Ambient T6 40°C. Optional T5 with ambients up to 65°C. Assembly instruction data sheet No. A.I. 273. For PL615.

Construction and test standards IEC 60079-0, IEC 60079-7, IEC 61241-0 andIEC 61241-1. EN 60079-0, EN 60079-7, EN61241-0 andEN 61241-1.

IECEx BAS 06.0028X.ZPL615 BASEEFA Certificate No. BAS 01 ATEX 2101U. Baseefa 06ATEX0116U.

Alternative Certification Options Available.

For full Technical Specification see page 13.

4 off 7mm Dia. Mounting Holes

4 off M5 Stainless Steel SocketHead Cap Screws, Key Size-4mm

134mm sq. CRS

150mm sq. 93.5mm

9.5mm

Face A

Face C

Face

B

Face

D

InternationalConnection Solutionswww.ehawke.com

Amps Amps

Max. PhysicalTerminal Content

Reduced Terminal Contentat Max. Terminal Amps

MAXIMUM QUANTITY OF ENTRIES PER FACE

TerminalType

Conductor Size (mm²)

Min. Max.

Max.Volts

Max. PerPillar:

2 x 10mm²3 x 6mm²4 x 4mm²

4 x 0.5mm² MIN

TerminalQuantity

TerminalQuantity

TERMINAL CAPACITY DATA

WDU 2.5WDU 4WDU 6WDU 10WDU 16

HTB6 0.5 550

ConductorSize mm²

Max AmpsPer Pillar

0.50.50.5

2.546

1.51.5

1016

550690

690

550550

141297

6

1311976

N/A N/A

1722294053

1

1621294053

0.50.75

11.52.54610

1181015212637

Thread Size

Quantity

M16/M20

2 2 1

M25 M32

PL6

Seri

es G

RP

Encl

osur

es

To the best of our knowledge the information contained in this leaflet, is accurate at the time of going to print and the company reserves the right to improve or modify any product illustrated without notification. The company is unable to accept liability for any inaccuracies, errors or omissions that may exist. It is the customer's responsibility to ensure that the product is suitable for their application.

All copyright reserved-Hubbell Ltd 2008. This document and all copyrighttherein is the property of: Hawke International a trading name of Hubbell Ltd(A member of the Hubbell Inc Group of Companies). Copyright Condition: This document shall be used only for the purpose for which it is provided and no reproduction or publication of the document may be made and no article may be manufactured or assembled in accordance with information contained in the document without prior written consent of the owner.

Increased Safety ExeGlass Reinforced Polyester PL615

Enclosure Type

AExe II/Exe II.Exe II.

Approx. weight : 1.2kg

Technical Data

HWK80 July '08

Note: For Cable Entry Positions see page 12.# Not possible with an earth continuity plate.

Notes: For Junction Box Wattage Factor & Combined Terminal Resistance see pages 37 - 39. An earth terminal equal to that of the largest power terminal will be fitted.

Approx. weight : 3.0kg

Increased Safety Exe. II 2 GD Exe II, ExtD. PL620 BASEEFA Certificate No. BAS 01 ATEX 2107X. Baseefa 06ATEX0117X.

IECEx Bas 06.0027U. Suitable for use in Zone 1, Zone 2, Zone 21 & Zone 22.

IP66 and IP67 ingress protection to IEC 60529 and EN 60529. DTS01 deluge protection witnessed by EECS. Operating temperature range -60°C to +75°C. Temperature Class and Ambient T6 40°C. Optional T5 with ambients up to 65°C. Assembly instruction data sheet No. A.I. 273. For PL620.

Construction and test standards IEC 60079-0, IEC 60079-7, IEC 61241-0 andIEC 61241-1. EN 60079-0, EN 60079-7, EN61241-0 andEN 61241-1.

IECEx BAS 06.0028X.ZPL620 BASEEFA Certificate No. BAS 01 ATEX 2101U. Baseefa 06ATEX0116U.

Alternative Certification Options Available.

For full Technical Specification see page 13.

4 off 8.5mm Dia. Mounting Holes

4 off M6 Stainless Steel SocketHead Cap Screws, Key Size-5mm

180mm sq. CRS

200mm sq. 126.5mm

11.5mm

Face A

Face C

Face

B

Face

D

InternationalConnection Solutionswww.ehawke.com

Amps Amps

Max. PhysicalTerminal Content

Reduced Terminal Contentat Max. Terminal Amps

MAXIMUM QUANTITY OF ENTRIES PER FACE

TerminalType

Conductor Size (mm²)

Min. Max.

Max.Volts Terminal

QuantityTerminalQuantity

TERMINAL CAPACITY DATA

WDU 2.5WDU 4WDU 6WDU 10WDU 16WDU 35WDU 70N

0.50.50.5

2.546

1.51.52.5

10

10

163570

550690

690690690

550550

24201512964

18161210964

172229405387134

1621294053

13487

Thread Size

Quantity

M16/M20

6 4 2 1# 1#

M25 M32 M40 M50

PL6

Seri

es G

RP

Encl

osur

es

To the best of our knowledge the information contained in this leaflet, is accurate at the time of going to print and the company reserves the right to improve or modify any product illustrated without notification. The company is unable to accept liability for any inaccuracies, errors or omissions that may exist. It is the customer's responsibility to ensure that the product is suitable for their application.

All copyright reserved-Hubbell Ltd 2008. This document and all copyrighttherein is the property of: Hawke International a trading name of Hubbell Ltd(A member of the Hubbell Inc Group of Companies). Copyright Condition: This document shall be used only for the purpose for which it is provided and no reproduction or publication of the document may be made and no article may be manufactured or assembled in accordance with information contained in the document without prior written consent of the owner.

Increased Safety ExeGlass Reinforced Polyester PL620

Enclosure Type

AExe II/Exe II.Exe II.

Technical Data

HWK81 July '08

Notes: For Junction Box Wattage Factor & Combined Terminal Resistance see pages 37 - 39. An earth terminal equal to that of the largest power terminal will be fitted.

The terminals listed are restricted to a minimum operating temperature of -50°C.

Increased Safety Exe. II 2 GD Exe II, ExtD. PL626 BASEEFA Certificate No. BAS 01 ATEX 2107X. Baseefa 06ATEX0117X.

IECEx Bas 06.0027U. Suitable for use in Zone 1, Zone 2, Zone 21 & Zone 22.

IP66 and IP67 ingress protection to IEC 60529 and EN 60529. DTS01 deluge protection witnessed by EECS. Operating temperature range -60°C to +75°C. Temperature Class and Ambient T6 40°C. Optional T5 with ambients up to 65°C. Assembly instruction data sheet No. A.I. 273.

Construction and test standards IEC 60079-0, IEC 60079-7, IEC 61241-0 andIEC 61241-1. EN 60079-0, EN 60079-7, EN61241-0 andEN 61241-1.

IECEx BAS 06.0028X.ZPL626 BASEEFA Certificate No. BAS 01 ATEX 2101U. Baseefa 06ATEX0116U.

Alternative Certification Options Available.

For full Technical Specification see page 13.

InternationalConnection Solutionswww.ehawke.com

Amps Amps

Maximum Numberof Terminals

High PowerApplications

MAXIMUM QUANTITY OF ENTRIES PER FACE

TerminalType

Conductor Size (mm²)

Min. Max.

Max.Volts Terminal

QuantityTerminalQuantity

TERMINAL CAPACITY DATA

WDU 2.5WDU 4WDU 6WDU 10WDU 16WDU 35

0.50.50.5

2.546

1.51.52.5

101635

550690

690

690

550550

38322419

1612

151411986

17222940

5387

111520283962

Thread Size

Face A/C

Face B/D

M16

9

3

9

3

7

3

4

2 1

M20/O M20/A M32M25

3

PL6

Seri

es G

RP

Encl

osur

es

To the best of our knowledge the information contained in this leaflet, is accurate at the time of going to print and the company reserves the right to improve or modify any product illustrated without notification. The company is unable to accept liability for any inaccuracies, errors or omissions that may exist. It is the customer's responsibility to ensure that the product is suitable for their application.

All copyright reserved-Hubbell Ltd 2008. This document and all copyrighttherein is the property of: Hawke International a trading name of Hubbell Ltd(A member of the Hubbell Inc Group of Companies). Copyright Condition: This document shall be used only for the purpose for which it is provided and no reproduction or publication of the document may be made and no article may be manufactured or assembled in accordance with information contained in the document without prior written consent of the owner.

Increased Safety Exe Dual Certified ATEX/IECEx

Glass Reinforced Polyester PL626 Enclosure Type

Technical Data

HWK118 Oct '08

GOST R-Exe IIU.

4 off 7mm Dia. Slots

160m

m14

4mm

260mm244mm

13.5

mm

106.

5mm

Face A

A combination of different sized entries is possible, please contact Hawke formore information. The table below gives an indication of potential terminal arrangements. Please contact Hawke for information on other arrangements or empty enclosures. A combination of different sized terminals is possible, please contact Hawke for more information. Other terminal types are available.

Approx. weight : 3.0kg

Face C

Face

B

Face

D

Note: For Cable Entry Positions see page 12.# Not possible with an earth continuity plate.

Notes: For Junction Box Wattage Factor & Combined Terminal Resistance see pages 37 - 39. An earth terminal equal to that of the largest power terminal will be fitted.

Increased Safety Exe. II 2 GD Exe II, ExtD. PL630 BASEEFA Certificate No. BAS 01 ATEX 2107X. Baseefa 06ATEX0117X.

IECEx Bas 06.0027U. Suitable for use in Zone 1, Zone 2, Zone 21 & Zone 22.

IP66 and IP67 ingress protection to IEC 60529 and EN 60529. DTS01 deluge protection witnessed by EECS. Operating temperature range -60°C to +75°C. Temperature Class and Ambient T6 40°C. Optional T5 with ambients up to 65°C. Assembly instruction data sheet No. A.I. 273. For PL630.

Construction and test standards IEC 60079-0, IEC 60079-7, IEC 61241-0 andIEC 61241-1. EN 60079-0, EN 60079-7, EN61241-0 andEN 61241-1.

IECEx BAS 06.0028X.ZPL630 BASEEFA Certificate No. BAS 01 ATEX 2101U. Baseefa 06ATEX0116U.

Alternative Certification Options Available.

For full Technical Specification see page 13.

4 off 8.5mm Dia. Mounting Holes

4 off M6 Stainless Steel SocketHead Cap Screws, Key Size-5mm

280mm sq. CRS

300mm sq. 126.5mm

11.5mm

Face A

Face C

Face

B

Face

D

InternationalConnection Solutionswww.ehawke.com

Amps Amps

Max. PhysicalTerminal Content

Reduced Terminal Contentat Max. Terminal Amps

MAXIMUM QUANTITY OF ENTRIES PER FACE

TerminalType

Conductor Size (mm²)

Min. Max.

Max.Volts Terminal

QuantityTerminalQuantity

TERMINAL CAPACITY DATA

WDU 2.5WDU 4WDU 6WDU 10WDU 16WDU 35WDU 70N

0.50.50.5

2.546

1.51.52.5

10

10

163570

550690

690690690

550550

76644836302211

232117141297

172229405387134

912172534

10855

Thread Size

Quantity 10 8 3 3 2 2# 1#

M16/M20 M25 M32 M40 M63 M75M50

PL6

Seri

es G

RP

Encl

osur

es

To the best of our knowledge the information contained in this leaflet, is accurate at the time of going to print and the company reserves the right to improve or modify any product illustrated without notification. The company is unable to accept liability for any inaccuracies, errors or omissions that may exist. It is the customer's responsibility to ensure that the product is suitable for their application.

All copyright reserved-Hubbell Ltd 2008. This document and all copyrighttherein is the property of: Hawke International a trading name of Hubbell Ltd(A member of the Hubbell Inc Group of Companies). Copyright Condition: This document shall be used only for the purpose for which it is provided and no reproduction or publication of the document may be made and no article may be manufactured or assembled in accordance with information contained in the document without prior written consent of the owner.

Increased Safety ExeGlass Reinforced Polyester PL630

Enclosure Type

AExe II/Exe II.Exe II.

Approx. weight : 4.5kg

Technical Data

HWK82 July '08

All Dimensions in millimetres.

All Dimensions in millimetres.

InternationalSmarter productswww.ehawke.com

EntriesPer Face

Standard Positions of Entries(Maximum Sizes Shown - Equivalent Parallel Threads or Smaller Permissible)

PL615 CABLE GLAND ENTRY POSITIONS

1

M16/M20 M25 M32

2

1Y 1Y 1Y

2Y 3Y 2Y 3Y -

EntriesPer Face

Standard Positions of Entries(Maximum Sizes Shown - Equivalent Parallel Threads or Smaller Permissible)

PL612 CABLE GLAND ENTRY POSITIONS

1

M16/M20 M25 M32

2 $

8Y #

9Y #

1Y

1Y *

2Y & 3Y

4Y & 5Y --

Yor

or6Y #

7Y #

1Yor

or

(No Continuity Plate)

(With Continuity Plate)Max. Gland Size 24 A/F

Shroud not Possible

* Continuity Plate not permitted.# This entry position is offset from the terminal rail.$ Double entries may not be possible with full terminal rail capacitysee page 41.Note : Non-standard/mixed entry positions may be available. Please contact Hawke Sales.

Note : Non-standard/mixed entry positions may be available. Please contact Hawke Sales.

Y

HWK05 Mar '02

PL6

Seri

es G

land

Ent

ry P

osit

ions

To the best of our knowledge the information contained in this leaflet, is accurate at the time of going to print and the company reserves the right to improve or modify any product illustrated without notification. The company is unable to accept liability for any inaccuracies, errors or omissions that may exist. It is the customer's responsibility to ensure that the product is suitable for their application.

Copyright Condition: This document shall be used only for the purpose for which it is provided and no reproduction or publication of the document may be made and no article may be manufactured or assembled in accordance with information contained in the document without prior written consent of the owner.

17.5 17.5

14.0

2 4 8 6 7 91 5 3

2 1 3

21.021.0

14.0

12.0 12.0

6.0 6.0

15.0

34.0

46.0

74.0

Increased Safety Exe PL6 Series GRP Enclosures Cable Gland Entry Positions

All copyright reserved-Hubbell Ltd. This document and all copyright thereinis the property of: Hawke International a division of Hubbell Ltd. (A member of the Hubbell Group of Companies).

* Continuity Plate not permitted.Note : Non-standard/mixed entry positions may be available. Please contact Hawke Sales.

* Continuity Plate not permitted.Note : Non-standard/mixed entry positions may be available. Please contact Hawke Sales.

InternationalHWK05 Mar '02

Smarter productswww.ehawke.com

EntriesPer Face

Standard Positions of Entries(Maximum Sizes Shown - Equivalent Parallel Threads or Smaller Permissible)

PL620 CABLE GLAND ENTRY POSITIONS

1

M16/20 M25 M32 M40/50

2

3

4

5

6

3Y 3Y 3Y 3Y*

2Y 4Y 2Y 4Y

2X 4X 2X 4X3Z 3Z

2X 4X 2X 4X2Z 4Z

1X 3Y 5X1Z 5Z

1X 3X 5X1Z 3Z 5Z

2Z 4Z

2Y 4Y -

--

--

--

--

-

-

EntriesPer Face

Standard Positions of Entries(Maximum Sizes Shown - Equivalent Parallel Threads or Smaller Permissible)

PL630 CABLE GLAND ENTRY POSITIONS

1

M16/M20 M25 M75*M32 or M40 M50 or M63*

2

3

4

5

6

7

8

9

10

6Y 6Y 6Y 6Y 6Y

3Y 9Y 3Y 9Y

2Y 6Y 10Y

1Y 5Y 7Y 11Y 1Y 5Y 7Y 11Y

2Y 6Y 10Y 2Y 6Y 10Y

Select from below

Select from below

Select from below

1X 6X 11X1Z 6Z 11Z

1X 5X 7X 11X1Z 5Z 7Z 11Z

1X4X6X8X11X1Z4Z6Z8X11Z

1X 5X 7X 11X1Z 5Z 7Z 11Z

1X 6Y 11X1Z 11Z

1Y 4Y 5Y8Y 11Y

1X 6X 11X1Z 6Z 11Z

3Y 9Y 3Y 9Y

-

-

-

--

--

-

-

-

-- -

-

--

--

-

-- -

-- -

-

PL6

Seri

es G

land

Ent

ry P

osit

ions

To the best of our knowledge the information contained in this leaflet, is accurate at the time of going to print and the company reserves the right to improve or modify any product illustrated without notification. The company is unable to accept liability for any inaccuracies, errors or omissions that may exist. It is the customer's responsibility to ensure that the product is suitable for their application.

Copyright Condition: This document shall be used only for the purpose for which it is provided and no reproduction or publication of the document may be made and no article may be manufactured or assembled in accordance with information contained in the document without prior written consent of the owner.

1 2

38 3829 29

3 4 5

1

80 80

68 68

54 54

40 40

27 27

2 3 4 7 8 9 10 1165

Z

Y

X

Z

Y

X

36.558.580

.5

39.561.583

.5All Dimensions in millimetres.

All Dimensions in millimetres.

Increased Safety Exe PL6 Series GRP Enclosures Cable Gland Entry Positions

All copyright reserved-Hubbell Ltd. This document and all copyright thereinis the property of: Hawke International a division of Hubbell Ltd. (A member of the Hubbell Group of Companies).

GeneralThese enclosures are a self coloured black anti-static glass reinforced polyester design that meet the requirements of Exe to IEC 60079-0, IEC 60079-7, IEC 61241-0 and IEC 61241-1. EN 60079-0, EN 60079-7, EN 61241-0 and EN 61241-1. The PL6 Series enclosures are of a robust design with a very high impact strength of up to 20Nm and have excellent electrical insulation properties.

Application These enclosures may be supplied with fitted terminals or as an empty component approved enclosure. If supplied as the latter, then final certification by the customer after fitting their own equipment must be obtained. In this case the prefix 'Z' is used ie. ZPL612.

SpecificationCertification : II2 GD Exe II. Zones of Use : Zone 1, Zone 2, Zone 21 & Zone 22.Temperature Class & Ambients : T6 40°C as standard. Optional T5 with ambients up to 65°C.Operating Temperature Range : -60°C to +75°C.Degree of Protection : IP66, IP67 and Deluge proof to DTS01.Material : Glass Reinforced Polyester. Flame Retardant to (IEC92.1 clause 2.38).Finish : Natural Black.Impact Resistance : Up to 20Nm.Weatherproofing : By captive moulded clear silicone gasket.Certification Label : Stainless Steel or optional certified self adhesive foil.Lid Fixing Screws : Stainless Steel (complete with nylon retaining washer).Additional Options : Breather/Drain devices. Internal/external earth stud. Epoxy paint finish for colour coding. EMI/RFI coating for EMC requirements.Additional Labels : Stainless Steel or laminated plastic (traffolyte) for external use only or optional (certified) self adhesive foil for external and/or internal use.

Earth ContinuityThese enclosures may be fitted with an earth continuity plate in plated mild steel as standard or optional brass when requested by the customer. (Note: A locknut is required on cable glands and metal stopping plugs to ensure earth continuity through the plate).

Technical Notes To ensure that the maximum temperature as permitted by certification is not exceeded, the Dissipated Wattage Factor Formula is used : W = N x F x I². (See page 38 for enclosure wattage). It is not permitted to fit more than one conductor per side in rail or direct mounted terminals unless using an insulated Bootlace Ferrule. Different quantities of terminals. Linked and mixed terminal arrangements other than those specified in the data tables are available but the voltage and current figures will be affected to ensure the maximum certified wattage factor is not exceeded. Please contact Hawke Technical Sales. When connecting a terminal with a conductor that is less than maximum size permitted for that terminal type, the maximum amps per pole must be reduced to suit. i.e. an RM10 (10mm²) terminal fitted with a 4mm² conductor will have the current rating reduced to that of the current rating permitted through the RM4 (4mm²) terminal. For Intrinsically Safe Applications, Exe power terminals can be supplied in blue on request. (Note: the enclosure will remain Exe certified). An earth terminal must be fitted inside the enclosure in accordance with EN 50014 : 1997 : clause 15.4. (Note: Power terminals may be used as 'clean earths'). The enclosure has tapped Metric entry threads as standard. Alternative parallel threads are available provided they are to a recognised standard eg. BSPP, ET etc. Tapered threads are not permitted in plastic enclosures due to risk of stress cracking. The customer may drill and tap entry holes in the enclosure providing they are in accordance with the relevant code of practice and comply with the details shown in this catalogue. When mixed entries are accommodated on a face they must be in the positions shown in this catalogue for the largest gland entry on that face. For complex mixed entries contact Hawke Technical Sales. Entries into the enclosure must be via a suitable, approved entry device. All unused entry holes must be fitted with a stopping plug as listed on the enclosures 'ATEX' certificate only.

and options available).(

HWK109 July '08

InternationalConnection Solutionswww.ehawke.com

PL6

Seri

es G

RP

Encl

osur

es

To the best of our knowledge the information contained in this leaflet, is accurate at the time of going to print and the company reserves the right to improve or modify any product illustrated without notification. The company is unable to accept liability for any inaccuracies, errors or omissions that may exist. It is the customer's responsibility to ensure that the product is suitable for their application.

All copyright reserved-Hubbell Ltd 2008. This document and all copyrighttherein is the property of: Hawke International a trading name of Hubbell Ltd(A member of the Hubbell Inc Group of Companies). Copyright Condition: This document shall be used only for the purpose for which it is provided and no reproduction or publication of the document may be made and no article may be manufactured or assembled in accordance with information contained in the document without prior written consent of the owner.

PL6 Series GRP Enclosures Technical Information

PL7

Ser

ies

PL7se r ies

Features

Integral Steel Earth Continuity Plate Provides internal/external earth continuity through to the two external mounting feet.

Corrosion Resistant Stainless Steel Lid Fixing Screws with Nylon Retaining Washers

External Mounting Feet

Anti-Static Properties

The Ultimate in Robust GRP Construction Designed to withstand impact resistance up to 20Nm.GRP Construction provides a high degree of resistance to corrosive atmospheres.

Removes the risk of ignition sources through static induced sparkingresistivity.

Eliminates the need to remove the lid when mounting the enclosure on the wall.

Prevents loss of screws during assembly and maintenance.

Stainless Steel Rating Label Highly durable and corrosion resistant.

Insulation Resistance in accordance with EN 50014 : 1998, which does not exceed 1 G Ω.

One Piece Durable Captive Moulded Silicone Gasket

Provides Ingress Protection to IP66. Optimum performance at low and high temperature extremes.

DTS01 deluge protection witnessed by EECS.

InternationalSmarter productswww.ehawke.com

PL7

Seri

es E

nclo

sure

s

To the best of our knowledge the information contained in this leaflet, is accurate at the time of going to print and the company reserves the right to improve or modify any product illustrated without notification. The company is unable to accept liability for any inaccuracies, errors or omissions that may exist. It is the customer's responsibility to ensure that the product is suitable for their application.

Copyright Condition: This document shall be used only for the purpose for which it is provided and no reproduction or publication of the document may be made and no article may be manufactured or assembled in accordance with information contained in the document without prior written consent of the owner.

Increased Safety ExePL7 Series Enclosures

Glass Reinforced Polyester

HWK05 Mar '02

All copyright reserved-Hubbell Ltd. This document and all copyright thereinis the property of: Hawke International a division of Hubbell Ltd. (A member of the Hubbell Group of Companies).

Note: For Cable Entry Positions see page 19.Optional: Earth continuity plate.

Increased Safety Exe II 2 GD Exe IIC, Gb, IIIC, Db. PL712 Certificate No. Baseefa 08ATEX0272X. & IECEx BAS 08.0091X. ZPL712 Certificate No. Baseefa 08ATEX0271U. & IECEx BAS 08.0090U. Suitable for use in Zone 1, Zone 2, Zone 21 & Zone 22. Construction and test standards IEC/EN 60079-0, IEC/EN 60079-7, IEC/EN 61241-0 and IEC/EN 61241-1. IP66 ingress protection to IEC/EN 60529. DTS01 deluge protection witnessed by EECS. Operating temperature range -60°C to +75°C. Temperature Class and Ambient T6 40°C. Optional T5 with ambients up to 65°C. Assembly instruction data sheet No. A.I. 285. for PL712. Assembly instruction data sheet No. A.I. 286. for ZPL712.

Alternative Certification Options Available.

Notes: For Junction Box Wattage Factor & Combined Terminal Resistance see pages 37 - 39. An earth terminal equal to that of the largest power terminal will be fitted.

For full Technical Specification see page 20.

The terminals listed are restricted to a minimum operating temperature of -50°C.

InternationalConnection Solutionswww.ehawke.com

Amps Amps

Max. PhysicalTerminal Content

Reduced Terminal Contentat Max. Terminal Amps

MAXIMUM QUANTITY OF ENTRIES PER FACE

TerminalType

Conductor Size (mm²)

Min. Max.

Max.Volts

Max. PerPillar:

2 x 10mm²3 x 6mm²4 x 4mm²

4 x 0.5mm² MIN

TerminalQuantity

TerminalQuantity

TERMINAL CAPACITY DATA

WDU 2.5WDU 4WDU 6WDU 10

MK6/6

HTB6

BK6

WDU 2.5N 0.5

0.5 550

ConductorSize mm²

Max AmpsPer Pillar

2.5 420

420

0.50.50.5

2.546

46

1.5 10

550690550550275

12101076

14 88754

N/AN/A

N/AN/A

N/A N/A

1717222940

11

11

1

151825342026

0.50.75

11.52.54610

1181015212637

Thread Size

Quantity 2 1

M16/M20 M25

PL7

Seri

es G

RP

Encl

osur

es

To the best of our knowledge the information contained in this leaflet, is accurate at the time of going to print and the company reserves the right to improve or modify any product illustrated without notification. The company is unable to accept liability for any inaccuracies, errors or omissions that may exist. It is the customer's responsibility to ensure that the product is suitable for their application.

All copyright reserved-Hubbell Ltd 2008. This document and all copyrighttherein is the property of: Hawke International a trading name of Hubbell Ltd(A member of the Hubbell Inc Group of Companies). Copyright Condition: This document shall be used only for the purpose for which it is provided and no reproduction or publication of the document may be made and no article may be manufactured or assembled in accordance with information contained in the document without prior written consent of the owner.

Glass Reinforced Polyester PL712 Enclosure Type

Increased Safety Exe Dual Certified ATEX/IECEx

Approx. weight : 1.0kg

Face A

Face C

Face

B

Face

D

2 off 6.25mm Dia. Mounting Holes.

4 off M5 Stainless Steel Socket Head Cap Screws, Key Size-4mm

106mm sq. CRS

120mm sq. 84mm

12mm

Technical Data

HWK77 July '08UPD 03 02 09

GOST R-Exe IIU.

AExe II/Exe II.Exe II.

Note: For Cable Entry Positions see page 19.Optional: Earth continuity plate.

Notes: For Junction Box Wattage Factor & Combined Terminal Resistance see pages 37 - 39. An earth terminal equal to that of the largest power terminal will be fitted. The terminals listed are restricted to a minimum operating temperature of -50°C.

Increased Safety Exe II 2 GD Exe II,C Gb, IIIC, Db. PL722 Certificate No. Baseefa 08ATEX0272X. & IECEx BAS 08.0091X. ZPL722 Certificate No. Baseefa 08ATEX0271U. & IECEx BAS 08.0090U. Suitable for use in Zone 1, Zone 2, Zone 21 & Zone 22. Construction and test standards IEC/EN 60079-0, IEC/EN 60079-7, IEC/EN 61241-0 and IEC/EN 61241-1. IP66 ingress protection to IEC 60529 and EN 60529. DTS01 deluge protection witnessed by EECS. Operating temperature range -60°C to +75°C. Temperature Class and Ambient T6 40°C. Optional T5 with ambients up to 65°C. Assembly instruction data sheet No. A.I. 285. For PL722. Assembly instruction data sheet No. A.I. 286. For ZPL722.

Alternative Certification Options Available.

For full Technical Specification see page 20.

206mm Base Fixing CRS

220mm 84mm

120m

m

106m

m

12mm2 off 6.25mm Dia. Mounting Holes.

4 off M5 Stainless Steel Socket Head Cap Screws, Key Size-4mm

Approx. weight : 2.0kg

Face A

Face C

Face

B

Face

D

InternationalConnection Solutionswww.ehawke.comUPD 03 02 09

Amps Amps

Max. PhysicalTerminal Content

Reduced Terminal Contentat Max. Terminal AmpsTerminal

Type

Conductor Size (mm²)

Min. Max.

Max.Volts Terminal

QuantityTerminalQuantity

TERMINAL CAPACITY DATA

WDU 2.5WDU 4WDU 6WDU 10

0.50.50.5

2.546

1.5

550690550550

35292217

986510

17222940

8111522

MAXIMUM QUANTITY OF ENTRIES PER FACE

M16/M20

5 3

2 1

M25Thread Size

Top & Bottom Faces A & C Quantity

Side Faces B & DQuantity

PL7

Seri

es G

RP

Encl

osur

es

To the best of our knowledge the information contained in this leaflet, is accurate at the time of going to print and the company reserves the right to improve or modify any product illustrated without notification. The company is unable to accept liability for any inaccuracies, errors or omissions that may exist. It is the customer's responsibility to ensure that the product is suitable for their application.

All copyright reserved-Hubbell Ltd 2008. This document and all copyrighttherein is the property of: Hawke International a trading name of Hubbell Ltd(A member of the Hubbell Inc Group of Companies). Copyright Condition: This document shall be used only for the purpose for which it is provided and no reproduction or publication of the document may be made and no article may be manufactured or assembled in accordance with information contained in the document without prior written consent of the owner.

Glass Reinforced Polyester PL722 Enclosure Type

Increased Safety Exe Dual Certified ATEX/IECEx

Technical Data

HWK78 July '08

GOST R-Exe IIU.

AExe II/Exe II.Exe II.

HWK119 Oct '08

InternationalConnection Solutionswww.ehawke.comUPD 03 02 09

EntriesPer Faces

A & C

Standard Positions of Entries(Maximum Sizes Shown - Equivalent Parallel Threads or Smaller Permissible)

PL722 CABLE GLAND ENTRY POSITIONS

1

M16/M20 M25

2

3

4

5

F1 F1

Select Frombelow

Select Frombelow

1F 10F 11F

4F 5F 12F 13F

1F 6F 7F12F 13F

1F 10F 11F

EntriesPer Faces

B & D

Standard Positions of Entries(Maximum Sizes Shown - Equivalent Parallel Thread or Smaller Permissible)

PL722 CABLE GLAND ENTRY POSITIONS

1

M16/M20 M25

2

3

C1 C1

C2 C3

-

-

-

-

-

*

All Dimensions in millimetres.

All Dimensions in millimetres.

EntriesPer Face

Standard Positions of Entries(Maximum Sizes Shown - Equivalent Parallel Thread or Smaller Permissible)

PL712 CABLE GLAND ENTRY POSITIONS

1

M16/M20 M25

2

3

C1 C1

C2 C3

-

-

-

Note: Non-standard/mixed entry positions may be available. Please contact Hawke Sales.

* Maximum locknut size = 24 Across Flats.

Note: Non-standard/mixed entry positions may be available. Please contact Hawke Sales.

PL7

Seri

es G

land

Ent

ry P

osit

ions

To the best of our knowledge the information contained in this leaflet, is accurate at the time of going to print and the company reserves the right to improve or modify any product illustrated without notification. The company is unable to accept liability for any inaccuracies, errors or omissions that may exist. It is the customer's responsibility to ensure that the product is suitable for their application.

All copyright reserved-Hubbell Ltd 2008. This document and all copyrighttherein is the property of: Hawke International a trading name of Hubbell Ltd(A member of the Hubbell Inc Group of Companies). Copyright Condition: This document shall be used only for the purpose for which it is provided and no reproduction or publication of the document may be made and no article may be manufactured or assembled in accordance with information contained in the document without prior written consent of the owner.

72 72

86103

86

69.560

69.560

36 3623 23

3653

36

22.5 22.518.518.5

F

C

6 4 5 7 9 1113151

4 3 512

1214 10

35

Tapp

ing

Enve

lope

Tapp

ing

Enve

lope

12

3512

34

34

Tapping Envelope

3653

36

22.5 22.518.518.5

A

C

4 3 512

Tapp

ing

Enve

lope

3512

34

Increased Safety Exe PL7 Series GRP Enclosures Cable Gland Entry Positions

GeneralThese enclosures are a self coloured black anti-static glass reinforced polyester design with integral continuity plate that meet the requirements of Exe to IEC/EN 60079-0, IEC/EN 60079-7, IEC/EN61241-0 and IEC/EN 61241-1.The PL7 Series enclosures are of a robust design with a very high impact strength of up to 20Nm and have excellent electrical insulation properties.

Application These enclosures may be supplied with fitted terminals or as an empty component approved enclosure. If supplied as the latter, then final certification by the customer after fitting their own equipment must be obtained. In this case the prefix 'Z' is used ie. ZPL712.

SpecificationCertification : II2 GD Exe IIC, Gb, IIIC, Db ( and options available). Zones of Use : Zone 1, Zone 2, Zone 21 & Zone 22.Temperature Class & Ambients : T6 40°C as standard. Optional T5 with ambients up to 65°C.Operating Temperature Range : -60°C to +75°C.Degree of Protection : IP66 and Deluge proof to DTS01.Material : Glass Reinforced Polyester. Flame Retardant to (IEC92.1 clause 2.38).Finish : Natural Black.Impact Resistance : Up to 20Nm.Weatherproofing : By captive moulded clear silicone gasket.Certification Label : Stainless Steel or optional certified self adhesive foil.Lid Fixing Screws : Stainless Steel (complete with nylon retaining washer).Additional Options : Breather/Drain devices. Internal/external earth stud if not using earth/mounting feet. Epoxy paint finish for colour coding. EMI/RFI coating for EMC requirements.Additional Labels : Stainless Steel or laminated plastic (traffolyte) for external use only or optional (certified) self adhesive foil for external and/or internal use.

Earth ContinuityThese enclosures can be supplied with an optional earth continuity plate in plated mild steel as standard with option for brass.

Technical Notes To ensure that the maximum temperature as permitted by certification is not exceeded, the Dissipated Wattage Factor Formula is used : W = N x F x I². (See page 38 for enclosure wattage). It is not permitted to fit more than one conductor per side in rail or direct mounted terminals unless using an insulated Bootlace Ferrule. Different quantities of terminals. Linked and mixed terminal arrangements other than is specified in the data tables are available but the voltage and current figures will be affected to ensure the maximum certified wattage factor is not exceeded. Please contact Hawke Technical Sales. When connecting a terminal with a conductor that is less than maximum size permitted for that terminal type, the maximum amps per pole must be reduced to suit. i.e. an WDU10 (10mm)² terminal fitted with a 4mm² conductor will have the current rating reduced to that of the current rating permitted through the WDU4 (4mm²) terminal. For Intrinsically Safe Applications, Exe power terminals can be supplied in blue on request. (Note: the enclosure will remain Exe certified). An earth terminal must be fitted inside the enclosure in accordance with IEC/EN 60079-0. (Note: Power terminals may be used as 'clean earths'). The enclosure has tapped Metric entry threads as standard. Alternative parallel threads are available provided they are to a recognised standard eg. BSPP, ET etc. Tapered threads are not permitted in plastic enclosures due to risk of stress cracking. The customer may drill and tap entry holes in the enclosure providing they use a special stepped drill available from Hawke, and the holes are in accordance with the relevant code of practice and comply with the details shown in this catalogue. When mixed entries are accommodated on a face they must be in the positions shown in this catalogue for the largest gland entry on that face. For complex mixed entries contact Hawke Technical Sales. Entries into the enclosure must be via a suitable approved entry device. All unused entry holes must be fitted with a stopping plug as listed on the enclosures certificate.

InternationalConnection Solutionswww.ehawke.comUPD 03 02 09

PL7

Seri

es G

RP

Encl

osur

es

To the best of our knowledge the information contained in this leaflet, is accurate at the time of going to print and the company reserves the right to improve or modify any product illustrated without notification. The company is unable to accept liability for any inaccuracies, errors or omissions that may exist. It is the customer's responsibility to ensure that the product is suitable for their application.

All copyright reserved-Hubbell Ltd 2008. This document and all copyrighttherein is the property of: Hawke International a trading name of Hubbell Ltd(A member of the Hubbell Inc Group of Companies). Copyright Condition: This document shall be used only for the purpose for which it is provided and no reproduction or publication of the document may be made and no article may be manufactured or assembled in accordance with information contained in the document without prior written consent of the owner.

PL7 Series GRP Enclosures Technical Information

HWK100 July '08

S Se

ries

S se r ies

Softer Finished Rounded Edges Safer manual handling of enclosure and gland plates.

Stainless Steel Lid Fixing Screws with Nylon Retaining Washers

Rigid Slotted External Mounting Feet

Robust Stainless Steel Construction

Superior Silicone Sponge GasketDTS01 deluge protection witnessed by EECS. Provides ingress protection to IP66. Durable with excellent UV stability and chemical resistance. Good chemical resistance - EMC mesh option.

Enclosure material thickness ranges between 1.2 - 2.0mm with 3mmthick gland plates.Durable stainless steel rating label.

Allows enclosure to be hung onto the structure.

Electropolished Surface FinishProvides high levels of corrosion resistance.

Prevents loss of screws during assembly and maintenance.

Extensive Range of Enclosure Sizes Available Nine enclosure sizes available. Sizes range from 153 x 233 x 130 to 740 x 1000 x 210.

Gland plates offered on two sides (Faces B & D) and bottom (Face C) of each enclosure.

Features

InternationalHWK05 Mar '02

Smarter productswww.ehawke.com

S Se

ries

Sta

inle

ss S

teel

Enc

losu

res

To the best of our knowledge the information contained in this leaflet, is accurate at the time of going to print and the company reserves the right to improve or modify any product illustrated without notification. The company is unable to accept liability for any inaccuracies, errors or omissions that may exist. It is the customer's responsibility to ensure that the product is suitable for their application.

Copyright Condition: This document shall be used only for the purpose for which it is provided and no reproduction or publication of the document may be made and no article may be manufactured or assembled in accordance with information contained in the document without prior written consent of the owner.

Increased Safety ExeEnclosures

S Series Stainless Steel

All copyright reserved-Hubbell Ltd. This document and all copyright thereinis the property of: Hawke International a division of Hubbell Ltd. (A member of the Hubbell Group of Companies).

Notes: For Junction Box Wattage Factor & Combined Terminal Resistance see pages 37 - 39. The box is supplied with an integral internal/external earth stud assembly.

Note: For Cable Entry Positions see page 32.

# Serrated Washers/Locknuts with large outside diameters may foul on adjacent glands.* Serrated Washers/Locknuts must not foul on aperture wall.

For full Technical Specification see page 35.

Increased Safety Exe. II 2 GD Exe II ExtD A21SIZE 1 Certificate No. Baseefa 08 ATEX 0208X & IECEx BAS 08.0065XZSIZE 1 Certificate No. Baseefa 08 ATEX 0207U & IECEx BAS 08.0064USuitable for use in Zone 1, Zone 2, Zone 21 & Zone 22.Construction and test standards IEC/EN 60079-0 & IEC/EN 60079-7,IEC/EN 61241-0 & IEC/EN 61241-1.IP66 ingress protection to IEC/EN 60529. DTS01 deluge protection witnessed by EECS.Operating temperature range -60°C to +80°C.Temperature Class and Ambient T6 40°C. Optional T5 with ambients up to 65°C.Assembly instruction data sheet No. A.I. 266.For SIZE 1.Assembly instruction data sheet No. A.I. 267.For ZSIZE1.210mm deep option available.

Alternative Certification Options Available.

The terminals listed are restricted to a minimum operating temperature of -50°C.

M10 IntegralEarth Stud

M6 GlandPlate Fixing

Screws

153mm208mm

108mm

58mm

130mm

Face A

Face C

Face D Face B

4 x M10Mounting

Holes

152m

m

108m

m

233m

m

58m

m

Captive LidGasket

Ø8mm Padlocking

Facility

Approx. weight : 3.7kg

(210mm option)

Gland Plates on Faces B, C and D only.

InternationalConnection Solutionswww.ehawke.comUPD 03 02 09

Amps Amps

Max. PhysicalTerminal Content

Reduced Terminal Contentat Max. Terminal AmpsTerminal

Type

Conductor Size (mm²)

Min. Max.

Max.Volts Terminal

QuantityTerminalQuantity

TERMINAL CAPACITY DATA

WDU 2.5WDU 4WDU 6WDU 10WDU 16WDU 35

0.50.50.5

2.546

1.51.52.5

101635

550690

690690

550550

30251915139

1816131196

172229405387

131724344575

MAXIMUM QUANTITY OF ENTRIES PER FACE

Thread Size

Quantity

M16

3 2 1

M20/O M20/A M25 M32

5 #*

5 #*

S Se

ries

Sta

inle

ss S

teel

Enc

losu

res

To the best of our knowledge the information contained in this leaflet, is accurate at the time of going to print and the company reserves the right to improve or modify any product illustrated without notification. The company is unable to accept liability for any inaccuracies, errors or omissions that may exist. It is the customer's responsibility to ensure that the product is suitable for their application.

All copyright reserved-Hubbell Ltd 2008. This document and all copyrighttherein is the property of: Hawke International a trading name of Hubbell Ltd(A member of the Hubbell Inc Group of Companies). Copyright Condition: This document shall be used only for the purpose for which it is provided and no reproduction or publication of the document may be made and no article may be manufactured or assembled in accordance with information contained in the document without prior written consent of the owner.

Increased Safety ExeStainless Steel Size 1

Enclosure Type

Dual Certified ATEX/IECEx

Technical Data

HWK84 July '08

GOST R-Exe IIU.

AExe II/Exe II.

Exe II.

Note: For Cable Entry Positions see page 32.

# Serrated Washers/Locknuts with large outside diameters may foul on adjacent glands.* Serrated Washers/Locknuts must not foul on aperture wall.

Notes: For Junction Box Wattage Factor & Combined Terminal Resistance see pages 37 - 39. The box is supplied with an integral internal/external earth stud assembly. The terminals listed are restricted to a minimum operating temperature of -50°C.

For full Technical Specification see page 35.

Increased Safety Exe. II 2 GD Exe II ExtD A21SIZE 2 Certificate No. Baseefa 08 ATEX 0208X & IECEx BAS 08.0065XZSIZE 2 Certificate No. Baseefa 08 ATEX 0207U & IECEx BAS 08.0064USuitable for use in Zone 1, Zone 2, Zone 21 & Zone 22.Construction and test standards IEC/EN 60079-0 and IEC/EN 60079-7,IEC/EN 61241-0 & IEC/EN 61241-1.IP66 ingress protection to IEC/EN 60529.DTS01 deluge protection witnessed by EECS.Operating temperature range -60°C to +80°C.Temperature Class and Ambient T6 40°C. Optional T5 with ambients up to 65°C.Assembly instruction data sheet No. A.I. 266.For SIZE 2.Assembly instruction data sheet No. A.I. 267.For ZSIZE2.210mm deep option available.

Alternative Certification Options Available.

InternationalConnection Solutionswww.ehawke.comUPD 03 02 09

Amps Amps

Max. PhysicalTerminal Content

Reduced Terminal Contentat Max. Terminal AmpsTerminal

Type

Conductor Size (mm²)

Min. Max.

Max.Volts Terminal

QuantityTerminalQuantity

TERMINAL CAPACITY DATA

WDU 2.5WDU 4WDU 6WDU 10WDU 16WDU 35

0.50.50.5

2.546

1.51.52.5

101635

550690

690690

550550

605042362820

17161311107

172229405387

91216223152

2.5 35 1100 6 6 7676WDU 70NWFF 35

10 70 690 8 5 134113

MAXIMUM QUANTITY OF ENTRIES PER FACE

Thread Size M16

12 6 4

8 4

3

2 2

M20/O M20/A M25 M32 M40 M50

Bottom Face CQuantity

Side Faces B & DQuantity

17#

#

17#

11 #9

*

*

2

1

S Se

ries

Sta

inle

ss S

teel

Enc

losu

res

To the best of our knowledge the information contained in this leaflet, is accurate at the time of going to print and the company reserves the right to improve or modify any product illustrated without notification. The company is unable to accept liability for any inaccuracies, errors or omissions that may exist. It is the customer's responsibility to ensure that the product is suitable for their application.

All copyright reserved-Hubbell Ltd 2008. This document and all copyrighttherein is the property of: Hawke International a trading name of Hubbell Ltd(A member of the Hubbell Inc Group of Companies). Copyright Condition: This document shall be used only for the purpose for which it is provided and no reproduction or publication of the document may be made and no article may be manufactured or assembled in accordance with information contained in the document without prior written consent of the owner.

Increased Safety ExeStainless Steel Size 2

Enclosure Type

Dual Certified ATEX/IECEx

Technical Data(210mm option)

M10 IntegralEarth Stud

M6 GlandPlate Fixing

Screws

263mm316mm

218mm

78mm

160mm

Face A

160m

m

293m

m

78m

m

Captive LidGasket

Ø8mm Padlocking

Facility

Face C

Face D Face B

4 x M10Mounting

Holes

170m

m

Approx. weight : 6.5kg

Gland Plates onFaces B, C and D only.

HWK85 July '08

GOST R-Exe IIU.

AExe II/Exe II.

Exe II.

Note: For Cable Entry Positions see pages 32 - 33.

# Serrated Washers/Locknuts with large outside diameters may foul on adjacent glands.* Serrated Washers/Locknuts must not foul on aperture wall.

Notes: For Junction Box Wattage Factor & Combined Terminal Resistance see pages 37 - 39. The box is supplied with an integral internal/external earth stud assembly. The terminals listed are restricted to a minimum operating temperature of -50°C.

For full Technical Specification see page 35.

Increased Safety Exe. II 2 GD Exe II ExtD A21SIZE 3 Certificate No. Baseefa 08 ATEX 0208X & IECEx BAS 08.0065XZSIZE 3 Certificate No. Baseefa 08 ATEX 0207U & IECEx BAS 08.0064USuitable for use in Zone 1, Zone 2, Zone 21 & Zone 22.Construction and test standards IEC/EN 60079-0 and IEC/EN 60079-7,IEC/EN 61241-0 & IEC/EN 61241-1.IP66 ingress protection to IEC/EN 60529. DTS01 deluge protection witnessed by EECS.Operating temperature range -60°C to +80°C.Temperature Class and Ambient T6 40°C. Optional T5 with ambients up to 65°C.Assembly instruction data sheet No. A.I. 266.For SIZE 3.Assembly instruction data sheet No. A.I. 267.For ZSIZE3.210mm deep option available.

Alternative Certification Options Available.

InternationalConnection Solutionswww.ehawke.comUPD 03 02 09

Amps Amps

Max. PhysicalTerminal Content

Reduced Terminal Contentat Max. Terminal AmpsTerminal

Type

Conductor Size (mm²)

Min. Max.

Max.Volts Terminal

QuantityTerminalQuantity

TERMINAL CAPACITY DATA

WDU 2.5WDU 4WDU 6WDU 10WDU 16WDU 35

0.50.50.5

2.546

1.51.52.5

101635

550690

690690

550550

1129472564836

19171512118

172229405387

7913192541

2.5 35 1100 11 11 7676WDU 70NWFF 35

10 70 690 14 6 13490

MAXIMUM QUANTITY OF ENTRIES PER FACE

Thread Size M16

12 6 4

16 8

3

5 4

M20/O M20/A M25 M32 M40 M50

Bottom Face CQuantity

Side Faces B & DQuantity

17 # 17 #

# #23 23

*2

*3

(210mm option)

Gland Plates onFaces B, C and D only.

M10 IntegralEarth Stud

M6 GlandPlate Fixing

Screws

263mm316mm

218mm

78mm

160mm

Face A

303m

m

413m

m

78m

m

Captive LidGasket

Ø8mm Padlocking

Facility

Face C

Face D Face B

4 x M10Mounting

Holes

250m

m

Approx. weight : 7.9kg

S Se

ries

Sta

inle

ss S

teel

Enc

losu

res

To the best of our knowledge the information contained in this leaflet, is accurate at the time of going to print and the company reserves the right to improve or modify any product illustrated without notification. The company is unable to accept liability for any inaccuracies, errors or omissions that may exist. It is the customer's responsibility to ensure that the product is suitable for their application.

All copyright reserved-Hubbell Ltd 2008. This document and all copyrighttherein is the property of: Hawke International a trading name of Hubbell Ltd(A member of the Hubbell Inc Group of Companies). Copyright Condition: This document shall be used only for the purpose for which it is provided and no reproduction or publication of the document may be made and no article may be manufactured or assembled in accordance with information contained in the document without prior written consent of the owner.

Increased Safety ExeStainless Steel Size 3

Enclosure Type

Dual Certified ATEX/IECEx

Technical Data

HWK86 July '08

GOST R-Exe IIU.

AExe II/Exe II.

Exe II.

Note: For Cable Entry Positions see page 33.

# Serrated Washers/Locknuts with large outside diameters may foul on adjacent glands.* Serrated Washers/Locknuts must not foul on aperture wall.

Notes: For Junction Box Wattage Factor & Combined Terminal Resistance see pages 37 - 39. The box is supplied with an integral internal/external earth stud assembly. The terminals listed are restricted to a minimum operating temperature of -50°C.

For full Technical Specification see page 35.

Increased Safety Exe. II 2 GD Exe II ExtD A21SIZE 4 Certificate No. Baseefa 08 ATEX 0208X & IECEx BAS 08.0065XZSIZE 4 Certificate No.Baseefa 08 ATEX 0207U & IECEx BAS 08.0064USuitable for use in Zone 1, Zone 2, Zone 21 & Zone 22.Construction and test standards IEC/EN 60079-0 & IEC/EN60079-7,IEC/EN 61241-0 & IEC/EN 61241-1.IP66 ingress protection to IEC/EN 60529.DTS01 deluge protection witnessed by EECS.Operating temperature range -60°C to +80°C.Temperature Class and Ambient T6 40°C. Optional T5 with ambients up to 65°C.Assembly instruction data sheet No. A.I. 266.For SIZE 4.Assembly instruction data sheet No. A.I. 267.For ZSIZE 4.210mm deep option available.

Alternative Certification Options Available.

InternationalConnection Solutionswww.ehawke.comUPD 03 02 09

Amps Amps

Max. PhysicalTerminal Content

Reduced Terminal Contentat Max. Terminal AmpsTerminal

Type

Conductor Size (mm²)

Min. Max.

Max.Volts Terminal

QuantityTerminalQuantity

TERMINAL CAPACITY DATA

WDU 2.5WDU 4WDU 6WDU 10WDU 16WDU 35

WFF 35 WFF 70 WFF 120

0.50.50.5

2.546

1.51.52.5

101635

550690

690690

550550

168141108847254

22201714139

172229405387

6811162236

WDU 70NWDU 70/95WDU 70/95WDU 120/150WDU 120/150

101616

35

2.52.56

707095120

35150

70120

690

690

690

110011001100

301111991197

768771197

134

134

162

76116162

6794104144

76116162

153

MAXIMUM QUANTITY OF ENTRIES PER FACE

Thread Size M16

18 9 6 4

M20/O M20/A M25 M32 M40 M50

26 4 Faces B, C & DQuantity

# 26 # *

Gland Plates onFaces B, C and D only.

(210mm option)

M10 IntegralEarth Stud

373mm423mm160mm

78mm

Face A

Captive LidGasket

Ø8mm Padlocking

Facility

Face C

Face D Face B

4 x M10Mounting

Holes

328m

m

305m

m

425m

m

M6 GlandPlate Fixing

Screws

Approx. weight : 13kg

S Se

ries

Sta

inle

ss S

teel

Enc

losu

res

To the best of our knowledge the information contained in this leaflet, is accurate at the time of going to print and the company reserves the right to improve or modify any product illustrated without notification. The company is unable to accept liability for any inaccuracies, errors or omissions that may exist. It is the customer's responsibility to ensure that the product is suitable for their application.

All copyright reserved-Hubbell Ltd 2008. This document and all copyrighttherein is the property of: Hawke International a trading name of Hubbell Ltd(A member of the Hubbell Inc Group of Companies). Copyright Condition: This document shall be used only for the purpose for which it is provided and no reproduction or publication of the document may be made and no article may be manufactured or assembled in accordance with information contained in the document without prior written consent of the owner.

Increased Safety ExeStainless Steel Size 4

Enclosure Type

Dual Certified ATEX/IECEx

Technical Data

HWK87 July '08

GOST R-Exe IIU.

AExe II/Exe II.Exe II.

Note: For Cable Entry Positions see page 34.

# Serrated Washers/Locknuts with large outside diameters may foul on adjacent glands.* Serrated Washers/Locknuts must not foul on aperture wall.

Notes: For Junction Box Wattage Factor & Combined Terminal Resistance see pages 37 - 39. The box is supplied with an integral internal/external earth stud assembly. The terminals listed are restricted to a minimum operating temperature of -50°C.

For full Technical Specification see page 35.

Increased Safety Exe. II 2 GD Exe II ExtD A21SIZE 5 Certificate No. Baseefa 08 ATEX 0208X & IECEx BAS 08.0065XZSIZE 5 Certificate No. Baseefa 08 ATEX 0207U & IECEx BAS 08.0064USuitable for use in Zone 1, Zone 2, Zone 21 & Zone 22.Construction and test standards IEC/EN 60079-0 & IEC/EN 60079-7,IEC/EN 61241-0 & IEC/EN 61241-1.IP66 ingress protection to IEC/EN 60529. DTS01 deluge protection witnessed by EECS.Operating temperature range -60°C to +80°C.Temperature Class and Ambient T6 40°C. Optional T5 with ambients up to 65°C.Assembly instruction data sheet No. A.I. 266.For SIZE 5.Assembly instruction data sheet No. A.I. 267.For ZSIZE 5.210mm deep option available.

Alternative Certification Options Available.

InternationalConnection Solutionswww.ehawke.comUPD 03 02 09

Amps Amps

Max. PhysicalTerminal Content

Reduced Terminal Contentat Max. Terminal AmpsTerminal

Type

Conductor Size (mm²)

Min. Max.

Max.Volts Terminal

QuantityTerminalQuantity

TERMINAL CAPACITY DATA

WDU 2.5WDU 4WDU 6WDU 10WDU 16WDU 35

WFF 35 WFF 70 WFF 120

0.50.50.5

2.546

1.51.52.5

101635

550690

690690

550550

2281921441209672

21201614129

1722294053134

579131931

WDU 70NWDU 70/95WDU 70/95WDU 120/150WDU 120/150

101616

35

2.52.56

707095

120

35150

70120

690

690

690

110011001100

401515121215129

77978

14119

134

134

162

76116162

5893105126

75114163

134

MAXIMUM QUANTITY OF ENTRIES PER FACE

Thread Size M16

24 20 10 3 2

M20/O M20/A M25 M32 M40 M50 M63 M75

40 40 5 Faces B, C & DQuantity

8 #* *# #

S Se

ries

Sta

inle

ss S

teel

Enc

losu

res

To the best of our knowledge the information contained in this leaflet, is accurate at the time of going to print and the company reserves the right to improve or modify any product illustrated without notification. The company is unable to accept liability for any inaccuracies, errors or omissions that may exist. It is the customer's responsibility to ensure that the product is suitable for their application.

All copyright reserved-Hubbell Ltd 2008. This document and all copyrighttherein is the property of: Hawke International a trading name of Hubbell Ltd(A member of the Hubbell Inc Group of Companies). Copyright Condition: This document shall be used only for the purpose for which it is provided and no reproduction or publication of the document may be made and no article may be manufactured or assembled in accordance with information contained in the document without prior written consent of the owner.

Increased Safety ExeStainless Steel Size 5

Enclosure Type

Dual Certified ATEX/IECEx

Technical Data

M10 IntegralEarth Stud

373mm423mm210mm

128mm

Face A

Captive LidGasket

Ø8mm Padlocking

Facility

Face C

Face D Face B

4 x M10Mounting

Holes

328m

m

330m

m

523m

m

M6 GlandPlate Fixing

Screws

Approx. weight : 19.5kg

Gland Plates onFaces B, C and D only.

HWK88 July '08

GOST R-Exe IIU.

AExe II/Exe II.Exe II.

Note: For Cable Entry Positions see page 34.

# Serrated Washers/Locknuts with large outside diameters may foul on adjacent glands.* Serrated Washers/Locknuts must not foul on aperture wall.

Notes: For Junction Box Wattage Factor & Combined Terminal Resistance see pages 37 - 39. The box is supplied with an integral internal/external earth stud assembly. The terminals listed are restricted to a minimum operating temperature of -50°C.

Increased Safety Exe. II 2 GD Exe II ExtD A21SIZE 6 Certificate No. Baseefa 08 ATEX 0208X & IECEx BAS 08.0065XZSIZE 6 Certificate No. Baseefa 08 ATEX 0207U & IECEx BAS 08.0064USuitable for use in Zone 1, Zone 2, Zone 21 & Zone 22.Construction and test standards IEC/EN 60079-0 & IEC/EN 60079-7,IEC/EN 61241-0 & IEC/EN 61241-1.IP66 ingress protection to IEC/EN 60529. DTS01 deluge protection witnessed by EECS.Operating temperature range -60°C to +80°C.Temperature Class and Ambient T6 40°C. Optional T5 with ambients up to 65°C.Assembly instruction data sheet No. A.I. 266.For SIZE 6.Assembly instruction data sheet No. A.I. 267.For ZSIZE 6.210mm deep option available.

Alternative Certification Options Available.