Bomba Dosadora Milton Roy _ Primeroyal

-

Upload

vibropac -

Category

Engineering

-

view

125 -

download

10

Transcript of Bomba Dosadora Milton Roy _ Primeroyal

Since 1936, Milton Roy pumps have been valued by customers for their durability and dependability in critical chemical dosing applications. PRiMeRoyal continues that tradition with a variety of frames and configurations that fit the needs of the most demanding processes.

The PRiMeRoyal series foundation is based on a robust gear mechanism and a modular design that accepts several styles of liquid ends and capacity control options. This means every pump is tuned to the specific needs of its application. The use of solid engineering principles assures that even the smallest detail of the design is focused on providing continuous operation with the longest possible time between scheduled maintenance. The final product is a trustworthy metering pump that is an integral part of your process.

PRIMEROYAL® Controlled Volume Metering Pumps

• Built to API 675 standards

• 4 frame sizes

• Multiplexable in any combination of frame sizes

• Variable eccentric gear mechanism for maximum performance in the smallest available footprint.

• Variable stroke length or fixed stroke length available

• Capacity adjustable while running or stopped

• Multiple standard liquid end configurations available • High performance diaphragm (HPD) for pressures up to 3,500 psi (240 Bar) • Critical service high pressure disc diaphragm • Metallic diaphragms for pressures up to 30,000 psi (2069 Bar) • Packed Plunger for pressures up to 20,000 psi (1380 Bar)

• Special liquid end configurations available for specific needs

• Standard liquid end materials include: • 316ss • PVC • Alloy 20

• Optional materials such as Alloy C22, titanium, PVDF, etc. available.

• Various mount options for NEMA and IEC flange mounted motors

• Unique designs easily accommodated

General Specifications

1

PRIMEROYAL® Capacity and Pressure Ratings

The PRiMeRoyal® variable eccentric drive enables precise control of the pump delivery rate while meeting or exceeding industry standards for steady state accuracy and repeatability. The design provides this high level of performance within a small space, so PRiMeRoyal® can fit into tight spaces.

The variable eccentric mechanism changes the stroke length by changing the position of the center of the shaft in the eccentric. To understand this better, assume the setting is at 0%. At 0%, the shaft is dead center of the eccentric and does not transfer any motion to the plunger. By increasing the capacity setting, the center point of the shaft moves from the center point of the mechanism and stroke length gradually increases until the setting is at 100%.

The PRiMeRoyal® variable eccentric is a non lost motion design as compared to designs that have stop plates or rods to limit the plunger travel. These lost motion units also rely on spring return mechanisms to keep the plunger in contact with the eccentric. The PRiMeRoyal® powers the full stroke cycle thus avoiding the mechanical and hydraulic shocks inherent in lost motion drives.

in critical processes, the variable eccentric drive assures both durability and optimum performance for the entire chemical dosing system.

Variable Eccentric Drive Design

Primeroyal®

complete control

2

PRIMEROYAL® Standard Liquid Ends

Milton Roy’s HPD liquid end has proven its value to customers for decades. it combines the bestcharacteristics of traditional liquid ends into a simple but elegant design.

• Hydraulically balanced diaphragm minimizes stress and assures long diaphragm life.

• Diaphragm PTFE wetted surface provides wide application coverage while composite materials allow maximum flexibility

• Patented diaphragm design is reusable after pump disassembly

• 3 psia net positive inlet pressure required

• Adjustable internal relief valve in hydraulic system protects pump from overpressure

• Patented MARS hydraulic fluid compensation system eliminates the need for process side diaphragm containment that restricts flow

• Diaphragm design life of 49,000 hours continuous duty

• Handles pressures up to 3,500 psi (240 Bar) without impact on diaphragm life

• Optional materials handle temperatures up to 300° F

Packed Plunger

The packed plunger liquid end offers the best performance when net positive inlet pressure (NPIP) is an issue.

The plunger is in direct contact with the process fluid creating the most efficient pumping performance.

• Excellent for viscous fluids and slurries

• 1 psia net positive inlet pressure required

• Options available to handle temperatures as high as 600° F

• Pressures up to 20,000 psi (1380 Bar)

• Standard ceramic plungers provide long plunger life

HPD – High Performance Diaphragm

Discharge Ball Check Valve

Grease Fitting

Packing

lantern Ring

Process Fluid

Suction BallCheck Valve

Piston

3

Milton Roy’s CSD liquid end is specifically engineered for demanding applications, and incorporates all the features required to assure optimum performance in high end processes. The CSD liquid end is designed to allow customization for specific applications. This assures that the pump is always tuned to the needs of the process. • Pressures up to 5,000 psi (345 Bar)

• Hydraulically balanced diaphragm minimizes stress and assures long diaphragm life

• 3 psia net positive inlet pressure required • Patented MARS hydraulic fluid compensation system eliminates need for process side diaphragm containment that restricts flow • Each pump is specifically configured for each process according to flow, pressure, process fluid compatibility

Discharge BallCheck Valve

DisplacementChamber

Plunger Sleeve

Diaphragm Head

Diaphragm HeadBolts/Nuts

Disc Diaphragm

Milton Roy’s metallic diaphragm liquid end handles the most severe high pressure applications with ease. each pump is carefully configured for its specific application, assuring long term success, reliability, and efficiency.

• High pressure applications up to 30,000 psi (2065 Bar)

• Hydraulically balanced diaphragm minimizes stress

• Standard diaphragm material 301 full hard stainless steel – modified materials available to suit the process fluid

• Sealless liquid end design assures leak free operation

CSD - Critical Service Diaphragm Metallic Diaphragm

Plunger

Process Fluid

Hydraulic Fluid

4

Suction Ball Check Valve

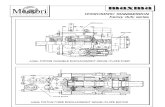

PriMEroyal® Modular Flexiblity

PRiMeRoyal R Triplex with CSD critical service liquid end

PRiMeRoyal L Duplex with Metallic Diaphragm liquid end and diaphragm rupture detection

PRiMeRoyal L Triplex with CSD critical service liquid end

PRiMeRoyal L Simplex with HPD liquid end

PRiMeRoyal R Simplex with Metallic Diaphragm liquid end, diaphragm rupture detection and electronic capacity control

5

The PRiMeRoyal series offers the options needed to meet the requirements most applications.

• Electronic Capacity Control • Variable speed drives • Flanged, NPT, and other connections as required • liquid end materials • 316 ss • Alloy 20 • Alloy C • PVC • PVDF • others as required • Multiplex configurations of same frame or mixed model

PriMEroyal® options

• Manifold piping for multiplex units• Special base plates• Diaphragm Rupture Detection system• Steam or cooling jackets• Remote head• Slurry or viscous fluid check valves• Packing lubrication systems• High temperature configurations• low temperature options• NEMA and IEC flange motor mount options

PriMEroyal® Typical industries and applications

6

PRIMEROYAL Metering Pumps are used in a wide range of Industries and applications. The following are partial lists:

industriesadditives and SealantsBiofuelsChemical ProcessingCleaning and Detergentselectronicsenergy and Power GenerationFood and Beverage

Typical application Chemicalsacetic acidaminesammoniaantifoamBenzineBiocideButaneCatalystCausticCO2 (Carbon Dioxide) CoagulantsCondensateCorrosion InhibitorDemulsifierDieselDimethyl EtherDMAC (Dimethylacetamide)DMDS (Dimethyl Disulfide)Drag Reducer

industrial ProcessesMining and MineralsMunicipal Water and Wasteoil and GasPaint, Ink, and CoatingsPersonal CarePharmaceutical

Plastics and RubberPlatingPulp and PaperRefiningSupercritical Fluid ProcessesTextilesGeneral industrial Water and Waste Treatment

Emulsion BreakersethanolFlocculantsFuel AdditivesGlycolH2S ScavengersH2SO4HCLHCL AnhydrousHydrate InhibitorsHydrazineHydrogen PeroxideisobutaneMeGMethanolMolten SulphurNAOHOxygen ScavengersPentane

PhosphatePolymersPropanePropaneScale inhibitorsSiHCL (Trichlorosilane)Silicone oilSodium HypochloriteSodium MethoxideSodium PhosphateStearic acidTEA (Triethaonlamine)Trisodium PhosphateWaterWater - DeionizedWater - Demineralized Water (Supercritical)Wax or Parafin InhibitorsXylene

MILTON ROY201 Ivyland Road • Ivyland, PA 18974 • tel 215.441.0800 • fax 215.441.8620

www.miltonroy.com • [email protected]

Brochure #49753 rev 3/2013