BROSUR- Inovenso Electrospinning nano ceramics conference flyer

-

Upload

alper-emin-tuerkoglu -

Category

Documents

-

view

40 -

download

2

description

Transcript of BROSUR- Inovenso Electrospinning nano ceramics conference flyer

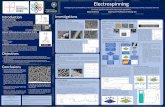

Why Electrospinning And Why Nanofibers?

The size of an electrospun fiber can be in the nano scale and the fibers may possess nano scale surface texture, leading to different modes of interaction with other materials compared with macroscale materials The ultra-fine fibers produced by electrospinning are expected to have two main properties, a very high surface to volume ratio, and a relatively defect free structure at the molecular level. This first property makes electrospun material suitable for activities requiring a high degree of physical contact, such as providing sites for chemi-cal reactions, or the capture of small sized particulate material by physical entanglement – filtration. The second property should allow electrospun fibers to approach the theoretical maximum strength of the spun material, opening up the possibility of making high mechanical performance.

As Inovenso Co., we supply most versatile, reliable and proven quality electrospinning units for all ranges of producti-on levels, even first stage researchers to advanced pre-manufacturing process of high tech nanofiber based products.

CONTACT:

+90 212 328 03 33

İTÜ Ayazağa OTAM 103İstanbul / TURKEY

www.inovenso.com

Our References All Over The World

• National Research Center of Membrane Tech., Turkey

• Northeastern University Boston, USA

• 3M Minnesota, USA

• Nanyang Technological University, Singapore

• Universitatsklinikum Freiburg, Germany

• Ghent University, Belgium

• King Saud University Riyadh, Saudi Arabia

• Istanbul Technical University, Turkey

• University of California, Riverside, USA

• Alexandria Research and Technology Center, Egypt

• University of Basque Country, Spain

Lab Scale Electrospinning Units

• Nansospinner 24- Multinozzle advanced level Pre-manufacturing and end phase advanced researches demands mostly, enables high surface area coating with high throughput of nanofiber membrane production.

• NE300 – Multinozzle optimized levelAdvanced researches for medium size coating area and high throughput production with optimized specifications.

• NE200 – Single nozzle advanced modelRelatively small surface area coating with single nozzle feeding but advanced level of specification for less volume of polymer solution consumption.

• NE100- Single nozzle optimized levelNewly started researches with a versatile and easy to use for quick and reliable results with single nozzle feeding electrospinning of nanofiber coatings.

• Basic System- Single nozzle basic levelBudget and user friendly model basic electrospinning apparatus providing fast response for your researches.

Bicomponent Nozzle

Inovenso Co., is one of the leading supplier of semi-in-dustrial scale and laboratory scale nanofiber production equipments. Our unique design and well educated and highly experienced team also provides technical support for the researchers within their R&D projects.

At Inovenso we are dedicated to provide versatile and reliable equipments and technical support for semi- indust-rial scale and research level production of nanofiber coatings, and hence contribute to the improvement of the quality of production lead to high tech industries.

Do not hesitate to contact with us so let us help you with your researches.