Ch-1, Introduction to SCM

-

Upload

sumitkragarwal -

Category

Documents

-

view

218 -

download

0

Transcript of Ch-1, Introduction to SCM

-

8/8/2019 Ch-1, Introduction to SCM

1/48

Introduction to Supply ChainManagement

-

8/8/2019 Ch-1, Introduction to SCM

2/48

What is a SCM?

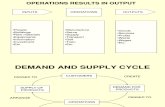

Flow of products and services from: Raw materials manufacturers Intermediate products manufacturers End product manufacturers Wholesalers and distributors and RetailersConnected by transportation and storageactivities

Integrated through information, planning, andintegration activitiesCost and service levels

-

8/8/2019 Ch-1, Introduction to SCM

3/48

What Is Supply Chain Management?

Supply chain management is a set of approaches utilized to efficiently integratesuppliers, manufacturers, warehouses, andstores, so that merchandise is produced anddistributed at the right quantities, to the rightlocations, and at the right time, in order to

minimize system wide costs while satisfyingservice level requirements.

-

8/8/2019 Ch-1, Introduction to SCM

4/48

Two Other Formal Definitions

The design and management of seamless, value-added process across organizational boundaries tomeet the real needs of the end customer

Institute for Supply ManagementManaging supply and demand, sourcing rawmaterials and parts, manufacturing and assembly,warehousing and inventory tracking, order entryand order management, distribution across allchannels, and delivery to the customer

The Supply Chain Council

-

8/8/2019 Ch-1, Introduction to SCM

5/48

PC Industry Supply ChainPC Industry Supply Chain

Tracing

back the screen you stare at for the bulk of your time.

-

8/8/2019 Ch-1, Introduction to SCM

6/48

Cisco s Value Network

-

8/8/2019 Ch-1, Introduction to SCM

7/48

SCM Definition

Source

Supplier

Supplier

Distributo r

Distributor

Retailer

End-User

Converte r

Converter Consumers

Information Flow

Funds/Demand Flow

Value-Added Services

M aterial Flow

Reuse/Maintenance/After Sales Service Flow

-

8/8/2019 Ch-1, Introduction to SCM

8/48

The SCM Network

-

8/8/2019 Ch-1, Introduction to SCM

9/48

Key Observations

Every facility that impacts costs need to beconsidered Suppliers suppliers

Customers customersEfficiency and cost-effectiveness throughout thesystem is required System level approach

Multiple levels of activities Strategic Tactical Operational

-

8/8/2019 Ch-1, Introduction to SCM

10/48

ChallengesSupply chain strategy linked to theDevelopment Chain

Challenging to minimize system costs andmaximize system service levelsInherent presence of uncertainty and risk

-

8/8/2019 Ch-1, Introduction to SCM

11/48

The Development Chain

Set of activities and processes associated withnew product introduction. Includes:

product design phase

associated capabilities and knowledge sourcing decisions production plans

-

8/8/2019 Ch-1, Introduction to SCM

12/48

Intersection of SCM and TheDevelopment Chain

The enterprise development and supply chain

-

8/8/2019 Ch-1, Introduction to SCM

13/48

Global Optimization

Geographically dispersed complex networkConflicting objectives of different facilitiesDynamic system Variations over time Matching demand-supply difficult Different levels of inventory and backordersSystem Variations over time-Seasonal fluctuations, trends, advertising

and promotions. Competitors pricingstrategies etc.

-

8/8/2019 Ch-1, Introduction to SCM

14/48

Global Apparel Value Chain

Tracing back the dress you are wearing

-

8/8/2019 Ch-1, Introduction to SCM

15/48

-

8/8/2019 Ch-1, Introduction to SCM

16/48

Globally Dispersed Manufacturing

An Illustration: How Li & Fung LimitedMight Make a Dress

QC & Shipping[Hong Kong]

Product Design[Hong Kong]

Zippers+[Japan+]

Stitching[Indonesia]

Weaving[Taiwan]

Yarn Spinning[Korea]

-

8/8/2019 Ch-1, Introduction to SCM

17/48

ncerta nty an s actors:Challenges

1. Matching supply and demandREASON(1)Raw material shortages

Internal and supplier parts shortagesProductivity inefficienciesEXAMPLEBoeing Aircraft s inventory write-down of $2.6billion in Oct 1997 due to raw materialshortages, internal & supplier parts shortages &productivity inefficiencies.

-

8/8/2019 Ch-1, Introduction to SCM

18/48

REASONS(2,3,4) EXAMPLES

Sales and earnings shortfallLarger than anticipated inventories

Sales at U.S. Surgical Corporationdeclined 25 percent, resulting in aloss of $22 million

Stiff competitionGeneral slowdown in the PC

market

Intel reported a 38 percent declinein quarterly profit

Higher than expected orders for new products over existingproducts

EMC Corp. missed its revenueguidance of $2.66 billion for thesecond quarter of 2006 by around$100 million

-

8/8/2019 Ch-1, Introduction to SCM

19/48

contd .

2. Fluctuations of Inventory and Backordersthroughout the Supply Chain

-

8/8/2019 Ch-1, Introduction to SCM

20/48

Uncertainty and Risk Factors contd

3. Forecasting is not a solution4. Demand is not the only source of uncertainty-

delivery lead times, manufacturing yields,transportation times, component availability etc.

5. Recent trends make things more uncertain- focuson cost reduction

Lean manufacturing Outsourcing Off-shoring

-

8/8/2019 Ch-1, Introduction to SCM

21/48

Uncertainty and Risk Factors

August 2005 Hurricane Katrina P&G coffee supplies from sites around New Orleans Six month impact

2002 West Coast port strike Losses of $1 B/ day Store stock-outs, factory shutdowns1999 Taiwan earthquake

Supply interruptions of H P, Dell2001 India ( Gujarat state) earthquake Supply interruptions for apparel manufacturers

-

8/8/2019 Ch-1, Introduction to SCM

22/48

Evolution of Supply ChainManagement

1950s 1960s 1970s 1980s 1990s 2000s Beyond

Traditional Mass Manufacturing

Inventory Management/CostOptimization

JIT, TQM, BPR,Alliances

SCM Formation/Extensions

Further Refinement of SCM Capabilities

-

8/8/2019 Ch-1, Introduction to SCM

23/48

Complexity: The MagnitudeCompaq computer s loss of $500 million to $1 billion in salesin one year

Laptops and desktops were not available when and where customerswere ready to buy them

Boeing s forced announcement of write-downs of $2.6b Raw material shortages, internal and supplier parts shortages .

Cisco s multi-billion ($2.2b) dollar write-off of inventories in2001-2002 Customers balked on orders due to market meltdown

-

8/8/2019 Ch-1, Introduction to SCM

24/48

Complexity: The MagnitudeU.S. companies spend more than $1 trillion in supply-relatedactivities (10-15% of Gross Domestic Product) Transportation 58% Inventory 38%

Management 4%The grocery industry could save $30 billion (10% of operatingcost) by using effective logistics strategiesA typical box of cereal spends 104 days getting from factory tosupermarket.

A typical new car spends 15 days traveling from the factory tothe dealership.

-

8/8/2019 Ch-1, Introduction to SCM

25/48

Supply Chain Management:The True Magnitude

Compaq estimates it lost $.5 billion to $1billion in sales in 1995 because laptops werenot available when and where neededP&G estimates it saved retail customers $65million by collaboration resulting in a bettermatch of supply and demand

-

8/8/2019 Ch-1, Introduction to SCM

26/48

Transactional Complexity

National Semiconductors:Production: Produces chips in six different locations: four in the US, one in

Britain and one in Israel Chips are shipped to seven assembly locations in Southeast Asia.

Distribution The final product is shipped to hundreds of facilities all over the

world 20,000 different routes

12 different airlines are involved 95% of the products are delivered within 45 days 5% are delivered within 90 days.

-

8/8/2019 Ch-1, Introduction to SCM

27/48

PC Value ChainPerformance of Traditional PC

Manufacturer

-

8/8/2019 Ch-1, Introduction to SCM

28/48

PC Value Chain: Focus on CostReduction

Performance of Dell Computers

-

8/8/2019 Ch-1, Introduction to SCM

29/48

Magnitude of Supply Chain CostsCost Elements of a Typical Trade Book

-

8/8/2019 Ch-1, Introduction to SCM

30/48

Magnitude of Supply Chain CostsExample: The Apparel Industry

Manufacturer

Distributor Retailer Customer

Cost per Percent

Shirt Saving

$52.72 0%

$41.34 28 %

$2 0.45 62 %

Manufacturer

Distributor Retailer Customer

Manufacturer

Distributor Retailer Customer

-

8/8/2019 Ch-1, Introduction to SCM

31/48

Supply Chain: The PotentialP&G s estimated savings to retail customers of $65 million throughlogistics gains

Dell Computer s outperforming of the competition in terms of shareholdervalue growth over more than two decades by over 3,000% using:

Direct business model

Build-to-order strategy

Wal-Mart transformation into the world s largest retailer by changing itslogistics system:

highest sales per square foot, inventory turnover and operating profit of anydiscount retailer

-

8/8/2019 Ch-1, Introduction to SCM

32/48

The Complexity

Three critical abilities that successful firms mustpossess:

1. The ability to match supply chain strategieswith product strategies2. The ability to replace traditional supply chain

strategies-globally optimized supply chain.3. The ability to effectively manage uncertainty

and risk.

-

8/8/2019 Ch-1, Introduction to SCM

33/48

Key issues in SCM

1.The strategic Level deals with the decisionsthat have a long-lasting effect on the firm.

2.T

he tactical level includes decisions that aretypically updated anywhere b / w once every Q or once every yr.3. The operational level refers to day-to-daydecisions.

-

8/8/2019 Ch-1, Introduction to SCM

34/48

Strategic level-product design, what to makeinternally & what to outsource, supplierselection, strategic partnering as well asdecisions on the number, location & capacityof warehouses & manufacturing plants andthe flow of material through the logistic

network.

-

8/8/2019 Ch-1, Introduction to SCM

35/48

Tactical level- purchasing and productiondecisions, inventory policies, transportationstrategies.Operational level- scheduling, lead timequotations, routing etc.

-

8/8/2019 Ch-1, Introduction to SCM

36/48

Key Issues in SCM

Distribution Network ConfigurationInventory ControlProduction SourcingDistribution StrategiesSC Integration & Strategic PartneringOutsourcing and Offshoring StrategiesProduct DesignIT and Decision Support Systems

Customer ValueSmart PricingLocal Issues

-

8/8/2019 Ch-1, Introduction to SCM

37/48

Distribution Network Configuration

How to select a set of warehouse locationsand capacities, determine production level foeeach and set transportation flow in order tominimize total prod n, inventory and TC andsatisfy service level requirements- a complexoptimization problem

-

8/8/2019 Ch-1, Introduction to SCM

38/48

Inventory Control

Why should the retailer hold inventory at thefirst place?W

hat is the impact of forecasting?What inventory turnover ratio should beused?

-

8/8/2019 Ch-1, Introduction to SCM

39/48

Production Sourcing

Balance Transportation and Manufacturingcost

-

8/8/2019 Ch-1, Introduction to SCM

40/48

Supply Contracts

Relationship b / w supplier and buyer isestablished that specifies pricing & volumediscounts, delivery lead times, qualityreturns..

-

8/8/2019 Ch-1, Introduction to SCM

41/48

Distribution Strategies

How much to centralizeWhat is the impact of each strategy on theInventory, transportation and service level?

-

8/8/2019 Ch-1, Introduction to SCM

42/48

SC Integration & Strategic Partnering

Information Sharing and Operational planningare the keys

-

8/8/2019 Ch-1, Introduction to SCM

43/48

Product Design

Certain product design may increase inventoryholding or TC while others may facilitatemanufacturing lead time

-

8/8/2019 Ch-1, Introduction to SCM

44/48

IT and Decision-Support Systems

Which data to be transferred?How frequently should data be transferredand analyzed?Role of Internet, E-commerceCan these technologies be viewed as the maintools used to achieve competitive advantagein the market?

-

8/8/2019 Ch-1, Introduction to SCM

45/48

Customer Value

Measure of a company s contribution to itscustomer

-

8/8/2019 Ch-1, Introduction to SCM

46/48

Smart Pricing

The firm integrates pricing and inventory toinfluence market demand and improve thebottom line.

-

8/8/2019 Ch-1, Introduction to SCM

47/48

Local issues

Supply and distribution of common use likefood and waterSkill sets- an understanding of local dynamics,customer preferences, government policies,infrastructural constraints and Strengths &weaknesses of SC partners.

Issues- Reverse logistics and environmentconcerns

-

8/8/2019 Ch-1, Introduction to SCM

48/48

Key Issues in Supply Chain Management

ChainG

lobal Optimization Managing risk & uncertainty

Chain Managing Risk and Uncertainty

Distribution Network Configuration Supply Y

Inventory Control Supply Y

Production Sourcing Supply Y

Supply Contracts Both Y Y

Distribution Strategies Supply Y Y

SC Integration &Strategic Partnering

Development Y

Outsourcing and Offshoring DevelopmentY

Product Design DevelopmentY

Information Technology &Decision Support Systems

SupplyY Y

Customer Value Both

Y Y

Smart Pricing Supply

Y