DRIVE-IN PALLET RACKING - Home - Victor Industries racking storage is designed for high volume, low...

Transcript of DRIVE-IN PALLET RACKING - Home - Victor Industries racking storage is designed for high volume, low...

Drive-In racking storage is designed for high volume, low stock rotation use Drive-In Pallet Rack Systems load and retrieve from the same side, creating Last-In-First-Out (LIFO) inventory retrieval organization.

Drive-Through Pallet Rack Systems load from one side and unload from the other to create First-In-First-Out inventory retrieval (FIFO); forklifts

can enter from either aisle.

SHOWROOM: 69 Portage Road Otahuhu, Auckland 1062, New Zealand.

Tel: +64 9 973 4113, Fax: +64 9 973 4114Email: [email protected] Web: www.novalok.co.nz

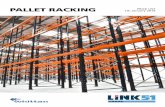

DRIVE-IN PALLET RACKING

[email protected]: 0508 668 256

Performance Data• Space utilisation storage area up to 70%

• Space utilisation operating aisle 70% down to 20%

• Average aisle width 3 to 6 meters

• Access to individual pallets 50 to 20%

Often used in freezer environments, where first in last out (FILO)

doesn’t matter, and high space utilization is critical. To remove the

pallet that was loaded in first, all pallets in front will have to be moved.

There are no cross support beams with Drive-In racking so pallets will be

of a specified user standard size.

This system requires a fairly narrow forklift. Generally, any modern forklift

up to 1.8 tonne will fit easily. A standard pallet width is 1200mm. If larger

pallet widths are used, then a larger forklift can be used. What you find

is that specific industries often have a pallet size that is standard to the

industry, such as the fertilizer industry seems to use 1400 wide pallets, the

printing industry uses smaller pallets. You will need a forklift under 1100

wide to load 1200 wide pallets. Forklifts don’t come much narrower than

1100mm so if you want a drive-in system for smaller than standard pallets

you will need to sit your small pallet on a standard pallet to make it work.

Novalok engineering team will assist you with the documentation

process to enable your organisations racking project to be ‘Certified’

as compliant with the relevant standards. Furthermore, Novalok assures

you that our product will meet all required installation and manufacturing

standards subject to proper use and operation within maximum

load ratings.

TOP BEAM

GUIDE RAIL

UPRIGHT FRAME

HORIZONTAL BRACE

D

C

B

A

E

F

BACK CROSS BRACE

SUPPORT ARMUPRIGHT PROTECTOR

SUPPORT ARM RAILA B

C D

E F