BACKGROUND INFORMATION DOCUMENT - SAHRIS · This document provides interested and or affected...

Transcript of BACKGROUND INFORMATION DOCUMENT - SAHRIS · This document provides interested and or affected...

1

BACKGROUND INFORMATION DOCUMENT

FOR THE ESTABLISHMENT OF AN OPEN PIT MINE BY VANADIUM

RESOURCES (PTY) LTD, DISTRICT OF TUBATSE, LIMPOPO PROVINCE

COMPILATION OF ENVIRONMENTAL MANAGEMENT PROGRAMME IN TERMS OF THE MINERAL AND PETROLEUM DEVELOPMENT ACT, 2002 (MPRDA) IN SUPPORT

OF AN APPLICATION FOR MINING RIGHT

JANUARY 2015

DMR REFERENCE NUMBER: LP 30//5/1/2/2/10095MR

1. INTRODUCTION

Vanadium Resources (Pty) Ltd has applied for a Mining Right for Iron, Titanium and Vanadium with respect to Portion 1, 2, 3, 4, 5, 6 and Remaining Extent of the farm Steelpoortdrift 365 KT, in the Magisterial District of Tubatse, Limpopo Province. The Department of Mineral Resources has subsequently accepted the application by Vanadium Resources (Pty) Ltd on 02 December 2014. The proposed mining operations will also require a water use licence in terms of National Water Act No. 36 of 1998. The following reports will be submitted to the relevant competent authorities:

(i) Scoping Report and Environmental Management Programme including supporting documents and technical reports to the DMR and ;

(ii) Integrated water use licence to the Department of Water and Sanitation (DWS), Limpopo Province.

The applicant, Vanadium Resources (Pty) Ltd, has appointed Jomela Consulting as the independent Environmental Assessment Practitioner to undertake the public environmental impact assessment process and compile an environmental management programme in terms of the requirements of the MPRDA.

The following major authorities are relevant to this application:

AUTHORITY APPLICABLE LEGISTLATION COMPETENCE

Department of Mineral Resources (DMR)

Mineral and Petroleum Resources Development Act, 2002 (Act No. 28 of 2002) MPRDA, with specific reference to sections 22, 2 and 39.

Decision making authority on activities related to mining

2

Limpopo Department of Economic Development, Environment and Tourism

Section 24 of National Environmental Management Act (Government Gazette of 18 June 2010)

The lead and commenting authority for the activities requiring environmental authorisation

Limpopo Dept. of Agriculture

Conservation of Agricultural Resources Act (Act no. 43 of 1983)

Commenting authority on matters related to soil and agricultural resources

Department of Water and Sanitation(DWS)

National Water Act, 1998 (Act No. 36 of 1998)

Decision making authority on matters related to water resources

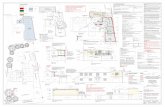

2. PROJECT LOCALITY

Vanadium Resources Porject is situated within the Sekhukhune District Municipality in the Greater Tubatse Local Municipality in the Limpopo Province.

The farm Steelpoort 365 KT is located some 30 km south-west of the town of Steelpoort (refer to locality map). A tarred road runs more or less parallel to the western boundary of the farm, and to the south the farm is separated from the R555 main road from Steelpoort to Middelburg by the Steelpoort River. Scattered low-density housing is present across most of the property, with particular concentrations in the south-west. The Dr Eiselen dam on the Shakwaneng River is immediately north-west of the project area.

Farm Sub-Division Size Surface Rights Holder

Mineral Rights Holder

Title Deed No.

Steelpoortdrift 365 KT

Remaining Extent (includes Portions 1, 2, 3,

4, 5, 6)

2456.5752

hectares

Government of the Republic of South

Africa

Government of the Republic of

South Africa

T23967/1988T13467/2013

3

3. PURPOSE OF THIS DOCUMENT

This document provides interested and or affected parties (I&APs) with background information on the proposed project, its potential impacts, the application and EIA/public participation process. It also outlines the manner in which I&APs can become involved in the project, receive information and raise issues that may be of interest and/or concern to them. The development of the impact assessment process involves technical and scientific investigations related to the potential impacts of the proposed project. It is therefore essential that I&APs, through the public participation process, become actively involved in the project’s environmental assessment process project in order to share information and give input that will be useful in assisting the relevant authorities in decision-making as far as this project is concerned.

4. OVERVIEW OF THE PROPOSED PROJECT

Vanadium Resources (Pty) Ltd applied for a Mining Right in terms of section 22 of the MPRDA to mine Iron, Titanium and Vanadium and, which application was accepted on 02 December 2014.

The area required for mining is approximately 2456.5752 hectares whereas the area required for infrastructure, roads, servitudes, etc. is less than or equal to 20 hectares.

During the late 1990s Vantech negotiated with the local and government authorities, then moved and compensated house owners located above the Upper and Lower Magnetitite Units and the future opencast area so as not to sterilize this deposit for future mining.

A prospecting right for vanadium over the farm Steelpoortdrift 365 KT is held by Vanadium Resources (Pty) Ltd (formerly Veriprop (Pty) Ltd) under reference number LP 972 PR (Registered under prospecting permit No 1036/2007PR). The licence expired on 30 August

4

2010. Application for renewal was approved by the Minister on 29 March 2011, and the licence has been renewed for a further period of three years, commencing on 5 March 2012 and ending on 4 March 2015. In addition to the aforesaid Prospecting Right for vanadium, Vanadium Resources (Pty) Ltd was also granted under Section 102 on 08 August 2012 the prospecting rights on the same farm for the minerals titanium and iron.

The following is the summary of primary mining and processing activities that are expected to be undertaken by the project proponent:

CONSTRUCTION PHASE ACTIVITIES The following construction activities are planned to take place during construction phase: (a) selective clearing of vegetation in areas designated for surface infrastructure; (b) stripping and stockpiling topsoil and sub-soil; (c) digging of foundations and trenches; (d) drilling and blasting associated with the development of boxcut; (e) dewatering, if required; (f) establishment of new access roads; (g) construction of mine infrastructure; (h) construction of plant infrastructure including processing plant, stockpile pads, tailings facilities, etc. (i) construction of services including storm water management facilities, solid wast management facilities, sewage plant, water supply infrastructure, power supply infrastructure, etc. Construction Phase Support Services These facilities will either be removed at the end of the construction phase or incorporated into the layout of the proposed infrastructure. Support services that will be required include: (a) contractors laydown areas; (b) temporary handling and storage are for constrcuction materials (paints, solvents, oils, grease); (c) temporary storage area for non-mineralized waste prior to removal by appropriated contractor; (d) temporary water supply will be supplied by borehole and/or trucks; (e) power supply will be by temporary diesel-powered electricity generator; (f) workshops and wash bays; (g) fuel handling and storage area; (h) temporary offices, construction workers camp and temporary chemical toilets. Construction workers will preferably be housed off-site and transported to site by the construction contractor to be appointed. OPERATIONAL PHASE ACTIVITIES The life of the mine is anticipated to be 10 years. Mining: The pit will be designed with 5 m benches and will be accessed via a 20 m ramp at a gradient of not more than 8%. The foot/low wall will follow the 14° dip of the ore body while the high wall will have an overall slope angle of 60°.

5

Ripping The top 10 m of material is weathered which allows for free digging and where necessary the material will be ripped using a 40 ton track dozer. All activities shall take place in compliance with the conditions of the EMPR. Drilling and blasting The lower 10 m of material is fresh hard material which will require drilling and blasting. Drilling will be done using a 78 mm hole diameter track mounted drill rig. Holes will be drilled to a depth of 5.5 meters (5 m hole depth and 0.5 m sub drill). Blasting will be done using a ready mixed power-gel explosive delivered to the mine by the explosive supplier. The explosives will be pumped into the drill holes directly from the explosives truck. Boosters with electronic delay detonators will be used for initiating and detonating the blasts. A powder factor of 0.4kg/ton will be used. Loading and hauling Loose material (ripped or blasted) will be loaded using a 3.2 m3 bucket excavator into 20 ton articulated dump trucks. The dump trucks will haul the ore from the pit to the crusher or stockpile. Overburden will be hauled to designated dumps alongside the pit. The excavator will be positioned on the bench above and load into the trucks on the bench below. Mining Mining will be done by conventional truck and shovel operations adopting the open strip method of mining. The mining fleet will be diesel powered and will be either mine or contractor owned and operated. Due to the extent of the deposit along strike and the economics in mining to depth, mining will take place following the 14° dip of the ore body down to a depth of 20 m leaving a 60° high-wall. The deposit dips at 14° from the surface outcrop. The initial top 10 m layer of material is weathered and allows for ripping and free-digging. The remaining 10 m layer of waste and ore will be drilled and blasted. Stripping will take place in 4 phases complying with the conditions of the EMPR:

Pre-stripping consisting of bush clearing and topsoil removal takes place up to 60 m in advance of the mining operations;

Waste stripping follows the pre-stripping and consists of overburden removal

to expose the ore;

Ore is then mined and hauled to the crusher, and;

Rehabilitation then follows the mining operation with waste material being dozed back into the open pit and topsoil is placed over the waste material

Waste will be mined to a depth of 20 m and 50 m along strike. During this period approximately 77,400 tons of overburden and 32,370 tons of topsoil will be mined. Overburden will be hauled and dumped alongside the open pit on the low-wall side to allow for dozing back into the pit during the rehabilitation phase. There shall be minimal equipment and activities impacting on the cost of electricity as diesel powered engines shall be the main sources of power in undertaking the mining opertion.

6

There shall be minimal equipment and/or activities of which may impact on the amount of water reuired for mining as the use of water shall be minimal. It is anticipated that one of the few uses of water shall be for the purposes of wetting roads with a view to suppressing any dust pollution. Water shall be sourced from either boreholes and/or the near by Steelpoort River

EQUIPMENT MODEL QUANTITY Excavators CAT 345 (3.3 m3 bucket) 2 ADT Haul Trucks CAT 725 AT (20 ton) 3 Water Truck CAT 725 WT 1 Track Dozer CAT D9 1 Grader CAT 14M 1 Wheel Loader CAT 924 (1.8m3 bucket) 1 Production Drill Sandvik DX Ranger (76mm hole) 1 In Pit Pump Flygt 1

Processing: The plant for the processing of Vanadium Resources (Pty) Ltd’s ore is divided into 2 plants and is described as such. Plant 1 is the ore receiving, crushing, screening section with subsequent stockpiling of the coarse ore. Plant 2 is processing of the fine ore. General Run-of-Mine Characteristics are summarised below in Table 1 Table 1 General ROM Characteristics Details Units Value Annual Production ROM feed tpa 360,000 Monthly Throughput ROM feed tpm 30,000 Head Grade V205 % 1.35 Plant Availability Crushing and Screening % 82%

Days per Year dpa 365 Solids SG Ore solids SG t/m3 2.78 ROM bulk density t/m3 1.55

ROM Particle Size DistributionMaterial top size mm 600

Process Description Plant 1: Run of mine ore will be received into a 200 t bin fitted with a static grizzly to remove any oversize rocks (+500 mm). A rock breaker will be used to break any oversized material. From the bin, the ore is passed over a vibrating grizzly feeder to separate the +150 mm material, which will be fed into the jaw crusher with CSS of 100 mm. The crushed ore and grizzly undersize will be sized on a classifying screen. The screen oversize will then be stockpiled while the screen undersize will be collected on the fine ore stockpile for further treatment. The process design criteria for plant 1 are shown below.

7

Plant 1 – Design Criteria Plant 1 – Ore Receibing and Crushing Operating Schedule Operate during day shift only for 12 hours per day at availability of 90%. Opertaing Hours Hours per day hpd 12

Hours per day inclduing avail hpd 10 Hours per annum hpa 3,600 Feed Rate tph 100 ROM Ore Receiving ROM feedbin capacity tonnes 200 Vibrating grizzly cut size mm 150 Jaw crusherCSS mm 60 - 1 00 Primary Crushing Feed ore top size m 150 Portion to grizzly oversize % 45% Jaw crisher product mm 100 Ore Sizing Portion to Coarse Ore % 85% Portion to Fine Ore % 15% Coarse Ore Stockpile Coarse Ore - Annual Tonnes tpa 306,000 Coarse Ore - Monthly Tonnes tpm 25,500 Coarse Ore Stockpile days 1 Stockpile size - nominal tonnes 850 Stockpile size - maximum tonnes 1,000

Process Description Plant 2: Fines from the classifying screen will be collected on a stockpile and fed via a front end loader into the fines bin. The fines will be conveyed over a magnetic drum separator where feldspars and other gangue minerals will be removed from the Ti-magnetite resulting in an upgraded Ti-magnetite product and the magnetic portion will be stockpiled. The efficiency of the process, an estimate of the mineral recovery rate and the expected mass/volume of mine waste is 75% All non-magnetic discard shall be collected on a dump for manual removal Current planning is to operate the tailings dam for the first trimester of production after which tailings will be redirected to a worked out section of the mine. Material in the tailings dam will also be loaded and used for rehabilitation purposes.

8

OPERATIONAL PHASE ACTIVITIES AND FACILITIES Roads: A good internal network of roads, from the mine to the plant, will be built. The external road network allows easy excess onto the property. Railways: The transnet railway siding at Steelpoort will be used to dispatch ore to the Ngcura harbour at Port Elizabeth via the national railway system. Electricity: Electricity for the mine will be supplied mainly by diesel power. Make up electricity by ESKOM will be required through the national grid system and the mine’s own transformer system. Water: The following sources of water supply are available - Production water will be sources from boreholes, Dr Eiselen dam and the Shakwaneng River immediately north-west of the project area. The feasibility of the water sources and availability will be finalized as part of the water use licence application that is underway. - Drinking water will be obtained from Lepelle Northern Water - Open cast mine used for dust suppression Communication Systems: The communication system as provided by Telkom (National Telephone Communication Network – land line) and cellular-relay towers operated by MTN and Vodacom is adequate. Security facilities: Security systems will be outsourced to a security contractor. Offices: The following buildings/offices will be constructed after the Mining Right have been awarded: • Reception, administrative and financial • Workshops • Temporary offices for blasting and mining contractors will be located at themine. Tailings Dam and Rock Dump: Waste rock will be stockpiled on a waste rock dump in the initial phase and later backfilled into the depleted pit. Tailings/slimes produced during the crushing and screening operations will be pumped to the tailings dams. Housing: Employees will be housed off-site. They will be encouraged to purchase their own houses in terms of the mine's social and labour plan. Some temporary mobile structures maybe required for security personnel. Maintenance: A full maintenance team will employed to ensure maximum availability of plant by monitoring the equipment on a day to day basis to identify problems and initiates repairs when needed. Regular inspections and condition status assessments will be carried out on major / critical equipment and installations (i.e. transformers / substations and other process equipment) by independent specialistinstitutions.

9

Stores: Spares supply agreements shall be negotiated with supply companies to deliver spares (with short to medium lead times) within 24 hours on order. Certain suppliers cater for immediate delivery of emergency spares upon breakdown. Major spares components and insurance spares (with long lead times) are provided for by keeping them in the mine stores. Spares availability is managed by utilising a min/max control and reorder system taking cognisance of delivery times. Staffing: The mine will appoint suitably qualified and experienced persons in the following senior position directly responsible to the Board of Directors to operate the envisaged mine on a daily basis: • Mine and Engineering Manager; • Mining Foreman • Mine Manager's Assistant Functions performed by mine employees: • Management and Financial • Engineering • Plant maintenance Outsourced functions performed by contractors: • Drilling and blasting • Loading and hauling to primary crusher • Metallurgy • Security

The mine will employ 36 permanent employees and some employees through contractors who perform outsourced functions. DECOMMISSIONING PHASE ACTIVITIES In broad terms, decommissioning activities associated with the proposed site includes the demolition and the removal of infrastructure, preparation of final land forms for closure and prompting vegetation growth in order to reduce the effects of soil erosion and to re-establish landscape functionality.

CLOSURE PHASE ACTIVITIES After decommissioning, closure activities will include maintenance and aftercare that is required to ensure that rehabilitation is successful. In this regard, although closure objectives have not been finalised, one of the options that will be considered is rehabilitation to grazing potential land.

5. OVERVIEW OF THE AUTHIRISATION APPLICATION PROCESS

In terms of the MPRDA, section 22(4) requires that the applicant submit a Scoping Report and conduct an Environmental Impact Assessment and submit an Environmental Management Programme for approval by the DMR.

In terms of the National Environmental Management Act (NEMA as amended) and the EIA regulations, 2010, prior to the commencement of activities on site, an environmental authorisation is required as the project, will potentially trigger listed the following activities that required environmental authorisation:

10

Activity Listing NEMA (Act 107 of 1998) GNR 544 of 2010: Activities: 9. Infrastructure exceeding 1000 metres in length for the bulk transportation of water, sewage or

storm water - (i) with an internal diameter of 0,36 metres or more; or (ii) with a peak throughput of 120 litres per second or more,

10 The construction of facilities or infrastructure for the transmission and distribution of electricity -

(i) outside urban areas or industrial complexes with a capacity of more than 33 but less than 275 kilovolts

11. The construction of: (i) canals; (ii) channels; (iii) bridges; (iv) dams; (v) weirs; (vi) bulk storm water outlet structures; (vii) marinas; (viii) jetties exceeding 50 square metres in size; (ix) slipways exceeding 50 square metres in size; (x) buildings exceeding 50 square metres in size; or (xi) infrastructure or structures covering 50 square metres or more where such construction occurs within a watercourse or within 32 metres of a watercourse, measured from the edge of a watercourse, excluding where such construction will occur behind the development setback line.

13. Storage, or for the storage and handling, of a dangerous good, where such storage occurs in containers with a combined capacity of 80 but not exceeding 500 cubic metres;

18. The infilling or depositing of any material of more than 5 cubic metres into, or the dredging,

excavation, removal or moving of soil, sand, shells, shell grit, pebbles or rock from (i) a watercourse; (ii) the sea; (iii) the seashore; (iv) the littoral active zone, an estuary or a distance of 100 metres inland of the high-water

mark of the sea or an estuary, whichever distance is the greater- but excluding where such infilling, depositing, dredging, excavation, removal or moving (i) is for maintenance purposes undertaken in accordance with a management plan agreed

to by the relevant environmental authority; or (ii) occurs behind the development setback line.

19. Any activity which requries a prospecting right or renewal thereof in terms of section 16 – 18 respectively of the Mineral and Petroleum Resources Act (Act No. 28 of 2002).

20. Any activitiy which requires a mining right or renewal of thereof as contemplated in sections 22 and 24 respectively of the Mineral and Petroleum Resources Act (Act No. 28 of 2002).

22. The construction of a road, outside urban areas,

(i) with a reserve wider than 13,5 meters or, (ii) where no reserve exists where the road is wider than 8 metres, or for which an environmental authorisation was obtained for the route determination in terms of activity 5 in Government Notice 387 of 2006 or activity 18 in Notice 545 of 2010.

11

NEMA (Act 107 of 1998) GNR 545 of 2010: Activities:

10. The construction of facilities or infrastructure for the transfer of 50 000 cubic metres or more

water per day, from and to or between any combination of the following: (i) water catchments, (ii) water treatment works; or (iii) impoundments, excluding treatment works where water is to be treated for drinking purposes.

15. Physical alteration of undeveloped, vacant or derelict land for residential, retail, commercial, recreational, industrial or institutional use where the total area to be transformed is 20 hectares or more; except where such physical alteration takes place for: (i) linear development activities; or (ii) agriculture or afforestation where activity 16 in this Schedule will apply.

20. Any activity which requires a mining right or renewal thereof as contemplated in sections 22

and 24 respectively of the Mineral and Petroleum Resources Development Act, 2002 (Act No. 28 of 2002).

NEMA (Act 107 of 1998) GNR 546 of 2010: 13. The clearance of an area of 1 hectare or more of vegetation where 75% or more of the

vegetative cover constitutes indigenous vegetation. 14. The clearance of an area of 5 hectares or more of vegetation where 75% or more of the

vegetative cover constitutes indigenous vegetation. National Water Act (Act No. 36 of 1998) Application for an integrated water use license in terms of S.21 of the National Water Act, Act 36 of 1998 to undertake the following activities:

(a) taking water from a water resource; (b) storing water; (c) impeding or diverting the flow of water in a watercourse; (g) disposing of waste in a manner which may detrimentally impact on a water resource; (i) altering the bed, banks, course or characteristics of a watercourse; (j) removing, discharging or disposing of water found underground if it is necessary for the

efficient continuation of an activity or for the safety of people;

The Application Process including Public Participation can be summarised in the following phases:

5.1 Submission of Application (a) Application to the DMR for a mining right

Vanadium Resources lodged an application for Mining Right with the DMR in the Polokwane regional office.

5.2 Acceptance/Acknowledgement of Application The application for Mining Right was accepted on 2 December 2014.

5.3 Notification to I&APs

12

A database of I&APs will be developed. Notices will be placed in strategic places and where addresses are available written correspondence will be sent out to inform I&APs of the proposed project. Emails and telephonic media will also be used to convey the message to I&APs. Adverts will be placed on a local as well as a regional newspaper. A 30 day period will be provided within which I&APs will be expected to register their interest in the project and raise issues of concern.

5.4 Compilation of the Scoping Report

A Draft Scoping Report (DSR) has been compiled which identifies activities and the process to be followed for the application. Copies of the Draft Report and project information may be distributed to all registered I&APs and made available at strategic places (e.g. library) and/or through available media.

All I&APs will be provided with a 30 day period within which to raise issues of concern with regards to the Draft Scoping Report.

Inputs will be incorporated into the Environmental Impact Assessment Report (FSR) and submitted to the authorities for their consideration.

5.5 Compile Draft and Final EIA/EMP Reports

Once authorities have considered the Scoping Report and given a go-ahead thereon, a process of developing the Environmental Impact Assessment report unfolds which culminates in a Draft Environmental Assessment Report (EIR) and draft Environmental Management Programme. Specialist investigations are also commissioned which will provide scientific and technical input into the EIA process. As part of the public participation process, I&APs are allowed 30 days to review the draft documents and provide comments.

Once comments have been received from I&APs at the end of the review period, issues raised are addressed and inputs incorporated into the Final EIR and EMP. The Final EIR and Final EIA&EMP document are submitted to the DMR for their decision making. I&APs will be notified of the submission to the DMR.

5.6 Notification of the Outcome of the Decision-making Process

The competent authority/ies will issue a Record of Decision (RoD) on the submitted documents. The registered I&APs will be notified in writing of the outcome of the decision-making process. This is to ensure that I&APs have the opportunity to appeal such decision if they are not satisfied with such decision.

6. POTENTIAL IMPACTS OF THE PROJECT

Potential Impacts may include:

Impact on surface and ground water quality and quantity

Dust Pollution

Noise impacts

Alteration of topography

Visual impacts

Impact on heritage / archaeological and culturally features

13

Impact on soil and land capability

Destruction and loss of biodiversity

Increase traffic volumes and impact on roads

Employment opportunities

Stimulation of local and regional economy

Impact of socio-economic structure of the local communities

Sterilization of mineral resources

7. REGISTRATION AS INTERESTED AND AFFECTED PARTY TO PARTICIPATE IN THIS PROCESS

It is a requirement in terms of regulation 55 (1) (b) of Government Notice R 543 that interested and affected parties are to request in writing that their names be placed on the register of interested and affected parties. Should you wish to register as an interested and affected part or have any comments on the proposed project, kindly complete the registration and response form below and provide comments, concerns or inputs regarding any potential environmental, cultural, socio-economic aspects that you deem necessary for consideration about the proposed project. Clearly state the nature of interest that you may have with regards to this matter. By registering on the project database you will be notified as and when information on the project is available. If your comments are not received from you within 30 days of receipt of this notice, it will be assumed that you do not have any issues with regard to the project.

Please forward your detailed response and full name, address and contact numbers in writing (via fax or email) to the attention of Mr. Cecil Khosa of Jomela Consulting (Pty) Ltd Contact Details: P.O. Box 415, Celtis Ridge, 0130 Tel/Mobile: (+27) 79 885 9666 Fax: (+27) 86 626 4839 Email: [email protected]

As interested and affected party you are kindly requested to complete the registration and response form and give any comment/concerns or input with regard to the environment that you may have, on the proposed development. If we do not receive any comment from you within 30 days of receipt of this notice, it will be accepted that you do not have any objections/comments with regard to the project.

14

EIA/EMP I&AP REGISTRATION AND RESPONSE FORM

PROJECT NAME: VANADIUMK RESOURCES MINE

DMR REFERENCE NUMBER: LP 30//5/1/2/2/10095 MR

REGISTRATION PERSONAL/ORGANISATIONAL DETAILS

Name

Organisation

Postal Address

Telephone

Fax

RESPONSE

I would like to attend public meeting YES NO

Date and venue of public meeting to be provided in due course

Concerns/ Suggestions/ Comments

Signature of I&AP

Date

Note: if the form is insufficient, please add more pages of your own.