Supplementary Materials apoptosis and arresting cell cycle ...

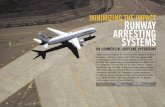

AIRCRAFT ARRESTING BARRIER Stanchion System with TEXTILE ...

Transcript of AIRCRAFT ARRESTING BARRIER Stanchion System with TEXTILE ...

TekSav Teknoloji Elektrik Elektronik Makine San .ve Tic. A.Ş10016 Sok. No:20 A.O.S.B. - Çiğli / İzmir - Türkiye

tel/Fax:232-3281141web site : http://www.teksav-teknoloji.com

e-mail : [email protected]@teksav-teknoloji.com

AIRCRAFT ARRESTING BARRIER Stanchion System

with TEXTILE BRAKE

AT-AB/1STEK - TB10-150

BRIEF INTRODUCTION

Published by : TekSav Teknoloji Elektrik Elektronik Makine Sanayi ve Tic. A.S.Address : 10016 Sokak No: 20 A.O.S.B. Cigli Izmir – TurkeyTel : +90-232-3281141 (PBX)Fax : +90-232-3281141E-mail :[email protected], [email protected] Web-site :http://www.teksav-teknoloji.com

Document no : 200705Date : May 2007

AT-AB-1S TEK - TB10-150 AIRCRAFT BARRIER

TekSav Teknoloji Elektrik Elektronik Makine San .ve Tic. A.Ş10016 Sok. No:20 A.O.S.B. - Çiğli / İzmir - Türkiye

tel/Fax:232-3281141web site : http://www.teksav-teknoloji.com

e-mail : [email protected]@teksav-teknoloji.com

REVISION SHEET

DOC NO: 200109-1DATE DESCRIPTION DONE BY APPROVED BY

Sept. 2001 Initial Dr. S. AkdurakMay 2007 upgraded Dr. S. AkdurakMay 2007 Revised and upgraded Dr. S. Akdurak

All changes to this document have to be recorded to the revision sheet.

AT-AB-1S TEK - TB10-150 AIRCRAFT BARRIER

TekSav Teknoloji Elektrik Elektronik Makine San .ve Tic. A.Ş10016 Sok. No:20 A.O.S.B. - Çiğli / İzmir - Türkiye

tel/Fax:232-3281141web site : http://www.teksav-teknoloji.com

e-mail : [email protected]@teksav-teknoloji.com

INDEX

1. INTRODUCTION1. INTRODUCTION ............................................................................................................................................................................................................................................................................ 88 1.1 OUTSTANDING FEATURES OF THE AT-AB /1 AIRCRAFT ARRESTING BARRIER SYSTEM1.1 OUTSTANDING FEATURES OF THE AT-AB /1 AIRCRAFT ARRESTING BARRIER SYSTEM ............................................ 99

2. GENERAL (TEXTILE BRAKE)2. GENERAL (TEXTILE BRAKE) ........................................................................................................................................................................................................................ 1010 2.1 PURPOSE 2.1 PURPOSE .................................................................................................................................................................................................................................................................................................................... 1010

2.2 OPERATION CAPACITY2.2 OPERATION CAPACITY ........................................................................................................................................................................................................................................................................ 1010

2.3 DESCRIPTION 2.3 DESCRIPTION ...................................................................................................................................................................................................................................................................................................... 1111

3. TECHNICAL DATA3. TECHNICAL DATA ................................................................................................................................................................................................................................................................ 1414 3.1 OPERATION CAPACITY OF TEXTILE BRAKE TB10-1503.1 OPERATION CAPACITY OF TEXTILE BRAKE TB10-150 .............................................................................................................................................................. 1414

3.2 DIMENSIONS AND MEASURES3.2 DIMENSIONS AND MEASURES ................................................................................................................................................................................................................................................ 1414 3.2.1 Braking modules ....................................................................................................................................... 14 3.2.2 Arrestment Capacity ................................................................................................................................. 14

4. INTRODUCTION OF STANCHION SYSTEM 4. INTRODUCTION OF STANCHION SYSTEM ............................................................................................................................................................................ 1515 4.1 PREFACE4.1 PREFACE ........................................................................................................................................................................................................................................................................................................................ 1515

4.2 AIM OF THE SYSTEM4.2 AIM OF THE SYSTEM ................................................................................................................................................................................................................................................................................ 1515

4.3 MAIN EQUIPMENT AND DESCRIPTIONS4.3 MAIN EQUIPMENT AND DESCRIPTIONS ................................................................................................................................................................................................................ 1515

4.4 OPERATING CONDITIONS4.4 OPERATING CONDITIONS ................................................................................................................................................................................................................................................................ 1616

4.5 PHYSICAL DIMENSIONS4.5 PHYSICAL DIMENSIONS .................................................................................................................................................................................................................................................................... 1717

4.6 STORAGE OF THE SYSTEM4.6 STORAGE OF THE SYSTEM .......................................................................................................................................................................................................................................................... 1717

5. DESCRIPTION OF THE SYSTEM5. DESCRIPTION OF THE SYSTEM ................................................................................................................................................................................................................ 1818 5.1 MOVEMENT CONTROL ROD5.1 MOVEMENT CONTROL ROD ........................................................................................................................................................................................................................................................ 1818

5.2 ACTUATOR5.2 ACTUATOR .................................................................................................................................................................................................................................................................................................................. 1818

5.3 GUY WIRES5.3 GUY WIRES ................................................................................................................................................................................................................................................................................................................ 1818

5.4 PNEUMATIC POWER SYSTEM5.4 PNEUMATIC POWER SYSTEM .................................................................................................................................................................................................................................................. 1818

5.5 LOCKING SYSTEM5.5 LOCKING SYSTEM ........................................................................................................................................................................................................................................................................................ 1919

5.6 ELECTRICAL CONNECTIONS AND ELECTRONIC CONTROL5.6 ELECTRICAL CONNECTIONS AND ELECTRONIC CONTROL ............................................................................................................................................ 1919

5.7 STRUCTURAL ASSEMBLY5.7 STRUCTURAL ASSEMBLY .............................................................................................................................................................................................................................................................. 2020 5.7.1 NITROGEN STORAGE TANK .................................................................................................................... 20 5.7.2 MASTS ........................................................................................................................................................ 20 5.7.3 NITROGEN TUBES ..................................................................................................................................... 20

5.7.3.1 HIGH PERFORMANCE SYSTEM (OPTIONAL) ........................................................................................................ 20

5.8 CONTROLS5.8 CONTROLS .................................................................................................................................................................................................................................................................................................................. 2020

5.9 REMOTE CONTROL WITH CABLE5.9 REMOTE CONTROL WITH CABLE ...................................................................................................................................................................................................................................... 2121

5.10 RADIO CONTROL (AIR CONTROL TOWER TO BARRIER) (OPTIONAL)5.10 RADIO CONTROL (AIR CONTROL TOWER TO BARRIER) (OPTIONAL) ........................................................................................................ 2121 5.10.1 TECHNICAL DATA ................................................................................................................................... 21 5.10.2 REMOTE OPERATION ............................................................................................................................. 21

6. OPERATION PRINCIPALS6. OPERATION PRINCIPALS ........................................................................................................................................................................................................................................ 2222

AT-AB-1S TEK - TB10-150 AIRCRAFT BARRIER

TekSav Teknoloji Elektrik Elektronik Makine San .ve Tic. A.Ş10016 Sok. No:20 A.O.S.B. - Çiğli / İzmir - Türkiye

tel/Fax:232-3281141web site : http://www.teksav-teknoloji.com

e-mail : [email protected]@teksav-teknoloji.com

6.1 GENERAL6.1 GENERAL ...................................................................................................................................................................................................................................................................................................................... 2222

6.2 AUTOMATIC RECHARGING OF THE NITROGEN STORAGE TANK6.2 AUTOMATIC RECHARGING OF THE NITROGEN STORAGE TANK .......................................................................................................................... 2222

6.3 RAISING OF THE BARRIER6.3 RAISING OF THE BARRIER ............................................................................................................................................................................................................................................................ 2222

6.4 LOWERING OF THE BARRIER6.4 LOWERING OF THE BARRIER .................................................................................................................................................................................................................................................. 2222

6.5 LOCKING AND UNLOCKING OF THE STANCHION SYSTEM6.5 LOCKING AND UNLOCKING OF THE STANCHION SYSTEM ................................................................................................................................................ 2323 6.5.1 LOCKING .................................................................................................................................................... 23 6.5.2 UNLOCKING ............................................................................................................................................... 23

6.6 SEPARATION OF THE STANCHION SYSTEM AND BARRIER NET AFTER ARRESTMENT6.6 SEPARATION OF THE STANCHION SYSTEM AND BARRIER NET AFTER ARRESTMENT .............................................. 2323

6.7 STATUS OF THE POWER SYSTEM DURING OPERATION6.7 STATUS OF THE POWER SYSTEM DURING OPERATION ........................................................................................................................................................ 2323

7. ILLUSTRATED PART LIST OF MAIN EQUIPMENT7. ILLUSTRATED PART LIST OF MAIN EQUIPMENT .......................................................................................................................................................... 2424

8. TOOLS DELIVERED WITH THE SYSTEM 8. TOOLS DELIVERED WITH THE SYSTEM ...................................................................................................................................................................................... 4343

AT-AB-1S TEK - TB10-150 AIRCRAFT BARRIER

TekSav Teknoloji Elektrik Elektronik Makine San .ve Tic. A.Ş10016 Sok. No:20 A.O.S.B. - Çiğli / İzmir - Türkiye

tel/Fax:232-3281141web site : http://www.teksav-teknoloji.com

e-mail : [email protected]@teksav-teknoloji.com

AT-AB-1S TEK - TB10-150 AIRCRAFT BARRIER

TekSav Teknoloji Elektrik Elektronik Makine San .ve Tic. A.Ş10016 Sok. No:20 A.O.S.B. - Çiğli / İzmir - Türkiye

tel/Fax:232-3281141web site : http://www.teksav-teknoloji.com

e-mail : [email protected]@teksav-teknoloji.com

MAST ASSEMBLY

DURING PRODUCTION

THE SHIPMENT

AT-AB-1S TEK - TB10-150 AIRCRAFT BARRIER

TekSav Teknoloji Elektrik Elektronik Makine San .ve Tic. A.Ş10016 Sok. No:20 A.O.S.B. - Çiğli / İzmir - Türkiye

tel/Fax:232-3281141web site : http://www.teksav-teknoloji.com

e-mail : [email protected]@teksav-teknoloji.com

DURING PRODUCTIONBARRIER NET

BARRIER NET

SITEINSTALLATION

AT-AB-1S TEK - TB10-150 AIRCRAFT BARRIER

TekSav Teknoloji Elektrik Elektronik Makine San .ve Tic. A.Ş10016 Sok. No:20 A.O.S.B. - Çiğli / İzmir - Türkiye

tel/Fax:232-3281141web site : http://www.teksav-teknoloji.com

e-mail : [email protected]@teksav-teknoloji.com

1. INTRODUCTIONAT-AB/1 is the main family of an aircraft arresting barrier systems produced by TEKSAV TEKNOLOJI A.S. The AT-

AB/1 is a complete aircraft arresting barrier installation consisting of the stanchion system with a multiple element net.The stanchion system of two identical assemblies installed one each side of the runway overrun, symmetrical to the

center line. The system is remote controlled, with the trigger mechanism at either the control tower or a field cabinet located by the overrun equipped. Also, an option of radio remote control is available.

Every AT-AB/1 arresting barrier is so manufactured that it can be coupled with 12-3f, 500s or TB textile brake systems. The couplings required for connection of the net to the 12-3f , 500s or TB brake system is furnished together with each system.

The stanchion system and the brake system coupled to it can together arrest aircraft of up to 70000 lbs. With a velocity of maximum 190 knots in due course only a number of vertical strips may be damaged. The endurance of the horizontal elements is about 2200 kgf per strap. Connection elements are available at the bottom of the net attachment to the surface of the runway and the anchoring desks needed for this purpose are also furnished with the system. Depending on the braking system type and rated capacity, the energy absorbance ability above figures may change.

During electricity cutoffs, the stanchion system with the net installed may be raised and lowered 5 times on energy supplied by batteries and nitrogen storage tanks. If the cutoff happens during operation -i.e. while the masts are going up or down-, the system continues to operate until the movement is completed. If, on the other hand, the cutoff takes place while the masts are fully raised or fully lowered, the system remains as it is.

The barrier remote control panels at the control tower and at the field cabinet have luminous indicators for the positions (” up” or” down”) of the net as well as the status (“ready to operate “-”out of the order”) of the stanchion system. The panel also incorporates visual and audio alarm mechanisms and fault indicators.

A red flashing lamp is installed at the base of the system to indicate whether the system is up or down.The stanchion system may be combined with i-28, t-30 ,t-40 or HP-40 type nets to form the barrier installation. (Unless

otherwise specified, the system comes equipped with the t-30). The arresting net in all cases has no metal parts other than cutter pins.

The stanchion system maintains the rigidity of the net in both raised and lowered positions. When raised, the lowermost point of the net’s top line is at least 375 cm above the runway surface, adjustable by ± 30 cm.

The stanchion system is able to raise the masts from fully lowered (“down “) position to fully rose (“up “) position and hence have the arresting net ready within less than 1.5 to 6 seconds.

The barrier system is able to operate reliably within the ambient temperature range of -40°c - +55°c and in all sorts of weather conditions.

. Each system is delivered complete with the tool set and equipment needed for periodical inspection, maintenance and repair of the system.

The service life of the net made out of polyamide 66 and polyester is at least 3 years.This handbook covers the three main sections of AT-AB/1 aircraft arresting barrier.

A) The Braking system (textile brake)B) Stanchion system C) The arresting net (not included in this handbook

AT-AB-1S TEK - TB10-150 AIRCRAFT BARRIER

TekSav Teknoloji Elektrik Elektronik Makine San .ve Tic. A.Ş10016 Sok. No:20 A.O.S.B. - Çiğli / İzmir - Türkiye

tel/Fax:232-3281141web site : http://www.teksav-teknoloji.com

e-mail : [email protected]@teksav-teknoloji.com

1.1 Outstanding features of the AT-AB /1 aircraft arresting barrier system

• Variety of control methods: the AT-AB system offers the user great flexibility and security because it can be activated in any of the following ways:

1. By remote control from a panel at the control tower. (radio control optional)2. By remote control from a field cabinet3. Manually by controls on the system (in cases of power cutoff)

• Modular circuit boards : repair and maintenance time is reduced to a minimum by modular circuit boards that may be removed and installed in a matter of minutes.

• Fault indicating lamps (LEDs) on all electronic modules: This eliminates the need to go through exhausting tests to locate faults.

• Built-in alarm mechanisms : the user is automatically warned when the system is out of order or may become so shortly.

AT-AB-1S TEK - TB10-150 AIRCRAFT BARRIER

TekSav Teknoloji Elektrik Elektronik Makine San .ve Tic. A.Ş10016 Sok. No:20 A.O.S.B. - Çiğli / İzmir - Türkiye

tel/Fax:232-3281141web site : http://www.teksav-teknoloji.com

e-mail : [email protected]@teksav-teknoloji.com

2. GENERAL (TEXTILE BRAKE)

This manual contains the necessary information and instructions for the installation, operation, maintenance and overhaul of the Aircraft Arresting Barrier with a Textile Brake TB10-150

2.1 Purpose

The purpose of the Aircraft Arresting barriers is to safely stop an aircraft, which, for any reason would otherwise run off the end of the runway during a landing due to brake failure or reduced runway friction or an unsuccessful/aborted takeoff. The primary purpose of an aircraft arresting barrier is to save the lives of pilots. The secondary purpose is to prevent damage to the aircraft and to the landing facilities.

During an arrestment by TB10-150, braking is provided by the tearing of special textile straps of which the textile brake is composed.

2.2 Operation Capacity

The system is designed to operate at ;

Ambient temperature range : -40°C to + 55°C

Engaging velocities : < 160 knots,

Energy absorbing capacity : 108 MJ

Run out distance : <200 m

Aircraft weight : max. 32 ton

Maximum G : <2 G

AAT-AB-1S TEK - TB10-150 AIRCRAFT BARRIER

0,010,020,030,040,050,060,070,080,090,0

0 50 100 150 200 250

distance (m)

enga

gem

ent

spee

d m

/s speed m/sdeaccel m/sn2time t sec

TekSav Teknoloji Elektrik Elektronik Makine San .ve Tic. A.Ş10016 Sok. No:20 A.O.S.B. - Çiğli / İzmir - Türkiye

tel/Fax:232-3281141web site : http://www.teksav-teknoloji.com

e-mail : [email protected]@teksav-teknoloji.com

2.3 Description

The textile brake system TB10-150 consists of two braking units Which comprising:

• A braking line, composed of two braking units each,• Two extensions linking the braking units to the strops,• Two strops for connecting the textile brake units to the net assy,• The arresting system can be installed on concrete foundations (for permanent installation),or using earth anchors for

temporary installation (not covered in this manualThe material used in modules of the braking line must be from identical manufacturing lot which ensures the same

braking force on each side of the runway.

TB10-150

Figure -1

AAT-AB-1S TEK - TB10-150 AIRCRAFT BARRIER

TekSav Teknoloji Elektrik Elektronik Makine San .ve Tic. A.Ş10016 Sok. No:20 A.O.S.B. - Çiğli / İzmir - Türkiye

tel/Fax:232-3281141web site : http://www.teksav-teknoloji.com

e-mail : [email protected]@teksav-teknoloji.com

Figure 2a

Figure 2b

AT-AB-1S TEK - TB10-150 AIRCRAFT BARRIER

TekSav Teknoloji Elektrik Elektronik Makine San .ve Tic. A.Ş10016 Sok. No:20 A.O.S.B. - Çiğli / İzmir - Türkiye

tel/Fax:232-3281141web site : http://www.teksav-teknoloji.com

e-mail : [email protected]@teksav-teknoloji.com

Figure 2c

AT-AB-1S TEK - TB10-150 AIRCRAFT BARRIER

TekSav Teknoloji Elektrik Elektronik Makine San .ve Tic. A.Ş10016 Sok. No:20 A.O.S.B. - Çiğli / İzmir - Türkiye

tel/Fax:232-3281141web site : http://www.teksav-teknoloji.com

e-mail : [email protected]@teksav-teknoloji.com

3. TECHNICAL DATA

3.1 Operation Capacity of TEXTILE BRAKE TB10-150

The system is designed to operate at ;

Ambient temperature range : -40°C to + 55°CEngaging velocities : < 160 knots,Energy absorbing capacity : 108 MJRun out distance : <200 mAircraft weight : <32 ton

3.2 DIMENSIONS AND MEASURES

Designation Weight KgsBraking line 374Extension 14 ea.Braking system (Without anchors)

414

3.2.13.2.1 Braking modulesBraking modules

Length (Without harness) 1.30 mtWidth (Without harness) 0.35 mtWeight 18 kg ea.length of tear strap 50 mtextension nominal length 6.8 mtStrop Length 3 mt

3.2.23.2.2 Arrestment CapacityArrestment Capacity

At page 6 the performance characteristics of a TB10-150 is provided• arrestment capacity versus engaging velocity and aircraft weight,• decelerations vs. aircraft weight,

The performances curve belongs to TB10-150 system when only seven modules per braking unit are used.

AT-AB-1S TEK - TB10-150 AIRCRAFT BARRIER

TekSav Teknoloji Elektrik Elektronik Makine San .ve Tic. A.Ş10016 Sok. No:20 A.O.S.B. - Çiğli / İzmir - Türkiye

tel/Fax:232-3281141web site : http://www.teksav-teknoloji.com

e-mail : [email protected]@teksav-teknoloji.com

4.4. INTRODUCTION OF STANCHION SYSTEM INTRODUCTION OF STANCHION SYSTEM

4.1 PREFACE

This part of the handbook contains the introduction of "AT-AB/1 AIRCRAFT ARRESTING NET BARRIER AND STANCHION SYSTEM".

Above mentioned systems is designed and produced by TekSav Teknoloji Elektronik ve Makina Sanayi Ticaret A.S. a corporation with its principal place of business at

Address : Izmir Atatürk Organize Sanayi Bölgesi 10016 Sokak No: 20 Cigli - IZMIR / TURKEY

Telephone : +.90.232.328 11 41 (PBX)

Fax : +90.232.376 1141

E-mail : [email protected]

Web page : www.teksav-teknoloji.com

4.2 AIM OF THE SYSTEMThe AT-AB/1 Aircraft Arresting System is designed to arrest non-stopping aircrafts at either end of the runway in case of

failure during taxiing before take-off or landing. The system operates automatically by pushing a button on a tower control panel or by the help of site control cabinet.

It is also possible to lower the barrier net by releasing the air manually.Raising time can easily be adjusted between 1 - 6 seconds.

4.3 MAIN EQUIPMENT AND DESCRIPTIONSAT-AB/1 Aircraft Arresting Stanchion Systems are sited on both sides of the runway which are the same with each other

consists of mainly (see Fig. 7.2)

Movement Control RodActuatorsGuy wirePneumatic Power System (valve group)Locking SystemSite Control Cabinet and Tower Control Panel Mounting SystemNitrogen Storage TankMastsNitrogen TubesPanel for Pneumatic Gauges and Valves

AT-AB-1S TEK - TB10-150 AIRCRAFT BARRIER

TekSav Teknoloji Elektrik Elektronik Makine San .ve Tic. A.Ş10016 Sok. No:20 A.O.S.B. - Çiğli / İzmir - Türkiye

tel/Fax:232-3281141web site : http://www.teksav-teknoloji.com

e-mail : [email protected]@teksav-teknoloji.com

Descriptions :

Raising Actuator : Cylinder Diameter : 250 mm.Stroke : 500 mmRod Diameter : 70 mm

Locking Actuator : Actuated by means of a 24 DC electric motor coupled a velocity reducer.

Nitrogen Tubes : Volume : 40 Liters (2 ea.)Operation Pressure: 150 bar at 150CTest Pressure : 225 bar at 150C

Nitrogen Storage Tank : Volume : 70 LitersLength : 2060 mmDiameter : 240 mm Operation Pressure: 40 Bar at 150CTest Pressure : 70 Bar at 150C

Masts : Seamless, steel pipesLength : 7500 mm (telescope adjustment -/+200 mm)Outer Diameter : 180 mm

4.4 OPERATING CONDITIONSThe necessary operating pressure to a raise TT-30, TT 2X20, I-28 nets or other nets with equal weight is between 18

and 25 bars. It is necessary to raise the pressure 6 bars more in case of using 40 elements nets.All equipments are designed according to operate between -400C and +550C ambient temperature. For a group sited only one runway end it is necessary to supply energy of 24 V DC and a power of 75 Watts. This

power is supplied by a 12 V, 60 Ah batteries. The batteries are charged continuously and automatically by 220V, 50 Hz alternative current.

Depending on the operation pressure, it is possible to make at least 15 raising without recharging the nitrogen tubes.

AT-AB-1S TEK - TB10-150 AIRCRAFT BARRIER

TekSav Teknoloji Elektrik Elektronik Makine San .ve Tic. A.Ş10016 Sok. No:20 A.O.S.B. - Çiğli / İzmir - Türkiye

tel/Fax:232-3281141web site : http://www.teksav-teknoloji.com

e-mail : [email protected]@teksav-teknoloji.com

4.54.5 PHYSICAL DIMENSIONSPHYSICAL DIMENSIONS

DESCRIPTION QTY. PER. SYSTEM

UNIT WEIGHT

(Kg)

MEASURESmm

1-Raising Masts2-Nitrogen Tube3-Actuators4-Movement Control Rod5-Nitrogen Storage Tanks6-Chain Set7-Guy wire ground fixing plates8-Textile NetTotal WeightA system per one end

24242221

19051(Empty)3201619540156002400

L=7500 D=180D=170 L=1670600 x 920 x 302080 x 25 x 1080L=2060 D=240L=4500

58000 x 4000

4.6 STORAGE OF THE SYSTEMAll the equipment, especially the textile net should be stored at a protected place and kept in transportation packing.

AT-AB-1S TEK - TB10-150 AIRCRAFT BARRIER

TekSav Teknoloji Elektrik Elektronik Makine San .ve Tic. A.Ş10016 Sok. No:20 A.O.S.B. - Çiğli / İzmir - Türkiye

tel/Fax:232-3281141web site : http://www.teksav-teknoloji.com

e-mail : [email protected]@teksav-teknoloji.com

5.5. DESCRIPTION OF THE SYSTEMDESCRIPTION OF THE SYSTEM

5.1 MOVEMENT CONTROL ROD

Two control rods with the measures 80 X 25 X 1080 mm. are located on both sides of the mast. These rods are connected to the mast flanges and to the base of the actuator by two 40 mm diameter pins spaced 1m apart.

By the help of these rods the actuator drive load is transmitted to the mast.

5.2 ACTUATORThe piston rod is stationary and also attached to the main structure from one end. The actuator cylinder moves in the

main structure by means of two rollers and transfers the movement to the mast.The stroke of the actuator system is approximately 500 mm. The inner diameter of the cylinder is 250 mm, and the

diameter of the piston rod is 70 mm.Maximum operation pressure is 40 bars.The pressure chamber of the actuator is the place where the main movement is supplied. The second chamber is

closed in normal position and is equipped with an air relief valve, and serves as back pressure chamber. While the mast is in lowered position the pressure in this chamber is zero. After raising the volume in this chamber decreases and so the pressure increases. By the help of air relief valve the air flow is regulated and thus the needed raising velocity is reached and the movement is damped.

5.3 GUY WIRESThe tensile loads on the barrier suspension columns are transmitted to the steel guy wires and the needed suspension

is so maintained.The guy wire system consists of an 11 meters long steel wire having 12 tons braking strength and a chain 4.5 meters

long. The wire and the chain are connected by a quick fastened lock.By means of the chain the length of the guy wire is adjusted and it is connected to the ground by another quick-fastened

lock. The length of the chain is adjusted according to the position of the anchor points and tensile of the net.The guy wire is connected to the textile net by means of a shear column which separates the net from the stanchion

system when engagement occurs.

5.4 PNEUMATIC POWER SYSTEMThe Pneumatic Power System includes the below mentioned units:Two pressure manometers;One HP (High Pressure) pressure manometer showing the nitrogen pressure in the nitrogen tubesOne LP (Low Pressure) pressure manometer showing the pressure in the nitrogen storage tankA manual controlled pressure regulator which reduces the nitrogen pressure in the tubes to the needed operation

pressureNitrogen tubes charging system;Pressure control panel is mounted on a console which is on the main structure. This console is designed portable so it

becomes possible to reach pneumatic components in case of repair or maintenance.A set of Solenoid Valves;These valves provide raising and lowering of the barrier. A double solenoid valve set is installed so that the system

continues working in case of a failure of one set of solenoid valves.

AT-AB-1S TEK - TB10-150 AIRCRAFT BARRIER

TekSav Teknoloji Elektrik Elektronik Makine San .ve Tic. A.Ş10016 Sok. No:20 A.O.S.B. - Çiğli / İzmir - Türkiye

tel/Fax:232-3281141web site : http://www.teksav-teknoloji.com

e-mail : [email protected]@teksav-teknoloji.com

The solenoid valves and the pressure regulation block are so connected to the piston rod that by disconnecting only the hoses and unplug the electrical cables the maintenance time is shortened.

The necessary electric power supply for the solenoid valves is 24V DC -/+ 10%. The power consumption for one solenoid valve is approximately 14 watts.

5.5 LOCKING SYSTEM

In order to avoid the risk of accidental raising of the masts during control and maintenance works a locking system is added.

This locking system operates manually. After raising the red signal Flag mast the fixing rod is inserted into the hole and so the mast becomes fixed and locked. After doing this the red signal lamp becomes off automatically.

After finishing the control and / or maintenance works the fixing rod is taken out and the red signal flag mast is lowered. In order to prevent the flag mast to be raised again this fixing rod is inserted in its place. Just during this position the red signal lamp on the stanchion system becomes on and at the same time the lamp on the tower control panel indicates that the system is ready to operate.

W A R N I N G :

-LOCKING IS APPLIED DURING CONTROL OR MAINTENANCE WORK ONLY

-NO PERMISSION IS GIVEN FOR CONTROL OR MAINTENANCE WORKS WITHOUT LOCKING THE MASTS.

5.6 ELECTRICAL CONNECTIONS AND ELECTRONIC CONTROLAll the functions are controlled from the tower control panel or site control cabinet. Operating and repairing panel and

cabinet are very simple.The tower control panel is connected to site control cabinet by an 8x1.5 mm2 cable. Raising units are connected to the

site control cabinet by 4x1.5 mm2 or 4x2.5 mm2 cables having 8 conductors.Control system is procured as three main units:

A) Raising unitsB) Site Control Cabinetc) Tower Control Panel

It is possible to control the raising units both from tower control panel and site control cabinet.In case of any failure the led lamps indicate the failure section. This failure signal is given as sound and light on the

tower control panel also.Detailed knowledge is given in the AT-AB/1 ELECTRIC AND ELECTRONIC CONTROL SYSTEM HANDBOOK.

AT-AB-1S TEK - TB10-150 AIRCRAFT BARRIER

TekSav Teknoloji Elektrik Elektronik Makine San .ve Tic. A.Ş10016 Sok. No:20 A.O.S.B. - Çiğli / İzmir - Türkiye

tel/Fax:232-3281141web site : http://www.teksav-teknoloji.com

e-mail : [email protected]@teksav-teknoloji.com

5.7 STRUCTURAL ASSEMBLYThe main body is manufactured of steel plates and steel profiles. In order to protect the actuator and pneumatic power

system a metal plate cover is provided on the main body.

5.7.1 NITROGEN STORAGE TANK

The nitrogen gas necessary for raising is stored in storage tank. This tank is a hollow cylinder flanged from both ends. With the gas stored in this tank only one raising is realized.

On the mast rotation axis side there are pressure hoses and muffs to drain the tank. And also there is a globe valve to drain the condensed water and a spring safety valve.

The volume of this tank is 70 liters.

5.7.2 MASTS

Below mentioned elements procure a mast assembly:180 mm outer diameter170 mm inner diameter. (First part of the mast 3200 mm length)160 mm outer diameter150 mm inner diameter. (Second part of the mast 4300 mm length)(With a total length of 7500 mm, telescope adjustment, seamless steel pipe mast)A removable mast head placed on the upper end of the mast where the guy wire travels.

5.7.3 NITROGEN TUBES

These tubes are used to store energy (high pressure nitrogen) for raising the masts.Each contains 40 liters of nitrogen gas at 150 bar (two tubes makes 80 liters) and serves at least for ten raisings at 25

bars. It makes 13-14 raising at 18 bars.

5.7.3.1 HIGH PERFORMANCE SYSTEM (OPTIONAL)By adding four more nitrogen tubes (two for each side) it is possible to double raising operations without recharging

the tubes. Those additional tubes are placed on special frameworks sided by the stanchion body. Additional connecting hoses are part of this system.

5.8 CONTROLSManual control or remote control of the aircraft arresting system is possible. All action is reported back by lighting the

front panel indicator LED lamps on RCU. System can also be remote controlled either with remote control unit (RCU) or by any air band radio wireless. All the electronic boards have conformal coating to protect against the environment.

AT-AB-1S TEK - TB10-150 AIRCRAFT BARRIER

TekSav Teknoloji Elektrik Elektronik Makine San .ve Tic. A.Ş10016 Sok. No:20 A.O.S.B. - Çiğli / İzmir - Türkiye

tel/Fax:232-3281141web site : http://www.teksav-teknoloji.com

e-mail : [email protected]@teksav-teknoloji.com

5.9 REMOTE CONTROL WITH CABLEAT-AB/1 System can be remote controlled by the remote control unit (RCU). RCU is plugged in to radio receiver

junction box on the system with a cable (four wires, two for power, 2 for the transmission of the serial signal RS232). On the remote unit (RCU), main switches are employed to raise up/down. In addition, indicator lamps will indicate the condition of the system

5.10 RADIO CONTROL (air CONTROL TOWER to BARRIER) (Optional)System l can also be remote controlled by any air band radio wireless, which usually exists as on board transceivers or

at the control tower. Either by clicking known number of times on - off the PTT switch or by up/down buttons raising and lowering is accomplished.

ICOM-A5 transceiver works for receiving the clicks from the aircraft and automatic receiver antenna is integrated to the system

In the radio receiver control box, a microcontroller board manages the communication and control of the system.

5.10.1 TECHNICAL DATA

TX/RX :118.000 -136.975 MHz (Frequency: 118 to 136 MHz).The UNICOM frequency of 122.8 MHz is commonly selected for the aircraft)

Modes : TX/RX AM and RX FM Channel spacing : 25 kHz Output power : 5W pep Receiver sensitivity : FM less than 1.0 microvolt (at 12 dB SINAD) AM less than 1.0 microvolt (at 6 dB SINAD) Selectivity : more than 7.5 kHz /-6 dB Less than 25 kHz / -60 dBThe frequency can be selected 25 kHz spacing by tipping in the channel number or turning the knob on top. Once

frequency selection established, whenever the receiver is turned it automatically works at previously selected frequency. Squelch levels should be adjusted according to the environment.

The transmitting radio must have the same frequency of the receiver on the system. In the radio receiver control box, a microcontroller board has jumpers to select modes of operation to control the

system.

5.10.2 REMOTE OPERATION

On the radio receiver junction box Put up the mains switch (SW1) and observe lamp (LP1) lit.Put up the antenna switch (SW2).If the system will be remote controlled than turn the switch to REMOTE position.If the system will be controlled manually then select the MANUAL position.

AT-AB-1S TEK - TB10-150 AIRCRAFT BARRIER

TekSav Teknoloji Elektrik Elektronik Makine San .ve Tic. A.Ş10016 Sok. No:20 A.O.S.B. - Çiğli / İzmir - Türkiye

tel/Fax:232-3281141web site : http://www.teksav-teknoloji.com

e-mail : [email protected]@teksav-teknoloji.com

6. OPERATION PRINCIPALS

6.1 GENERALGenerally, the main functions performed by AT-AB/1 are as follows:

A-Raising of the barrierB-Lowering of the barrier C-Separation of the stanchion system and barrier net after arrestment.

6.26.2 AUTOMATIC RECHARGING OF THE NITROGEN STORAGE TANKAUTOMATIC RECHARGING OF THE NITROGEN STORAGE TANKAfter raising operations, or in case of a leakage or because of temperature drop between charging the tank and raising

of the barrier, the storage tank should be recharged at rated pressure for a probable raising. This function is automatically realized in AT-AB/1 system.

6.3 RAISING OF THE BARRIERAfter the raising command send by the remote control system below mentioned action takes simultaneously:The solenoid valves at the outlet of the nitrogen storage tank are energized (V1 and V2, 14 mm orifice diameter,

actuator cylinder filling valves) and become open. Nitrogen passing through these valves fills the actuator cylinder and then the actuator travels and compresses the pressure chamber of the actuator and by the effect of the pressure piston rod travels and raises the mast.

In order to obtain a fixed raising velocity there a needle valve is obtained. Besides this, a safety valve is obtained on the pressure collector to prevent probable pressure shocks. In order to limit the raising angle of the masts by less than 85 degrees there a limiting system is obtained. After reaching the desired raising angle the storage tank filling valves are de energized and become closed automatically. Just at the same time movement is limited by the pneumatic bumpers.

6.4 LOWERING OF THE BARRIERAfter lowering command sent by the remote control system or given from site control cabinet the two releasing solenoid

valves (V3 and V4) are opened and the gas is released to the atmosphere. By means of two velocity control valves each sited in front of the valves V3 and V4 a slow lowering is obtained. At this instant filling valves are closed.

NOTE: There is no gas consumption during lowering. Just the gas taken in the cylinder during raising is released to the atmosphere.

AT-AB-1S TEK - TB10-150 AIRCRAFT BARRIER

TekSav Teknoloji Elektrik Elektronik Makine San .ve Tic. A.Ş10016 Sok. No:20 A.O.S.B. - Çiğli / İzmir - Türkiye

tel/Fax:232-3281141web site : http://www.teksav-teknoloji.com

e-mail : [email protected]@teksav-teknoloji.com

6.5 LOCKING AND UNLOCKING OF THE STANCHION SYSTEM

6.5.1 LOCKING

In order to avoid from a risk of accidental raising of the masts during control and maintenance works a locking system is added. This locking system operates manually. After raising the red signal flag mast the fixing rod is inserted in to the hole and so the mast becomes fixed and locked. After doing this the red signal lamp becomes off automatically.

6.5.2 UNLOCKING

After finishing the control and / or maintenance works the fixing rod is taken out and the red signal flag mast is lowered. In order to prevent the flag mast to be raised again this fixing rod is inserted in its place. Just during this position the red signal lamp on the stanchion system becomes on and at the same time the lamp on the lower control panel indicates that the system is ready to operate.

W A R N I N G :

-LOCKING IS APPLIED DURING CONTROL OR MAINTENANCE WORKS ONLY

-NO PERMISSION IS GIVEN FOR CONTROL OR MAINTENANCE WORKS WITHOUT LOCKING THE MASTS.

6.6 SEPARATION OF THE STANCHION SYSTEM AND BARRIER NET AFTER ARRESTMENTAt the beginning of the arrestment, when the air craft enters into the net the tension on the guy wires increases. This

tension transfers directly to the shear columns and when the tension reaches 3000 kg (for each shear column) the shear columns are broken and separate from the stanchion system.

After separation a part of the shear column is driven by the net while the other part remains with the guy wire.

6.7 STATUS OF THE POWER SYSTEM DURING OPERATIONThe status of the solenoid valves during raising and lowering operations are as follows:While raising the barrier two 1" solenoid valves are open. After reaching the desired raising angle those valves are de

energized. During raising the lowering solenoid valves are closed and de energized.During lowering phase, two 1" lowering solenoid valves are energized and are open to atmosphere.Nitrogen gas coming from tubes as 150 bar decreases to the needed pressure after passing through pressure regulator

and continuously recharge the storage tank.

AT-AB-1S TEK - TB10-150 AIRCRAFT BARRIER

TekSav Teknoloji Elektrik Elektronik Makine San .ve Tic. A.Ş10016 Sok. No:20 A.O.S.B. - Çiğli / İzmir - Türkiye

tel/Fax:232-3281141web site : http://www.teksav-teknoloji.com

e-mail : [email protected]@teksav-teknoloji.com

7. ILLUSTRATED PART LIST OF MAIN EQUIPMENT

Figure no:

7.1 AIRCRAFT ARRESTING BARRIER NET AND STANCHION SYSTEM

7.2 GENERAL VIEW7.3 COMPLETE STANCHION SYSTEM MOUNTING PLAN7.4 MAST7.5 RAISING ACTUATOR7.6 LOCKING SYSTEM MOUNTING DETAILS7.6A LOCKING SYSTEM SCHEMATIC VIEW7.7 ILLUMINATED WARNING LAMP7.8 MAIN BODY ASSEMBLY.7.9 PNEUMATIC POWER SYSTEM7.9 A PRESSURE MANOMETERS7.9 B PRESSURE MANOMETERS MOUNTING PANEL7.10 HIGH PRESSURE NITROGEN TUBES7.11 NITROGEN STORAGE TANK7.12 SUSPENSION CABLES, GUY WIRE, ANCHORING PLATE7.13 SITE CONTROL CABINET7.14 BATTERY HOLDER7.15 TOWER CONTROL PANEL7.16/1-2 SCHEMATIC FLOW DIAGRAM OF PNEUMATIC SYSTEM7.17 LUBRICATION TABLE

AT-AB-1S TEK - TB10-150 AIRCRAFT BARRIER

TekSav Teknoloji Elektrik Elektronik Makine San .ve Tic. A.Ş10016 Sok. No:20 A.O.S.B. - Çiğli / İzmir - Türkiye

tel/Fax:232-3281141web site : http://www.teksav-teknoloji.com

e-mail : [email protected]@teksav-teknoloji.com

FIG. 7.1: AIRCRAFT ARRESTING BARRIER NET AND STANCHION SYSTEM

AT-AB-1S TEK - TB10-150 AIRCRAFT BARRIER

TekSav Teknoloji Elektrik Elektronik Makine San .ve Tic. A.Ş10016 Sok. No:20 A.O.S.B. - Çiğli / İzmir - Türkiye

tel/Fax:232-3281141web site : http://www.teksav-teknoloji.com

e-mail : [email protected]@teksav-teknoloji.com

FIG 7.2 STANCHION SYSTEM VIEW

AT-AB-1S TEK - TB10-150 AIRCRAFT BARRIER

TekSav Teknoloji Elektrik Elektronik Makine San .ve Tic. A.Ş10016 Sok. No:20 A.O.S.B. - Çiğli / İzmir - Türkiye

tel/Fax:232-3281141web site : http://www.teksav-teknoloji.com

e-mail : [email protected]@teksav-teknoloji.com

FIG. 7.3: STANCHION ASSEMBLY

AT-AB-1S TEK - TB10-150 AIRCRAFT BARRIER

TekSav Teknoloji Elektrik Elektronik Makine San .ve Tic. A.Ş10016 Sok. No:20 A.O.S.B. - Çiğli / İzmir - Türkiye

tel/Fax:232-3281141web site : http://www.teksav-teknoloji.com

e-mail : [email protected]@teksav-teknoloji.com

FIG. 7.4: MAST ASSEMBLY

AT-AB-1S TEK - TB10-150 AIRCRAFT BARRIER

TekSav Teknoloji Elektrik Elektronik Makine San .ve Tic. A.Ş10016 Sok. No:20 A.O.S.B. - Çiğli / İzmir - Türkiye

tel/Fax:232-3281141web site : http://www.teksav-teknoloji.com

e-mail : [email protected]@teksav-teknoloji.com

FIG. 7.5: ACTUATOR ASSEMBLY

AT-AB-1S TEK - TB10-150 AIRCRAFT BARRIER

TekSav Teknoloji Elektrik Elektronik Makine San .ve Tic. A.Ş10016 Sok. No:20 A.O.S.B. - Çiğli / İzmir - Türkiye

tel/Fax:232-3281141web site : http://www.teksav-teknoloji.com

e-mail : [email protected]@teksav-teknoloji.com

FIG. 7.6: LOCKING ASSEMBLY

AT-AB-1S TEK - TB10-150 AIRCRAFT BARRIER

TekSav Teknoloji Elektrik Elektronik Makine San .ve Tic. A.Ş10016 Sok. No:20 A.O.S.B. - Çiğli / İzmir - Türkiye

tel/Fax:232-3281141web site : http://www.teksav-teknoloji.com

e-mail : [email protected]@teksav-teknoloji.com

FIG. 7.7: SIGNAL LAMP ASSEMBLY

AT-AB-1S TEK - TB10-150 AIRCRAFT BARRIER

TekSav Teknoloji Elektrik Elektronik Makine San .ve Tic. A.Ş10016 Sok. No:20 A.O.S.B. - Çiğli / İzmir - Türkiye

tel/Fax:232-3281141web site : http://www.teksav-teknoloji.com

e-mail : [email protected]@teksav-teknoloji.com

FIG. 7.8: MAST ASSEMBLY

AT-AB-1S TEK - TB10-150 AIRCRAFT BARRIER

TekSav Teknoloji Elektrik Elektronik Makine San .ve Tic. A.Ş10016 Sok. No:20 A.O.S.B. - Çiğli / İzmir - Türkiye

tel/Fax:232-3281141web site : http://www.teksav-teknoloji.com

e-mail : [email protected]@teksav-teknoloji.com

FIG 7.9 PNEUMATIC POWER ASSEMBLY

AT-AB-1S TEK - TB10-150 AIRCRAFT BARRIER

TekSav Teknoloji Elektrik Elektronik Makine San .ve Tic. A.Ş10016 Sok. No:20 A.O.S.B. - Çiğli / İzmir - Türkiye

tel/Fax:232-3281141web site : http://www.teksav-teknoloji.com

e-mail : [email protected]@teksav-teknoloji.com

FIG. 7.10: NITROGEN TUBES ASSEMBLY

AT-AB-1S TEK - TB10-150 AIRCRAFT BARRIER

TekSav Teknoloji Elektrik Elektronik Makine San .ve Tic. A.Ş10016 Sok. No:20 A.O.S.B. - Çiğli / İzmir - Türkiye

tel/Fax:232-3281141web site : http://www.teksav-teknoloji.com

e-mail : [email protected]@teksav-teknoloji.com

FIG. 7.11: NITROGEN STORAGE TANK

AT-AB-1S TEK - TB10-150 AIRCRAFT BARRIER

TekSav Teknoloji Elektrik Elektronik Makine San .ve Tic. A.Ş10016 Sok. No:20 A.O.S.B. - Çiğli / İzmir - Türkiye

tel/Fax:232-3281141web site : http://www.teksav-teknoloji.com

e-mail : [email protected]@teksav-teknoloji.com

FIG 7.12 GUYWIRE ASSEMBLY

AT-AB-1S TEK - TB10-150 AIRCRAFT BARRIER

TekSav Teknoloji Elektrik Elektronik Makine San .ve Tic. A.Ş10016 Sok. No:20 A.O.S.B. - Çiğli / İzmir - Türkiye

tel/Fax:232-3281141web site : http://www.teksav-teknoloji.com

e-mail : [email protected]@teksav-teknoloji.com

FIG. 7.13/1: SITE CONTROL CABINET

AT-AB-1S TEK - TB10-150 AIRCRAFT BARRIER

TekSav Teknoloji Elektrik Elektronik Makine San .ve Tic. A.Ş10016 Sok. No:20 A.O.S.B. - Çiğli / İzmir - Türkiye

tel/Fax:232-3281141web site : http://www.teksav-teknoloji.com

e-mail : [email protected]@teksav-teknoloji.com

FIG. 7.13/2: SITE CONTROL CABINET INNER VIEW

FIG. 7.14 : BATTERY HOLDER

AT-AB-1S TEK - TB10-150 AIRCRAFT BARRIER

TekSav Teknoloji Elektrik Elektronik Makine San .ve Tic. A.Ş10016 Sok. No:20 A.O.S.B. - Çiğli / İzmir - Türkiye

tel/Fax:232-3281141web site : http://www.teksav-teknoloji.com

e-mail : [email protected]@teksav-teknoloji.com

FIG. 16/1 : PNEUMATIC FLOW DIAGRAM RAISED POSITION

AT-AB-1S TEK - TB10-150 AIRCRAFT BARRIER

TekSav Teknoloji Elektrik Elektronik Makine San .ve Tic. A.Ş10016 Sok. No:20 A.O.S.B. - Çiğli / İzmir - Türkiye

tel/Fax:232-3281141web site : http://www.teksav-teknoloji.com

e-mail : [email protected]@teksav-teknoloji.com

FIG. 16/2 : PNEUMATIC FLOW DIAGRAM LOWERED POSITION

AT-AB-1S TEK - TB10-150 AIRCRAFT BARRIER

TekSav Teknoloji Elektrik Elektronik Makine San .ve Tic. A.Ş10016 Sok. No:20 A.O.S.B. - Çiğli / İzmir - Türkiye

tel/Fax:232-3281141web site : http://www.teksav-teknoloji.com

e-mail : [email protected]@teksav-teknoloji.com

FIG. 17/1 : POINTS TO BE LUBRICATED

AT-AB-1S TEK - TB10-150 AIRCRAFT BARRIER

TekSav Teknoloji Elektrik Elektronik Makine San .ve Tic. A.Ş10016 Sok. No:20 A.O.S.B. - Çiğli / İzmir - Türkiye

tel/Fax:232-3281141web site : http://www.teksav-teknoloji.com

e-mail : [email protected]@teksav-teknoloji.com

8. TOOLS delivered with the system

TOOL BOX

S/N ITEM DESCRIPTION QUANTITY1 MULTIMETER 12 DOUBLE OPEN END SPANNER (12 pcs.) 13 PLIERS 14 SCREW DRIVER 45 HAMMER (300 gr.) 16 HAMMER (1000 gr.) 17 FIRE EXTINGUISHER 18 WHEEL BOLT TOOL 19 JACK (4 tons) 1

AT-AB-1S TEK - TB10-150 AIRCRAFT BARRIER