Auditing of water use on construction sites - Phase I ... of water use on... · Auditing of water...

Transcript of Auditing of water use on construction sites - Phase I ... of water use on... · Auditing of water...

Final Report

Auditing of water use on construction sites - Phase I & Phase II

This report summarises the findings from an evaluation of water use on constructions sites. These findings include the results of a limited water audit programme which comprised a snapshot one day audit of nine construction sites (Phase I), and a subsequent water audit programme which comprised an audit of three construction sites over an extended period (Phase II), in the United Kingdom. Project Code: WAS908-004 & HWL101-504

Research date: February 2011 to April 2012

Date: December 2012

WRAP’s vision is a world without waste, where resources are used sustainably. We work with businesses and individuals to help them reap the benefits of reducing waste, develop sustainable products and use resources in an efficient way. Find out more at www.wrap.org.uk

Written by: Derek J. McNab, Michael Lynch and Paul Young of Mabbett & Associates Ltd

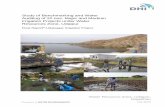

Front cover photography: [Rain gun dust suppression operating from the back of a water bowser.]

WRAP and Mabbett & Associates Ltd believe the content of this report to be correct as at the date of writing. However, factors such as prices, levels of recycled content and

regulatory requirements are subject to change and users of the report should check with their suppliers to confirm the current situation. In addition, care should be taken in using any of the cost information provided as it is based upon numerous project-specific assumptions (such as scale, location, tender context, etc.). The report does not claim to be exhaustive, nor does it claim to cover all relevant products and specifications available on the market. While steps have been taken to ensure

accuracy, WRAP cannot accept responsibility or be held liable to any person for any loss or damage arising out of or in connection with this information being inaccurate, incomplete or misleading. It is the responsibility of the potential user of a material or product to consult with the supplier or manufacturer and ascertain whether a particular product will satisfy their specific requirements. The listing or featuring of a particular product or company does not constitute an endorsement by WRAP and WRAP cannot guarantee the performance

of individual products or materials. This material is copyrighted. It may be reproduced free of charge subject to the material being accurate and not used in a misleading context. The source of the material must be identified and the copyright status acknowledged. This material must not be used to endorse or used to suggest WRAP’s endorsement of a commercial product or service. For more detail, please refer to WRAP’s Terms & Conditions on its web site: www.wrap.org.uk

1

Executive Summary Within the construction sector, the joint government and industry Strategy for Sustainable Construction published in 2008, highlighted the issue of water use by construction activities and included a number of targets pertaining to more efficient use of water. One such target identified water usage on construction sites as a priority area. The target, identified by the industry itself, is that: “By 2012, water use in the manufacturing and construction phase to be reduced by 20% compared to 2008 usage”. The body responsible for delivering the water target is the Strategic Forum for Construction (SFfC) Water Subgroup who has developed an Action Plan to work towards this target. WRAP (Waste and Resources Action Programme) is a representative on the SFfC Water Subgroup. The SFfC Water Subgroup developed an Action Plan to assist the construction industry in reducing the volume of water used on construction sites. The Action Plan highlights two major themes. Firstly, the need to gather information on where water is used, and where water is wasted on construction sites, along with identification of suitable water conservation measures. Secondly, the Action Plan aims to improve site water use behaviour through embedding principles of water conservation throughout the construction process. A 2008

baseline figure of 148 m3 per £million contractors output at constant (2005) prices will be used to assess any improvement. Mabbett & Associates Ltd (Mabbett) were commissioned by WRAP on behalf of the Subgroup to deliver a limited programme of audit work before the end of March 2011 to support the Action Plan with the following objectives:

To develop robust primary data quantifying where water is wasted and the associated water using processes on

construction sites through a series of site audits across a range of sites.

To establish an evidence base of good practice for reduction of water use in the construction process.

This initial audit work is hereafter referred to as Phase I. WRAP proposed a series of audits be carried out using a predefined methodology (and further refined by Mabbett to take account of the project time limitations) in delivering the

required Phase I project outputs between 15 February 2011 and 31 March 2011; a total of 6 weeks. In total, nine (9)

sites were audited in this Phase I of work.

Mabbett were subsequently commissioned by WRAP to deliver a further programme of audit work over an extended period, hereafter referred to as Phase II. The objective of this work was to further develop the findings from Phase I, to include:

Longer term monitoring;

Capturing the outstanding high priority activities (e.g. hydro-demolition); and

Better quantifying the savings potential of conservation measures.

Three (3) sites were audited between November 2011 - April 2012. The SFfC Water Subgroup has identified those activities expected to be ‘high priority’ i.e. the activities expected to provide the greatest opportunities for water efficiency savings. These are: Table 1: High Priority Activities

Water Using Activity High Priority Activity

Dust Suppression General, site roads, wheel washes

Hydro-demolition with high pressure water

Cleaning

Ready mixed concrete wagons

Site/general cleaning

Specialist/high pressure cleaning

Commissioning & Test Building plant/services

These activities were the primary focus of the auditing programme, though information on those activities considered low priority was also gathered/collected.

2

The following points summarise some of the main findings from the project:

There is little consistency throughout the construction sector in relation to water management. Some sites had metered supplies and paid for their water regularly, based on volumetric consumption, whilst other sites were not even registered with the local water provider (i.e. were not paying for water). It is suggested that if each construction company paid for their water based on volumetric consumption, the additional focus this would provide alone may achieve significant water savings.

Monitoring (and targeting) of water consumption data needs to improve if the construction sector wants to achieve a significant reduction in their water consumption - even some of the sites with water meters in place were unaware of how much water they were using.

Improved housekeeping (e.g. reporting/repairing leaks, etc) should provide a simple method of reducing water consumption.

As expected, dust suppression and cleaning were identified as high priority areas for achieving significant water savings. Possible methods of achieving these savings are discussed in the main body of the report.

Additional investigation into commissioning and testing water consumption is required before further comment can be made with respect to potential improvements in this area, as this was only assessed at one site.

All activities initially deemed low priority were generally observed to be so, with the exception of domestic and

welfare water consumption. Whilst this area may generally be perceived as a low water use, it is the one constant during all phases of a construction project, and findings to date suggest it will account for a significant portion of a site’s total water consumption. It is suggested this is henceforth considered a high priority area.

Water saving opportunities were identified at all audited sites, with savings typically ranging from 13% - 24%, and as high as 40% - 83% where significant leaks were observed.

Based on the findings to date, achieving the SFfC Water Subgroup’s target of a 20% reduction in the water consumption of construction sites may be achievable.

Some of the main opportunities for improving water efficiency are discussed in greater detail below: Following the auditing programme, it became clear that the one area where all sites could make improvements to water efficiency was domestic and welfare water consumption. This water requirement is unique at construction sites, in that it is present at each site for (generally) the full project duration. As such, it seems to account for a significant portion of a site’s water consumption, and represents an excellent (and relatively simple) opportunity for improving water efficiency in the construction sector. Another area where the majority of sites could improve was monitoring and targeting of water consumption. Where a site is unaware of how much water they are consuming (this was particularly prevalent at sites which did not pay for their water consumption on a variable basis), they are less likely to make improvements in this area. As such, ensuring each site is aware of exactly how much they are using (at a minimum) is likely to help promote a more water efficiency culture. At a number of sites, hoses without trigger-operated spray gun control were in operation. Generally, this is considered poor practice, and can lead to instances where hoses are left operational whilst not in use. It should prove a relatively simple (and inexpensive) matter to retro-fit spray guns to these hoses to eliminate this risk. Leaks were observed (or suspected) at multiple sites, some of which accounted for a significant portion of a site’s water consumption. In addition, unrepaired leaks can act to detract from a water efficient culture, and may lead to additional water efficiencies elsewhere on site. As such, site management should ensure that a formal system is in place for

checking/reporting/repairing leaks, on a regular basis. The dust suppression systems which were observed (or reported) were water inefficient in a number of instances, and significant improvements could be made in this area. When operational, these systems will generally account for a significant portion of a site’s water consumption, and as such water savings could be high. However, further work is required to more accurately quantify the mains water requirement associated with these activities. When operational, hydro-demolition is likely to be one of the largest water consuming activities at any construction site, and as such it is recommended that this water using activity is quantified where possible. However, it is suspected that the opportunity for water savings is relatively low. The first revision of this report was published in July 2011, and incorporated the findings from Phase I only. The second revision of this report, published in August 2012, includes both the results of Phase I and Phase II.

3

Contents 1.0 Introduction 6

2.0 Sites 8

3.0 Audit Methodology 10

3.1 Introduction 10

3.2 Validity & Limitations of the Collected Data 10

3.3 Overview of Mabbett Applied Methodology 11

3.3.1 Phase 1 11

3.3.2 Phase II 12

4.0 Water Saving Devices & Practices: General Activities 13

4.1 Water Supply 13

4.2 Housekeeping 13

4.3 Monitoring and Targeting 14

4.3.1 Water Quantification 14

4.3.2 Meter Readings 15

4.3.3 KPIs 15

4.3.4 Targeting 15

4.4 Other Business Benefits 15

5.0 Water Saving Devices & Practices: High Priority Activities 16

5.1 Dust Suppression (General) 16

5.1.1 Rain Guns & Manual Hosing 17

5.1.2 Fan Misting Systems 17

5.2 Dust Suppression (Site Roads) 18

5.2.1 Dust Suppression Vehicles (Splash Plate Operation) 19

5.2.2 Dust Suppression Vehicles (Hydraulic Spinning System) 19

5.2.3 Road Sweepers 20

5.2.4 Hard-standing Ground 21

5.3 Dust Suppression (Wheel Wash) 21

5.3.1 High Pressure Washer (Wheel Wash) 22

5.3.2 Drive-on Wheel Wash 22

5.4 Dust Suppression (Hydro-demolition with high pressure water) 24

5.5 Chemical Additives 25

5.6 Control Systems 25

5.7 Cleaning (Ready Mixed Concrete Wagons) 26

5.8 Cleaning (Site/General Cleaning/Specialist/High Pressure) 29

5.8.1 Auto-isolation of Flow 29

5.8.2 High Pressure (Low Flow) Washers 30

5.8.3 Consult the Marketplace 31

5.9 Commissioning & Testing 31

6.0 Water Saving Devices & Practices: Low Priority Activities 32

6.1 Site Cabins/Temporary Accommodation 32

6.1.1 Wash Hand Basins 33

6.1.2 Sinks 34

6.1.3 Toilet Cisterns 34

6.1.4 Urinal Cisterns 34

6.1.5 Showers 35

6.1.6 Canteens 35

6.2 General Site Activities 35

6.2.1 Tool Washing 35

6.2.2 Rinsing 36

6.3 Wet Trades 36

6.3.1 Concreting & Bentonite Mixing 36

6.3.2 Intermediate Vessels 37

6.3.3 Mortar 37

4

Contents

6.0 Water Saving Devices & Practices: Low Priority Activities (Cont'd)

6.4 Groundworks 38

6.4.1 Grouting 38

6.4.2 Drilling/Piling 38

6.5 Cleaning 38

7.0 Further Work Required 39

7.1 High Priority Activity Auditing 39

7.2 Auditing Methodology 39

7.3 Matrix of Sites for Water Audits 39

Appendix 1: Site 1: Leisure (Sports Hall/Centre) Venue 40

Appendix 2: Site 2: Leisure (Theatre) Venue 46

Appendix 3: Site 3: Civil Engineering (Road) Site 53

Appendix 4: Site 4: Commercial Retail (Department Store) Site 63

Appendix 5: Site 5: Leisure (Sports Hall/Centre) Venue 69

Appendix 6: Site 6: Civil Engineering (Road) Site 78

Appendix 7: Site 7: Education (High School) Site 86

Appendix 8: Site 8: University (Laboratory) Building 93

Appendix 9: Site 9: Leisure (Theatre) Venue 99

Appendix 10: Water Audit Methodology 104

Appendix 11: Site 10: Commercial & Residential (Laboratory) Development 115

Appendix 12: Site 11: Civil Engineering (Railway) Site 120

Appendix 13: Site 12: Civil Engineering (Airport) Site 128

5

Acknowledgements The Waste and Resource Action Programme (WRAP) has commissioned Mabbett & Associates Ltd (Mabbett) to prepare this ‘auditing of water use on construction sites’ report.

This report is subject to and issued in connection with the Mabbett Confidential Tender dated 24 January 2011 (Issue

00); Mabbett Confidential Tender Clarification Note dated 07 February 2011 (Issue 01); WRAP Instruction Letter (Ref:

FRA046-029v1-IL01v1) dated 14 February 2011; Mabbett Confidential Tender dated 09 August 2011 (Issue 00); and

WRAP Instruction Letter (Ref: FRA036-13-014v1-ILO2v1) dated 14 September 2011.

Mabbett would like to acknowledge and thank the following for their assistance and contribution during this programme of work:

The Strategic Forum for Construction Water Subgroup;

The construction companies who volunteered sites for audit;

Ms Carmen Snowdon (Senior Project Manager, Water Supply team) at WRc plc;

Mr Jim Wiltshire (Programme Area Manager – Design for Resource Efficiency) at WRAP;

Clugston Construction Ltd;

Lend Lease Corporation;

Sir Robert McAlpine Ltd;

Balfour Beatty Civil Engineering Ltd;

Clark Contracts Ltd;

Morgan Sindall plc;

Simons Group Ltd; and

Balfour Beatty Construction Ltd.

This report has been prepared by the following Mabbett personnel:

____________________________________ ____________________________________

Mr Michael Lynch, MEng, MIChemE Mr Paul Young, MEng, AMIChemE

Senior Environmental Engineer Environmental Engineer

Environmental Engineering Group Environmental Engineering Group

This report has been reviewed and approved by:

MABBETT & ASSOCIATES LTD

BY:

_____________________________________________

Mr Derek J. McNab, CEng, CSci, CEnv, FIChemE, MIEMA

Senior Environmental Engineer & Scientist

Environmental Engineering Group

6

1.0 Introduction

The following introduction is provided to set the scene for the project.

a. Within the construction sector the joint government and industry Strategy for Sustainable Construction, published

in 2008, highlighted the issue of water use by construction activities and included a number of targets pertaining to more efficient use of water. One such target identified water usage on construction sites as a priority area. The target, identified by the industry itself, is that:

“By 2012, water use in the manufacturing and construction phase to be reduced by 20% compared to 2008 usage”.

b. The body responsible for delivering the water target is the Strategic Forum for Construction (SFfC) and more

directly by SFfC’s Water Subgroup comprising representatives from industry including contractors, manufacturers, government departments and agencies. WRAP (Waste and Resources Action Programme) is a representative on the SFfC Water Subgroup.

c. The SFfC Water Subgroup developed an Action Plan to assist the construction industry in reducing the volume of

water used on construction sites. The Action Plan highlights two major themes. Firstly, the need to gather information on where water is used, and where water is wasted on construction sites, along with identification of suitable water conservation measures. Secondly, the Action Plan aims to improve site water use behaviour through embedding principles of water conservation throughout the construction process. A 2008 baseline figure of 148 m3 per £million contractors output at constant (2005) prices will be used to assess any improvement.

d. Mabbett & Associates Ltd (Mabbett) were commissioned by WRAP on behalf of the Subgroup to deliver a limited

programme of audit work before the end of March 2011 to support the Action Plan with the following objectives:

To develop robust primary data quantifying where water is wasted and the associated water using processes

on construction sites through a series of site audits across a range of sites.

To establish an evidence base of good practice for reduction of water use in the construction process.

This initial audit work is hereafter referred to as Phase I.

e. WRAP proposed a series of audits be carried out using a predefined methodology (and further refined by Mabbett to take account of the project time limitations) in delivering the required Phase I project outputs between 15 February 2011 and 31 March 2011; a total of 6 weeks.

f. It was envisaged that at least six (6) sites would be audited before the end of March 2011 across the following

project types:

civil engineering;

commercial offices;

commercial other;

commercial retail;

education;

healthcare;

industrial buildings;

leisure;

mixed use developments;

public buildings; and

residential.

In total, nine (9) sites were audited in this Phase I of work.

7

g. Mabbett were subsequently commissioned by WRAP to deliver a further programme of audit work over an extended period, hereafter referred to as Phase II. The objective of this work was to further develop the findings from Phase I, to include:

Longer term monitoring;

Capturing the outstanding high priority activities (e.g. hydro-demolition); and

Better quantifying the savings potential of conservation measures.

Three (3) sites were audited between November 2011 - April 2012. h. This summary report has been prepared by Mabbett - Environmental, Health and Safety Consultants and Engineers.

The findings, observations, and conclusions presented in this report, are limited by the scope of services outlined in the Mabbett Confidential Tender dated 24 January 2011 (Issue 00); Mabbett Confidential Tender Clarification Note dated 07 February 2011 (Issue 01); WRAP Instruction Letter (Ref: FRA046-029v1-IL01v1) dated 14 February 2011; Mabbett Confidential Tender dated 09 August 2011 (Issue 00); and WRAP Instruction Letter (Ref: FRA036-13-014v1-ILO2v1) dated 14 September 2011. The professional opinions and findings presented in this report are based on facts and information conveyed to, or observed by Mabbett during completion of the project. Furthermore, assessment and field operations have been performed in accordance with generally accepted engineering practices. No other warranty, expressed or implied, is made.

i. The first revision of this report was published in July 2011, and incorporated the findings from Phase I only. The

second revision of this report, published in August 2012, includes both the results of Phase I and Phase II.

8

2.0 Sites

The following sites were volunteered and received water audits. Site 1 - Site 9 relates to Phase I, and Site 10 - Site 12 relates to Phase II.

Table 2: Site Summary

Site Classification Project Use

Class Value

(£million) Project Type Audit Date

Constant Price Strategic Forum KPI (m3/£million

contractors output)

Potential Savings

Identified Processes Operational During Audit

1 Leisure Sports Hall/

Centre

7.2 Refurbishment 24 February 2011 170.6 13.0% Domestic and welfare facilities

2 Leisure Theatre 14.5 New Build 02 March 2011 77.2 19.8% Domestic and Welfare Facilities internal wet-trades Mortar Silos Dust Suppression - Block Cutting

3 Civil

Engineering Road 380.0 New Build 03 March 2011 92.5 24.3% Concrete Batching Plant

High Pressure Vehicle Washer Domestic & Welfare Facilities Hydraulically Bound Material (HBM)

Machine Caravan Park Laboratory Road Sweepers

4 Commercial Retail

Department Store

49.0 New Build 07 March 2011 11.5 18.5% Domestic and welfare facilities

5 Leisure Sports Hall/ Centre

93.0 New Build 11 March 2011 288.0 82.5% Domestic and Welfare Facilities Wheel Wash Mortar Silos High Pressure Washer

6 Civil Engineering

Road 445.0 New Build 14 March 2011 Unknown N/A Batching Plant Road Sweepers Domestic and welfare facilities

7 Education High School 23.0 Demolition and New Build

23 March 2011 182.0 15.3% Domestic and welfare facilities Agitator High Pressure Washer

8 Education University/ College

10.0 New Build and Refurbishment

23 March 2011 144.0 39.7% Domestic and Welfare Facilities Mortar Silos

9

Site Classification Project Use

Class Value

(£million) Project Type Audit Date

Constant Price Strategic Forum KPI (m3/£million

contractors output)

Potential Savings

Identified Processes Operational During Audit

9 Leisure Theatre Undisclosed New Build 29 March 2011 Unknown 22.2% Domestic and Welfare Facilities

10 Commercial & Residential

Call Centre, Department

Store, Apartments

150 New Build November 2011 – April 2012

57 21.3% Wet trades (e.g. block work, screeding, plastering, etc.)

Slip forming Welfare (toilets, food preparation

canteen and offices) Manual cleaning activities Drinking water

11 Civil Railway 50 New Build & Refurbishment

November 2011 – April 2012

Unknown N/A Drive-on wheel wash High pressure washing Vehicular dust suppression Welfare (toilets, food preparation

canteen and offices) Road sweeper Hydrodemolition Dust suppression (stockpile) Bentonite mixing Piling

12 Civil Airport 500 New Build November 2011 – April 2012

118 >15% Road sweepers Vehicular dust suppression Cleaning operations Dust suppression (stockpile) Welfare (toilets, food preparation

canteen and offices) Boot wash Bentonite mixing Mortar mixing Laboratory activities Crushing operations

Calculation of the KPI for each site is preliminary only, as the projects were on-going at the time of audit. Assumptions have been made in order to calculate each, using data which in some instances is limited.

10

3.0 Audit Methodology

3.1 Introduction The SFfC Water Subgroup has developed an Action Plan to assist the construction industry in reducing the volume of water used on construction sites. The collection of data on water using processes on sites and the identification of where water is wasted are the first steps of the Action Plan as there is currently very limited knowledge on this subject. A water audit methodology has been devised by the SFfC Water Subgroup as part of this Action Plan to assist the construction industry in reducing the volume of water used on construction sites. The priority for implementing water conservation measures on construction sites is on reducing water wastage with the following site processes identified by the SFfC Water Subgroup as likely to be the most water wasting activities:

dust Suppression, to include general, site road and wheel washing;

hydro-demolition with high pressure water;

cleaning, to include ready mixed concrete wagons and other applications; and

commissioning and testing of building plant/services.

Accordingly, the water audits were initially targeted on collecting information on these activities where available.

3.2 Validity & Limitations of the Collected Data This report presents the findings from nine (9) one day water audits, and a subsequent three (3) extended duration audits, across a wide spectrum of construction project types providing a start to understanding where water is used and where wastage occurs. While this is a start, the construction sector has a long way to go to develop a full understanding of water use on construction sites. The limited ~6 week duration of Phase I identified barriers including:

A lack of availability of suitable control sites, which reduces the options for estimating the savings associated with particular water using processes or behaviours.

Limited project duration which restricted the capture of the total volume of water used. As such, if the water consumed on the day of the audit was dissimilar to the average figure, the estimated water consumption of the site will be inaccurate.

Limited audit duration which restricted the identification of the proportion of total site use against each water using activity - an increase project duration will allow this information to be estimated with a greater degree of accuracy.

Weather related impacts (e.g. dust suppression and wheel wash activities not operating on a wet day in March), meaning some high priority activities could not be fully assessed.

The scheduling of audits to fit with the contacts from each of the companies volunteering the sites. While the data collected is robust relative to the sites’ water consumptions on the day of the audit, the implementation of a long-term monitoring plan on a sample of control sites is needed to begin to identify the following: ‘total volume used’ To understand the total volume used per activity it will be necessary to follow the

water using activity during the course of the construction process from groundwork through to project handover on a selection of control sites.

‘proportion of total site use’ Similarly, this parameter will only be understood when all the water using activities can

be captured on a control site during the full construction process. While it is envisaged the SFfC-devised water audit methodology will work well on a long-term monitoring opportunity, its use is restrictive to a ~6 week programme. To obtain the best value from the project, Mabbett worked in general accordance with the water audit methodology with our initial focus on identifying and quantifying water wastage of the high priority activities noted above (specific site processes where possible); identifying and quantifying water wastage of other activities; and identification of suitable control sites for further work. To ascertain the savings associated with potential water saving devices and practices (conservation measures), Mabbett used a combination of:

Actual monitored water use data gathered from the volunteered sites; and

Pre-existing knowledge of the water saving devices and practices and the typical reduction achieved from their use. It is key to note that the volume of water saved through a particular conservation measure will depend on the existing water using activity practice which may well be highly variable, especially where behavioural influences are a factor.

11

The extended ~6 month duration of Phase II allowed Mabbett to develop a more robust understanding of water consumption across the selected sites. It is noted, however, that no site has yet been audited from ground breaking through to project handover. Typically, sites which are of interest (i.e. those with large water consumption and which involve high priority water using activities) will run for a number of years, and so multi-year auditing would be required. Therefore, the project duration is still considered a barrier to following the SFfC Water Subgroup’s preferred audit methodology fully.

3.3 Overview of Mabbett Applied Methodology While Mabbett generally applied the water audit methodology noted in Appendix 10, our team made modifications to assist add value to the project, meet the limited project timelines and minimise the impact at the construction sites.

3.3.1 Phase I Rather than trying to put in place a long-term monitoring system which could potentially be a barrier to the project (i.e. another task for the staff at site), Mabbett utilised a combination of a non-intrusive ultrasonic flowmeter and manual meter reads to monitor water use generally over a one day period, where local circumstances allowed. This approach

had the benefits of overcoming the potential barriers of putting in place a long-term monitoring system e.g. the lead time and/or cost to install a meter, situations where no temporary power supply is available, etc. Where appropriate, Mabbett also used other direct measurement techniques to quantify water use such as a measuring cylinder and stopwatch, and indirect methods such as volume and time calculations, data taken from operating and maintenance manuals, calculations from basic principles (e.g. calculating flow from pressure), etc. In advance of an audit, our team requested the following data generally in line with the Form A - Preparation Checklist (see Appendix 10 for details): Table 3: Audit Data Request

Data Purpose

Personal Protective Equipment

Requirements

To ensure the Mabbett Team fully complied with the on site health and safety

rules during the auditing activities.

Copy of Water Supply Contract (or the terms of supply) and Wastewater Disposal Arrangements.

To understand the supply and charging arrangements which will assist us consider if there is a financial benefit to water efficiency or simply an environmental benefit. This data can assist prepare an economic argument for any water saving devices or practices.

Copies of Water and Effluent Bills

This tariff optimisation task will ensure the site is benefiting from the lowest fixed and variable costs.

Site Map To understand the site layout and water using areas.

Description of Construction Project

To provide an understanding of the project construction stages in relation to water efficiency and to assist compare against future construction projects.

Estimate of Construction Site Users and Associated Operating Plan

To understand the expected domestic use of water for assistance in constructing a water mass balance. This will be compared against actual 24 hour flow monitoring data to check for consistency and to identify any improvement opportunities.

Meter Inventory To build a picture of water use and on site flow monitoring strategy.

Water Using Equipment Inventory

To understand water using processes on site.

Domestic Arrangements To understand the water use for domestic arrangements on site (e.g. temporary toilet or fixed water supply).

Other Water Sources (borehole supply, river abstraction, tankered supply, etc.)

To provide data on all water sources supplying the construction site so an accurate and representative water mass balance is constructed and cost impact is understood.

Our approach while on site was to ‘follow the pipe’ starting from the site water supply through to point of use. This approach assisted us to minimise the risk of missing a water using activity which may have been overlooked by the site staff. We then recorded all important matters by compiling a photographic record on site and taking extensive notes. The Mabbett Team spoke with staff, both at managerial and operator level where possible, to gain their understanding

of water use, water efficiency and equipment use.

12

The Mabbett Team then completed: Form A - Preparation Checklist; Form B - Site Processes by Meter; and Form C - Data Collection (using Form D - Information for Form C) where appropriate - refer to Appendix 10 for further details. On return to our offices, the Mabbett Team interpreted the data collected and integrated the findings into this report.

3.3.2 Phase II

Due to the extended duration of Phase II, Mabbett were able to further improve upon the methodology utilised during

Phase I. These improvements included:

Multiple site visits and investigative work over a number of months; and

Installation of sub-meters and metered standpipes to improve robustness of quantitative information.

13

4.0 Water Saving Devices & Practices: General Activities

The following section is provided to set the scene for the water use on construction site generally.

4.1 Water Supply

The type of water used on site and the type of wastewater generated by site operations/activities will determine how

much a company pays for water supply and wastewater disposal. Generally the source of water for each of the sites is

either mains water or water abstracted from surface water.

There are a number of charging schemes for mains water and wastewater (sewerage, surface water and trade effluent

charges) in the U.K. with the amount paid depending on: the service provider, volume used, rateable value, and the size

of meter. Therefore, mains water is generally more expensive than direct abstraction. As a number of water using

activities on construction sites do not have to be of a potable standard, it is suggested construction sites consider the

use of Sustainable Urban Drainage Systems (SUDS) and/or settlement lagoons to collect surface water for at least part

of a sites water requirement.

As a result of the on site audit activities it is clear that that the type of water used plays a factor in water efficiency on

site with those sites that are charged for mains water supply on a volumetric basis generally having a better water

efficiency.

4.2 Housekeeping

Creating a culture within the construction sector that changes staff’s attitude and behaviour to accept ownership of

water efficiency is fundamental to improving the use of water in an efficient manner. Good housekeeping (e.g.

reporting/repairing leaks, turning off taps which are not in use, and generally using water in an efficient manner) can

assist a construction site reduce its overall water use. The range of attitudes identified across the sites that have been

audited is vast, from those that believe water should be minimised (almost regardless of cost impact) to those that view

water as a cheap commodity with a ‘don’t pay, don’t care’ attitude. None of the sites audited were able to provide

evidence of providing their site staff with regular awareness training on water efficiency, and this is an area which could

be improved. In this first instance, contractors should ensure that staff are aware of how much water is being

consumed, as well as any water efficiency targets which may apply at the site. Following this, general housekeeping

issues could be covered during a short workshop to help promote a water efficient culture over the duration of the

project. Lastly, if there are any water using applications which are particularly significant (e.g. concrete batching plant),

specific training could be provided to the relevant operators.

14

The following examples of poor housekeeping were identified during the site audits:

Image 1: Leaking Standpipe Image 2: Leaking Standpipe

Image 3: Leaking Mortar Silo

Leaks were notably the largest example of ‘poor housekeeping’ across the audited sites. As part of a site’s housekeeping programme, it is recommended that regular (e.g. monthly) walk-rounds are undertaken, for the purposes of leak

detection (and subsequent repair). Where walk-rounds are already undertaken for health and safety reasons, as was the

case at site 11, these could be combined to form a multi-purpose walk-round.

4.3 Monitoring and Targeting As has been evidenced by the SFfC Water Subgroup experience to date, there were few construction companies taking

regular meter readings. The amount of monitoring on site varied from no monitoring to regular weekly meter readings

being taken by on site staff.

There are 5 key areas which construction companies should consider. In typical order of priority, these are:

Ensure all areas of site water consumption are quantified.

Consider splitting welfare and “site-based” water consumption.

Record site water consumption on a regular basis.

Create Key Performance Indicators (KPIs) to assist tracking of water efficiency.

Utilise consumption or KPI data to set improvement targets.

4.3.1 Water Quantification

Construction companies should ensure all water sources are accurately quantified, though mains water is particularly important. This may include installing sub-meters at strategic locations around the distribution network, and/or utilising

metered standpipes. It is recommended that unmetered standpipes are gradually phased out of use at sites, regardless

of whether they are required by the utility provider.

Metered standpipes, which are not common throughout the UK construction sector, were purchased from the following

organisation for the Phase II work: www.aqua-check.co.uk/. A single 1” standpipe cost £242, and a 2.5” standpipe cost £618, excluding VAT. These are the most common standpipe sizes and should suit most applications. Some utility

providers may place restrictions on the type of standpipes which can be used. For example, Thames Water require

standpipes to be less than four years old, and fitted with a double-check valve – this should always be checked with the utility provider.

15

Quantifying consumption is the first step to improving water efficiency, and a number of sites did not currently undertake this practice.

Where water consumption is not recorded, implementing water efficiency improvements is made significantly more challenging.

4.3.2 Meter Readings

Regular meter readings should be taken from all meters, sub-meters and metered standpipes (weekly is recommended

in most instances) - this will allow the construction company to track how water consumption varies throughout a project, and may help identify (and eliminate) erroneous consumption. As part of this process, it may prove useful to

take regular out-of-hours meter readings - this helps confirm there are no leaks or other unwarranted consumptions.

4.3.3 KPIs

It is generally expected that water consumption throughout the different phases of a construction project will vary,

sometimes significantly so, as site operations will regularly change. As such, an increase in water consumption may not

necessarily mean water efficiency has reduced (or vice versa). By creating KPIs, which relate site water consumption to

some measure of site activity, it can help track water efficiency more accurately.

This will not always be a simple process for construction sites, due to the varying nature of site operations. Based on the

findings to date, it would appear ‘average staff numbers on site’ (or similar such as hours worked) over the monitoring

period may represent a suitable option in some instances. As such, the following could be tracked on a regular basis:

m3 of water consumed per average staff number on site

However, each site should be assessed on its own merit, and the most appropriate KPI selected.

Where sub-metering allows it, process-specific KPIs can be used. For example, where a concrete batching plant is sub-

metered, water consumption relative to raw material input or volume/mass of concrete produced could be used.

Note – the SFfC Water Subgroup’s 2008 baseline KPI of 148 m3 per £million contractors output at constant (2005) prices

is not intended to assess the performance of individual sites, as water consumption can be highly variable depending on

the construction activities taking place - it is solely for assessing the construction sector as a whole.

4.3.4 Targeting

Once the construction company is familiar with regular monitoring of water consumption and KPIs, this data can then be

used to set water efficiency targets for the site. For example, the site could target a 10% reduction in the average water

KPI over a period of 6 months. Such targets are a useful exercise to assist maintain an on-going focus on water

efficiency at the site.

4.4 Other Business Benefits As well as the direct financial benefit which normally applies to reducing water consumption (where water is charged for

on a volumetric basis), there are a number of other potential benefits which may apply, and which merit consideration. These include:

Reduced wastewater disposal costs (e.g. sewer discharge, tanker removal).

Reduced risk from potential water shortage, particularly in parts of England and Wales.

Improved Public Relations (PR) from highly visible water efficiency measures – atomising/misting dust suppression

equipment for sites in highly populated areas can be very effective.

Reduced need to tanker in water at relatively high unit cost.

Reduced energy consumption (where water is heated or cooled).

Reduced on-site treatment costs (where water or wastewater is treated before use/discharge).

Reduced environmental impact (e.g. in relation to environmental impact associated with water operators’ collecting, treating and distributing water in the mains network).

The direct cost of mains water is the most obvious expense when assessing water efficiency, but it can be seen that there are potentially a large number of additional business benefits which are relevant.

16

5.0 Water Saving Devices & Practices: High Priority Activities

The following section has been prepared based on information gathered/collected during the site audits which were

undertaken, and summarises good practice recommendations for the activities which have been identified as high

priority. Individual reports have been prepared for each site (see Appendices), and this section should be read in

conjunction with these reports.

The SFfC Water Subgroup has identified those activities expected to be ‘high priority’ i.e. the activities expected to

provide the greater opportunities for water efficiency savings. These are:

Table 4: High Priority Activities

Water Using Activity High Priority Activity

Dust Suppression General, site roads, wheel washes

Hydro-demolition with high pressure water

Cleaning

Ready mixed concrete wagons

Site/general cleaning

Specialist/high pressure cleaning

Commissioning & Test Building plant/services

As a general comment, contractors should firstly ensure that non-mains water sources are fully utilised (where it is

practical to do so) before considering how water efficiency on site can be improved. For example, abstracting water from

rivers, Sustainable Urban Drainage Systems (SUDS) or settlement lagoons on or near the site may provide water of

sufficient quantity/quality for a number of water-intensive actions, such as dust suppression or wheel washing. Where

using water in such a fashion, care must be taken to ensure that any legal requirements are met in the first instance

(e.g. suitable abstraction licence obtained from environmental regulator).

5.1 Dust Suppression (General)

The following table summarises where dust suppression (general) activities were noted/reported during the site audits:

Table 5: Dust Suppression (General) Summary

Site(s) Activity Comment

1 Manual spray units Small, manually operated spray units.

Area not deemed a high priority - current water consumption and potential for water savings deemed low. As such, this activity will not be discussed further here.

2 Block cutting Worker manually pours water from a bucket whilst block cutting is occurring.

Area not deemed a high priority - current water consumption and potential for water savings deemed low. As such, this activity will not be discussed further here.

6, 7 Rain guns High capacity rain guns are generally used to suppress dust from stockpiles, building demolition, etc.

Although this was not observed during any of the site audits, photograph evidence has been viewed for sites 6 and 7.

This is a high priority area with potential for significant water savings, and is discussed further below.

11,12 Open Hosing Open hosing can be used for general dust suppression where rain guns are considered excessive or are unavailable.

Although this was not witnessed at any site, it was reported as occurring prior to the commencement of the auditing.

This is a high priority area with potential for significant water savings, and is discussed further below.

17

5.1.1 Rain Guns & Manual Hosing

Rain guns are generally simple in operation - water is fired at a high velocity from the back of a water bowser over the

targeted area in order to suppress dust. The following photograph relates to operation of a rain gun at site 6:

Image 4: Rain Gun Operation

A similar system was used at site 7 during the demolition of a building.

Such systems can generally be considered water inefficient, due to the basic flow pattern (i.e. jet) which is apparent. No

manufacturer has been able to provide typical flow rates for an operational rain gun, but based on the apparent velocity

at which the water exits the bowser it is likely to be high. Assuming the flow rate is similar to that of a splash plate

system at full capacity (see Section 5.2.1 below for more details on splash plate systems), it may be in the region of

1,150 lpm (i.e. 69 m3/h). In reality, the flow rate may be higher. It is also likely to vary from system to system.

Manual hosing for general dust suppression is similar in practice to rain guns though operate on a smaller scale, and

may be used where rain guns are considered excessive or are unavailable. Similar to rain guns, the basic flow pattern is

inefficient and represents room for improvement.

A water efficient alternative to rain guns and open hosing for general dust suppression is fan misting systems.

5.1.2 Fan Misting Systems

By utilising fan misting systems, dust suppression efficiency can be maintained (or improved) relative to rain guns or

open hosing, whilst significantly reducing water consumption. Fan misting systems atomise the water prior to dispersion,

creating a more effective dust suppression pattern.

The following picture, taken from a manufacturer’s website, shows a fan misting system in operation – no such systems

were in use at any of the audited sites:

Image 5: Fan Misting System Operation

18

The water consumption of such a system will vary depending on the manufacturer/model. However, a typical

consumption may be in the region of 35 lpm (this is based on Ace Plant’s Dustfighter 7500MP). As such, it can be seen

that significant water savings are on offer relative to using rain guns.

The disadvantages of fan misting systems, relative to rain guns, may include:

More expensive to hire/purchase.

Power connection required, and so they are less mobile.

Mains quality water likely required (i.e. no river, SUDS or settlement lagoon water to be used).

General dust suppression activities will often by undertaken by sub-contractors, who may bring their own

plant/equipment to site, and water efficiency should be discussed with potential sub-contractors prior to site work

commencing - retrospectively considering water efficiency, after water inefficient plant/equipment is already being used

on site, adds complexity to the issue and reduces the chance of improvement. Where possible, sub-contractors who offer

water efficient alternatives to traditional plant/equipment should be preferred.

5.2 Dust Suppression (Site Roads)

The following table summarises where dust suppression (site roads) activities were noted/reported during the site

audits:

Table 6: Dust Suppression (Site Roads) Summary

Sites Activity Comment

3, 6, 11,

12

Dust Suppression

Vehicles

Dust suppression vehicles with splash plate operation were in use at sites 3, 6 and 11 (though not always on the day of the audit). Generally, splash plate systems are water inefficient, due to the rudimentary flow pattern of the water.

An operator from site 3 advised that SUDS water is used for their dust suppression vehicles, and that they vary the water output from their vehicle based on road conditions at the time. As such, although water inefficient splash plate systems are in use, there is no opportunity for mains water savings in this instance.

Site 6 either used river water or mains water for their dust suppression vehicles. No operator was available in order to discuss specific operating methodology.

Site 11 utilised abstracted groundwater within their dust suppression vehicle. As such, although water inefficient splash plate systems are in use, there is no opportunity for mains water savings in this instance.

Site 12 utilised a water efficient alternative to the traditional splash plate

method of operation (discussed further below), and did not represent an opportunity for improvement.

Where mains water is used, dust suppression vehicles with splash plate operation are a high priority area with potential for significant savings, and are discussed further below.

3, 4, 6,

11, 12

Road Sweepers Road sweepers were observed to be in use at sites 3, 6, 11 and 12, and were reported (but not observed) at site 4.

The operator at site 3 reported that he only uses water for dust suppression when road conditions require it, and that he also can control the water output (high and low pressure settings available).

The operator at site 6 reported that he also has high and low pressure settings, and will typically operate on the low pressure setting.

The operator at Site 11 utilised a single Johnston Sweeper 650 (containing a 1,300 litre water tank), which utilises a front-loaded spray bar and single spray nozzle adjacent to the side channel brush.

19

Sites Activity Comment

The operator has on/off control of each of these spray systems, and can also vary the flow rate from within the cab, and as such the road sweeper can be

considered relatively water efficient. The system also has a high pressure washer.

There are 2 contractors operating road sweepers on Site 12, hereafter referred to as Contractor A and Contractor B. Both contractors utilise Johnston Sweepers. Contractor A operates 2 VT650 road sweepers, which contain 1,300 litre water tanks. Contractor B operates 1 - 2 VT800 road sweepers, which contain 1,850 litre water tanks. The road sweepers utilise a front-loaded spray bar and single spray nozzle adjacent to the side channel brush. The operators have on/off control of each of these spray systems, and can also vary the flow rates from within the cab, and as such can be considered relatively water efficient. The systems also have a high pressure washer.

Some road sweepers have an optional water recirculation system, whereby a portion of the recovered wastewater is filtered and then transferred to the

clean water tank. This can provide water savings of up to 50%, though a figure of 30% may be more realistic. This is discussed further below.

5.2.1 Dust Suppression Vehicles (Splash Plate Operation)

Based on observations made during the site audits, as well as discussions with various contacts in the marketplace,

splash plate operation appears to be the most popular system-type for vehicular dust suppression. These rudimentary systems will typically direct high pressure (i.e. pumped) water against a flat metal plate at the rear of the vehicle to

create an outward spray pattern for dust suppression - see picture below:

Image 6: Splash Plate Operation

The basic spraying pattern which can be seen is water inefficient in terms of dust suppression. Typically, such a system

may consume around 1,150 lpm (this is based on ACE Plant’s Splash Plate system), and there is more advanced

technology on the marketplace which can achieve similar results with vastly reduced water consumption. One such system is the hydraulic spinning system, which is discussed further below.

5.2.2 Dust Suppression Vehicles (Hydraulic Spinning System)

As discussed above, the basic water pattern of splash plate operation is water inefficient for dust suppression systems.

By atomising the water to create a fine mist, similar (or better) results can be achieved using significantly less water - a picture of such a system in operation at Site 12 is shown below:

20

Image 7: Hydraulic Spinning System Operation

3 manufacturers were found who are able to provide such a system, and each used a hydraulic spinning disk to create

the necessary misting effect. Quantitative information was available from ACE Plant, who advise their gravity-fed hydraulic spinning system typically consumes around 100 lpm - this is around 9% of their equivalent splash plate

system. As such, as well as significant water savings, the time between re-fills is also lengthened - on larger sites, this

should prove an excellent additional benefit.

The disadvantages of hydraulic spinning systems, relative to splash plate systems, may include:

More expensive to hire/purchase.

Mains quality water likely required (i.e. no river, SUDS or settlement lagoon water to be used).

Vehicular dust suppression activities will often by undertaken by sub-contractors, who may bring their own

plant/equipment to site, and water efficiency should be discussed with potential sub-contractors prior to site work

commencing – retrospectively considering water efficiency, after water inefficient plant/equipment is already being used

on site, adds complexity to the issue and reduces the chance of improvement. Where possible, sub-contractors who offer

water efficient alternatives to traditional plant/equipment should be preferred.

5.2.3 Road Sweepers A typical industrial road sweeper will utilise water for dust suppression, as well as to agitate/loosen contaminants which are on the ground, when conditions require it. This is generally achieved by a front-loaded spray bar and single spray nozzle adjacent to the side channel brush. The vehicles may also have a stand-alone washer system for manual cleaning operations when the vehicle is stationary. Based on observations made during the site audits, most vehicles appear to be manufactured by Johnson Sweepers Limited (JSL), though the vehicle is typically “branded” with the operator’s company details. Additional information on the different JSL vehicles can be found at: www.johnstonsweepers.com/. There is generally a clean water storage tank, as well as a wastewater storage tank, located on-board. Water is sprayed from one or more outlets when the road sweeper is operational, and a portion of this water is collected from the ground via suction before passing to the wastewater storage tank for eventual disposal. A photograph of the side of Site 6’s road sweeper is shown below:

Image 8: Road Sweeper

A spray nozzle, sweeping brush and suction duct can be seen.

21

The normal capacity of a typical road sweeper may be around 35 lpm (based on JSL’s VT650 model). Based on the road sweepers which were analysed, the operators were generally able to reduce the water output (down to dry operation in some instances) based on the site conditions at the time. As such, the average water consumption of a typical road sweeper is likely to be significantly below capacity. Key water efficiency measures for road sweepers include:

Operators should have variable control of each spray bar/nozzle, to allow vehicle performance to be matched to actual requirements depending on site conditions.

Staff training (or discussion with sub-contractor) should be undertaken to ensure available controls are fully utilised to minimise water consumption (e.g. where possible, don’t just use water at full capacity).

Stand-alone washer system should be high pressure (low flow) type, with trigger-operated control (i.e. auto-isolation of flow).

Consider use of water recirculation system – this is discussed further below. In order to improve the water efficiency of road sweepers, it is possible to recycle a portion of collected wastewater. The following shows the system used by JSL, who are the only supplier to date who have been identified as a potential

provider of such a system:

Figure 1: Road Sweeper Water Recycling System (JSL)

Water saving data was requested, and JSL advised that typically savings of around 30% may be achieved, though up to 50% is possible. The 30% savings are based on reducing the operating flow rate from 7.2 lpm to 4.9 lpm. At this stage no recirculation systems have been assessed first-hand, and so these savings could not be confirmed. As well as providing water savings, a water recycling system will significantly lengthen the time between re-fills - on large sites, this is an excellent additional benefit. The biggest disadvantage to such a system may be the additional cost involved.

Road sweeping activities will often by undertaken by sub-contractors, who may bring their own plant/equipment to site,

and water efficiency should be discussed with potential sub-contractors prior to site work commencing – retrospectively

considering water efficiency, after water inefficient plant/equipment is already being used on site, adds complexity to the

issue and reduces the chance of improvement. Where possible, sub-contractors who offer water efficient alternatives to

traditional plant/equipment should be preferred.

5.2.4 Hard-standing Ground

Where feasible, the contractor should look to implement hard-standing roads, car parks, etc. across the site. In addition,

this should be done as early in the project as is practical. This should assist in reducing dust suppression requirements

(and thus water consumption) over the duration of the project.

5.3 Dust Suppression (Wheel Wash)

Note - the primary use of water in the following wheel wash systems is not for dust suppression, but is included in the

dust suppression section to remain consistent with WRAP’s previous publications.

22

The following table summarises where dust suppression (wheel wash) activities were noted/reported:

Table 7: Dust Suppression (Wheel Wash) Summary

Site Activity Comment

3 High Pressure Washer Site 3 was the only site where a manually operated wheel wash system was in operation. A high pressure washer was used to clean wheels, and also the general exterior of the vehicle. All water was collected in a sump, before passing to drain - no recycling of water took place.

This is a high priority area with potential for significant water savings, and is discussed further below.

4, 5, 6, 11

Drive-on Wheel Wash Drive-on wheel washing was observed in operation at site 5 and 11.

Although wheel washing systems were noted at sites 4 and 6, neither system was in use on the day of the audit.

The standard set-up of the drive-on wheel wash systems typically followed a standard format, which incorporated a settlement tank and a recycling system. However, both good practice (site 4) and poor practice (site 5) was noted.

This is a high priority area with potential for significant water savings, and is discussed further below.

5.3.1 High Pressure Washer (Wheel Wash)

The high pressure washer at site 3 is pictured below:

Image 9: High Pressure Washer

The ground around the washing area is hard-standing, and most of the wastewater will pass to a collection sump before

passing to drain. The system has a rated water consumption of 15 lpm. There are 2 main water inefficiencies associated

with a system such as this:

There is no attempt to recycle the wastewater for re-use.

Based on the picture above, it appears that operators may use the system to clean more than just the wheels of their vehicles. Potentially, this will lead to more water being used than is required to meet the minimum cleaning

standards required by the site.

As a general rule, manually operated wheel washing without water recycling should be avoided where it is practical to do

so. There are a number of suppliers across the UK market who can provide drive-on systems with built-in water

recycling, and who offer bespoke systems as well as their standard range to accommodate for most wheel washing

requirements. These systems are discussed further below.

5.3.2 Drive-on Wheel Wash

Site 4 typified good practice for wheel washing activities. A drive-on system with water recycling was located at the site

entrance - see pictures below:

23

Image 10: Drive-on Wheel Wash Settlement Tank Image 11: Drive-on Wheel Wash Wash Area

Wastewater from the wash area (picture right) is automatically recycled to the settlement tank (pictured left) for re-use.

In addition, when the settlement tank requires to be topped-up, water is pumped in from a nearby SUDS. As such, the

entire system has no mains water requirement.

Site 5 was an example of poor practice for drive-on wheel washing activities. The water top-up to the settlement tank

was uncontrolled - there is an open hose feeding mains water in, which runs constantly when the site is operational:

Image 12: Uncontrolled Top-up to Wheel Wash

Once this settlement tank is full, the water over-flows from a discharge pipe at the rear of the unit. Thus, the unit is

discharging suitable quality water to the ground for a significant portion of the time it is operational. In addition to the

uncontrolled top-up mechanism, the water pump remains on for a few seconds after a vehicle is finished washing. In

this short period an apparently large volume of water is sprayed outwards beyond the catchment system.

The mains water supply to the settlement tank was monitored for several hours and averaged at 37 lpm. As such, it can

be seen that a poorly controlled drive-on wheel wash may actually consume more than a manually operated high

pressure washer without recycling (~ 15 lpm - see Section 5.3.1 above for details). For this reason, it is key that drive-

on wheel washing systems are correctly installed, commissioned and maintained.

The following good practice is suggested for drive-on wheel washing systems:

Ensure water top-up to settlement tank is controlled. Typically, this can be achieved using a simple ball float-valve.

Ensure system is designed to switch off wash water pump as soon as is practical after vehicle has exited the wash area. If necessary, an optical sensor could be used to control this.

Ensure wash water supply pressure is set to correct level, through manual control of the isolation valve on the supply pipework (pictured below). The maximum (and normal) operating pressure will typically be in excess of what is required to achieve the required level of cleaning, particularly when site conditions are favourable. The operating pressure (and flow rate) should be adjusted on a regular basis to suit site conditions. This was trialled at Site 11 and the water consumption per wash was reduced from 94 litres to 40 litres (a 43% reduction) without any noticeable reduction in washing effectiveness.

Implement a regular cleaning schedule for the filter grille contained within the ultimate settlement tank (pictured below). If this grille becomes blocked, it can lead to an overflow from the settlement tank.

24

Image 13: Throttled Supply Valve Image 14: Filter Grille Cleaning

There are also waterless-type drive-on wheel wash systems available on the marketplace. These systems offer the maximum possible savings on water and energy, as they have no associated utility consumption. Instead, they rely on an angled grid system to flex the tyre treads open and closed repeatedly, which reportedly leads to contaminant

removal. These systems have not been witnessed at any of the audited sites and so no comments on their effectiveness can be made at this time.

5.4 Dust Suppression (Hydro-demolition with high pressure water)

Note - the primary use of water during hydro-demolition is not dust suppression, but is included in the dust suppression

section to remain consistent with WRAP’s previous publications. As part of Phase II, Mabbett undertook an assessment of two separate hydro-demolition projects. The first was associated with Site 11, and the second was not one of the twelve sites which received a full audit – it was visited solely to inspect the hydrodemolition activities. Both sites were utilising high pressure water to break-out concrete. Site 11 advised that hydro-demolition activities on site consume around 50 lpm of water when operational, but was unable to provide any additional information relating to system operation (e.g. pressure, level of breakout achieved, etc.). The second site reported they were using water at around 1,200 bar to break-out pre-cast concrete beams, which had been weakened due to fire. The flow rate of the water was around 50 – 55 lpm, and the site was able to break out around 1 m3 of concrete per day (over an 8 – 9 hour shift), which corresponds to around 25.5 m3 of water used per m3 of concrete broken out (25.5 m3 water/m3 concrete). It is suspected that the weakened nature of the concrete allowed an above-average rate of progress. The site operator reported this pressure and flow rate of water is typical for large volume concrete demolition. It was also noted by the site operator that in some instances (not at the site in question) they use ultra-high pressure hydro-demolition, which involves using water at a significantly reduced flow rate and around 2,750 – 3,450 bar. This is used where a more accurate level of hydro-demolition is required, and reduces the level of break possible markedly – perhaps by around 90%. Based on the two sites which were audited, it appears that around 50 lpm may be the typical water flow rate for large scale hydro-demolition of concrete. When operational, hydro-demolition is likely to be one of the largest water consuming activities at any construction site, and as such it is recommended that this water using activity is quantified (via sub-meter or metered standpipe) where possible. However, although these activities could not be inspected first-hand (due to the health and safety risk), it is suspected that the opportunity for water savings is relatively low. The reasons of this include:

25

Water flow rates are likely to be those required for efficient hydro-demolition, and as such may be unsuitable for reduction.

The primary concern during hydro-demolition activities is controlling health and safety, due to the relatively high risk of the activity. As such, staff training to improve break down levels (if it were deemed possible, which is currently unknown) is not considered a practical option for water savings.

Potentially, the hydro-demolition water could be re-used elsewhere on site, likely after some level of treatment. This would require assessment on a case-by-case basis, and would depend on a number of factors (e.g. the volume of water involved, water quality of re-use activity, etc.).

5.5 Chemical Additives There are a variety of chemical additives available on the UK market which may assist reduction in water consumption of dust suppression activities. For example, some additives act to reduce the surface tension of dust suppression water, which effectively increases the time taken for the water to dry out, and ultimately reduces the total volume of dust suppression water required.

One such additive, Calcium Magnesium Acetate (CMA), was trialled at Site 11 over a number of weeks during the Phase II work. CMA was added to the vehicular dust suppression bowser, which reportedly was able to reduce its water consumption by one-third without adversely affecting the level of dust suppression achieved. It should be noted that this particular additive can’t be used on site which are utilising bentonite, due to the risk of an adverse chemical reaction.

5.6 Control Systems Where possible, the contractor should ensure that dust suppression systems are specified (during the hiring/purchasing stage) with a sufficient degree of control over their operation to allow their operation to be altered (if required) for different applications, weather conditions, etc. Primarily, this will involve alteration of the water pressure and thus flow rate. For a nozzle-based distribution of water, the following graph shows how flow rate varies with distribution pressure:

Figure 2: Water Distribution Pressure Vs. Water Consumption (Jets, Nozzles and Orifices)

26

The following table provides some examples of situations where additional control of dust suppression systems may lead

to water savings:

Table 8: Dust Suppression System Additional Control Examples

System Comment

Rain Guns Consider that a rain gun is used for dust suppression during building demolition. The next time it is to be used, it is required to suppress dust from a stockpile, which may require a significantly different volume of dust suppression water.

If the pressure is variable, the rain gun will be suited to a greater number of applications, which should help minimise water waste.

Dust Suppression Vehicles (Splash Plate)

The flow rate of water required for dust suppression vehicles with splash plate operation will vary, depending on factors such as road width and weather. As such, if the water pressure can be varied, water wastage can be minimised.

Drive-on Wheel

Wash

The level of wheel washing required is likely to vary depending on the weather and site

conditions. A typical drive-on wheel wash systems may be designed on a ‘worst-case’ basis (i.e. it is capable of cleaning extremely dirty wheels). However, this level of cleaning may not be required in most instances. As such, by allowing variation in the wash water distribution pressure, water savings should be possible.

5.7 Cleaning (Ready Mixed Concrete Wagons)

The following table summarises where cleaning of ready mixed concrete wagons was noted/reported:

Table 9: Cleaning (Ready Mixed Concrete Wagons) Summary

Site Activity Comment

3 Cleaning concrete wagons Site 3 had a concrete batching plant on site. Concrete wagons were

washed internally at this area, prior to be being filled with concrete from the plant. Additionally, concrete wagons are washed externally after they have been filled. Wastewater is collected in a sump, and a portion of this wastewater is used as ingredient in the concrete batching process.

Cleaning of concrete wagons is a high priority area, and site 3 shows both good and poor practice in this respect - this is discussed further below.

7 Cleaning concrete wagons (externally only)

Site 7 has an on site agitator (i.e. stationary concrete wagon), which is regularly filled with concrete (via mobile concrete wagons) from a local concrete batching plant. Cleaning operations on site were limited to:

Third party mobile concrete wagons cleaning in and around their vehicle’s delivery chute, after delivering concrete into agitator. Each

wagon had its own water tank and hose in order to undertake these cleaning operations.

Cleaning concrete waste from around agitator area, using a hose or pressure washer associated with the system.

Cleaning operations at site 7 could be improved, though they are relatively small scale - most of the cleaning water in this instance will be associated with the mobile concrete wagons, once they get back to the batching plant (i.e. when cleaning wagon internally). As such, site 7 will not be discussed further below.

The concrete batching plant at site 3 consumes around 91.6 m3/week of water (average figure based on available meter

data), and this water is associated with the following applications:

Ingredient water used in concrete batching process.

Mains pressure hose for washing concrete wagons.

High pressure washer for cleaning batching plant ‘rotating heads’.

The current split of water consumption between each application is currently unknown.

27

Filling of a concrete wagon is shown below:

Image 15: Concrete Wagon Filling

In order to wash the wagons, a standard mains pressure hose (controlled by a quarter-turn isolation valve) is used:

Image 16: Mains Pressure Hose

Shown below is a picture of this system in use:

Image 17: Operational Mains Pressure Hose

28

Generally speaking, the wagons will be washed over hard-standing ground, and the wastewater will drain to a collection sump:

Image 18: Collection Sump

The water is then re-used as an ingredient in the concrete mixing process, although there is a maximum amount which can be used (reportedly around 50% by volume). However, once this sump is full, the wagons are washed adjacent to the hard-standing ground, and the wastewater passes to ground without recycling:

Image 19: Standby Wash Area

The concrete batching plant operator reported that they currently use as much recycled water as they can for concrete mixing, and as such, unless another use for the recycled water can be used, improved collection of wastewater (e.g. through increasing the sump volume) would not achieve any further mains water savings. The system at site 3 combines elements of both good and poor practice. The current method of recycling wastewater and using it as ingredient in the concrete batching process is good practice. However, utilising a mains pressure hose with a basic flow pattern (and which is controlled by a quarter-turn isolation valve) is water inefficient, and could be improved.

29

The following table summarises water conservation measures which could be considered good practice for washing concrete wagons: Table 10: Cleaning (Ready Mixed Concrete Wagons) Good Practice Measures

Water Conservation Measure Comment

Hard-standing ground of sufficient size and design around washing area.

This will ensure as much water as is practical is collected and passes to the wastewater sump for potential re-use.

Sufficiently designed wastewater sump. The sump should typically be sized to ensure that as much wastewater as can potentially be re-used (as ingredient or other re-use application) is stored. Where a degree of settlement is required prior to re-use, this should also be considered in the design.

Utilise high pressure washer Mains pressure hoses with basic flow patterns are generally water inefficient for cleaning operations. Use of a high pressure (low volume) washer, which has trigger-operated control, should act to minimise the volume of wash water which is required.

Operators should discuss their requirements with a number of potential vendors, to ensure that the correct system (e.g. most suitable nozzle technology, lowest volume flow which will still provide required level of cleaning, etc.) for the particular application is selected - see Section 5.8 below for more details.

Manage level of wastewater which is re-used

Where wastewater is to be re-used, the site should ensure that this is undertaken to the maximum, practical extent.

For example, where water is to be re-used as an ingredient in a concrete batching operation, the contractor should ensure plant operators are aware of exactly how much wastewater each concrete batch is allowed to use, before quality could potentially be compromised.

5.8 Cleaning (Site/General Cleaning/Specialist/High Pressure) Each manual cleaning application should be assessed on its own merit, and there are no absolute rules for water efficiency. However, by considering 3 key areas, water efficiency should generally be achieved - these are discussed further below. Typical cleaning activities, as observed during the site audits, include: Boot cleaning; Manual vehicle washing; and Rinsing soil/aggregate samples.

5.8.1 Auto-isolation of Flow The contractor should ensure flow from cleaning devices auto-isolates once it is no longer in use. In almost all instances, this will involve the use of trigger-control. This ensures there is no possibility of an unused cleaning device being left

operational (i.e. using water) when it is not in use. Both good and poor practice in this respect was observed at the audited sites. For standard hoses, trigger-operated spray guns should be used:

Image 20: Operational Trigger-operated Spray Gun

30