DON'T GET LEFT IN THE COLD · 03/2018 DON'T GET LEFT IN THE COLD Hilti HIT-ICE Hilti HIT-ICE is the...

Transcript of DON'T GET LEFT IN THE COLD · 03/2018 DON'T GET LEFT IN THE COLD Hilti HIT-ICE Hilti HIT-ICE is the...

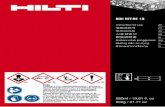

DONT GET LEFT IN THE COLDHilti HIT-ICE Adhesive Anchor System

032

018

DONT GET LEFT IN THE COLDHilti HIT-ICE

Hilti HIT-ICE is the solution for cold weather adhesive anchoring applications in cracked and uncracked concrete and grout filled masonry for a wide variety of anchoring applications The formulation of Hilti HIT-ICE ensures consistent dispensing in challenging cold weather applications as low as -10degF-23degC Dont get left in the cold on your next project choose Hilti HIT-ICE

DUST CONTROL

Download yourcomplimentaryPROFIS Anchorsoftware today

THE TRADITIONAL METHODBlow and brush

All Hilti adhesive anchors can be cleaned with the traditional blow-brush-blow method

Note OSHA 19261153 Table 1 requires a HEPA rated vacuum filter with this procedure

Drill Blow twice Brush twice Blow twice Set

Drill 2x 2x 2x Done

Drill Set

Drill Install

HOLES THAT CLEAN THEMSELVESHilti TE-CD and TE-YD Hollow Drill Bits in conjunction with the Hilti VC 150 and VC 300 Series Vacuum and HIT-ICE make subsequent hole cleaning completely unnecessary Dust is removed by the Hilti VC 150 and VC 300 Series Vacuum system while drilling is in progress which leads to faster drilling and a virtually dustless working environment

bull The Hilti TE-CDTE-YD hollow drill bits together with a VC 150 and VC 300 series vacuum cleaner is a specified exposure control method per OSHAs silica standard (OSHA 19261153)

bull Because no separate hole cleaning is needed a HEPA filter is not required for the hollow drill bit system

PROFIS ANCHOR SOFTWAREHilti PROFIS Anchor represents the next generation in anchor design software PROFIS Anchor performs calculations for cast in place anchors and Hilti post-installed anchors in accordance with the Strength Design provisions of ACI 318 CSA A233 and the International Building Code Ask your Hilti Field Engineer or visit Hilti Online for details

HIT-ICE and the new alternative installation methods are now included in PROFIS Anchor Look for TE-CD TE-YD Hollow Drill Bit options when designing your next project

Note OSHA 19261153 Table 1 - compliant control metnods require a vacuum cleaner with 99 filter efficiency and a filter cleaning mechanism - HEPA not required

1

HIT-ICE Technical Supplement

032

018

PRODUCT DESCRIPTION

HIT-ICE with Threaded Rod Rebar and HIS-N InsertsMortar Systems Features and Benefits

Hilti HIT-ICE Cartridge

bull Winter formulation for base material temperatures down to -10degF (-23degC)

bull Two hole cleaning options including the Hilti SafeSettrade System using the TE-CD or TE-YD Hollow Drill Bit in conjunction with a Hilti Vacuum to remove the dust as you drill

bull Small edge distance and anchor spacing allowance

bull Mixing tube provides proper mixing and accurate dispensing of mixed resin

bull Contains no styrene and virtually odorless

bull Cures quickly over a large range of base material temperatures

bull Excellent weathering resistance and resistance to high temperatures

bull High load capacities

Threaded RodHASHAS-EHIT-V

Rebar

Hilti HIS-N

MATERIAL SPECIFICATIONS

Table 1 - Material properties of cured HIT-ICE adhesiveCompressive strength 72 MPa 10440 psiTensile strength 12 MPa 1740 psiWater absorption DIN 53495 24Electrical resistance DINVDE 0303T3 2x1011 OHMcm 51x1011 OHMin

For material specifications for anchor rods and inserts please refer to section 328 of the Hilti North American Tech Guide volume 2 Anchor Fastening Technical Guide Edition 17

ApprovalsListingsUS Green Building Council LEEDreg Credit 41-Low Emitting Materials

Uncracked concrete

Cracked concrete

Grout-filled concrete masonry

SafeSettrade System with Hollow Drill Bit

ProfisAnchordesign software

2

032

018

Table 2 - Hilti HASHIT-V Rod installation specifications installed with Hilti HIT-ICE adhesive system

Setting information Symbol UnitsNominal rod diameter

38 12 58 34 78 1 1-14Nominal bit diameter do in 716 916 34 78 1 1-18 1-38

Effective embedment

minimum hefmin

in 2-38 2-34 3-18 3-12 3-12 4 5(mm) (60) (70) (79) (89) (89) (102) (127)

maximum hefmax

in 7-12 10 12-12 15 17-12 20 25(mm) (191) (254) (318) (381) (445) (508) (635)

Minimum diameter offixturehole

through-set in 12 58 13161 15161 1-181 1-141 1-121

preset in 716 916 1116 1316 1516 1-18 1-38

Installation torque Tinst

ft-lb 15 30 60 100 125 150 200(Nm) (20) (40) (80) (136) (169) (203) (271)

Minimum concrete thickness hmin

in hef+1-14 (hef+30) hef+2do(mm)

Minimum edge distance2 cmin

in 1-78 2-12 3-18 3-34 4-38 5 5-58(mm) (48) (64) (79) (95) (111) (127) (143)

Minimum anchor spacing smin

in 1-78 2-12 3-18 3-34 4-38 5 5-58(mm) (48) (64) (79) (95) (111) (127) (143)

1 Install using (2) washers See Figure 32 Edge distance of 1-34-inch (44mm) is permitted provided the installation torque is reduced to 030 Tinst for 5d lt s lt 16-in and to 05Tinst for s gt16-in

Perm

issi

ble

conc

rete

co

nditi

ons

Uncrackedconcrete

Dryconcrete

Perm

issi

ble

drilli

ngm

etho

d

Hammer drilling with carbide tipped drill bit

Crackedconcrete

Water saturatedconcrete

Hilti TE-CD or TE-YD Hollow Drill Bit

Figure 1 - Hilti HASHIT-V threaded rod installation conditions

Hilti HAS threaded rod Hilti HIT-V threaded rod

Figure 2 - HASHIT-V threaded rods

Figure 3 - Installation with (2) washers

TECHNICAL DATA

Hilti HIT-ICE with HASHIT-V Threaded Rod

3

HIT-ICE Technical Supplement

032

018

ACI 318-14 Chapter 17 design

Load Resistance Factored Design of anchors is described in the provisions of ACI 318-14 Chapter 17 for post-installed anchors tested and assessed in accordance with ACI 3552 for mechanical anchors and ACI 3554 for adhesive anchors This section contains the Load Resistance Factored Design tables with unfactored characteristic loads that are based on testing in accordance withACI3554ThesetablesarefollowedbyHiltiSimplifiedDesignTablesTheloadvaluesinthesetablesweredevelopedusingthe Strength Design parameters developed through testing per ACI 3554 and the equations within ACI 318-14 Chapter 17 For adetailedexplanationoftheHiltiSimplifiedDesignTablesrefertotheoftheHiltiNorthAmericanProductTechnicalGuideVolume 2 Anchor Fastening Technical Guide Edition 17 (PTG Vol 2)For additional information or technical assistance contact Hilti at 800-879-5000 (US) or 800-363-4459 (CA)

Table 3 - Hilti HIT-ICE design information with HASHIT-V threaded rods in holes drilled with a hammer drill and carbide bit (or hollow drill bit) in accordance with ACI 318-14 Ch 171

Design parameter Symbol UnitsNominal rod diameter (in) Ref

ACI 318-14 38 12 58 34 78 1 1-14

Nominal anchor diameter da

in 38 12 58 34 78 1 1-14(mm) (95) (127) (159) (191) (222) (254) (318)

Effective minimum embedment hefmin2

in 2-38 2-34 3-18 3-12 3-12 4 5(mm) (60) (70) (79) (89) (89) (102) (127)

Effective maximum embedment hefmax2

in 7-12 10 12-12 15 17-12 20 25(mm) (191) (254) (318) (381) (445) (508) (635)

Minimum concrete thickness hmin2

in hef + 1-14 (hef + 30) hef + 2d0

(8)

(mm)

Critical edge distance cacin

(mm)

Minimum edge distance cmin3

in 1-78 2-12 3-18 3-34 4-38 5 6-14(mm) (48) (64) (79) (95) (111) (127) (159)

Minimum anchor spacing smin

in 1-78 2-12 3-18 3-34 4-38 5 6-14(mm) (48) (64) (79) (95) (111) (127) (159)

Effectiveness factor for uncracked concrete kcuncr4 -

2417422

(10)

Effectiveness factor for cracked concrete kccr4 -

1717422

(71)Strength reduction factor for tension concrete failure modes5 ФcN - 065 1733Strength reduction factor for shear concrete failure modes5 ФcV - 070 1733

Tem

pera

ture

ra

nge

A6 Characteristic bond stress in cracked concrete7 τkcr

psi 715 615 520 420 325na na 1745

(MPa) (49) (42) (36) (29) (22)

Characteristic bond stress in uncracked concrete7 τkuncr

psi 1215 1200 1185 1075 1060 1050 10201745

(MPa) (84) (83) (82) (74) (73) (72) (70)

Perm

issi

ble

inst

alla

tion

cond

ition

s Strength reduction factor for tension bond failure modes dry concrete

- - 2 1 2 1 1 1 1- - 055 065 055 065 065 065 065

Strength reduction factor for tension bond failure modes water saturated concrete

- - 2 1 2 1 1 1 1- - 055 065 055 065 065 065 065

1 Design information in this table is based on testing in accordance with ACI 35542 Seefigure2and3ofthissection3 Minimumedgedistancemaybereducedto1-34(44mm)lecmin lt 5d provided Tinst is reduced to 030 Tinst for 5d lt s lt 16-in and to 05Tinst for s gt16-in4 ForalldesigncasesψcN=10Theappropriatecoefficientforbreakoutresistanceforcrackedconcrete(kccr) or uncracked concrete (kcuncr) must be used5 Valuesprovidedforpost-installedanchorsunderConditionBwithoutsupplementaryreinforcementasdefinedinACI318-141733 ForcaseswherethepresenceofsupplementaryreinforcementcanbeverifiedthereductionfactorsassociatedwithConditionAmaybeused6 Temperature range A Max short term temperature = 130degF (54degC) max long term temperature = 110degF (43degC) Short term elevated concrete temperatures are those that occur over brief intervals eg as a result of diurnal cycling Long term concrete temperatures are roughly

constantoversignificantperiodsoftime7 Bond strength values corresponding to concrete compressive strength fc = 2500 psi (172 Mpa) For concrete compressive strength fc between 2500 psi

(172 Mpa) and 8000 psi (552 Mpa) the tabulated characteristic bond strength may be increased by a factor of ( fc 2500 )01 [ for SI ( fc 172 )01 ]8 d0 = drilled hole diameter

4

032

018

Table 4 - Hilti HIT-ICE adhesive design strength with concrete bond failure for threaded rod in uncracked concrete12345678

Nominal anchor

diameter in

Effective embedment

in (mm)

TensionmdashФNn ShearmdashФVn

ƒ´c = 2500 psi (172 MPa)

lb (kN)

ƒ´c = 3000 psi (207 MPa)

lb (kN)

ƒ´c = 4000 psi (276 MPa)

lb (kN)

ƒ´c = 6000 psi(414 MPa)

lb (kN)

ƒ´c = 2500 psi (172 MPa)

lb (kN)

ƒ´c = 3000 psi (207 MPa)

lb (kN)

ƒ´c = 4000 psi (276 MPa)

lb (kN)

ƒ´c = 6000 psi(414 MPa)

lb (kN)

38

2-38 1870 1905 1960 2040 2380 2425 2495 2595(60) (83) (85) (87) (91) (106) (108) (111) (115)

3-38 2655 2705 2785 2900 6765 6890 7090 7380(86) (118) (120) (124) (129) (301) (306) (315) (328)

4-12 3545 3610 3715 3865 9020 9185 9450 9845(114) (158) (161) (165) (172) (401) (409) (420) (438)7-12 5905 6015 6190 6445 15030 15305 15755 16405(191) (263) (268) (275) (287) (669) (681) (701) (730)

12

2-34 3370 3430 3530 3680 7255 7390 7605 7920(70) (150) (153) (157) (164) (323) (329) (338) (352)

4-12 5515 5615 5780 6020 11875 12095 12445 12960(114) (245) (250) (257) (268) (528) (538) (554) (576)

6 7350 7485 7705 8025 15835 16125 16595 17280(152) (327) (333) (343) (357) (704) (717) (738) (769)10 12250 12480 12840 13375 26390 26875 27660 28805

(254) (545) (555) (571) (595) (1174) (1195) (1230) (1281)

58

3-18 4000 4075 4190 4365 9280 10165 10670 11110(79) (178) (181) (186) (194) (413) (452) (475) (494)

5-58 7200 7330 7545 7855 18325 18660 19205 20000(143) (320) (326) (336) (349) (815) (830) (854) (890)7-12 9600 9775 10060 10475 24430 24880 25605 26665(191) (427) (435) (447) (466) (1087) (1107) (1139) (1186)

12-12 15995 16290 16765 17460 40720 41465 42675 44445(318) (711) (725) (746) (777) (1811) (1844) (1898) (1977)

34

3-12 5105 5595 6040 6290 11000 12050 13010 13545(89) (227) (249) (269) (280) (489) (536) (579) (603)

6-34 11115 11320 11650 12130 23935 24375 25090 26125(171) (494) (504) (518) (540) (1065) (1084) (1116) (1162)

9 14820 15090 15530 16175 31915 32500 33450 34835(229) (659) (671) (691) (719) (1420) (1446) (1488) (1550)15 24695 25150 25885 26955 53190 54170 55750 58060

(381) (1098) (1119) (1151) (1199) (2366) (2410) (2480) (2583)

78

3-12 5105 5595 6460 7235 11000 12050 13915 15585(89) (227) (249) (287) (322) (489) (536) (619) (693)

7-78 14915 15190 15635 16280 32125 32715 33670 35065(200) (663) (676) (695) (724) (1429) (1455) (1498) (1560)

10-12 19885 20255 20845 21705 42835 43620 44895 46750(267) (885) (901) (927) (965) (1905) (1940) (1997) (2080)

17-12 33145 33755 34740 36175 71390 72700 74825 77920(445) (1474) (1501) (1545) (1609) (3176) (3234) (3328) (3466)

1

4 6240 6835 7895 9360 13440 14725 17000 20165(102) (278) (304) (351) (416) (598) (655) (756) (897)

9 19295 19650 20225 21065 41565 42330 43565 45365(229) (858) (874) (900) (937) (1849) (1883) (1938) (2018)12 25730 26205 26970 28085 55420 56435 58085 60490

(305) (1145) (1166) (1200) (1249) (2465) (2510) (2584) (2691)20 42885 43670 44945 46805 92365 94060 96810 100815

(508) (1908) (1943) (1999) (2082) (4109) (4184) (4306) (4484)

1-14

5 8720 9555 11030 13510 18785 20575 23760 29100(127) (388) (425) (491) (601) (836) (915) (1057) (1294)

11-14 29290 29830 30700 31970 63085 64250 66125 68860(286) (1303) (1327) (1366) (1422) (2806) (2858) (2941) (3063)15 39055 39770 40935 42625 84115 85665 88165 91810

(381) (1737) (1769) (1821) (1896) (3742) (3811) (3922) (4084)25 65090 66285 68220 71045 140195 142775 146940 153020

(635) (2895) (2948) (3035) (3160) (6236) (6351) (6536) (6807)1 See section 318 of PTG Vol 2 (Ed 17) for explanation on development of load values2 See Section 3186 of PTG Vol 2 (Ed 17) to convert design strength value to ASD value3 Linear interpolation between embedment depths and concrete compressive strengths is not permitted4 Apply spacing edge distance and concrete thickness factors in tables 7 - 18 as necessary to the above values Compare to the steel values in table 6

The lesser of the values is to be used for the design5 Data is for temperature range A Max short term temperature = 130degF (54degC) max long term temperature = 110degF (43degC)

Short term elevated concrete temperatures are those that occur over brief intervals eg as a result of diurnal cycling Long term concrete temperatures are roughly constantoversignificantperiodsoftime

6 Tabular values are for dry concrete conditions For water saturated concrete multiply design strength value by 0857 Tabular values are for short term loads only For sustained loads including overhead use see Section 3188 of PTG Vol 2 (Ed 17)8 TabularvaluesarefornormalweightconcreteonlyForlightweightconcretemultiplydesignstrengthbyλa as follows

Forsand-lightweightλa=051Forall-lightweightλa = 045

5

HIT-ICE Technical Supplement

032

018

Table 5 - Hilti HIT-ICE adhesive design strength with concrete bond failure for threaded rod in cracked concrete12345678

Nominal anchor

diameter in

Effective embedment

in (mm)

TensionmdashФNn ShearmdashФVn

ƒ´c = 2500 psi (172 MPa)

lb (kN)

ƒ´c = 3000 psi (207 MPa)

lb (kN)

ƒ´c = 4000 psi (276 MPa)

lb (kN)

ƒ´c = 6000 psi(414 MPa)

lb (kN)

ƒ´c = 2500 psi (172 MPa)

lb (kN)

ƒ´c = 3000 psi (207 MPa)

lb (kN)

ƒ´c = 4000 psi (276 MPa)

lb (kN)

ƒ´c = 6000 psi(414 MPa)

lb (kN)

38

2-38 1100 1120 1155 1200 1400 1425 1470 1530(60) (49) (50) (51) (53) (62) (63) (65) (68)

3-38 1565 1590 1640 1705 3980 4055 4170 4345(86) (70) (71) (73) (76) (177) (180) (185) (193)

4-12 2085 2125 2185 2275 5305 5405 5560 5790(114) (93) (95) (97) (101) (236) (240) (247) (258)7-12 3475 3540 3640 3795 8845 9005 9270 9655(191) (155) (157) (162) (169) (393) (401) (412) (429)

12

2-34 1725 1760 1810 1885 3720 3790 3900 4060(70) (77) (78) (81) (84) (165) (169) (173) (181)

4-12 2825 2880 2960 3085 6085 6200 6380 6645(114) (126) (128) (132) (137) (271) (276) (284) (296)

6 3770 3835 3950 4110 8115 8265 8505 8855(152) (168) (171) (176) (183) (361) (368) (378) (394)10 6280 6395 6580 6855 13525 13775 14175 14760

(254) (279) (284) (293) (305) (602) (613) (631) (657)

58

3-18 1755 1785 1840 1915 4465 4550 4680 4875(79) (78) (79) (82) (85) (199) (202) (208) (217)

5-58 3160 3215 3310 3450 8040 8190 8425 8775(143) (141) (143) (147) (153) (358) (364) (375) (390)7-12 4210 4290 4415 4595 10720 10920 11235 11700(191) (187) (191) (196) (204) (477) (486) (500) (520)

12-12 7020 7150 7355 7660 17870 18195 18730 19505(318) (312) (318) (327) (341) (795) (809) (833) (868)

34

3-12 2250 2295 2360 2455 4850 4940 5080 5295(89) (100) (102) (105) (109) (216) (220) (226) (236)

6-34 4340 4420 4550 4740 9350 9525 9800 10205(171) (193) (197) (202) (211) (416) (424) (436) (454)

9 5790 5895 6070 6320 12470 12700 13070 13610(229) (258) (262) (270) (281) (555) (565) (581) (605)15 9650 9825 10115 10530 20780 21165 21780 22685

(381) (429) (437) (450) (468) (924) (941) (969) (1009)

78

3-12 2030 2070 2130 2220 4380 4460 4590 4780(89) (90) (92) (95) (99) (195) (198) (204) (213)

7-78 4575 4655 4795 4990 9850 10030 10325 10750(200) (204) (207) (213) (222) (438) (446) (459) (478)

10-12 6095 6210 6390 6655 13135 13375 13765 14335(267) (271) (276) (284) (296) (584) (595) (612) (638)

17-12 10160 10350 10650 11090 21890 22290 22940 23890(445) (452) (460) (474) (493) (974) (992) (1020) (1063)

1 See section 318 of PTG Vol 2 (Ed 17) for explanation on development of load values2 See Section 3186 of PTG Vol 2 (Ed 17) to convert design strength value to ASD value3 Linear interpolation between embedment depths and concrete compressive strengths is not permitted4 Apply spacing edge distance and concrete thickness factors in tables 7-18 as necessary to the above values Compare to the steel values in table 6

The lesser of the values is to be used for the design5 Data is for temperature range A Max short term temperature = 130degF (54degC) max long term temperature = 110degF (43degC)

Short term elevated concrete temperatures are those that occur over brief intervals eg as a result of diurnal cycling Long term concrete temperatures are roughly constantoversignificantperiodsoftime

6 Tabular values are for dry concrete conditions For water saturated concrete multiply design strength value by 0857 Tabular values are for short term loads only For sustained loads including overhead use see Section 3188 of PTG Vol 2 (Ed 17)8 TabularvaluesarefornormalweightconcreteonlyForlightweightconcretemultiplydesignstrengthbyλa as follows

Forsand-lightweightλa=051Forall-lightweightλa = 0459 Tabular values are for static loads only Seismic applications are not permitted

6

032

018

Table 6 - Steel design strength for Hilti HIT-V and HAS threaded rods1

Nominalanchor

diameterin

HIT-VASTM A307 Grade A4

HAS-EISO 898 Class 584

HAS-E B7ASTM A193 B75

HAS-V HAS-V HDGASTM F1554 Gr 364

HAS-E HAS-E HDGASTM F1554 Gr 554

HAS-B and HAS-B HDG4 ASTM A193 B7 and

ASTM F 1554 Gr 105

HAS-R Stainless Steel4 ASTM F593

(38-in to 1-in) ASTM A193

(1-18-in to 1-14-in)

HAS-R stainless steelASTM F 593 - AISI

304316 SS4

Tensile2

ϕNsalb (kN)

Shear3

ϕVsalb (kN)

Tensile2

ϕNsalb (kN)

Shear3

ϕVsalb (kN)

Tensile2

ϕNsalb (kN)

Shear3

ϕVsalb (kN)

Tensile2

ϕNsalb (kN)

Shear3

ϕVsalb (kN)

Tensile2

ϕNsalb (kN)

Shear3

ϕVsalb (kN)

Tensile2

ϕNsalb (kN)

Shear3

ϕVsalb (kN)

Tensile2

ϕNsalb (kN)

Shear3

ϕVsalb (kN)

Tensile2

ϕNsalb (kN)

Shear3

ϕVsalb (kN)

383025 1395 3655 1685 7265 3150 3370 1750 4360 2270 7270 3780 5040 2790 5040 2325(135) (62) (163) (75) (323) (140) (150) (78) (194) (101) (323) (168) (224) (124) (224) (103)

125535 3065 6690 3705 13300 6915 6175 3210 7985 4150 13305 6920 9225 5110 9225 5110(246) (136) (298) (165) (592) (308) (275) (143) (355) (185) (592) (308) (410) (227) (410) (227)

588815 4880 10650 5900 21190 11020 9835 5110 12715 6610 21190 11020 14690 8135 14690 8135(392) (217) (474) (262) (943) (490) (437) (227) (566) (294) (943) (490) (653) (362) (653) (362)

3413045 7225 15765 8730 31360 16305 14550 7565 18820 9785 31360 16310 18485 10235 18480 10235(580) (321) (701) (388) (1395) (725) (647) (337) (837) (435) (1395) (726) (822) (455) (822) (455)

78 - -21755 12050 43285 22505 20085 10445 25975 13505 43285 22510 25510 14125 25510 14125(968) (536) (1925) (1001) (893) (465) (1155) (601) (1925) (1001) (1135) (628) (1135) (628)

123620 13085 28540 15805 56785 29525 26350 13700 34075 17720 56785 29530 33465 18535 33465 18535(1051) (582) (1270) (703) (2526) (1313) (1172) (609) (1516) (788) (2526) (1314) (1489) (824) (1489) (824)

1-14 - -45670 25295 90850 47240 42160 21920 54515 28345 90855 47245 41430 21545 53540 29655(2031) (1125) (4041) (2101) (1875) (975) (2425) (1261) (4041) (2102) (1843) (958) (2382) (1319)

1 See Section 3186 of PTG Vol 2 (Ed 17) to convert design strength value to ASD value2 Tensile=ФAseN futa as noted in ACI 318 Chapter 173 Shear=Ф060AseV futaasnotedinACI318Chapter17For38-indiameterthreadedrodshear=Ф050AseV futa4 HIT-V HAS and HAS-R threaded rods are considered brittle steel elements HIT-V does not comply with elongation requirements of ASTM A307 Grade A steel

HAS-E does not comply with elongation requirements of ISO 898-15 HAS-E B7 rods are considered ductile steel elements

7

HIT-ICE Technical Supplement

032

018

Table 7 - Load adjustment factors for 38-in diameter threaded rods in uncracked concrete123

38-inuncracked concrete

Spacing factorin tension

ƒAN

Edge distance factor in tension

ƒRN

Spacing factorin shear4

ƒAV

Edge distance in shear

Concrete thickness factor in shear5

ƒHV

Toward edge

ƒRV

To edge

ƒRV

Embedment hef

in 2-38 3-38 4-12 7-12 2-38 3-38 4-12 7-12 2-38 3-38 4-12 7-12 2-38 3-38 4-12 7-12 2-38 3-38 4-12 7-12 2-38 3-38 4-12 7-12(mm) (60) (86) (114) (191) (60) (86) (114) (191) (60) (86) (114) (191) (60) (86) (114) (191) (60) (86) (114) (191) (60) (86) (114) (191)

Spac

ing

(s)

Edg

e di

stan

ce (c

a) C

oncr

ete

thic

knes

s (h

) - i

n (m

m)

1-34 (44) na na na na 044 032 023 013 na na na na 030 011 008 005 044 022 016 010 na na na na1-78 (48) 061 059 057 054 046 033 024 014 058 054 053 052 033 012 009 005 046 024 018 010 na na na na

2 (51) 062 060 057 054 048 034 025 014 059 054 054 053 036 013 010 006 048 027 020 012 na na na na3 (76) 069 065 061 057 061 043 031 018 063 057 055 054 066 025 018 011 061 043 031 018 na na na na

3-58 (92) 072 068 063 058 071 050 036 021 065 058 056 055 088 033 024 015 071 049 036 021 078 na na na4 (102) 074 070 065 059 079 053 038 022 067 059 057 055 100 038 028 017 079 053 038 023 082 na na na

4-58 (117) 078 073 0671 060 091 061 044 026 070 060 058 056 047 035 021 091 061 044 026 089 063 na na5 (127) 080 075 069 061 098 066 048 028 071 061 060 056 053 040 024 098 066 048 028 092 066 na na

5-34 (146) 085 078 071 068 100 075 055 032 074 063 060 057 065 049 030 100 075 055 032 099 071 064 na6 (152) 086 080 072 063 079 057 0332 075 063 061 058 069 052 031 079 057 033 100 072 066 na7 (178) 093 085 076 066 092 067 039 080 065 063 059 087 065 040 092 067 039 078 071 na8 (203) 099 090 080 068 100 076 044 084 067 064 060 100 080 048 100 076 044 083 076 na

8-34 (222) 100 093 082 069 084 048 087 069 066 061 091 055 084 048 087 080 0679 (229) 094 083 070 086 050 088 070 066 062 095 057 086 050 088 080 068

10 (254) 099 087 072 096 055 092 072 068 063 100 067 096 055 093 085 07111 (279) 100 091 074 100 061 097 074 070 064 077 100 061 098 089 07512 (305) 094 077 066 100 076 072 065 088 066 100 093 07814 (356) 100 081 078 080 075 068 100 078 100 08516 (406) 086 088 085 079 070 089 09118 (457) 090 100 089 082 073 010 09624 (610) 100 100 093 081 100 10030 (762) 100 08836 (914) 096

gt48 (1219) 100

Table 8 - Load adjustment factors for 38-in diameter threaded rods in cracked concrete123

38-incracked concrete

Spacing factorin tension

ƒAN

Edge distance factor in tension

ƒRN

Spacing factorin shear4

ƒAV

Edge distance in shear

Concrete thickness factor in shear5

ƒHV

Toward edge

ƒRV

To edge

ƒRV

Embedment hef

in 2-38 3-38 4-12 7-12 2-38 3-38 4-12 7-12 2-38 3-38 4-12 7-12 2-38 3-38 4-12 7-12 2-38 3-38 4-12 7-12 2-38 3-38 4-12 7-12(mm) (60) (86) (114) (191) (60) (86) (114) (191) (60) (86) (114) (191) (60) (86) (114) (191) (60) (86) (114) (191) (60) (86) (114) (191)

Spac

ing

(s)

Edg

e di

stan

ce (c

a) C

oncr

ete

thic

knes

s (h

) - i

n (m

m)

1-34 (44) na na na na 059 054 049 043 na na na na 036 013 010 006 059 027 020 012 na na na na1-78 (48) 061 059 057 054 061 056 050 044 059 055 054 053 040 015 011 007 061 030 022 013 na na na na

2 (51) 062 060 057 054 063 057 051 044 060 055 054 053 044 016 012 007 063 032 024 015 na na na na3 (76) 068 065 061 057 079 070 060 049 064 057 056 054 081 030 022 013 079 059 045 027 na na na na

3-58 (92) 072 068 063 058 091 079 066 053 067 059 057 055 100 040 030 018 091 079 059 036 084 na na na4 (102) 074 070 065 059 098 084 070 055 069 060 058 056 046 034 021 098 084 069 041 088 na na na

4-58 (117) 078 073 067 060 100 093 076 058 072 061 059 057 057 043 026 100 093 076 051 094 068 na na5 (127) 0804 075 069 061 099 080 060 074 062 061 057 064 048 029 099 080 058 098 070 na na

5-34 (146) 085 078 071 063 100 089 065 078 064 062 058 079 059 036 100 089 065 100 075 069 na6 (152) 086 080 072 063 091 066 079 065 062 059 084 063 038 091 066 077 070 na7 (178) 093 085 076 066 100 072 084 067 064 060 100 079 048 100 072 083 076 na8 (203) 099 090 080 068 078 089 070 066 062 097 058 078 089 081 na

8-34 (222) 100 093 082 069 083 092 072 068 063 100 067 083 093 085 0719 (229) 094 083 070 085 093 072 068 063 070 085 094 086 072

10 (254) 099 087 072 091 098 075 070 065 081 091 099 090 07611 (279) 100 091 074 098 100 077 073 066 092 098 100 095 08012 (305) 094 076 100 080 075 067 100 100 099 08414 (356) 100 081 085 079 070 1000 09016 (406) 086 090 083 073 09618 (457) 090 095 087 076 10024 (610) 100 100 099 08530 (762) 100 09436 (914) 100

gt48 (1219)

1 Linear interpolation not permitted2 Shaded area with reduced edge distance is permitted provided the installation torque is reduced to 030 Tmaxfor5dlesle16-inandto05Tmax for s gt 16-in3 When combining multiple load adjustment factors (eg for a four-anchor pattern in a corner with thin concrete member) the design can become very conservative

To optimize the design use Hilti PROFIS Anchor Design software or perform anchor calculation using design equations from ACI 318-14 Chapter 174 Spacing factor reduction in shear applicable when c lt 3hef ƒAV is applicable when edge distance c lt 3hefIfcge3hef then ƒAV = ƒAN5 Concrete thickness reduction factor in shear ƒHV is applicable when edge distance c lt 3hefIfcge3hef then ƒHV = 10

8

032

018

Table 9 - Load adjustment factors for 12-in diameter threaded rods in uncracked concrete123

12-inuncracked concrete

Spacing factorin tension

ƒAN

Edge distance factor in tension

ƒRN

Spacing factorin shear4

ƒAV

Edge distance in shear

Concrete thickness factor in shear5

ƒHV

Toward edge

ƒRV

To edge

ƒRV

Embedment hef

in 2-34 4-12 6 10 2-34 4-12 6 10 2-34 4-12 6 10 2-34 4-12 6 10 2-34 4-12 6 10 2-34 4-12 6 10(mm) (70) (114) (152) (254) (70) (114) (152) (254) (70) (114) (152) (254) (70) (114) (152) (254) (70) (114) (152) (254) (70) (114) (152) (254)

Spac

ing

(s)

Edg

e di

stan

ce (c

a) C

oncr

ete

thic

knes

s (h

) - i

n (m

m)

1-34 (44) na na na na 0404 0275 020 012 na na na na 011 007 005 003 022 014 011 006 na na na na2-12 (64) 062 059 057 054 049 032 024 014 055 054 053 052 019 012 009 006 037 025 018 011 na na na na

3 (76) 064 061 058 055 054 035 026 015 057 055 054 053 024 016 012 007 049 032 024 015 na na na na4 (102) 068 065 061 057 067 042 031 018 059 057 055 054 038 025 019 011 067 042 031 018 059 na na na5 (127) 073 069 064 058 083 049 036 021 061 058 057 055 053 035 026 016 083 049 036 021 066 na na na

5-34 (146) 076 071 066 060 096 055 041 024 063 059 058 056 065 043 032 019 096 055 041 024 071 062 na na6 (152) 078 072 067 060 100 058 042 025 063 060 058 056 069 046 034 021 100 058 042 025 072 063 na na7 (178) 082 076 069 062 067 049 029 065 062 060 057 087 057 043 026 067 049 029 078 068 na na

7-14 (184) 083 077 070 062 070 05 030 066 062 060 057 092 060 045 027 069 051 030 079 069 063 na8 (203) 087 080 072 063 077 056 033 067 063 061 058 100 070 053 032 077 056 033 083 073 066 na9 (229) 091 083 075 065 086 063 037 070 065 062 059 084 063 038 086 063 037 088 077 070 na

10 (254) 096 087 078 067 096 070 041 072 066 064 060 098 073 044 096 070 041 093 081 074 na11-14 (286) 100 092 081 069 100 079 046 074 069 065 061 100 088 053 100 079 046 099 086 078 066

12 (305) 094 083 070 085 049 076 070 066 062 097 058 085 049 100 089 081 06914 (356) 100 089 073 099 058 080 073 069 064 100 073 099 058 096 087 07416 (406) 094 077 100 066 085 076 072 065 089 100 066 100 093 07918 (457) 100 080 074 089 080 074 067 100 074 099 08320 (508) 083 082 093 083 077 069 082 100 08822 (559) 087 091 098 086 080 071 091 09224 (610) 090 099 100 089 083 073 099 09630 (762) 100 100 099 091 079 100 10036 (914) 100 099 085

gt48 (1219) 100 096

Table 10 - Load adjustment factors for 12-in diameter threaded rods in cracked concrete123

12-incracked concrete

Spacing factorin tension

ƒAN

Edge distance factor in tension

ƒRN

Spacing factorin shear4

ƒAV

Edge distance in shear

Concrete thickness factor in shear5

ƒHV

Toward edge

ƒRV

To edge

ƒRV

Embedment hef

in 2-34 4-12 6 10 2-34 4-12 6 10 2-34 4-12 6 10 2-34 4-12 6 10 2-34 4-12 6 10 2-34 4-12 6 10(mm) (70) (114) (152) (254) (70) (114) (152) (254) (70) (114) (152) (254) (70) (114) (152) (254) (70) (114) (152) (254) (70) (114) (152) (254)

Spac

ing

(s)

Edg

e di

stan

ce (c

a) C

oncr

ete

thic

knes

s (h

) - i

n (m

m)

1-34 (44) na na na na 0526 049 045 041 na na na na 015 010 008 005 030 020 015 009 na na na na2-12 (64) 062 059 057 054 061 056 050 044 057 055 054 053 026 017 013 008 052 034 026 015 na na na na

3 (76) 064 061 058 055 067 060 053 046 058 056 055 054 034 022 017 010 067 045 034 020 na na na na4 (102) 068 065 061 057 080 070 060 049 061 058 057 0549 052 035 026 016 080 069 052 031 066 na na na5 (127) 073 069 064 058 093 080 067 053 064 060 059 056 073 048 036 022 093 080 067 043 0736 na na na

5-34 (146) 076 071 066 060 100 089 073 056 066 062 060 057 090 060 045 027 100 089 073 054 079 069 na na6 (152) 078 072 067 060 091 075 057 066 062 060 057 096 063 048 029 091 075 057 081 070 na na7 (178) 082 076 069 062 100 083 062 069 064 062 058 100 080 060 036 100 083 062 087 076 na na

7-14 (184) 083 077 070 062 085 063 070 065 062 059 084 063 038 085 063 089 077 070 na8 (203) 087 080 072 063 091 066 072 066 064 060 098 073 044 091 066 093 081 074 na9 (229) 091 083 075 065 100 070 074 069 065 061 100 087 052 100 070 099 086 078 na

10 (254) 096 087 078 067 075 077 071 067 062 100 061 075 100 091 082 na11-14 (286) 100 092 081 069 081 081 073 069 064 073 081 096 087 074

12 (305) 094 083 070 085 083 075 070 064 081 085 099 090 07614 (356) 100 089 073 095 088 079 074 067 100 095 100 097 08216 (406) 094 077 100 093 083 077 069 100 100 08818 (457) 100 080 099 087 081 072 09320 (508) 083 100 091 084 074 09822 (559) 087 095 087 077 10024 (610) 090 099 091 07930 (762) 100 100 100 08636 (914) 093

gt48 (1219) 100

1 Linear interpolation not permitted2 Shaded area with reduced edge distance is permitted provided the installation torque is reduced to 030 Tmaxfor5dlesle16-inandto05Tmax for s gt 16-in3 When combining multiple load adjustment factors (eg for a four-anchor pattern in a corner with thin concrete member) the design can become very conservative

To optimize the design use Hilti PROFIS Anchor Design software or perform anchor calculation using design equations from ACI 318-14 Chapter 174 Spacing factor reduction in shear applicable when c lt 3hef ƒAV is applicable when edge distance c lt 3hefIfcge3hef then ƒAV = ƒAN5 Concrete thickness reduction factor in shear ƒHV is applicable when edge distance c lt 3hefIfcge3hef then ƒHV = 10

9

HIT-ICE Technical Supplement

032

018

Table 11 - Load adjustment factors for 58-in diameter threaded rods in uncracked concrete123

58-inuncracked concrete

Spacing factorin tension

ƒAN

Edge distance factor in tension

ƒRN

Spacing factorin shear4

ƒAV

Edge distance in shear

Concrete thickness factor in shear5

ƒHV

Toward edge

ƒRV

To edge

ƒRV

Embedment hef

in 3-18 5-58 7-12 12-12 3-18 5-58 7-12 12-12 3-18 5-58 7-12 12-12 3-18 5-58 7-12 12-12 3-18 5-58 7-12 12-12 3-18 5-58 7-12 12-12(mm) (79) (143) (191) (318) (79) (143) (191) (318) (79) (143) (191) (318) (79) (143) (191) (318) (79) (143) (191) (318) (79) (143) (191) (318)

Spac

ing

(s)

Edg

e di

stan

ce (c

a) C

oncr

ete

thic

knes

s (h

) - i

n (m

m)

1-34 (44) na na na na 039 026 019 011 na na na na 009 005 004 002 0187 010 008 005 na na na na3-18 (79) 062 060 057 054 052 032 023 014 056 054 053 052 022 012 009 006 045 025 019 011 na na na na

4 (102) 065 062 059 055 062 036 027 016 058 055 054 053 032 018 014 008 062 036 027 016 na na na na4-58 (117) 067 064 060 056 069 040 029 017 059 056 055 054 040 022 017 010 069 040 029 017 060 na na na

5 (127) 068 0648 061 057 074 042 031 018 060 057 056 054 045 025 019 011 074 042 031 018 063 na na na6 (152) 072 068 063 058 0891 047 035 020 062 058 057 055 059 033 025 015 089 047 035 020 069 na na na7 (178) 076 071 066 059 100 054 040 023 064 059 058 055 075 042 031 019 100 054 040 023 074 na na na

7-18 (181) 076 071 066 060 055 040 024 064 059 058 056 077 043 032 019 055 040 024 075 062 na na8 (203) 080 074 068 061 062 045 027 066 061 059 056 091 051 038 023 062 045 027 079 065 na na9 (229) 083 077 070 062 069 051 030 068 062 060 057 100 061 045 027 069 051 030 084 069 063 na

10 (254) 087 080 072 063 077 057 033 070 063 061 058 071 053 032 077 057 033 089 073 06 na11 (279) 091 083 074 065 085 062 036 072 065 062 059 082 061 037 085 062 036 093 076 0694 na12 (305) 094 086 077 066 092 068 040 074 066 063 059 093 070 042 092 068 040 097 080 073 na14 (356) 100 092 081 069 100 079 046 077 069 065 061 100 088 053 100 079 046 100 086 078 06616 (406) 097 086 071 090 053 081 071 068 063 100 065 090 053 092 084 07118 (457) 100 090 074 100 060 085 074 070 064 077 100 060 098 089 07520 (508) 094 077 066 089 077 072 066 090 066 100 094 07922 (559) 099 079 073 093 080 074 067 100 073 098 08324 (610) 100 082 079 097 082 076 069 079 100 08626 (660) 085 086 100 085 079 070 086 09028 (711) 087 093 087 081 072 093 09330 (762) 090 099 090 083 073 099 09736 (914) 098 100 098 089 078 100 100

gt 48 (1219) 100 100 100 087

Table 12 - Load adjustment factors for 58-in diameter threaded rods in cracked concrete123

58-incracked concrete

Spacing factorin tension

ƒAN

Edge distance factor in tension

ƒRN

Spacing factorin shear4

ƒAV

Edge distance in shear

Concrete thickness factor in shear5

ƒHV

Toward edge

ƒRV

To edge

ƒRV

Embedment hef

in 3-18 5-58 7-12 12-12 3-18 5-58 7-12 12-12 3-18 5-58 7-12 12-12 3-18 5-58 7-12 12-12 3-18 5-58 7-12 12-12 3-18 5-58 7-12 12-12(mm) (79) (143) (191) (318) (79) (143) (191) (318) (79) (143) (191) (318) (79) (143) (191) (318) (79) (143) (191) (318) (79) (143) (191) (318)

Spac

ing

(s)

Edg

e di

stan

ce (c

a) C

oncr

ete

thic

knes

s (h

) - i

n (m

m)

1-34 (44) na na na na 049 046 043 040 na na na na 014 009 006 004 028 017 013 008 na na na na3-18 (79) 062 059 057 054 061 056 050 044 058 056 055 053 033 020 015 009 061 040 030 018 na na na na

4 (102) 065 062 059 055 070 062 055 046 0602 057 056 054 048 029 022 013 070 058 044 026 na na na na4-58 (117) 067 064 060 056 076 067 058 048 062 059 057 055 060 036 027 016 076 067 055 033 069 na na na

5 (127) 068 065 061 057 080 070 060 049 063 059 058 055 067 041 031 018 080 070 060 037 071 na na na6 (152) 072 068 063 058 091 078 066 053 065 061 059 057 088 054 040 024 091 078 066 048 078 na na na7 (178) 076 071 066 059 100 087 072 056 068 063 061 058 100 068 051 030 100 087 072 056 085 na na na

7-18 (181) 076 071 066 060 088 073 056 068 063 061 058 069 052 031 088 073 056 085 072 na na8 (203) 080 074 068 061 096 078 060 070 065 062 059 083 062 037 096 078 059 090 077 na na9 (229) 083 077 070 062 100 085 063 073 067 064 060 099 074 044 100 085 063 096 081 074 na

10 (254) 087 080 072 063 091 066 076 068 065 061 100 087 052 091 066 100 086 078 na11 (279) 091 083 074 065 098 070 078 070 067 062 100 060 098 070 090 082 na12 (305) 094 086 077 066 100 073 081 072 068 063 068 100 073 094 085 na14 (356) 100 092 081 069 081 086 076 071 065 086 081 100 092 07816 (406) 097 086 071 089 091 079 074 067 100 089 098 08318 (457) 100 090 074 097 096 083 077 069 097 100 08820 (508) 094 077 100 100 087 080 072 100 09322 (559) 099 079 090 083 074 09724 (610) 100 082 094 086 076 10026 (660) 085 098 089 07828 (711) 087 100 092 08030 (762) 090 095 08236 (914) 098 100 089

gt 48 (1219) 100 100

1 Linear interpolation not permitted2 Shaded area with reduced edge distance is permitted provided the installation torque is reduced to 030 Tmaxfor5dlesle16-inandto05Tmax for s gt 16-in3 When combining multiple load adjustment factors (eg for a four-anchor pattern in a corner with thin concrete member) the design can become very conservative

To optimize the design use Hilti PROFIS Anchor Design software or perform anchor calculation using design equations from ACI 318-14 Chapter 174 Spacing factor reduction in shear applicable when c lt 3hef ƒAV is applicable when edge distance c lt 3hefIfcge3hef then ƒAV = ƒAN5 Concrete thickness reduction factor in shear ƒHV is applicable when edge distance c lt 3hefIfcge3hef then ƒHV = 10

10

032

018

Table 13 - Load adjustment factors for 34-in diameter threaded rods in uncracked concrete123

34-inuncracked concrete

Spacing factorin tension

ƒAN

Edge distance factor in tension

ƒRN

Spacing factorin shear4

ƒAV

Edge distance in shear

Concrete thickness factor in shear5

ƒHV

Toward edge

ƒRV

To edge

ƒRV

Embedment hef

in 3-12 6-34 9 15 3-12 6-34 9 15 3-12 6-34 9 15 3-12 6-34 9 15 3-12 6-34 9 15 3-12 6-34 9 15(mm) (89) (171) (229) (381) (89) (171) (229) (381) (89) (171) (229) (381) (89) (171) (229) (381) (89) (171) (229) (381) (89) (171) (229) (381)

Spac

ing

(s)

Edg

e di

stan

ce (c

a) C

oncr

ete

thic

knes

s (h

) - i

n (m

m)

1-34 (44) na na na na 039 024 018 010 na na na na 009 004 003 002 017 009 006 004 na na na na3-34 (95) 062 059 057 054 057 032 024 014 057 054 054 053 027 013 010 006 053 027 020 012 na na na na

4 (102) 063 060 057 054 060 033 025 014 057 055 054 053 029 015 011 007 059 030 022 013 na na na na5 (127) 066 062 059 056 070 038 028 016 059 056 055 053 041 021 015 009 070 038 028 016 na na na na

5-14 (133) 067 063 060 056 073 039 029 017 060 056 055 054 044 022 017 010 073 039 029 017 062 na na na6 (152) 069 065 061 057 083 043 031 018 061 057 056 054 054 027 020 012 083 041 031 018 067 na na na7 (178) 073 067 063 058 092 048 035 021 063 058 057 055 068 034 026 015 092 048 035 021 072 na na na8 (203) 076 070 065 059 100 053 039 023 065 059 058 056 083 042 031 019 100 053 039 023 077 na na na

8-12 (216) 077 071 066 059 057 042 024 066 060 058 056 091 046 034 021 057 042 024 079 063 na na9 (229) 079 072 067 060 060 044 026 067 061 059 056 099 050 037 022 060 044 026 081 065 na na

10 (254) 082 075 069 061 067 049 027 068 062 060 057 100 058 044 026 067 049 029 086 068 na na10-34 (273) 085 077 070 062 072 053 031 070 063 060 057 065 049 029 072 053 031 089 071 064 na

12 (305) 089 080 072 063 080 059 034 072 064 062 058 077 057 035 080 059 034 094 075 068 na14 (356) 095 085 076 066 093 069 040 076 066 063 060 097 072 043 0931 068 040 100 081 073 na16 (406) 100 090 080 068 100 079 046 080 069 065 061 100 089 053 100 078 046 086 078 na

16-34 (425) 091 081 069 082 048 081 070 066 061 095 057 082 048 088 080 06818 (457) 094 083 070 088 052 083 071 067 062 100 063 088 052 092 083 07020 (508) 099 087 072 098 057 087 073 069 064 074 098 057 096 088 07422 (559) 100 091 074 100 063 091 076 071 065 086 100 063 100 092 07824 (610) 094 077 069 094 078 073 066 098 069 096 08126 (660) 098 079 074 098 080 075 068 100 074 100 08428 (711) 100 081 080 100 083 077 069 080 08730 (762) 083 086 085 079 071 086 09136 (914) 090 100 092 085 075 100 099

gt 48 (1219) 100 100 096 083 100

Table 14 - Load adjustment factors for 34-in diameter threaded rods in cracked concrete123

34-incracked concrete

Spacing factorin tension

ƒAN

Edge distance factor in tension

ƒRN

Spacing factorin shear4

ƒAV

Edge distance in shear

Concrete thickness factor in shear5

ƒHV

Toward edge

ƒRV

To edge

ƒRV

Embedment hef

in 3-12 6-34 9 15 3-12 6-34 9 15 3-12 6-34 9 15 3-12 6-34 9 15 3-12 6-34 9 15 3-12 6-34 9 15(mm) (89) (171) (229) (381) (89) (171) (229) (381) (89) (171) (229) (381) (89) (171) (229) (381) (89) (171) (229) (381) (89) (171) (229) (381)

Spac

ing

(s)

Edg

e di

stan

ce (c

a) C

oncr

ete

thic

knes

s (h

) - i

n (m

m)

1-34 (44) na na na na 047 044 042 039 na na na na 014 008 006 004 028 016 012 007 na na na na3-34 (95) 062 059 057 054 063 056 050 044 060 057 055 054 043 025 018 011 063 049 037 022 na na na na

4 (102) 063 060 057 054 065 057 051 044 060 057 056 054 048 027 020 012 065 056 040 024 na na na na5 (127) 066 062 059 056 074 063 056 047 063 059 057 055 067 038 028 017 074 063 056 034 na na na na

5-14 (133) 067 063 060 056 076 065 057 048 063 059 058 055 072 041 030 018 076 065 057 037 073 na na na6 (152) 070 065 061 057 083 070 060 049 065 060 059 056 088 050 037 022 083 070 061 045 078 na na na7 (178) 073 067 063 058 092 077 065 052 068 062 060 057 100 062 047 028 092 077 065 052 084 na na na8 (203) 076 070 065 059 100 084 070 055 070 064 062 058 076 057 034 100 084 070 055 090 na na na

8-12 (216) 078 071 066 059 088 072 056 072 065 062 059 084 063 038 088 072 056 093 077 na na9 (229) 080 072 067 060 091 075 057 073 066 063 059 091 068 041 091 075 057 096 079 na na

10 (254) 082 075 069 061 099 080 060 075 067 064 060 100 080 048 099 080 060 100 083 na na10-34 (273) 085 077 070 062 100 084 062 077 069 065 061 090 053 100 084 062 087 079 na

12 (305) 089 080 072 063 091 066 081 071 067 062 100 063 091 066 091 083 na14 (356) 095 085 076 066 100 072 086 074 070 064 079 100 072 099 090 na16 (406) 100 090 080 068 078 091 078 073 066 097 078 100 096 na

16-34 (425) 091 081 069 081 093 079 074 067 100 081 098 08318 (457) 094 083 070 085 096 081 076 068 085 100 08620 (508) 099 087 072 091 100 085 079 070 091 09022 (559) 100 091 074 098 088 082 073 098 09524 (610) 094 077 100 092 084 075 100 09926 (660) 098 079 095 087 077 10028 (711) 100 081 099 090 07930 (762) 083 100 093 08136 (914) 090 100 087

gt 48 (1219) 100 099

1 Linear interpolation not permitted2 Shaded area with reduced edge distance is permitted provided the installation torque is reduced to 030 Tmaxfor5dlesle16-inandto05Tmax for s gt 16-in3 When combining multiple load adjustment factors (eg for a four-anchor pattern in a corner with thin concrete member) the design can become very conservative

To optimize the design use Hilti PROFIS Anchor Design software or perform anchor calculation using design equations from ACI 318-14 Chapter 174 Spacing factor reduction in shear applicable when c lt 3hef ƒAV is applicable when edge distance c lt 3hefIfcge3hef then ƒAV = ƒAN5 Concrete thickness reduction factor in shear ƒHV is applicable when edge distance c lt 3hefIfcge3hef then ƒHV = 10

11

HIT-ICE Technical Supplement

032

018

Table 15 - Load adjustment factors for 78-in diameter threaded rods in uncracked concrete123

78-inuncracked concrete

Spacing factorin tension

ƒAN

Edge distance factor in tension

ƒRN

Spacing factorin shear4

ƒAV

Edge distance in shear

Concrete thickness factor in shear5

ƒHV

Toward edge

ƒRV

To edge

ƒRV

Embedment hef

in 3-12 7-78 10-12 17-12 3-12 7-78 10-12 17-12 3-12 7-78 10-12 17-12 3-12 7-78 10-12 17-12 3-12 7-78 10-12 17-12 3-12 7-78 10-12 17-12(mm) (89) (200) (267) (445) (89) (200) (267) (445) (89) (200) (267) (445) (89) (200) (267) (445) (89) (200) (267) (445) (89) (200) (267) (445)

Spac

ing

(s)

Edg

e di

stan

ce (c

a) C

oncr

ete

thic

knes

s (h

) - i

n (m

m)

1-34 (44) na na na na 040 023 017 010 na na na na 009 003 002 001 018 006 005 003 na na na na4-38 (111) 062 059 057 054 063 033 024 014 058 054 054 053 035 013 009 006 063 025 019 011 na na na na

5 (127) 064 061 058 055 068 035 026 015 060 055 054 053 043 015 012 007 068 031 023 014 na na na na5-12 (140) 065 062 059 055 071 037 027 016 060 055 054 053 050 018 013 008 071 035 027 016 065 na na na

6 (152) 067 063 060 056 075 039 028 017 061 056 055 054 057 020 015 009 075 039 028 017 068 na na na7 (178) 070 065 061 057 083 043 031 018 063 057 056 054 071 025 019 011 083 043 031 018 073 na na na8 (203) 072 067 063 058 092 047 035 020 065 058 056 055 087 031 023 014 092 047 035 020 078 na na na9 (229) 075 069 064 059 100 052 038 022 067 059 057 055 100 037 028 017 100 052 038 022 083 na na na

9-78 (251) 078 071 066 059 057 042 024 069 059 058 056 043 032 019 057 042 024 087 061 na na10 (254) 078 071 066 060 057 042 025 069 060 058 056 043 033 020 057 042 025 087 062 na na11 (279) 081 073 068 061 063 046 027 071 061 059 056 050 038 023 063 046 027 091 065 na na12 (305) 084 075 069 062 069 051 030 073 062 060 057 057 043 026 069 051 030 096 068 na na

12-12 (318) 085 077 070 062 072 053 031 074 062 060 057 061 046 027 072 053 031 098 069 063 na14 (356) 089 080 072 063 080 059 035 077 063 061 058 072 054 032 080 059 035 100 073 067 na16 (406) 095 084 075 065 092 067 040 080 065 063 059 088 066 040 092 067 040 078 071 na18 (457) 100 088 079 067 100 076 044 084 067 064 060 100 079 047 100 076 044 083 075 na

19-12 (495) 091 081 069 082 048 087 069 065 061 089 053 082 048 086 078 06620 (508) 092 082 069 084 049 088 069 066 061 092 055 084 049 087 079 06722 (559) 097 085 071 093 054 092 071 067 063 100 064 093 054 092 083 07024 (610) 100 088 073 100 059 096 073 069 064 073 100 059 096 087 07326 (660) 091 075 064 099 075 071 065 082 064 100 091 07628 (711) 094 077 069 100 077 072 066 092 069 094 07930 (762) 098 079 074 079 074 067 100 074 097 08236 (914) 100 084 089 084 078 070 089 100 090

gt 48 (1219) 096 100 096 088 077 100 100

Table 16 - Load adjustment factors for 78-in diameter threaded rods in cracked concrete123

78-incracked concrete

Spacing factorin tension

ƒAN

Edge distance factor in tension

ƒRN

Spacing factorin shear4

ƒAV

Edge distance in shear

Concrete thickness factor in shear5

ƒHV

Toward edge

ƒRV

To edge

ƒRV

Embedment hef

in 3-12 7-78 10-12 17-12 3-12 7-78 10-12 17-12 3-12 7-78 10-12 17-12 3-12 7-78 10-12 17-12 3-12 7-78 10-12 17-12 3-12 7-78 10-12 17-12(mm) (89) (200) (267) (445) (89) (200) (267) (445) (89) (200) (267) (445) (89) (200) (267) (445) (89) (200) (267) (445) (89) (200) (267) (445)

Spac

ing

(s)

Edg

e di

stan

ce (c

a) C

oncr

ete

thic

knes

s (h

) - i

n (m

m)

1-34 (44) na na na na 046 043 041 038 na na na na 016 007 006 003 032 015 011 007 na na na na4-38 (111) 062 059 057 054 063 056 050 044 062 057 056 054 063 029 022 013 063 056 044 026 na na na na

5 (127) 064 061 058 055 068 059 052 045 064 058 057 055 077 036 027 016 068 059 052 032 na na na na5-12 (140) 065 062 059 055 071 062 054 046 065 059 058 055 089 041 031 019 071 062 054 037 079 na na na

6 (152) 067 063 060 056 075 064 056 047 067 060 058 056 100 047 035 021 075 064 056 042 082 na na na7 (178) 070 0648 061 057 083 070 060 049 070 062 060 057 059 044 027 083 070 060 049 089 na na na8 (203) 072 067 063 058 092 076 064 052 072 063 061 058 072 054 033 092 076 064 052 095 na na na9 (229) 075 069 064 059 100 082 069 054 075 065 063 059 086 065 039 100 082 069 054 100 na na na

9-78 (251) 078 071 066 059 088 072 056 078 067 064 060 099 074 045 087 072 056 081 na na10 (254) 078 071 066 060 088 073 056 078 067 064 060 100 076 046 088 073 056 082 na na11 (279) 081 073 068 061 095 077 059 081 069 065 061 088 053 095 077 059 086 na na12 (305) 084 075 069 061 100 082 061 084 070 067 062 100 060 100 082 061 090 na na

12-12 (318) 085 077 070 062 084 062 085 071 067 062 064 084 062 092 083 na14 (356) 090 080 072 063 092 066 089 074 069 064 075 091 066 097 088 na16 (406) 095 084 075 065 100 071 095 077 072 066 092 100 071 100 094 na18 (457) 100 088 079 067 076 100 080 075 068 100 076 100 na

19-12 (495) 091 081 069 080 083 077 069 080 08820 (508) 092 082 069 082 084 078 070 082 08922 (559) 097 085 071 087 087 081 072 087 09324 (610) 100 088 073 093 090 083 074 093 09726 (660) 091 075 099 094 086 076 099 10028 (711) 094 077 100 097 089 078 10030 (762) 098 079 100 092 08036 (914) 100 085 100 086

gt 48 (1219) 096 097

1 Linear interpolation not permitted2 Shaded area with reduced edge distance is permitted provided the installation torque is reduced to 030 Tmaxfor5dlesle16-inandto05Tmax for s gt 16-in3 When combining multiple load adjustment factors (eg for a four-anchor pattern in a corner with thin concrete member) the design can become very conservative

To optimize the design use Hilti PROFIS Anchor Design software or perform anchor calculation using design equations from ACI 318-14 Chapter 174 Spacing factor reduction in shear applicable when c lt 3hef ƒAV is applicable when edge distance c lt 3hefIfcge3hef then ƒAV = ƒAN5 Concrete thickness reduction factor in shear ƒHV is applicable when edge distance c lt 3hefIfcge3hef then ƒHV = 10

12

032

018

Table 17 - Load adjustment factors for 1-in diameter threaded rods in uncracked concrete123

1-inuncracked concrete

Spacing factorin tension

ƒAN

Edge distance factor in tension

ƒRN

Spacing factorin shear4

ƒAV

Edge distance in shear

Concrete thickness factor in shear5

ƒHV

Toward edge

ƒRV

To edge

ƒRV

Embedment hef

in 4 9 12 20 4 9 12 20 4 9 12 20 4 9 12 20 4 9 12 20 4 9 12 20(mm) (102) (229) (305) (508) (102) (229) (305) (508) (102) (229) (305) (508) (102) (229) (305) (508) (102) (229) (305) (508) (102) (229) (305) (508)

Spac

ing

(s)

Edg

e di

stan

ce (c

a) C

oncr

ete

thic

knes

s (h

) - i

n (m

m)

1-34 (44) na na na na 038 023 017 010 na na na na 008 003 002 001 015 005 004 002 na na na na5 (127) 062 059 057 0542 063 032 024 014 059 054 053 052 037 012 009 005 063 024 018 012 na na na na6 (152) 065 061 058 0550 070 036 026 015 060 055 054 053 048 016 012 007 070 031 023 014 na na na na

6-14 (159) 065 062 059 0552 071 037 027 016 061 055 054 053 051 017 012 008 071 033 025 015 065 na na na7 (178) 067 063 060 0558 076 039 029 017 062 056 055 053 061 020 015 009 076 039 029 017 069 na na na8 (203) 070 065 061 0567 083 043 031 018 064 056 055 054 074 024 018 011 084 043 031 019 074 na na na9 (229) 072 067 063 0575 091 047 034 020 065 057 056 054 089 029 022 013 091 047 034 020 078 na na na

10 (254) 075 069 064 0583 098 050 037 022 067 058 057 055 100 034 025 015 098 050 037 022 083 na na na11 (279) 077 070 065 0592 100 055 041 024 069 059 057 055 039 029 017 100 055 041 024 087 na na na

11-14 (286) 078 071 066 0594 057 042 024 070 059 058 055 040 030 018 057 042 024 088 060 na na12 (305) 080 072 067 0600 060 044 026 071 060 058 056 044 033 020 060 044 026 091 062 na na13 (330) 082 074 068 0608 065 048 028 072 061 059 056 050 037 022 065 048 028 094 065 na na14 (356) 084 076 069 0617 070 052 030 074 061 059 057 056 042 025 070 052 030 098 067 na na

14-14 (362) 085 076 070 0619 072 053 031 074 062 060 057 057 043 026 072 053 031 099 068 062 na16 (406) 090 080 072 0633 080 059 035 077 063 061 058 068 051 031 080 059 035 100 072 065 na18 (457) 094 083 075 0650 090 066 039 081 065 062 059 081 061 035 090 0664 040 076 070 na20 (508) 099 087 078 0667 100 074 043 084 066 063 060 095 071 043 100 074 043 080 073 na22 (559) 100 091 081 0683 081 048 088 068 065 060 100 082 049 081 048 084 077 na

22-14 (565) 091 081 0685 082 048 088 068 065 061 084 050 082 048 085 077 06524 (610) 094 083 0700 089 052 091 069 066 061 094 056 089 052 088 080 06726 (660) 098 086 0717 096 056 094 071 067 062 100 063 096 056 092 083 07028 (711) 100 089 0733 100 061 098 073 069 063 071 100 061 095 086 07330 (762) 092 0750 065 100 074 070 064 079 065 098 089 07536 (914) 100 0800 078 079 074 067 100 078 100 098 083

gt 48 (1219) 0900 100 087 082 073 100 100 0951 Linear interpolation not permitted2 Shaded area with reduced edge distance is permitted provided the installation torque is reduced to 030 Tmaxfor5dlesle16-inandto05Tmax for s gt 16-in3 When combining multiple load adjustment factors (eg for a four-anchor pattern in a corner with thin concrete member) the design can become very conservative To

optimize the design use Hilti PROFIS Anchor Design software or perform anchor calculation using design equations from ACI 318-14 Chapter 174 Spacing factor reduction in shear applicable when c lt 3hef ƒAV is applicable when edge distance c lt 3hefIfcge3hef then ƒAV = ƒAN5 Concrete thickness reduction factor in shear ƒHV is applicable when edge distance c lt 3hefIfcge3hef then ƒHV = 10

Table 18 - Load adjustment factors for 1-14-in diameter threaded rods in uncracked concrete123

1-14-inuncracked concrete

Spacing factor in tension

ƒAN

Edge distance factor in tension

ƒRN

Spacing factor in shear4

ƒAV

Edge distance in shear

Concrete thickness factor in shear5

ƒHV

Toward edge

ƒRV

Toandaway from edge

ƒRV

Embedment hef

in 5 11-14 15 25 5 11-14 15 25 5 11-14 15 25 5 11-14 15 25 5 11-14 15 25 5 11-14 11-14 25(mm) (127) (286) (381) (635) (127) (286) (381) (635) (127) (286) (381) (635) (127) (286) (381) (635) (127) (286) (381) (635) (127) (286) (286) (635)

Spac

ing

(s)

Edg

e di

stan

ce (c

a) C

oncr

ete

thic

knes

s (h

) - i

n (m

m)

1-34 (44) na na na na 037 022 016 009 na na na na 005 002 001 001 011 003 002 002 na na na na6-14 (159) 062 059 057 0542 064 032 024 014 059 054 053 052 037 011 008 005 064 022 016 010 na na na na

7 (178) 064 060 058 0547 068 034 025 015 060 054 054 053 044 013 010 006 068 026 019 012 na na na na8 (203) 066 062 059 0553 073 037 027 016 061 055 054 053 053 016 012 007 073 032 024 015 066 na na na9 (229) 068 063 060 0560 079 040 029 017 062 056 055 053 063 019 014 009 079 038 028 017 070 na na na

10 (254) 070 065 061 0567 084 043 032 019 064 0561 055 054 074 022 017 010 084 043 032 019 074 na na na11 (279) 072 066 062 0573 090 046 034 020 065 057 056 054 086 026 019 012 090 046 034 020 078 na na na12 (305) 074 068 063 0580 096 049 036 021 066 057 056 054 098 029 022 013 096 049 036 021 081 na na na13 (330) 076 069 064 0587 100 053 039 023 068 058 057 055 100 033 025 015 100 053 039 023 084 na na na14 (356) 078 071 066 0593 057 042 025 070 059 057 055 037 028 017 057 042 025 088 058 na na

14-14 (362) 078 071 066 0595 058 043 025 070 059 057 055 038 028 017 058 043 025 088 058 na na15 (381) 080 072 067 0600 061 045 026 071 059 058 055 041 031 018 061 045 026 091 061 na na16 (406) 082 074 068 0607 065 048 028 072 060 058 056 045 034 020 065 048 028 094 062 na na17 (432) 084 075 069 0613 069 051 030 073 060 059 056 049 037 022 069 051 030 096 064 na na18 (457) 086 077 070 0620 073 054 032 075 061 059 056 053 040 024 073 054 032 099 066 060 na20 (508) 090 080 072 0633 081 060 035 077 062 060 057 063 047 028 081 060 035 100 070 063 na22 (559) 094 083 074 0647 089 066 039 080 063 061 058 072 054 033 089 066 039 073 067 na24 (610) 098 086 077 0660 097 072 042 083 065 062 058 082 062 037 097 072 042 077 070 na26 (660) 100 089 079 0673 100 078 046 086 066 063 059 093 070 042 100 078 046 080 072 na28 (711) 092 081 0687 084 049 088 067 064 060 100 078 047 084 049 081 075 06330 (762) 094 083 0700 090 053 091 068 065 061 086 052 090 053 086 078 06636 (914) 100 090 0740 100 063 099 072 068 063 100 068 100 063 094 085 072

gt 48 (1219) 100 0820 084 100 079 074 067 100 084 100 098 0831 Linear interpolation not permitted2 Shaded area with reduced edge distance is permitted provided the installation torque is reduced to 030 Tmaxfor5dlesle16-inandto05Tmax for s gt 16-in3 When combining multiple load adjustment factors (eg for a four-anchor pattern in a corner with thin concrete member) the design can become very conservative To

optimize the design use Hilti PROFIS Anchor Design software or perform anchor calculation using design equations from ACI 318-14 Chapter 174 Spacing factor reduction in shear applicable when c lt 3hef ƒAV is applicable when edge distance c lt 3hefIfcge3hef then ƒAV = ƒAN5 Concrete thickness reduction factor in shear ƒHV is applicable when edge distance c lt 3hefIfcge3hef then ƒHV = 10

13

HIT-ICE Technical Supplement

032

018

Figure 5 - Rebar installed with HIT-ICE adhesive

Perm

issi

ble

conc

rete

co

nditi

ons

Uncrackedconcrete

Dryconcrete

Perm

issi

ble

drilli

ngm

etho

d

Hammer drilling with carbide tipped drill bit

Crackedconcrete

Water-saturatedconcrete

Hilti TE-CD or TE-YD Hollow Drill Bit

Figure 4 - Rebar installation conditions

Hilti HIT-ICE adhesive with deformed reinforcing bars (rebar)

Table 19 - Rebar installation specifications with Hilti HIT-ICE adhesive system

Setting information Symbol UnitsRebar size

3 4 5 6 7 8 9 10 11Nominal bit diameter do in 12 58 34 78 1 1-18 1-38 1-12 1-34

Effective embedment

minimum hefmin

in 2-38 2-38 3 3 3-38 4 4-12 5 5-12(mm) (60) (60) (76) (76) (85) (102) (114) (127) (140)

maximum hefmax

in 7-12 10 12-12 15 17-12 20 22-12 25 27-12(mm) (191) (254) (318) (381) (445) (508) (572) (635) (699)

Minimum concrete thickness hmin

in hef + 1-14(hef + 2do)(mm) (hef + 30)

Minimum edge distance1 cmin

in 1-78 2-12 3-18 3-34 4-38 5 5-58 6-14 7(mm) (48) (64) (79) (95) (111) (127) (143) (159) (178)

Minimum anchor spacing smin

in 1-78 2-12 3-18 3-34 4-38 5 5-58 6-14 7(mm) (48) (64) (79) (95) (111) (127) (143) (159) (178)

1 Edge distance of 1-34-inch (44mm) is permitted provided the rebar remains un-torqued

14

032

018

Table 20 - Hilti HIT-ICE design information with Rebar holes drilled with a hammer drill and carbide bit (or hollow drill bit) in accordance with ACI 318-14 Ch 171

Design parameter Symbol UnitsNominal rod diameter (in) Ref

3 4 5 6 7 8 9 10 11 ACI 318-14

Nominal anchor diameter da

in 38 12 58 34 78 100 1-18 1-14 1-38(mm) (95) (127) (159) (191) (222) (254) (286) (318) (349)

Effective minimum embedment2 hefmin

in 2-38 2-34 3-18 3-12 3-12 4 4-12 5 5-12(mm) (60) (70) (79) (89) (89) (102) (114) (127) (114)

Effective maximum embedment2 hefmax

in 7-12 10 12-12 15 17-12 20 22-12 25 27-12(mm) (191) (254) (318) (381) (445) (508) (572) (635) (699)

Minimum concrete thickness2 hmin

in hef + 1-14 (hef + 30) hef + 2d0

(8)

(mm)

Critical edge distancein

(mm) -

Minimum edge distance cmin

in 1-78 2-12 3-18 3-34 4-38 5 5-58 6-14 7(mm) (48) (64) (79) (95) (111) (127) (143) (159) (178)

Minimum anchor spacing smin

in 1-78 2-12 3-18 3-34 4-38 5 5-58 6-14 7(mm) (48) (64) (79) (95) (111) (127) (143) (159) (178)

Effectiveness factor for uncracked concrete kcuncr4 -

2417422

(10)

Effectiveness factor for cracked concrete kccr4 -

1717422

(71)Strength reduction factor for tension concrete failure modes5 ФcN - 065 1733Strength reduction factor for shear concrete failure modes5 ФcV - 070 1733

Tem

pera

ture

ra

nge

A6 Characteristic bond stress in cracked concrete7 τkcr

psina na na na na na na na na 1745

MPa

Characteristic bond stress in uncracked concrete7 τkuncr

psi 1015 1005 990 975 965 950 935 920 9051745

(MPa) (70) (69) (68) (67) (67) (66) (64) (63) (62)

Perm

issi

ble

inst

alla

tion

cond

ition

s

Strength reduction factor for tension bond failure modes dry concrete

Anchor cat-

egory- 1 1 1 2 2 2 2 2 2

Фbdry - 065 065 065 055 055 055 055 055 055

Strength reduction factor for tension bond failure modes water saturated concrete

Anchor cat-

egory- 1 1 1 2 2 2 2 2 2

Фbws - 065 065 065 055 055 055 055 055 055

1 Design information in this table is based on testing in accordance with ACI 35542 Seefigure4ofthissection3 Minimum edge distance may be reduced to 1-34 (44mm) provided the rebar remains untorqued4 ForalldesigncasesψcN=10Theappropriatecoefficientforbreakoutresistanceforcrackedconcrete(kccr) or uncracked concrete (kcuncr) must be used5 Valuesprovidedforpost-installedanchorsunderConditionBwithoutsupplementaryreinforcementasdefinedinACI318-141733 ForcaseswherethepresenceofsupplementaryreinforcementcanbeverifiedthereductionfactorsassociatedwithConditionAmaybeused6 Temperature range A Max short term temperature = 130degF (54degC) max long term temperature = 110degF (43degC) Short term elevated concrete temperatures are those that occur over brief intervals eg as a result of diurnal cycling Long term concrete temperatures are roughly

constantoversignificantperiodsoftime7 Bond strength values corresponding to concrete compressive strength fc = 2500 psi (172 Mpa) For concrete compressive strength fc between 2500 psi

(172 Mpa) and 8000 psi (552 Mpa) the tabulated characteristic bond strength may be increased by a factor of ( fc 2500 )01 [ for SI ( fc 172 )01 ]8 d0 = drilled hole diameter

15

HIT-ICE Technical Supplement

032

018

Table 21 - Hilti HIT-ICE adhesive design strength with concrete bond failure for US rebar in uncracked concrete12345678

Rebar size

Effectiveembedment

in (mm)

TensionmdashϕNn ShearmdashϕVn

ƒ´c = 2500 psi (172 MPa)

lb (kN)

ƒ´c = 3000 psi (207 MPa)

lb (kN)

ƒ´c = 4000 psi (276 MPa)

lb (kN)

ƒ´c = 6000 psi (414 MPa)

lb (kN)

ƒ´c = 2500 psi (172 MPa)

lb (kN)

ƒ´c = 3000 psi (207 MPa)

lb (kN)

ƒ´c = 4000 psi (276 MPa)

lb (kN)

ƒ´c = 6000 psi (414 MPa)

lb (kN)

3

3-38 2625 2670 2750 2865 5650 5755 5920 6165(86) (117) (119) (122) (127) (251) (256) (263) (274)

4-12 3500 3560 3665 3820 7535 7670 7895 8225(114) (156) (158) (163) (170) (335) (341) (351) (366)7-12 5830 5935 6110 6365 12555 12785 13160 13705(191) (259) (264) (272) (283) (558) (569) (585) (610)

4

4-12 4620 4705 4840 5040 9945 10130 10425 10855(114) (206) (209) (215) (224) (442) (451) (464) (483)

6 6155 6270 6455 6720 13260 13505 13900 14475(152) (274) (279) (287) (299) (590) (601) (618) (644)10 10260 10450 10755 11200 22100 22510 23165 24125

(254) (456) (465) (478) (498) (983) (1001) (1030) (1073)

5

5-58 7105 7240 7450 7760 15310 15590 16045 16710(143) (316) (322) (331) (345) (681) (693) (714) (743)7-12 9475 9650 9930 10345 20410 20785 21395 22280(191) (421) (429) (442) (460) (908) (925) (952) (991)

12-12 15795 16085 16555 17240 34020 34645 35655 37130(318) (703) (715) (736) (767) (1513) (1541) (1586) (1652)

6

6-34 8530 8685 8940 9310 21710 22110 22755 23695(171) (379) (386) (398) (414) (966) (983) (1012) (1054)

9 11370 11580 11920 12410 28945 29480 30340 31595(229) (506) (515) (530) (552) (1288) (1311) (1350) (1405)15 18955 19300 19865 20685 48245 49130 50565 52655

(381) (843) (859) (884) (920) (2146) (2185) (2249) (2342)

7

7-78 11490 11700 12040 12540 29245 29785 30655 31920(200) (511) (520) (536) (558) (1301) (1325) (1364) (1420)

10-12 15320 15600 16055 16720 38995 39710 40870 42560(267) (681) (694) (714) (744) (1735) (1766) (1818) (1893)

17-12 25530 26000 26760 27870 64990 66185 68120 70935(445) (1136) (1157) (1190) (1240) (2891) (2944) (3030) (3155)

8

9 14775 15045 15485 16125 37605 38295 39415 41045(229) (657) (669) (689) (717) (1673) (1703) (1753) (1826)12 19700 20060 20645 21500 50140 51060 52555 54725

(305) (876) (892) (918) (956) (2230) (2271) (2338) (2434)20 32830 33435 34410 35835 83565 85105 87590 91210

(508) (1460) (1487) (1531) (1594) (3717) (3786) (3896) (4057)

9

10-18 18400 18740 19290 20085 46840 47705 49095 51130(257) (818) (834) (858) (893) (2084) (2122) (2184) (2274)

13-12 24535 24990 25715 26780 62455 63605 65460 68170(343) (1091) (1112) (1144) (1191) (2778) (2829) (2912) (3032)

22-12 40895 41645 42860 44635 104095 106010 109105 113620(572) (1819) (1852) (1906) (1985) (4630) (4716) (4853) (5054)

10

11-14 22355 22765 23430 24400 56900 57950 59640 62110(286) (994) (1013) (1042) (1085) (2531) (2578) (2653) (2763)15 29805 30355 31240 32535 75870 77265 79520 82810

(381) (1326) (1350) (1390) (1447) (3375) (3437) (3537) (3684)25 49675 50590 52065 54220 126450 128775 132535 138020

(635) (2210) (2250) (2316) (2412) (5625) (5728) (5895) (6139)

1 See section 318 of PTG (Ed 17) for explanation on development of load values2 See section 3186 of PTG (Ed 17) to convert design strength value to ASD value3 Linear interpolation between embedment depths and concrete compressive strengths is not permitted4 Apply spacing edge distance and concrete thickness factors in tables 23-30 as necessary to the above values Compare to the steel values in table 22 The lesser of the values is to be used for the design5 Data is for temperature range A Max short term temperature = 130deg F (55deg C) max long term temperature = 110deg F (43deg C) Short term elevated concrete temperatures are those that occur over brief intervals eg as a result of diurnal cycling Long term concrete temperatures are roughlyconstantoversignificantperiodsoftime6 Tabular values are for dry concrete conditions For water saturated concrete multiply design strength by 0857 Tabular values are for short term loads only For sustained loads including overhead use see section 3188 of PTG (Ed 17)8 Tabularvaluesarefornormal-weightconcreteonlyForlightweightconcretemultiplydesignstrength(factoredresistance)byλa as follows Forsand-lightweightλa=051Forall-lightweightλa = 045

16

032

018

Table 22 - Steel design strength for US rebar12

Rebar size

ASTM A615 Grade 40 4 ASTM A615 Grade 60 4 ASTM A706 Grade 60 4

Tensile3

ϕNsalb (kN)

Shear4

ϕVsalb (kN)

Tensile3

ϕNsalb (kN)

Shear4

ϕVsalb (kN)

Tensile3

ϕNsalb (kN)

Shear4

ϕVsalb (kN)

34290 2375 6435 3565 6600 3430(191) (106) (286) (159) (294) (153)

47800 4320 11700 6480 12000 6240(347) (192) (520) (288) (534) (278)

512090 6695 18135 10045 18600 9670(538) (298) (807) (447) (827) (430)

617160 9505 25740 14255 26400 13730(763) (423) (1145) (634) (1174) (611)

723400 12960 35100 19440 36000 18720(1041) (576) (1561) (865) (1601) (833)

830810 17065 46215 25595 47400 24650(1370) (759) (2056) (1139) (2108) (1096)

939000 21600 58500 32400 60000 31200(1735) (961) (2602) (1441) (2669) (1388)

1049530 27430 74295 41150 76200 39625(2203) (1220) (3305) (1830) (3390) (1763)

1 See Section 3186 of PTG (Ed 17) to convert design strength value to ASD value2 ASTM A706 Grade 60 rebar are considered ductile steel elements ASTM A615 Grade 40 and 60 rebar are considered brittle steel elements3 Tensile=фAseN futa as noted in ACI 318-14 Chapter 174 Shear=ф060AseN futa as noted in ACI 318-14 Chapter 17

17

HIT-ICE Technical Supplement

032

018

Table 23 - Load adjustment factors for 3 rebar in uncracked concrete123

3uncracked concrete

Spacing factor in tension

ƒAN

Edge distance factor in tension

ƒRN

Spacing factor in shear4

ƒAV

Edge distance in shear

Concrete thickness factor in shear5

ƒHV

Toward edge

ƒRV

To edge

ƒRV

Embedment hef

in 3-38 4-12 7-12 3-38 4-12 7-12 3-38 4-12 7-12 3-38 4-12 7-12 3-38 4-12 7-12 3-38 4-12 7-12(mm) (86) (114) (191) (86) (114) (191) (86) (114) (191) (86) (114) (191) (86) (114) (191) (86) (114) (191)

Spac

ing

(s)

Edg

e di

stan

ce (c

a) C

oncr

ete

thic

knes

s (h

) - i

n (m

m)

1-34 (44) na na na 033 024 014 na na na 013 010 006 026 020 012 na na na1-78 (48) 059 057 054 034 025 014 055 054 053 014 011 007 029 022 013 na na na

2 (51) 060 057 054 035 025 015 055 054 053 016 012 007 032 024 014 na na na3 (76) 065 061 057 045 033 019 057 056 054 029 022 013 045 033 019 na na na4 (102) 070 065 059 056 041 024 060 058 056 045 034 020 056 041 024 na na na

4-58 (117) 073 067 060 065 047 028 061 059 057 056 042 025 065 047 028 067 na na5 (127) 075 069 061 071 051 030 062 060 057 063 047 028 071 051 030 070 na na

5-34 (146) 078 071 063 081 059 034 064 062 058 078 058 035 081 059 034 075 068 na6 (152) 080 072 063 085 062 036 065 062 059 083 062 037 085 062 036 077 070 na7 (178) 085 076 066 099 072 042 067 064 060 100 078 047 099 072 042 083 075 na8 (203) 090 080 068 100 082 048 070 066 062 096 057 100 082 048 089 080 na

8-34 (222) 093 082 069 090 052 071 068 063 100 066 090 052 093 084 0719 (229) 094 083 070 092 054 072 068 063 068 092 054 094 085 072

10 (254) 099 087 072 100 059 074 070 064 080 100 059 099 090 07611 (279) 100 091 074 065 077 072 066 093 065 100 094 08012 (305) 094 077 071 079 074 067 100 071 099 08314 (356) 100 081 083 084 078 070 083 100 09016 (406) 086 095 089 082 073 095 09618 (457) 090 100 094 086 076 100 10024 (610) 100 100 099 08530 (762) 100 09336 (914) 100

gt 48 (1219)

Table 24 - Load adjustment factors for 4 rebar in uncracked concrete123

4uncracked concrete

Spacing factor in tension

ƒAN

Edge distance factor in tension

ƒRN

Spacing factor in shear4

ƒAV

Edge distance in shear

Concrete thickness factor in shear5

ƒHV

Toward edge

ƒRV

To edge

ƒRV

Embedment hef

in 4-12 6 10 4-12 6 10 4-12 6 10 4-12 6 10 4-12 6 10 4-12 6 10(mm) (114) (152) (254) (114) (152) (254) (114) (152) (254) (114) (152) (254) (114) (152) (254) (114) (152) (254)

Spac

ing

(s)

Edg

e di

stan

ce (c

a) C

oncr

ete

thic

knes

s (h

) - i

n (m

m)

1-34 (44) na na na 028 021 012 na na na 009 006 004 017 013 008 na na na2-12 (64) 059 057 054 033 024 014 055 054 053 015 011 007 029 022 013 na na na

3 (76) 061 058 055 036 027 016 056 055 053 019 014 009 036 027 016 na na na4 (102) 065 061 057 044 032 019 057 056 054 030 022 013 044 032 019 na na na5 (127) 069 064 058 052 038 022 059 058 055 041 031 019 052 038 022 na na na

5-34 (146) 071 066 060 059 043 025 061 059 056 051 038 023 059 043 025 065 na na6 (152) 072 067 060 062 045 027 061 059 057 054 041 024 062 045 027 067 na na7 (178) 076 069 062 072 053 031 063 061 058 068 051 031 072 053 031 072 na na

7-14 (184) 077 070 062 075 055 032 063 061 058 072 054 032 075 055 032 073 067 na8 (203) 080 072 063 082 060 035 065 062 059 084 063 038 082 060 035 077 070 na9 (229) 083 075 065 093 068 040 067 064 060 100 075 045 093 068 040 082 074 na

10 (254) 087 078 067 100 076 044 068 065 061 088 053 100 076 044 086 078 na11-14 (286) 092 081 069 085 050 071 067 062 100 063 085 050 091 083 070

12 (305) 094 083 070 091 053 072 068 063 069 091 053 094 086 07214 (356) 100 089 073 100 062 076 071 065 087 100 062 100 092 07816 (406) 094 077 071 080 074 067 100 071 099 08318 (457) 100 080 080 083 077 070 080 100 08820 (508) 083 088 087 081 072 088 09322 (559) 087 097 091 084 074 097 09824 (610) 090 100 094 087 076 100 10030 (762) 100 100 096 08336 (914) 100 089

gt 48 (1219) 100

1 Linear interpolation not permitted2 Shaded area with reduced edge distance is permitted provided the installation torque is reduced to 030 Tmaxfor5dlesle16-inandto05Tmax for s gt 16-in3 When combining multiple load adjustment factors (eg for a four-anchor pattern in a corner with thin concrete member) the design can become very conservative

To optimize the design use Hilti PROFIS Anchor Design software or perform anchor calculation using design equations from ACI 318-14 Chapter 174 Spacing factor reduction in shear applicable when c lt 3hef ƒAV is applicable when edge distance c lt 3hefIfcge3hef then ƒAV = ƒAN5 Concrete thickness reduction factor in shear ƒHV is applicable when edge distance c lt 3hefIfcge3hef then ƒHV = 10

18

032

018

Table 25 - Load adjustment factors for 5 rebar in uncracked concrete123

5uncracked concrete

Spacing factor in tension

ƒAN

Edge distance factor in tension

ƒRN

Spacing factor in shear4

ƒAV

Edge distance in shear

Concrete thickness factor in shear5

ƒHV

Toward edge

ƒRV

To edge

ƒRV

Embedment hef

in 4-12 6 10 4-12 6 10 4-12 6 10 4-12 6 10 4-12 6 10 4-12 6 10(mm) (114) (152) (254) (114) (152) (254) (114) (152) (254) (114) (152) (254) (114) (152) (254) (114) (152) (254)

Spac

ing

(s)

Edg

e di

stan

ce (c

a) C

oncr

ete

thic

knes

s (h

) - i

n (m

m)

1-34 (44) na na na 026 019 011 na na na 006 005 003 012 009 006 na na na3-18 (79) 059 057 054 033 024 014 055 054 053 015 011 007 030 022 013 na na na

4 (102) 062 059 055 038 028 016 056 055 054 021 016 010 038 028 016 na na na5 (127) 065 061 057 044 032 019 057 056 054 030 023 014 044 032 019 na na na6 (152) 068 063 058 050 037 021 059 057 055 039 030 018 050 037 021 na na na7 (178) 071 066 059 058 042 025 060 059 056 050 037 022 058 042 025 na na na

7-18 (181) 071 066 060 059 043 025 061 059 056 051 038 023 059 043 025 065 na na8 (203) 074 068 061 066 049 028 062 060 057 061 046 027 066 049 028 069 na na9 (229) 077 070 062 074 055 032 063 061 058 072 054 033 074 055 032 073 067 na

10 (254) 080 072 063 083 061 036 065 062 059 085 064 038 083 061 036 077 070 na11 (279) 083 074 065 091 067 039 066 064 060 098 073 044 091 067 039 081 074 na12 (305) 086 077 066 099 073 043 068 065 061 100 084 050 099 073 043 085 077 na14 (356) 091 081 069 100 085 050 071 067 062 100 063 100 085 050 091 083 07016 (406) 097 086 071 097 057 074 070 064 077 097 057 098 089 07518 (457) 100 090 074 100 064 077 072 066 092 100 064 100 094 07920 (508) 094 077 071 080 075 068 100 071 099 08422 (559) 099 079 078 083 077 069 078 100 08824 (610) 100 082 085 086 080 071 085 09226 (660) 085 092 089 082 073 092 09628 (711) 087 100 092 085 075 100 09930 (762) 090 095 087 076 10036 (914) 098 100 094 082

gt 48 (1219) 100 100 092

Table 26 - Load adjustment factors for 6 rebar in uncracked concrete123

6uncracked concrete

Spacing factor in tension

ƒAN

Edge distance factor in tension

ƒRN

Spacing factor in shear4

ƒAV

Edge distance in shear

Concrete thickness factor in shear5

ƒHV

Toward edge

ƒRV

To edge

ƒRV

Embedment hef

in 6-34 9 15 6-34 9 15 6-34 9 15 6-34 9 15 6-34 9 15 6-34 9 15(mm) (171) (229) (381) (171) (229) (381) (171) (229) (381) (171) (229) (381) (171) (229) (381) (171) (229) (381)

Spac

ing

(s)

Edg

e di

stan

ce (c

a) C

oncr

ete

thic

knes

s (h

) - i

n (m

m)

1-34 (44) na na na 024 018 010 na na na 005 004 002 009 007 004 na na na3-34 (95) 059 057 054 033 024 014 055 054 053 015 011 007 030 022 013 na na na

4 (102) 060 057 054 034 025 015 055 054 053 016 012 007 033 024 015 na na na5 (127) 062 059 056 039 028 017 056 055 054 023 017 010 039 028 017 na na na6 (152) 065 061 057 044 032 019 057 056 054 030 022 013 044 032 019 na na na7 (178) 067 063 058 049 036 021 059 057 055 038 028 017 049 036 021 na na na8 (203) 070 065 059 055 041 024 060 058 056 046 034 021 055 041 024 na na na

8-12 (216) 071 066 059 059 043 025 061 059 056 050 038 023 059 043 025 065 na na9 (229) 072 067 060 062 046 027 061 059 057 055 041 025 062 046 027 067 na na