Bomba Probiomed 2

-

Upload

benjamin-villegas -

Category

Documents

-

view

220 -

download

0

Transcript of Bomba Probiomed 2

-

8/3/2019 Bomba Probiomed 2

1/36

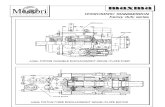

DurcoMark III ANSI

Process Pumps

ALLOY PUMPS

ANSI Standard

Lo-Flo

Sealmatic

Unitized Self-Priming

Recessed Impeller

Bulletin P-10-500c (E)

Rotating Equipment Division

-

8/3/2019 Bomba Probiomed 2

2/36

Pumps delivered worldwideare manufactured in Flowservefacilities, certified either to

ISO 9001 or to 9002.

Quality System Certificate

Rotating Equipment Division

Mark III

ANSI StandardPump

Features/Enhancements

Heavy-duty chemical service

pumps are world renowned fortheir reliability and durability.

Improved pump reliability and

extended MTBPM are achieved withexclusive features like the uniquereverse vane impeller, SealSentry

seal chambers and many othertechnological advancements.

Mark III Standard/4-5

Performance Curves/6Interchangeability/7

PumpSel DurcoPump Selection Guide/7

Power Ends/8-9

Seal Chambers/10-11

Impellers/12-13

Shaft Design/14

Baseplates/15-17

C-Flange andOther Options/18-19

Safety and InspectionOptions/20-21

Mark IIILo-FloPump

Radial vane impeller with circularconcentric casing is specifically

designed for high head/low flowapplications.

Lo-Flo/22-23

Durco Mark IIIANSI Process

Pumps

-

8/3/2019 Bomba Probiomed 2

3/36

Rotating Equipment Division

Mark IIISealmatic

Pump

Mark III

Self-PrimingPump

Dynamically sealed pumpeliminates the need for

conventional mechanical seals.

Sits high and dry, reduces costs

of vertical pump options andsimplifies maintenance.

In-Line

High Silicon Iron Chemstar ISO Standard

Guardian

Chemstar MD PolyChem

Power Monitor Genuine Durco pump parts

Durco alloy materials

Sealmatic/24-25

Pumps and Priming

Tanks/26-27

Other Durco Pumps andGeneral Information/30-35

Vortex action assures trouble-freepumping of large diameter solidsand slurry services. Also used to

process shear sensitive products.

Recessed Impeller/28-29

3

Mark IIIRecessed Impeller

Pump

Other Durco Pumps/General Information

-

8/3/2019 Bomba Probiomed 2

4/36

Rotating Equipment Division

4

Durco Mark IIIANSI Standard

Fastest MaintenanceTurnaround Time Micrometer type shaft and

impeller adjustment accuratelysets impeller clearance to rearcover in 20 secondsin theshop or field

Mechanical seals and all criticalsettings can be accurately set inthe shop (See page 9)

A Choice ofPower Ends Standard Mark IIIA power end

with double lip oil seals and topvent/breather or

ANSI 3A power end (shownhere) featuring Inpro VBX bearingisolators and up to a three-yearperformance guarantee(See page 8)

Truest Running ANSI Pump Four precision machined metal-

to-metal fit locations. (Seethru.) Other manufacturersoffer only two or threemachined fits

Precision machined metal-to-metal bearing carrier reducesstack-ups to improve shaftconcentricity

Superior to jackscrew designs

which can cause cocking Extends bearing and mechanicalseal life

1

2

Recognized worldwide as thepremier name in ANSI chemicalprocess pumps

The advanced design andprecision manufacture of therugged, heavy-duty Mark IIIchemical service pump signifi-cantly enhance bearing andseal life.

Flowserve is committed tohelping users maximize meantime between planned main-

tenance (MTBPM).The unique features andenhancements of Durco pumpsprovide significant performancebenefits for pump users.

-

8/3/2019 Bomba Probiomed 2

5/36

Rotating Equipment Division

5

MARKIIIANSISTANDARD

Reverse Vane ImpellerThe only ANSI pump impellerdesign that offers repeatablepump performance throughoutthe life of the pump.

Front Vane Open Style Impelleris also available as an option.(See pages 12 & 13)

SealSentry Family of SealChambers Featuring UniqueFlow ModifiersThe Vaaler Award winning FMdesign provides advanced self-flushing ability to: Extend mechanical seal life Utilize less expensive seal and

flush plan options in most cases Improve pump reliability

(See pages 10 & 11)

The Mark III ANSI Standardprocess pump covers a broadhydraulic range.

Thirty sizes Seven (7) Group I Sixteen (16) Group II Seven (7) Group IIICapacities 60 Hz To 7400 gpm (1680 m3/h) 50 Hz To 6120 gpm (1390 m3/h)Heads 60 Hz To 985 ft (300 m) 50 Hz To 655 ft (200 m)

(See pages 6-7 forperformance data and

component interchangeability.)

Enhancements have beendeveloped to offer superiorperformance and reliability.(See pages 9 thru 21)

An important element ofFlowserve quality is a full menuof superior materials cast to thehighest quality standards.(See page 7)

3

4

-

8/3/2019 Bomba Probiomed 2

6/36

-

8/3/2019 Bomba Probiomed 2

7/36

The thirty pumps in the Mark IIIfamily are built with only threedifferent power frames.

MARK III Standard Group II

POWEREND

REARCOVERS

ADAPTERS

REVERSEVANE

IMPELLERS

FRONTVANE

OPENSTYLE

IMPELLERS

CASINGS

3X2-8

4X3-82X1LF-10

2X1-10A

3X11/2-10A

3X2-10A

4X3-10

4X3-10H

6X4-10

6X4-10H

3X11/2LF-13

3X11/2-13

3X2-13

4X3-13

4X3-13HH

6X4-13A

OR

Mark III Standard Group II

Rotating Equipment Division

Durco Mark IIIInterchangeability

7

MARKIIIANSISTANDARD

POWEREND

REARCOVERS

REVERSEVANE

IMPELLERS

FRONT

VANE

OPENSTYLE

IMPELLERS

CASINGS

11/2X1LF-4

11/2X1-6

3X11/2-6

3X2-6

11/2X1LF-8

11/2X1-8

3X11

/2-8

OR

POWEREND

REARCOVERS

ADAPTERS

REVERSEVANE

IMPELLERS

FRONT

VANE

OPENSTYLE

IMPELLERS

CASINGS

8X6-14A

10X8-14

6X4-16

8X6-16A

10X8-16

10X8-16H

10X8-17

OR

Mark III Standard Group III

Mark III Standard Group I

SealSentry provides a choice offive different seal chamberoptions to best meet your

specific needs.

PumpSelThis accurate pump selectionsoftware program is availablefrom your local sales represen-tative. This software assures

correct sizing and selection ofpumps and magnetic couplingsto best suit your processapplication needs.

PumpSel also aids in checkingthe suitability of existing pumpswhen process requirementschange.

-

8/3/2019 Bomba Probiomed 2

8/36

Flowserve offers a choice of twopower ends: the standard MarkIIIA; or the optional ANSI 3A

(shown below).

Standard Mark IIIA power endsfeature: Double row angular contact

outboard/single row, deepgroove inboard bearings forexcellent axial and radial loadsupport

Double lip oil seals Top mounted vent and oil filler Trico oiler Large one inch (25 mm)

diameter reflective sight glass Micrometer adjustment Optional oil slinger

Rotating Equipment Division

Durco Mark IIIPower Ends

8

ANSI 3A power end is soadvanced it carries a three-year MTBPM guarantee.

Certified clean roomassembly

Inpro/Seals VBX non-contact Vapor BlockBearingIsolator keeps lubricants inand contaminants out

Magnetic drain plug collectsmetallic contaminants

Top vent replaced with plug Lubrication options

Synthetic lubricants canallow up to three years

between oil changes

Oil mist systems Shielded and grease

lubricated bearings

(two-year MTBPMguarantee)

Note: Adherence to properinstallation, operation andmaintenance program isnecessary for three-yearMTBPM guarantee.

Flowserve is the only pumpcompany in the world that

can commit to deliver allpower ends assembled ina clean room.

Unique, external micrometershaft adjustment Accurate impeller clearance

setting in 20 seconds Superior to jackscrew

designs as perpendicularityis maintained through metal-to-metal fit inherent withmachined threadconstruction

Threads protected withO-rings

Metal-to-metal construction

assures a true runningand concentric shaft,extending bearing andmechanical seal life.

Ductile iron frame adaptermeets ASME B73.1.

Large, one inch(25 mm) diameterreflective sight glassto accurately gaugeoil level.

Magnetic drainplug (optional).

Rigid foot design.

.010"

-

8/3/2019 Bomba Probiomed 2

9/36

Unique ExternalMicrometer ImpellerAdjustment

It reduces maintenancetimeand, most importantly,is precisely accurate.

Simply loosen the setscrews.Using a wrench rotate thebearing carriercounterclock-wise until the impeller lightlytouches the rear cover plate.

Select the impeller setting.Each notch on the carrier ringrepresents exactly 0.004 in(0.10 mm) of clearance. For animpeller setting of 0.020 in(0.5 mm) count five notchescounterclockwise.

Move the bearing carrierclockwise the selected numberof notches. Tighten thesetscrews and check theimpeller clearance with thefeeler gage.

The Heart of the Pump:Shaft and Bearing Design

Flowserve offers the largestshaft and bearing componentsavailable in standard ANSIpumps. The following com-parison of a Durco Group IIpower end with that of a majorcompetitor demonstrates thebenefits of heavy-duty design.

Bearings (see Table 1)Greater load handling ratingmeans extended MTBPM.

Extended bearing lifecomparison is the ratio of theload ratings to the third power,or:

I.B.= 13,4003

=1.59 (+59%)11,900

O.B.=19,200 3

=1.61(+61%)16,400

Shafts (see Table 2)Solid shafts are recommendedover shaft sleeves because theyreduce the harmful effects ofdeflection and vibration. Whileshaft sleeves may simplifymaintenance, solid shaftsreduce it.

Proper selection of wet endmaterials of construction andmechanical seal design offset

positive features of the shaftsleeve option.

The formula I=L3/D4 offers anindex of deflection to comparepump designs where:I = index of deflectionL = length of shaft overhang

from bearingD = rigid shaft diameter

Note: The Deflection Index pro-vides an approximate comparisonof shaft stiffness. A detailed

analysis should be made todetermine actual shaft deflection.

Flowserve 711/16 in 17/8 in 37 11/2 in 90(189 mm) (48 mm) (38 mm)

MajorCompetitor 83/8 in 13/4 in 63 11/2 in 116

(213 mm) (45 mm) (38 mm)

Table 2Deflection Comparison

Flowserve 6310 13,400 lb 5310 19,200 lb(6,078 kg) (8,709 kg)

MajorCompetitor 6309 11,900 lb 5309 16,400 lb

(5,398 kg) (7,439 kg)

Table 1Bearing Comparison

43-252% greater stiffness,indicated by lower index numbers,results in longer MTBPM.

Durco bearings are designed tolast up to 61% longer.

Group II I.B. Dynamic O.B. Dynamic

Bearing Load Rating Bearing Load Rating

Group II Overhang Solid Shaft Deflection Shaft DeflectionLength Diameter Index w/sleeve Index

Rotating Equipment Division

Durco Mark IIIHeavy Duty

Shaft andBearings

9

FEATURES/ENHANCEMENTS

-

8/3/2019 Bomba Probiomed 2

10/36

Winner of the Vaaler Awardfor design innovation.

Durco SealSentry family ofseal chambers offers threeFM (flow modifiers) models

and two cylindrical bore(CB) options. There is aSealSentry chamber to bestmeet your application needs.

Rotating Equipment Division

Durco Mark IIISealSentry

Chambers

10

FMSSame as FML but accommodatesseals withsmallgland bolt andgasket circles: Single seals with all seat

mounting configurations can beinstalled

This design is our secondaryrecommendation to the FML

FMICast-in integral gland is wellsuited for: Single internal, flexibly

mounted seals Sanitary-type

applications Utilizes sleeve for seal

setting and fast installation

CBLOversize, cylindrical step boredesigned for seals withlargeglandbolt and gasket circles: Dual internal component seals

isolate the seal chamber from theprocess with external sourceflush

Single seal with throttle bushingand flush to boost pressure overflash point

CBSCylindrical bore designed forpacking arrangements andconventional seals withsmallgland bolt and gasket circles

FMLPreferred selection in mostapplications. Designed for sealswithlargegland bolt and gasketcircles: Single internal cartridge seals Dual internal/external cartridge

seals Single internal component seals

with flexibly mounted seats Dual internal true tandem

design cartridge seals

-

8/3/2019 Bomba Probiomed 2

11/36

Advanced FM SealSentryDesign Technology Self-Flushing

Self-Venting Self-Draining

Seal life is extended due tosuperior purging of heat, solidsand vapors. Single seals canoften be selected where dualseals or external flush andthroat bushing combinationshad been used, such as onsolids, slurry and liquorservices. Flush plans 11, 32,52, 53, etc. can be eliminated.

Costs are reduced. Pumpreliability is increased.

Flow Modifiers ExtendMechanical Seal MTBPM Flow modifiers redirect flow

from circumferential to axial Balanced flow with low

pressure drop in the chamberhelps keep solids in suspension,minimizing erosivecharacteristics of the process

A mechanical seal creates acentrifuging action away fromits parts and into the returningflow path of the process liquid

Solids and slurry merge in thereturning flow path and areflushed out of the seal chamber

Rotating Equipment Division

Durco Mark IIISealSentry

FM SeriesSeal Chambers

11

The FM (flow modifiers)series features an enlarged,tapered bore with cast-inflow modifiers.

FEATURES/ENHANCEMENTS

Jacketed Seal ChamberDesigned for effective heattransfer in the seal chamberarea or across the entire sur-face area of the process fluid.

Jacketedstandard bore(CBS) whencooling the sealchamber is theobjective.

Jacketed FMchamber ispreferred whenprotection ofthe processtemperature isimportant.

Maximizing seal life involvesproper selection of the sealchamber and seal and gland

combination. Generally, the sealfaces should be located directlyin the flush path.

For SealSentry video and proofof performance contact yourlocal Flowserve sales office.

-

8/3/2019 Bomba Probiomed 2

12/36

For Low Flow and/or HighHead Applicationssee pages 22 and 23.

Exclusive reverse vane impellerwith balance holes offersimportant performance enhancing,maintenance reducing advantages.

Front vane open style impelleris fully interchangeable with thereverse vane impeller. Excellentchoice for stringy and certainapplications requiring highshear against the casing.

In-shop impelleradjustmentpractical aswell as productive! Rear cover

wear surfaceversus casingmeans lowerreplacementparts costs.

Low predictable sealchamber pressuremeans longer seal life. Clearance is set to the

rear cover in the shop not to the casing which isleft in the piping.

Lowest overallrequired NPSH ofany standard pump.

Rotating Equipment Division

Durco Mark IIIImpellers

12

Durco reverse vane impellersdeliver unequalled efficiencyand performance. This exclusive

impeller design extends bearingand seal life.

Low, predictable sealchamber pressure and thrustloads resulting from backvane pumping action andbalance holes

Low required NPSH, lowestoverall of any standard pump

Rear cover plate wearsurface as the flow path exitsthe rear of the impeller,

placing abrasive wear on therear cover rather than themore expensive casing

Note: Recessed impellerpumps offer excellentsolids handlingcapabilities.See page 28.

In-shop impeller adjustmentwith the only impeller designthat takes full advantage of the

back pull out feature. Since thecritical running clearance is setbetween the rear of the impellerand the rear cover plate, bothimpeller and mechanical sealsettings can be done in theshop, on the bench, instead ofunder adverse field conditions

Repeatable performanceassurance with the only impellerdesign that offers repeatabilityin seal chamber pressure and

bearing thrust loads

-

8/3/2019 Bomba Probiomed 2

13/36

Rotating Equipment Division

13

Only Durco reverse vaneimpellers offer repeatableperformance after wear andimpeller adjustment.

Performance Life Cycle:Durco Reverse Vane Impellerwith Balance Holes

Effects of Wear Thrust loads decrease as seal

chamber gap widens Chamber pressure increases as

gap widens

Effects of Impeller Adjustment toSeal Chamber Original pressures and loads

re-established after adjustment Repeatable MTBPM cycle life

Reverse Vane Impeller

An impeller cannot be adjustedto twolocations.

Seal and bearing life arereduced due to increased loadsafter wear and maintenanceadjustment.

Performance Life Cycle:Front Vane Open StyleImpeller with Pump Out Vanes

Effects of Wear Thrust loads increase as seal

chamber gap widens Chamber pressure increases

as gap widens

Effects of Impeller Adjustmentto Casing Chamber pressures and

bearing loads increase aftereach adjustment

Non-repeatable MTBPM

cycle lifeFront VaneOpen Style Impeller

The reverse vaneimpeller has only one setof pumping vanes and

one critical tolerancelocation between theimpeller and rear cover to establish: Performance Efficiencies Seal chamber pressures

(i.e., mechanical sealMTBPM)

Thrust/axial loads(i.e., bearing life)

Since an impeller can onlybe set in one direction, thereverse vane impeller hasinherent advantages.

The front vane openstyle impeller has twosets of pumping vanes

and two critical tolerancelocations: The front vane of the

impeller clearance tothe casing establishes: performance efficiencies

The impeller pump outvanes clearance to therear cover establishes: seal chamber

pressures and

seal life thrust loads andbearing life

ReverseVaneImpeller

Adjustment

FrontVaneImpeller

Adjustment

FEATURES/ENHANCEMENTS

Only OneToleranceImpeller VaneTo Cover

PumpOutVanes

PumpPerformanceVanes

-

8/3/2019 Bomba Probiomed 2

14/36

Shaft Material Choices

Standard: investmentcast or high alloy barstock available in a widerange of materials,including proprietaryDC8 and SD77 wet ends.

DC8 and SD77 offersuperior corrosionresistance and hardness

to minimize shaft fretcorrosion and maximizeshaft wet endperformance. DC8 a cobalt base

alloy with chromiumand molybdenum

SD77 or Superchlor

is a high silicon ironalloy

Flowserve recommends theuse of solid shafts rather thanshaft sleeves to reduce theharmful effects of deflectionand vibration. Shaft sleevesmay simplify maintenance butsolid shafts reduce it.

Rotating Equipment Division

Durco Mark IIIShafts & Sleeves

14

Accurate machining underbearings ensures perfect bearingfits without vibration or hotrunning.

Run-out of

-

8/3/2019 Bomba Probiomed 2

15/36

Extend MTBPM AtReduced Cost

Flowserves family of pre-engineered baseplate designsfurther extends MTBPM byreducing internal pump stressand vibrations. That is whyFlowserve recommendsreinforced rigid baseplates.

Plus, customers who know thevalue of pre-engineered and

BaseLine offers five (5)standard types (A through E)of baseplate designs.(See pages 16 & 17)

Rotating Equipment Division

Durco Mark IIIBaseLine

Pre-EngineeredBaseplateDesigns

15

reinforced baseplates help avoidpotential confusion in specifica-tion interpretation, delays in

shipments and added costs.BaseLine offers a broad rangeof metal and non-metallic, groutand stilt mounted designs andstandard options. This providesbroad flexibility in choosing thebaseplate that best meets applica-tion needs and operating budget.

1 Machined coplanar mounting surfaces to O O O O O O Y0.002 in/ft (0.17 mm/m) with 125 in (3.2 micron) finish

2 Added structural (cross member) support N N Y Y Y Y Y

3 Added torsional support with end caps NR Y Y D O O Y

4 Tapped holes for four (4) motor adjuster bolts O O O Y O O Y

5 Four (4) - SS transverse jack bolts - motor adjusters O O O Y O O Y

6 Sloped surface to an integral drain N N C N N N Y

7 Integral sloped drip rim around base N N N N N Y Y

8 4 in (102 mm) diameter grout holes -max. 30 in (762 mm) run to vent Y Y Y N Y Y Y

9 1/2 in (13 mm) vent holes at corner of each chamber NR O NR NA Y Y Y10 Lower surface shaped to anchor in grout N N N NA Y Y Y

11 Integral lifting eyes at four (4) corners O Y O O Y Y Y

12 Tapped leveling holes four (4) corners O O N S Y Y Y

13 Continuous seam weld construction NA Y NA O Y Y Y

14 Welded raised lip around grout hole(s) NR NR NR NA NR NR O

15 Stilt mounting options with floor cups NR NR O Y D D D

16 Spring mounted load designs NA NA O O D D D

17 Catch basin (304SS or other materials) O O O O O NR Y

18 Option for eight (8) total motor adjusters D D O D D D D

19 Dimensions to ANSI B73.1M-1991 Y Y Y Y Y Y Y

Y = Standard N = Not available NR = Not recommended D = Needs design timeO = Optional NA = Not applicable C = Sloped catch basin with 1 inch (25 mm) drain (option) S = Stilts for leveling

See pages 16-17 for BaseLine model descriptions

Item Standard Options Type A Type B Type C Type D Type D Type ENo. Gp I & II Gp III with Rim

FEATURES/ENHANCEMENTS

-

8/3/2019 Bomba Probiomed 2

16/36

Rotating Equipment Division

Durco Mark IIIBaseLine

Baseplate System

16

Type AStandard ANSI baseplate;foundation or limited stressstilt mounted.

Type BPolybase baseplate;foundation or stilt mounted.

Type CReinforced baseplate; stiltmounted.

Type DReinforced baseplate; foundationmounted; with optionaldrip rim.

Type EHeavy-duty, foundation mountedbaseplate; complies with PIP

RESP 002.

Reducing internal stressand vibration extendsMTBPM of pump/motorpackages.

Pump users specify rigidbaseplate designs to: Provide torsional lateral

and longitudinal rigidity Improve vibration

dampening through

greater mass anddesign stiffness Protect against transit

damage Resist twisting during

installation Maintain designed-in

shaft alignment Reduce installation and

shaft alignment time Reduce diaphragming

or separation fromgrout

Improve pump/motor/seal MTBPM

Reduce total life cyclepump/motor/seal costs

BaseLine can handle thestress. Rigid designbegins with thick plateconstruction.

Metal baseplate sizes: 139 to 258 feature

1/2 in (13 mm) steel

plate construction

264 to 280 feature 5/8 in(16 mm) steel plateconstruction

368 to 398 feature 3/4 in(19 mm) steel plateconstruction

Polybase baseplates areconstructed of 3 in (76mm) to4 in (102mm) solid polymerconcrete. Baseplate types B, C,D and E are reinforced withadded structural support forimproved rigidity.

Flowserve offers a family of fivetypes of pre-engineeredbaseplate designs to extend

MTBPM and reduce costs.

-

8/3/2019 Bomba Probiomed 2

17/36

Rotating Equipment Division

Durco SolidPolymer Concrete

Polybase

17

Featuring Durco SolidPolymer ConcretePolybase and Polybloc

Adjustment System

Polybloc MotorMounting Block

Flatter and morerepeatable heighttolerances than steel

Corrosion resistant

Superior vibrationdampening

Full foot support(no overhang)

Shown with optionalbloc-lock and fastenersupport

Available for otherpump/motor oralternate equipmentapplications

8-Point Adjuster

Allows precise motoradjustment to reducealignment time

Used with recessedbloc-lock device

Baseplates Provide TheBackbone for ExtendedMTBPM

The test stand provided threecorner support of the ungroutedbaseplates. The addition ofweights on the unsupportedfourth corner caused baseplatedistortion. This distortionresulted in measurable shaftmovement that can causeproblems with field installationsand negatively affect MTBPM.

The twist testis a means ofcomparing rigid baseplatedesigns. Correctly installedrigid baseplates should notexperience these twist effects.For more information about theresults of baseplate testingcontact your local Flowserve

sales representative.

Type B Polybase baseplate

Polybase

Low installed cost

Superior vibration dampening

Corrosion resistant

Superior resistance totwisting or diaphragming

Designed to be flat

Available with or withoutcatch basins and grout holes

Inserts can be located tomount alternate equipmentconfiguration requirements

Vibration damping of polymerconcrete versus cast iron.

Cast Iron0.125 Sec.

Polymer Concrete0.125 Sec.

John F. Kane, Composites Institute,The Society of the Plastics Industry, Inc.

Baseplate Rigidity Test Twist Mode

0.070 (1.78)

0.060 (1.52)

0.050 (1.27)

0.040 (1.02)

0.030 (0.08)

0.020 (0.51)

0.010 (0.25)

0.000 (0.00)

A

D

E

B

C

0 100 200(45) (91)

Load - lb (kg)

Deflection

inch(mm)

Type A 0.022 in (0.56 mm)

Type B 0.004 in (0.01 mm)

Type C 0.003 in (0.08 mm)

Type D 0.016 in (0.41 mm)

Type E 0.005 in (0.13 mm)

Maximum Parallel ShaftDeflection At Applied Force

FEATURES/ENHANCEMENTS

-

8/3/2019 Bomba Probiomed 2

18/36

Rotating Equipment Division

Options to SolveApplication

Problems

18

Adjustable RigidFoot Mount Assures accurate alignment to

the baseplate and piping Designed to support all normal

loads

Standard Footed Motors Special machine-cut C-Face of

assembled unit ensures shaftperpendicularity

Motor is cantilevered, or freehung (Footed design providessupport during shipping.)

Tested and proven through405TC frame to 100hp (75kW)to ensure rigid assembly and

freedom from excessivevibration and deflection

To extend MTBPM, uniquedesign technologies and com-ponent options with superior

pump application, installation,process and selection know-how are all necessary.

Certain applications needtechnical advancement in pumpdesign and performance en-hancing options to stay reliable.

Flowserves Unique C-PlusPrecision Alignment System(Four Point)To achieve the best processpump and motor MTBPMrequires shaft alignmentsof less than 0.002 in (0.05 mm).Flowserves unique C-PlusPrecision Alignment Systemroutinely delivers shaft alignmentsbelow 0.002 in (0.05 mm) in lessthan thirty minutes.

Ultralign Heavy-Duty/ RigidDesign C-Flange Adapter Cantilevered motor shaft stays

aligned with pump shaft evenwith undesirable movementcaused by piping and tempera-ture induced stress loads

Eliminates foot mounting ofmotor and pump power end tothe base. This greatly reducessoft foot and problems fromundesired baseplate twistingand diaphragming

0.007 in (0.18 mm) nominalparallel shaft alignment0.002 in (0.05 mm) with C-Plusprecision alignment option

-

8/3/2019 Bomba Probiomed 2

19/36

Motor and Bearing HousingFoot Mounting To Base IsNot Required OrRecommended Reduces soft foot potential Helps eliminate alignment

distortion caused byfulcrum effect of soft footbolting to the base

Optimizes the ability of theC-Flange design to movethe motor with the pumpshaft, maintainingalignment

Jacketed CasingsProvide temperature control.Either integral (as shown) orbolt-on jackets available.

Centerline Mounted CasingsMay be used to reduce loadscaused by thermal expansion.Jacketed feet with inlet/outletports further assure effectivetemperature control.

For Low Flow and/or HighHead Applicationssee pages 22 and 23.

Stilt Mounted Baseplate Provides relief of external pipe loads

by allowing the assembly to move tothe point of least resistance

Stilts can allow for improved pumpalignment to process pipe

Spring Load Option -Reduces the need for pipe loops or

expansion jointsAllows the pump to adjust to fluc-

tuating discharge pipe loads causedby changing process temperatures

Absorbs vibration

Rotating Equipment Division

19

FEATURES/ENHANCEMENTS

-

8/3/2019 Bomba Probiomed 2

20/36

This transparent, polycarbonateshield provides protection fromthe dangers of:

Process fluid spray Rotating shaft and sealcomponents

This splash and shaft guardis a one-piece shield thatenvelops the open areasbetween the bearing housingand the casing.

Fluid spray from a mal-functioning seal is deflectedby the shield

The shield protects fingersand clothing from exposure

to the rotating shaft Its transparency permits

visual inspection of theseal area

Constructed of UV-protectedpolycarbonate

Optionally available in PVDF

Applications from -70F(-57C) to 300F (149C)

Available for Mark II, Mark IIIand Chemstar pumps

Protected by US patentnumber 5,807,086

Rotating Equipment Division

DurcoShield

Pump Safety and

InspectionAccessory

20

DurcoShield is easy to install orto remove. Simply spread theshield apartfit around thebearing housing adapterandsnap into place. The spring-liketension holds the shield firmly inplace. No tools or fasteners arerequired.

Note:

DurcoShield is not a containmentsystem, nor a seal backup system.It is a limited protection device. Itwill reduce, but not eliminate, theprobability of injury.

Slots or holes to accommodateseal support piping/tubing can beeasily located and drilled or cut.

-

8/3/2019 Bomba Probiomed 2

21/36

The Durco ClearGuardpermits visual inspection ofcoupling components while

protecting personnel frompotential safety hazards ofrotating parts.

Constructed of tough, durable,transparent polycarbonatewith ultraviolet light inhibitors

Tinted yellow to alertpersonnel to potentialsafety hazard

Early Warning

The ability to inspect thecoupling through ClearGuardcan provide early warning ofdeteriorating or malfunctioningcomponents. It also permitsuse of a stroboscope to easilymeasure shaft rotation speed.

Global Application

ClearGuard meets machineryguard safety guidelines.Nothing larger than 6 mm(0.24 in) in diameter can enterthe shell.

Easy Assembly

Two identical shell halves aresecurely held together by thesupport legs and standardfasteners. The assembly isthen attached to the baseplatewith standard fasteners.

Rotating Equipment Division

DurcoClearGuard

Non-MetallicCoupling Guard

21

FEATURES/ENHANCEMENTS

Vented for adequate aircirculation

Non-sparking, corrosion

resistant and paint-free forenhanced safety, appearanceand sanitation

Available for all Durco MarkIII ANSI pumps with NEMAor IEC motors and ChemstarISO pumps with IEC motors

Patent pending

-

8/3/2019 Bomba Probiomed 2

22/36

Rotating Equipment Division

22

Durco Mark IIILo-Flo

Pumps

Expanding Volute Casing

Circular Concentric CasingInternal bypass is drilledthrough the discharge withoutbreaching the casing wall orcreating a potential leak path

Circular concentriccasing and radial vaneimpeller

The unique design ofthese componentsfurther extends MTBPMwhen compared withstandard pumps.

Radial loads arereduced up to 90% atlow flows

Shaft vibration is

reduced up to 50%(see graph)

Bearing life isextended

Mechanical seal lifeis extended

Radial vane impeller isspecifically designed for highhead/low flow applications

The first to introduce an ANSIstandard high head/low flowpump, Flowserve has refinedits design with a circularconcentric casing to complementits radial vane impeller. Theresult has been improvedpump reliability with extendedMTBPM at low flow rates.

Standard Mark IIIApower end maximizesinterchangeability

Optional ANSI 3Apower end shownhere

Conforms tostandard ANSIdimensions

Offered in awide selectionof metallurgy

ApplicationsUsed throughout theprocess industries forgeneral purpose applicationsrequiring high heads withlow flow rates.

-

8/3/2019 Bomba Probiomed 2

23/36

Rotating Equipment Division

23

LO-FLO

Flowserves superior radialvane impeller design provides:

Minimal thrust loads

Reduced NPSH requirements

Low seal chamber pressures Broader applications range

Longer seal and bearing life

Offered in a wideselection of metallurgy.

Four sizes 1K1.5 x 1LF-4 1K1.5 x 1LF-8 2K2 x 1LF-10 2K3 x 1.5LF-13Capacities 60 Hz

To 220 gpm(50 m3/h)

50 HzTo 175 gpm(40 m3/h)

Heads 60 Hz

To 985 ft(300 m)

50 HzTo 655 ft(200 m)

Pressures to 450 psi(3100 kPa)

Temperatures to700F (370C)

(See compositeperformance curvespage 6)

100%

75%

50%

25%

0%0 100 200

0 25 50Lo-Flo

Standard

Flow

Percentofmaximumv

ibration

ofthestandardpump

gpm

m3/h

SHAFT VIBRATION

-

8/3/2019 Bomba Probiomed 2

24/36

Rotating Equipment Division

24

Durco Mark IIISealmatic

Your choiceof three (3)sealingarrangements

Repellerchamber

Repeller

Liquid/airinterface

Stopped Running

Standard Mark IIIAoroptional ANSI 3A power endshown here (See page 8)

Optional ANSI 3A power endoffers three-year performanceguarantee

Available with most of thestandard and optional featuresof the Mark III ANSI Standardpump

Dynamically sealing repellereliminates the need forconventional mechanical seals

No mechanical seal is neededduring operation as centrifugalforce created by a spinningrepeller (expeller) removes fluidfrom the seal chamber. Whenthe pump is stopped, a static sealis used to keep it from leaking.The need for external flushingand process contaminationcontrol are eliminated.

Applications Tough services where sealing

is difficult

Services where a flush isundesirable (e.g., evaporatorfeed)

Continuous, around-the-clockservice

Batch operations where a rundry condition might exist

-

8/3/2019 Bomba Probiomed 2

25/36

Rotating Equipment Division

25

Seventeen Sizes Eleven Group II

2X1M-10A3X11/2M-10A3X2M-10A

4X3M-104X3M-10H6X4M-106X4M-10H3X11/2M-133X2M-134X3M-136X4M-13

Six Group III8X6M-14A10X8M-146X4M-168X6M-16A

10X8M-1610X8M-16HCapacities(Performance similarto Mark III StandardANSI. See page 6.) 60 Hz

To 7400 gpm(1680 m3/h)

50 HzTo 6120 gpm(1390 m3/h)

Heads 60 Hz

To 750 ft (230 m) 50 Hz

To 510 ft (155 m)

Maximum shaftdeflection of less than0.002 in (0.05 mm)

Available in all alloysand all metallic pumpdesigns.

Choice of static sealingoptions: Checkmatic lip seals Flexible graphite packing

and Dry-running end-face seal

options

Standard Mark III reversevane impeller for peakefficiency

Available with recessedimpeller option (See pages28 and 29)

MARKIIISEALMA

TIC

-

8/3/2019 Bomba Probiomed 2

26/36

Durco Mark IIIUnitized

Self-Priming

Rotating Equipment Division

26

Standard Mark IIIAoroptional ANSI 3A power endsshown here (See page 8)

Optional ANSI 3A power endoffers three-year performanceguarantee

Available with most of thestandard and optional featuresof the Mark III ANSI Standardpump

Conveniently located highand dry at ground level whereinstallation is simple and

maintenance more easily andmore economically performed

Costing less to buy, install andmaintain than submersiblepumps, the Mark III self-primingpump is designed to draw fromliquid sources below groundlevel or from sources which haveno positive pressure to naturallyprime the pump. Its compactdesign enables it to fit in tightclearance locationsit can be

easily mounted on a trailer formovement to various pumpinglocations such as wastewaterlagoon service.

Air BleedLine

Applications Sump service Tank car unloading Duplex pumping

lift station

-

8/3/2019 Bomba Probiomed 2

27/36

Eight Sizes Two Group I

1J11/2X1US-6

1K11/2x11/2US-82 Six Group II2K2X11/2US-10A2K3X2US-102K4X3US-10H2K3X2US-132K4X3US-132K6X4US-13A

Capacities 60 Hz

To 1400 gpm(320 m3/h)

50 HzTo 1170 gpm(265 m3/h)

Heads 60 Hz

To 400 ft (120 m) 50 Hz

To 280 ft (85 m)Static Suction Lift To 20 ft (6 m)

Rotating Equipment Division

27

Unitized casing has large primingchamber, air separator and volutein one integral piece.

MARKIIIUNITIZEDSELF-PRIMING

Durco Self-Priming TanksThese can be fitted to all Durcopumps to provide self-primingcapability.

Priming tank options can bespecified for larger capacityand higher heads and special

solids handling applications. Flows to 30,000 gpm

(6820 m3/h) Solids to 4 in (100 mm)

diameterHeads 60 Hz To 985 ft (300 m) 50 Hz To 655 ft (200 m)

Available in alloy andnonmetallic materials.

-

8/3/2019 Bomba Probiomed 2

28/36

Durco Mark IIIRecessed

Impeller

Rotating Equipment Division

28

Available withSealSentry orSealmatic chambers

Trouble-free pumping of solid,stringy or fibrous slurries

Combines the best designfeatures of the Mark III ANSIStandard pump with the vortexaction of a recessed impeller.These specific purpose featuresalong with thick wall, wet endcomponents offer extendedservice life when handling mediatypically too tough for an ANSIstandard pump.

Applications Light slurries

Corrosive/erosive services Large diameter solids Waste streams Fluid where shearing must be

avoided Protection of solids integrity

Standard Mark IIIAoroptional ANSI 3A powerends shown here (Seepage 8)

Optional ANSI 3A powerend offers three-yearperformance guarantee

Available with most of thestandard and optionalfeatures of the Mark IIIANSI Standard pump andthe Sealmatic dynamicallysealed repeller design

Tangential dischargeminimizes turbulence

-

8/3/2019 Bomba Probiomed 2

29/36

Rotating Equipment Division

29

Like the reverse vane, the

recessed impeller sets to therear cover

With only a fraction of themedia contacting the impeller,the vortex action minimizesabrasive wear while maintainingsolids integrity

Stocked in CD-4MCu duplexstainless steel

Available in all standard alloymaterials

Precision cast impeller

Ensures peak energyefficiency and lowNPSHR. Pump out vanesfurther control sealchamber pressure andkeep solids from criticalseal areas. Mechanicalseal and packing lifeare maximized.

Five Sizes

One Group I1J2X2R-6

Four Group II2K2X2R-102K3X3R-102K4X3R-132K6X4R-13

Capacities 60 Hz

To 2000 gpm(455 m3/h)

50 Hz

To 1735 gpm(394 m3/h)

BEP 60 Hz

To 1200 gpm(270 m3/h)

50 HzTo 1135 gpm(258 m3/h)

Heads 60 Hz

To 400 ft (120 m)

50 HzTo 270 (82 m)

Can be specified asself-priming pump withpriming tank option.(See page 27)

MAR

KIIIRECESSEDIMPELLER

-

8/3/2019 Bomba Probiomed 2

30/36

Rotating Equipment Division

30

Durco In-Line andHigh Silicon

Iron Pumps

Durco In-Line

The Durco In-Line ANSI pump,with its own independent

bearing housing and rigidC-flange style motor adapter,remains one of the mostreliable process pump designsavailable.

Nine sizes availableCapacities 60 Hz

To 1580 gpm (360 m3/h) 50 Hz

To 1280 gpm (290 m3/h)Heads 60 Hz

To 460 ft (140 m) 50 Hz

To 315 ft (96 m)

Please see Bulletin P-20-100for more complete information.

High Silicon Iron

Unmatched corrosionresistance of highsilicon iron. ExclusiveSuperchlor compositeshaft provides wear andcorrosion resistance.Five sizes are available.

Capacities 60 Hz

To 900 gpm(205 m3/h)

50 HzTo 750 gpm(170 m3/h)

Heads 60 Hz

To 180 ft (55 m) 50 Hz

To 125 ft (38 m)

For more completeinformation, please seeBulletin P-11-101.

-

8/3/2019 Bomba Probiomed 2

31/36

Durco Chemstar

ISO Standard

Rotating Equipment Division

Recognized worldwide as apremier name in ISO chemicalprocess pumps

Chemstar pumps conform toISO 2858 dimensional and ISO5199 design criteria.

Chemstar utilizes the sameunique features of the Mark IIIANSI pump for maximizing

performance and mean timebetween planned maintenance(MTBPM). Reverse vane impeller SealSentry family of seal

chambers Choice of power ends Fastest maintenance

turnaround time withmicrometer type shaft andimpeller adjustment

Twenty-seven sizes areavailable.Capacities

50 HzTo 400 m3/h(1760 gpm)

Heads 50 Hz

To 160 m (525 ft)

Available in most alloymaterials.

For completeinformation request

Bulletin ISO-10-EC-05/1998.

OTHERDURCOPUMPS/GENERALINFOR

MATION

31

-

8/3/2019 Bomba Probiomed 2

32/36

Rotating Equipment Division

32

Durco Guardianand Chemstar MD

Sealless MetallicMagnetic DrivePumps

Guardian and Chemstar MDpumps utilize the sameimpellers and casings as theconventionally sealed Mark IIIand Chemstar process pumps.

Silicon carbide bearings offerunmatched corrosion andabrasion resistance. Uniquehigh temperature bearingassembly compensates forthermal expansion.

Flowserve ANSI and ISO metallicmagnetic drive pumps are usedwherever process leakage

cannot be tolerated. Zeroleakage requirements include:

Emissions reduction

Toxic services

Flammable liquids

Expensive liquids

Ultrapure services

Difficult to seal liquids

Guardian

Durco Guardian pumpsconform to the ASME B73.1M

(ANSI) dimensional standard.

Chemstar MDDurco Chemstar MD pumpsconform to ISO 2858dimensional standards.

Broad ApplicationRange Temperatures to 550F

(288C) Wide range of alloysfor difficult services

Capacities 60 Hz

To 1650 gpm(375 m3/h)

50 HzTo 1375 gpm(312 m3/h)

Heads 60 Hz

To 705 ft (215 m) 50 Hz

To 490 ft (149 m)

See BulletinP-20-500 for moreinformation.

-

8/3/2019 Bomba Probiomed 2

33/36

OTHERDURCOPUMPS/GENERALINFOR

MATION

Rotating Equipment Division

33

Durco PolyChemNon-Metallic

Sealed andMagnetic DrivePumps

M-SeriesMagnetic Drive Pump Close coupled and long

coupled models Simple design with minimumnumber of parts

Separate inner magnet andimpeller components

Other non-metallicpumps

F-Series

Solid fiber reinforcedepoxy ANSI dimensional

L-Series Fiber reinforced

epoxy/PFA lined ANSI dimensional

S-SeriesSealed Pump Mark III power end features Tapered bore seal chamber

with flow modifiers foroptimum seal performance

Multiple mechanical sealingoptions available

Designed to global standardsfor superior performance andeconomy in highly corrosive

applications.

Available in ANSI, ISO and JISconfigurations

Global application Parts continuity

Fluoropolymer PFA linedwet end Superior corrosion resistance Temperatures to 300F

(150C)

Capacities 60 Hz

To 750 gpm

(170 m3

/h) 50 HzTo 625 gpm(140 m3/h)

Heads 60 Hz

To 450 ft (135 m) 50 Hz

To 310 ft (95 m)

Capacities 60 Hz

To 1400 gpm (320 m3/h) 50 Hz

To 1150 gpm (260 m3/h)Heads 60 Hz

To 760 ft (230 m) 50 Hz

To 530 ft (160 m)

Request Bulletin P-30-500 formore information.

-

8/3/2019 Bomba Probiomed 2

34/36

Rotating Equipment Division

34

Durco KW941Pump Power

Monitor

The KW941 Pump PowerMonitor monitors and displaysactual power to the pump,

offering simultaneous protectionfrom underload and overloadoperating conditions.

Easy setup & calibration Settings controlled from front

panel push buttons; no internaladjustments, dip switches orpotentiometers

Large digital display for easyviewing and accurate settings

One step calibration can beperformed without operatingpump. No need to run pump atoff-operating conditions tocalibrate power monitor

Settings can be viewed oradjusted during normal pumpoperation

The KW941 Power Monitoriseasyto install on new orexisting pump installations.All connections and controlsare located at motor starterelectrical enclosure as shown.

Costly instrumentation wiringto the pump is eliminated.

The KW941 helps to eliminatecostly downtime and expensivepump repairs caused by:

Dry running Pump overloads Cavitation Blocked lines Closed suction or

discharge valves Excessive wear or rubbing

Broad application range Works on all pumps

having steady (non-

pulsating) loads:centrifugal; gear;turbine; ANSI; API;paper stock; sealed;mag drive; cannedmotor; self-priming

One model for up to600 hp (450 kW)

Premium features forreliable protection Push buttons display

horsepower or kilo-

watts; automaticconversion whenswitching displays

Adjustable low powerand high power setpoints protect pumpfrom underload andoverload operation.Alarms can be trippedor pumps shut downbefore damage occurs

Adjustable trip delaytimers filter outnuisance trips causedby temporary powerfluctuations

Adjustable start-updelay timer is particularlyuseful in self-primingapplications

4 to 20 milliamp analogoutput facilitatesremote displays,operator interface andoutput to PLC or DCS

Two form C relay out-puts for low and highpower trips. Outputs canbe used to shut downpump or trip alarms

Automatic, manual andremote reset options forversatile operation

POWE

R

AMPERE

S

0% MOTOR LOAD 100%

Typical Low Flow/No Flow PumpProtection Zone

POWER/CURRENT

By sensing power and not justamperes, linear measurements areprovided with the sensitivity to detect

improper operation while eliminatingunwanted nuisance trips.

-

8/3/2019 Bomba Probiomed 2

35/36

OTHERDURCOPUMPS/GENERALINFOR

MATION

Rotating Equipment Division

35

DurcoPump Parts and

Alloy Materials

Specify genuine Durco parts foryour pump maintenance needs.

In addition to sure-betmaintenance savings onlyFlowserve offers: Parts that are guaranteed to

fitto last and to perform Lifetime castings guarantee Quality assured safety for

operating and maintenancepersonnel

Off-the-shelf availability froma computer-linked network

Machining and modification

service for special orders 24-hour emergency service Application and materials

expertise Complete analysis of your

maintenance needs withrecommended parts inventory

Tungsten carbide hardcoated parts are available

To meet the concerns of OSHA1910 for replacement partsequal to original manufacturers

specifications, it is recom-mended to use only genuineDurco pump parts.

Flowserves foundriesare widely regarded asamong the best in theworld pouring alloysfrom common austeniticstainless steels to lightreactive alloys such astitanium. All wet end

Durco castings carry alimited lifetime guarantee.

Attesting to the worldclass quality of its cast-ings, Flowserve was thefirst high alloy foundry inthe United States ofAmerica to have earnedapproval by GermanysTechnischer ber-wachungs Verein (TUV).

ACI Equivalent Wrought ASTMDesignation Symbol Designation Designation Specifications*

Ductile Iron DCI None None A395High Chrome Iron CR29 None None NoneCarbon Steel DS None Carbon Steel A216 Gr. WCBDurco CF-8M D4 CF-8M 316 A744, Gr. CF-8MDurcomet 100 CD4M CD-4MCu Ferralium A744, Gr. CD-4MCuDurimet 20 D20 CN-7M Alloy 20 A744, Gr. CN-7MDurcomet 5 DV None None None

Durco CY-40 DIN CY-40 Inconel 600 A744, Gr. CY-40Durco M-35 DM M-35-1 Monel 400 A744, Gr. M-35-1Nickel DNI CZ-100 Nickel 200 A744, Gr. CZ-100Chlorimet 2 DC2 N-7M Hastelloy B A494, Gr. N-7MChlorimet 3 DC3 CW-6M Hastelloy C A494, Gr. CW-6MDuriron D None None A518Durichlor 51 D51 None None A518Superchlor SD51 None None A518Durco DC-8 DC8 None None NoneTitanium Ti None Titanium B367, Gr. C-3Titanium-Pd Ti-Pd None Titanium-Pd B367, Gr. C-8AZirconium Zr None Zirconium B752, Gr. 702C*Durco alloys conform to the chemical and mechanical requirements of the latest edition of the ASTM specification.

Duriron, Durichlor 51 and Superchlor are registered trademarks of Flowserve Corporation Ferralium is a registered trademark of Langley Alloys Hastelloy is a registered trademark of Haynes International, Inc. Inconel and Monel are registered trademarks of International Nickel Co. Inc.

Durco Alloy Materials

-

8/3/2019 Bomba Probiomed 2

36/36

USA and CanadaFlowserve CorporationRotating Equipment DivisionMillennium Center222 Las Colinas Blvd., 15th FloorIrving, TX 75039-5421 USATelephone: 1 972 443 6500Telefax: 1 972 443 6800

Europe, Africa, Middle EastFlowserve Ltd.Rotating Equipment DivisionHarley House94 Hare Lane, Claygate, EsherSurrey KT10 ORB, UKTelephone: 44 1372 463700

Telefax: 44 1372 463801

Latin AmericaFlowserve de Venezuela S.A.Rotating Equipment DivisionTorre Ejecutiva No. 75-51Ave. 4 Bella Vista entre calles 75 y 761 er Piso Ofic. 1B, MaracaiboEdo. Zulia 4002-010. VenezuelaTelephone: 58 61 932 767Telefax: 58 61 933 114

Asia PacificFlowserve Pte. Ltd.Rotating Equipment Division12 Tuas Avenue 20Singapore 638824Republic of Singapore

Telephone: 65 862 3332Telefax: 65 868 4603

Rotating Equipment Division

Flowserve has numerous manufacturing, sales,and service operations throughout the world.Please contact one of the regional centers todetermine the location of the nearest office.

Your local Flowserve representative:

Hydraulic Engineering

Mechanical Design

Materials Expertise

Smart Technology

Manufacturing Technology