1. Introduction to SCM

Transcript of 1. Introduction to SCM

-

7/27/2019 1. Introduction to SCM

1/38

Supply Chain Management

Course Facil itator : Anas I ftikhar

Iqra University Alumni

MSc (Supply Chain & Logistics Management (Warwick)

-

7/27/2019 1. Introduction to SCM

2/38

Attendance Policy

- Only 5 min late after that Absent.

- No leniency or proxy

- Max 6 after that SOA

Supply Chain Management

-

7/27/2019 1. Introduction to SCM

3/38

Supply Chain Management

Marks Distribution:

- Class Quizzes: 10 %

- Assignments: 10%

- Mid Term / Monthly: 20 %

- Final Exam: 50 %

- Final Term Report: 10%

You may expect un announced quizzes and marked

assessment during the semester.

-

7/27/2019 1. Introduction to SCM

4/38

Course Outline1. Introduction to SCM

2. Procurement & Purchasing

3. Building Deep Supplier Relationship HBR Article

4. Logistics Management

5. Inventory Management

6. Warehousing Management

7. Manufacturing8. Production Planning Systems

9. Master Production Schedule

10. Material Requirement Planning

11. Vendor Managed Inventory

Recommended Books:

Principles of Supply chain management: A balanced approach byJoel D. Wisner

Essentials of Supply Chain Management by Michael Hugos

Designing and Managing the Supply Chain by Simchi-Levi, D and E and

Kaminsky, P.

-

7/27/2019 1. Introduction to SCM

5/38

Restaurant Supply Chain

When you buy a burger from McDonald or a Zinger

from KFC, have you thought where all of the

ingredients came from that produced your sandwich?

Depending on the restaurants location, McDonaldsand KFC source their ingredients from both local and

global suppliers.

The challenge is to ensure that all restaurants in their

network have enough ingredients to meet customer

demand.

-

7/27/2019 1. Introduction to SCM

6/38

Supply Chain Video

http://www.youtube.com/watch?v=XEWsgIUi

Hyo (Working at Beiersdorf)

http://www.youtube.com/watch?v=GHNuOLr

Awlo (Unilever Supply Chain)

http://www.youtube.com/watch?v=XEWsgIUiHyohttp://www.youtube.com/watch?v=XEWsgIUiHyohttp://www.youtube.com/watch?v=GHNuOLrAwlohttp://www.youtube.com/watch?v=GHNuOLrAwlohttp://www.youtube.com/watch?v=GHNuOLrAwlohttp://www.youtube.com/watch?v=GHNuOLrAwlohttp://www.youtube.com/watch?v=XEWsgIUiHyohttp://www.youtube.com/watch?v=XEWsgIUiHyo -

7/27/2019 1. Introduction to SCM

7/38

-

7/27/2019 1. Introduction to SCM

8/38

Brief Historical Background

Academic study of logistics management could be dated back to the 1850s, when Henry

Adams, an economist who was president of Yale University, Offered a course in theEconomics of Transportation

In 1962, Peter Drucker argues that logistics was unexplored and left behind as a dark

continent.

In the 1970s and 1980s the importance of logistics was brought to the surface.

Over the early 1980s, logistics has penetrated into a broader management philosophy

known as Supply Chain Management

The term supply chain management first appeared in a Financial Times article written by

Oliver and Webber in 1982 (Laseter, T, & Oliver, K., (2003). When will Supply ChainManagement Grow Up. Strategy and Business, 32, pp.1 5.) describing the range of

activities performed by the organization in procuring and managing supplies.

-

7/27/2019 1. Introduction to SCM

9/38

Brief Historical Background

The distinction between supply chain management and logistics is blurry in

the literature and the terms often used interchangeably.

Today it focuses more on dynamic buyer-supplier relationships towards the

entire supply chain integration, of which the implementation of e-business is

the new dimension.

-

7/27/2019 1. Introduction to SCM

10/38

Modern SC View

An effective SC ensures high level of Customer Service atoptimum level!

So simple yet extremly demanding......

Operational viewan efficient supply chain that ensures products are on the

shelf, available for sale, when Shoppers come to buythem ... all the time!

-

7/27/2019 1. Introduction to SCM

11/38

Supply Chain Flows

Material Flow

Information Flow

Finance Flow

Return Product Flow

-

7/27/2019 1. Introduction to SCM

12/38

Supply Chain Definitions

Managing supply and demand, sourcing raw materials andparts, manufacturing and assembly, warehousing and inventory

tracking, order entry and order management, distributionacross all channels, and delivery to the customer

The Supply Chain Council

-

7/27/2019 1. Introduction to SCM

13/38

Supply Chain Definitions

The planning and management of all activities involved in

sourcing and procurement, conversion, and all logistics

management activities also includes coordination with

channel partners, which can be suppliers, intermediaries,

third party service providers, and customers.

Council of Supply Chain Management

Professionals

-

7/27/2019 1. Introduction to SCM

14/38

-

7/27/2019 1. Introduction to SCM

15/38

-

7/27/2019 1. Introduction to SCM

16/38

Supply Chain Model

Source: Bowersox 1996

-

7/27/2019 1. Introduction to SCM

17/38

Supply Chain Network

Source: Nigel Slack, 2002

-

7/27/2019 1. Introduction to SCM

18/38

Supply Chain Management

A definition: Maximising added value and reducing

total cost across the entire trading process through

focusing on speed and certainty of response to themarket.

Tom McGuffog

-

7/27/2019 1. Introduction to SCM

19/38

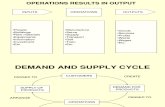

PLAN

DemandForecasting

Product Pricing

Inventory Management

SOURCE

Procurement

Credit & Collection

DELIVER

Order Management

Delivery Scheduling

MAKE

Product Design

Production Scheduling

Facility Management

Key Activities of Supply Chain Operations

-

7/27/2019 1. Introduction to SCM

20/38

Supply Chain Drivers

1.

PRODUCTION

What, how, and when

to produce

2.

INVENTORY

How much to make

and how much to

store

3.

LOCATION

Where best to do

what activity

4.

TRANSPORTATION

How and when to

move product

5.INFORMATION

The basis for

making these

decisions

-

7/27/2019 1. Introduction to SCM

21/38

Key Players in Supply Chain

A supply chain consists of all stages involved,

directly or indirectly in fulfilling a customer

request. The supply chain not only includes the

manufacturerand supplier, but also transporters,warehouses , retailers and customerthemselves

--- Chopra & Meindl

-

7/27/2019 1. Introduction to SCM

22/38

Why is SCM difficult?

Different facilities may have different, conflicting objectives

Suppliers want manufacturers to commit themselves to purchasing largequantities in stable volumes with flexible delivery dates

Manufacturers want continuous production runs, high quality, lowproduction cost.

Warehouses and Distribution Centers want to low inventory, reduced

transportation cost.

Reduction in inventory levels increase transportation costs

Customer need shorter lead times, low prices.

-

7/27/2019 1. Introduction to SCM

23/38

Cycle Time

A key aspect of supply chain management is cycle time. Cycletime refers to the total time required to complete a process.

Much of this can be wasted time or time that is not usedefficiently.

A number of factors can slow down cycle time: unnecessary steps;

Activities that may have been in place for a long time but no longer addvalue;

Ineffective or poorly utilized technology;

Excessive bureaucracy (procedures, controls, and forms that stagnate theprocess);

Poor communication, coordination, and cooperation.

-

7/27/2019 1. Introduction to SCM

24/38

Cycle Time

1. Supply Chain Cycle time - time spent by the supply chain to convert the

raw materials into final products plus the time needed to reach the products tothe customer

2. Order to delivery cycle time - the time elapsed between the placement ofan order by a customer and the delivery of products to the customer

"Work smarter, not harder

Elimination of unnecessary work

Any activity or process that is not adding any value must be eliminated

-

7/27/2019 1. Introduction to SCM

25/38

Customer Wait Time

Customer wait time refers to the time that is incurred in

fulfillment of a customer order.

Also called as Logistics Response Time

Function:

It looks at what is stocked locally, what is stocked

elsewhere, how long it takes to repair or procure items not

in stock, how long it takes to ship material, how long ittakes to receive shipments, and other factors.

-

7/27/2019 1. Introduction to SCM

26/38

Velocity management improves the speed and

accuracy with which materials and information

flow from providers to users. This in turn

reduces the need for massive stockpiles ofresources.The result has been impressive.

Accelerated deliveries of spare parts haveaccelerated the repairs of cars.

Velocity Management

-

7/27/2019 1. Introduction to SCM

27/38

Three Ts

-

7/27/2019 1. Introduction to SCM

28/38

Raw Materials

Transportation

Manufacturing

Distribution

Retail ShowRoom

Slow Moving,Industrial Mass

Markets

Vertically Integrated

Fragmented, FastMoving Markets

Raw MaterialsCompany

ManufacturingCompany

TransportationCompany

IndependentDistributor

Independent

Retailer

Old Supply Chains vs. New

-

7/27/2019 1. Introduction to SCM

29/38

What is the Bottom Line?

Efficient Supply Chain

-

7/27/2019 1. Introduction to SCM

30/38

Efficiently means with minimal commitment

of financial resources

Effectiveness means providing customer

satisfaction and value, which (combined with

efficiency) leads toprofitability

Ultimately its Competitive Advantage

-

7/27/2019 1. Introduction to SCM

31/38

Typical Benefits From Integrating the

Supply Chain

Enhanced Delivery Performance

Excess Inventory Reduction

Reduce Customer Wait Time

Enhanced Forecast Accuracy

Improvement in Overall Productivity

Lower Supply Chain Costs

-

7/27/2019 1. Introduction to SCM

32/38

The Heart of Supply Chain Management

Delivering

the right product

to the right placeat the right time and

at the right price

To all customers

For all the orders

At all the time

-

7/27/2019 1. Introduction to SCM

33/38

HOW?

-

7/27/2019 1. Introduction to SCM

34/38

Current Trends in Supply Chain Management

Expanding the Supply Chain

Firms are expanding partnerships and building

facilities in foreign markets

The expansion involves:

breadth- foreign manufacturing, office & retail sites,

foreign suppliers & customers

depth- second and third tier suppliers & customers

-

7/27/2019 1. Introduction to SCM

35/38

Current Trends in Supply Chain Management

(Cont.)

Increasing Supply Chain Responsiveness Firms will increasingly need to be more flexible and

responsive to customer needs

Shorter product life cycles, rapid product development,Samsung S1, S2, S3, Ipods, Iphone, Ipads.

Supply chains will need to benchmarkindustryperformance and meet and improve on a continuous

basis Supply chain responsiveness requires firms to

reevaluate their supply chain relationships, utilizebusiness process reengineering, design new products

and services.

-

7/27/2019 1. Introduction to SCM

36/38

Current Trends in Supply Chain Management

(Cont.)

The Greening of Supply Chains

- Producing, packaging, moving, storing, delivering and

other supply chain activities can be harmful to the

environment Supply chains will work harder to reduce

environmental degradation

Large majority (75%) of U.S. consumers influenced by

a firms environmental friendliness reputation

Recycling and conservation are a growing alternative

in response to high cost of natural resources

-

7/27/2019 1. Introduction to SCM

37/38

Current Trends in Supply Chain Management

(Cont.)

Reducing Supply Chain Costs

Cost reduction achieved through:

Reduced purchasing costs

Reducing waste

Reducing excess inventory, and

Reducing non-value added activities

Continuous Improvement through

Benchmarking-improve over competitors performance

Increased knowledge of supply chain processes

-

7/27/2019 1. Introduction to SCM

38/38

End of Topic

![Scm-Introduction [Compatibility Mode]](https://static.fdocuments.in/doc/165x107/577d21001a28ab4e1e943f2b/scm-introduction-compatibility-mode.jpg)