Brochure 31200 November 1996 New Microprocessor Radio ... Control Products/PDF... · of...

Transcript of Brochure 31200 November 1996 New Microprocessor Radio ... Control Products/PDF... · of...

31200

Mic

ropr

oces

sor R

adio

Loc

omot

ive

Cont

rol

HUBBELL

Hub

bell

72 &

450

MH

z Re

mot

e C

ontro

l Sys

tem

for

Loco

mot

ive

App

licat

ions

The Hubbell Intelligent Radio Loco-motive Systems features a micro-computer with statusdisplay and built-in di-agnostics along withour high speed, digi-tal, biphase modula-tion to provide reli-able, efficient andeconomical operationof diesel-electric loco-motives from a por-table transmitter.

By operating thetransmitter switches, a radio mes-sage is sent to the locomotivemounted receiver to control the di-rection and speed of the locomo-tive. Additional data bits are avail-able to perform special auxiliaryfunctions such as sounding of horn,application of brakes or control ofcouplers.

Each radio control system operateson a licensed frequency in the 72–76 MHz or the 450–470 MHzbands. The receiver is crystal con-trolled. A synthesized 72–76 MHzreceiver is also available.

Benefits• Easy to Maintain — Self diagnos-

tics identify problem areas via thestatus display.

• Fast Response — High Speed datarate offers fast, responsive operation.

• Frequency Conservation — Up tofour systems can share the sameradio frequency, which also saveson spare parts requirements.

• Cost Reduction — Operating crewis reduced on each shift. Paybackis realized in just a few months.

• Better Visibility — Remote controltakes the operator out of the cabproviding him with improved visibil-ity and total control from grade level.

• Simple Operation — Portable,lightweight transmitter is easier tooperate than manual controls.

Brochure 31200November 1996

New

Receiver Cabinet

Pneumatics Cabinet

Midsize Transmitter(See Spec 31110)

FeaturesMicrocomputer

Hubbell’s system uses asingle board micro com-puter which converts thebiphase data from the ra-dio receiver, decodes andverifies the message bychecking for errors. Thecomputer generates thecontrol outputs to the l/Ointerface boards. The ad-dress and message timeinterval is user program-mable. A hardwarewatchdog timer monitorsthe program operationand resets the processor ifthe program fails to exe-cute properly.

On-Board Diagnostics

The computer board em-ploys continuous diagnos-tics. System status is dis-played on a two digit al-pha numeric display.Upon power-up, the initial-ization test checks the I/Oboards, internal randomaccess memory (RAM), themotion controlling solidstate relays, and the pneu-matic system.

When a fault is detected,the computer will stop thelocomotive and the errorwill be displayed. Thefault must be correctedbefore operation cancontinue.

After initialization, the

watchdog circuit, the solidstate relays and the pneu-matic functions are contin-uously monitored. Any op-erational, communicationsor run mode faults willshutdown the locomotive,apply the brakes, and dis-play a fault code.

Input/Output Board

The l/O board acceptsthe control outputs from themicrocomputer and con-verts them into driving out-puts for the solid state re-lays. The l/O board alsoaccepts input from the sol-id state relays feedbackcircuits and provides thisinformation to the controllerfor diagnostic purposes.

Emergency Stop Board

The Emergency Stopboard monitors the Emer-gency Stop pushbuttonsmounted in the locomo-tive, the main air reservoirpressure, oil pressure, andcoolant water tempera-ture. If any of these func-tions are abnormal, a sig-nal is given to the micro toshut down the locomotiveand apply the brakes.

DC Solid State Output

Each solid state relayboard has eight circuits todrive the 24VDC interfac-ing relays and solenoidvalves to control the loco-motive functions.

Electro-MechanicalRelays

Electro-Mechanical Relaysare used to control loco-motive direction, throttle,head lamps, and Linternlights. The Lintern lightsprovide operations statusinformation for the remoteoperator.

Sensing Boards

Each sensing board moni-tors up to eight solid staterelay outputs and/or pres-sure switches. This pro-vides complete feedbackto the micro on relay andpressure switch status.

Receiver Cabinet

The electronics cabinet isof NEMA 12 constructionand houses the powersupply, the radio receiver,digital decoding logiccards, solid state driversand the output relays.

The receiver, digital logicdecoding circuits and thesolid state drivers pluginto common card cag-es. Edgemounted LED’son the circuit boards sim-plify system troubleshoot-ing and maintenancetasks. All modules are re-movable from the frontand the card cage ishinged to provide accessto backplane wiring.

Solid state drivers or out-put relays operate the lo-

System FeaturesSecure Control — Hubbell’s biphase data transmis-sion scheme and Cyclic Redundency Check code(CRC) prevent false motions and provides for con-trolled shutdowns. Digital messages are checked foraddress, format, and content before any motion orfunction is activated. While in motion, check circuitscontinuously monitor the received message and thequality of the RF carrier signal. Any error or loss of sig-nal integrity will de-energize all controlled functionsand apply the brakes.

Frequency Conservation — It is possible to have sev-eral transmitters operating in the same area, on thesame frequency, with practically no interference be-cause of different transmission rates for each transmit-ter. The unique address code of each transmitter andreceiver assures that only the matching receiver re-sponds to the radio commands. All other signals onthe same frequency are ignored.

“QSR” Design — Hubbell’s Quality, Serviceable, Reli-able product design philosophy is evident with the Lo-comotive Control System. Protective circuits are em-ployed to prevent transients or extreme voltage fluctua-tions from damaging components. The modular, solidstate design, housed in NEMA 12 enclosures, pro-vides reliable operation and long service life underthe most rugged and extreme conditions. Spares re-quirements are significantly reduced by virtue of theshared frequency capability and modular design.

Efficient and Flexible — The high speed data trans-mission technique provides faster and thereby moreresponsive operation. A lightweight, durable plastictransmitter is comfortable and easy to operate. Amanual/remote transfer switch can be provided forisolation between the manual and remote controlcomponents.

Security of the received signal and any resulting con-trol actions are safeguarded as follows:

• The received signal must be of the properfrequency.

• The received message must have the proper ad-dress and must be in the correct format.

• The receiver calculated CRC code must be identi-cal to the CRC code calculated by the transmitterand sent as part of each message.

• The preceding items must be met and all transmitterlever switches must be centered before the locomo-tive can be activated and the brakes released.

• To continue or change an energized function, re-quires the receipt of a “valid message” prior totime-out of the message timer (2 sec). If no validmessage is received, the system turns all outputsoff and applies the brakes.

• Two separate “watchdog timers” assure that alloutputs are switched off in case of a receivermalfunction.

HUBBELL

SpecificationsSupply Voltage ......................... 12VDC, 24VDC, 36VDC or 72VDC

Internal Power Requirements ........ +11.9–13.1VDC & +4.5–6.5VDC

Operating Temperature .............. –22°F (–30°C) to 140°F (+60°C)

Radio Receiver

Frequency Range ...................... 72–76 MHz or 450–470 MHz

Channel Availability .................. as required by user

Frequency Stability .................... ±5 ppm

Sensitivity ................................ 1 µv @ 20 dB quieting

Data Reception ......................... compatible with existing transmitters

Modulation .............................. biphase

Baud Rate ............................... 4800 bps

Message Format ....................... preamble, sync pattern, start flag, address, control, CRCcheck code

Control SectionSingle board computer consisting of 80C31BH controller, 64k EPROM, EPLD containing cir-cuits for message synchronizing, and processor watchdog

Switches ................................. 8 position address dip, 4 position message timer dip

Indicators ................................ 2 digit display (7 segment LED) for self diagnostics & errorconditions

Firmware ................................. written in 8031 assembly language structured for ease ofcustomization of output control

Functions ................................. message input address decoding, error checking, controlbit decoding, output control self diagnosis

Paralleled I/O ......................... basic system uses single board, up to three additionalboards may be added

Output per board ...................... 48 software programmable for input or output withreadback on all outputs

Driver per output ....................... TTL compatible for up to 25mA sink

DC Output SectionSolid state relay PC boards in card cage.

Type ....................................... Opto Isolated

Indicators ................................ Red: output activated

Output Voltage ......................... 24VDC

Input Voltage ............................ 4.5–6.5Vdc, active high

Load ....................................... 0.5A, 24VDC, inductive

Isolation .................................. 1500V

Input BoardInput 24 VDC sensing PC board in card cage.

Indicator ................................. Red: input activated

Input ....................................... 24VDC nominal

Isolation .................................. 1500V input to output & between circuits

Output .................................... Opto-isolated; active low

comotive magnetics andpneumatic systems in re-sponse to decoded controlcommands. The configura-tion of the manual controlswitches is duplicated andwired to industrially ratedterminals for interconnec-tion to the locomotive con-trols. A manual-remotetransfer switch is providedto completely isolate theradio system from the man-ual controllers.

The receiver antenna isnormally mounted on thelocomotive cab, and suffi-cient co-axial cable is pro-vided to connect the an-tenna to the radio receivermodule in the cabinet.

Pneumatic Cabinet

The pneumatics enclosureis of NEMA 12 construc-tion and houses the pneu-matic controls for the re-mote operation of the lo-comotive. The locomotivethrottle, independentbrakes, and the train linebrakes are normally oper-ated via binary pneumaticvalves for control of the airpressure. Other functionsand the horn are con-trolled by solenoid valves.This cabinet also containsthe pressure switches formain air, independentbrakes air, train linebrakes air, and throttle air.

Hubbell Offers• Factory Assembled — the transmitter, receiver,

and pneumatics cabinets are completely as-sembled and wired at the Hubbell factory.

• System Test — the entire system is tested for aminimum of 48 hours prior to shipment.

• Installation and Commissioning — Installationis accomplished quickly. Transfer switch ispre-wired and labeled, interconnecting termi-nals are provided to simplify installation. AHubbell field engineer can be contracted forinstallation and final check-out.

• Customer Support — Hubbell provides acomplete documentation package includingdrawings, operating manuals, service manu-als, spare parts, training and experienced fieldservice engineers.

Hubbell Industrial Controls, Inc.a subsidiary of Hubbell Incorporated

50 Edwards Street, Madison, Ohio 44057Telephone (440) 428-1161 • FAX (440) 428-7635

JPS-1196-.5M © 1996Printed in U.S.A.

HUBBELL 4301 Cheyenne Drive • Archdale, NC 27263(336) 434-2800 • Fax (336) 434-2801

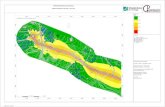

KeyComponentsCrane mounted NEMA 12receiver cabinet with powerconverter, radio receiver, mi-cro controller board, Input/Output board and solid stateoutput relays.

1. NEMA Type 12Receiver Cabinet

2. Radio/Micro CardCage

3. Micro ControllerCard with two digitdisplay.

4. Input/Output Card5. RF Receiver Module6. IF Receiver Board7. Data Demodulator

Board8. Solid State Relay

Board9. Fuse Blocks10. Relay Panel11. Terminal Blocks for

Interconnection12. Low Voltage Power

Supply Panel13. Transfer Switch

Local/Radio14. Pressure Switch15. Pressure Gauge16. Terminal Boards17. Air Cutoff Valve18. Binair Valve19. Pneumatic Valves20. NEMA Type 12

Pneumatics Cabinet

Microprocessor Locomotive ControlPneumatic Power Pack

24.00" 12.00"1.16"

30.0

0"

24.00" 12.00"1.16"

24.0

0"