AERZENER MASCHINENFABRIK GMBH - '+domain...

-

Upload

truongminh -

Category

Documents

-

view

259 -

download

6

Transcript of AERZENER MASCHINENFABRIK GMBH - '+domain...

A E R Z E N E R M A S C H I N E N F A B R I K

G M B H

A E R Z E N

S C R E W C O M P R E S S O R SAerzen screw compressor packages DELTA SCREW as compact units,

available in two pressure ranges with optimized power consumption

Pressure range 1 up to 3.0 bar (a) VML 18 R to VML 250Pressure range 2 up to 4.5 bar (a) VM 8 R to VM 140

with gearbox or belt drive

V1-018 06 EN3000 5.2005

Technical progressionThe Aerzener Maschinenfabrik GmbH has been manufacturing Screw Compressors since 1943. As the Market Leader in Europe, the company is one of the oldest and largest manufacturers of Roots Blowers and Screw Compressors. Technical expertise, experienced staff and a permanent dialogue with the customers all help to maintain the lead in technology now and for the future.The further development and introduction of the new DELTA SCREW Packages is an answer to the rising demands of our customers and the increasing demands of the future market.

Application fields and useThe units are specifically designed to match practical require-ments in the field. They are the ideal solution for the dry, oil-free and clean compression of air and neutral gases as required e.g. in the following application fields:• pneumatic conveying with air or nitrogen• aeration of sewage basins• homogenising of cement• vacuum production in the glass industry• prevention of ice build-up in harbours and lakes• oil booms• gas-air mixing plants• oxidation air for power stations• stationary unloading of silo vehicles• vacuum production in the paper industry• conveying and compression of neutral gases• blast air for production of spunbonded web

All DELTA SCREW-units can be delivered with ATEX 100 A - certification on customers request.

2

GeneralSingle-stage Aerzen screw compressors are manufactured as air-cooled units for intake volumes from 200 to 15.000 m3/h. Discharge pressures of up to p2 = 3.0 bar and 4.5 bar abs., dry, oil-free compression, temperature limit t2 maximum 250 °C. Vacuum operation is possible with the standard VML-compressors to a maximum of 70% (0.3 bar abs.) and as a modified unit to 85% (0.15 bar abs.).

Driving shaft sealed by peak seals, working maintenance-free in combination with a well-aimed oil-chamber release.

Energy consumptionDepending on the maximum discharge pressure 3+4 or 4+6 screw profiles are used. This results in an optimum use of energy despite other influences such as tolerances, pressure losses at accessories and deflections of the volume flow.

Large or small performances With all units of the DELTA SCREW series, rotor pro-file, internal compression ratio and accessories can be optimized to meet individual requirements.

TechnologyDELTA SCREW units are delivered complete with internal installation, piping and wiring, and are ready for connection to the customer’s system.By using a frequency converter the volume can be regulated over a large range with a ratio of approxi-mately 1:4. Relatively small rotor diameters and low risk of internal contamination preclude any additional imbalances that could increase vibration.Even under difficult operating conditions the calculated bearing lifetime is > 40.000 hours

AdaptabilityDepending on customer requirements the scope of supply can include for example:• Driving motor• Control - and power cabinet• Acoustic hood• Start-up unloading device• Full load / idle running system.

Simple operationAll operation and maintenance elements are acces-sible from one side, this includes instrument panel, oil filter, oil level sight glasses, air - and oil filters and therefore enable a simple operation and maintenance.

ChassisThe base frame for the compressor stages with belt drive has several functions. It is base support for the compressor stage, suction-silencer and oil reservoir in one. That reduces costly installation surface.

Ranges of pressureIn overpressure two discharge pressure ranges are available.VML up to 3,0 bar (a) VM up to 4,5 bar (a)In vacuum pressure:VML up to 0,3 bar (a) up to 0,15 bar (a) with pre-inlet

EfficiencyDuring the whole operating period of the compressor the efficiency remains virtually constant so that no reduction of the conveying capacity will occur.

With belt driveThe belt drive of DELTA SCREW - units is designed so that v-belt tension is constant in all operating conditions. The weight of the motor mounted on a hinged support ensures that the tension of the v-belts is always as it should be.

3

InstallationThe packages are delivered completely assembled, allowing their prompt and trouble-free installation. Installation procedures at site are limited to the con-nection of the power supply and plant piping resp. filling-up of oil. The standard package designed for pressure mode operation sucks in ambient atmos-pheric air through a filter. In vacuum mode and nitrogen operation, the intake filter is substituted by a suction silencer or pipe connection. An additional expansion joint with tie-rods ensures stress-free intake connec-tion to plant piping. The standard package is designed to accept motors having IP 55 type protection.In the case of packages equipped with an acoustic hood, the electrical wiring as well as the motor starter and pushbuttons can be installed in the standard instrument panel. (only applies for machines with gearbox).

DriveThe compressor is normally driven via an electric motor of B 3 design. Other drive configurations (e.g. diesel motor, turbine) are available upon request. When installing an acoustic hood, the following must be considered: - The fan is designed to provide sufficient cooling to maintain a maximum temperature rise within the hood of 10 °C. - The amount of the heat radiated from the compressor package surfaces represents approx. 25 % of the drive power, depending on the particular operating conditions and compressor size. However, some higher heat radiation values can be reached where machines are equipped with an intake throttling regulation valve. The internal pressure losses across the hood amount to max. 100 N/m2. - The ventilation of the acoustic hood is carried out by a mechanically driven fan, which is mounted to an extension of the driving shaft (VML 150/250 electrically driven).

4

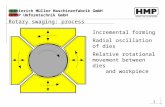

Compression process

DischargeThe compression is finished,

the discharge pressureachieved, the discharge starts.

Compression processBy progressing rotation of the rotors

the inlet opening is closed, the volumereduced, the pressure increases.

Suction The gas enters throughthe inlet opening into theopen thread of the rotors.

4

Compression process

DischargeThe compression is finished,

the discharge pressureachieved, the discharge starts.

Compression processBy progressing rotation of the rotors

the inlet opening is closed, the volumereduced, the pressure increases.

Suction The gas enters throughthe inlet opening into theopen thread of the rotors.

5

Construction and design(compressor stage)

Rotors:Profile VML: 3 + 4, VM: 4 + 6, asymmetric dynamically balanced according to DIN ISO 1940 T1, quality G = 2.5

Sealings:VM: conveying chamber: carbon ring labyrinth sealing at suction-and discharge side with chamber rings and neutral chamber. Driving shaft: peak sealVML: conveying chamber: piston rings at suction side, carbon ring labyrinth sealing at discharge side, each with neutral chamber. Driving shaft: peak seal

Materials:housing: grey cast GG 25rotors: steel C 45 Nsealings: Ek 305, steel / carbongear wheels: hardened steel

Bearings:Roller bearings with integrated forced-feed lubrication.

UnitConcerning the Delta Screw units there is always a standardized concept for the package. Two variants are possible:

1. Drive of the compressor stage directly via an inte-grated gearbox.

Arrangement of compressor stage and driving motor one behind the other, installed on a common base frame.

2. Drive of the compressor stage via belt drive.

Arrangement of compressor stage and driving motor side by side, hinged motor plate fixed laterally on the body of the compressor.

Start-up, regulationAs an option the VML-compressors can be provided with a self-controlled start-up unloading device. Upon request, VM-compressors can be supplied with an idling / full load regulation system, e.g. to unload the compressor in the case of star-delta starting, or to reduce energy consumption during intermittent operation (for star-delta starting, please consult the manufacturer first).

female rotor male rotor female rotor male rotor

VML VM

Construction and design (Drive and oil system)

Instrumentation and controlsThe instrumentation panel indicates and controls the following functions:

Belt drive:DriveHeavy-duty narrow V-belt, continuous belt tension due to motor weight

Oil system • oil reservoir integrated in the base frame • oil overflow valve • oil pump driven by female rotor, accessible from the outside • oil cooling as oil-/air cooler incl. oil temperature regulating valve (limited to 90 °C), aeration via mechanical fan on the driving shaft (applies starting from 40 °C intake temperature, cooler block installed on belt guard / hood ventilation) • oil filter as screw- down filter • oil chamber relief via oil demister, installed on the compressor stage

Gearbox: Drive Step-up gearbox integrated on the intake side with closely stepped gear ratios

Oil system • oil reservoir integrated in the compressor housing • oil overflow valve • oil pump driven by female rotor, accessible from the outside • oil cooling as oil-/air cooler incl. oil temperature regulating valve (limited to 90 °C), aeration via mechanical fan on the driving shaft (cooler block integrated in compressor stage) • oil filter as screw-down filter • oil chamber relief via oil demister, installed on the compressor stage

VML / VM Visual maintenance indicator in case of contamination of the air intake filter with additional protection by means of electrical pressure switches forsuction pressure, discharge pres-sure and oil pressuredischarge temperature and oil temperature. The switches are wired internally on the terminal strip. Extension of instrumentation acc. to design VM is possible (option).All sensing points are monitored by an electronic fault indication device featuring „first-out” indica-tion. Instrumentation to meet spe-cial requirements (e.g. ex-proof) is available upon request.

Alternatively for VM and VML: Aerzen Universal Control Unit including instru-mentation in analog technique with pressure trans-mitter for suction-, discharge- and oil pressure. Resistance thermometer for discharge- and oil tem-

perature. Indications are optionally (multi-lingual) available in the display. Control options for all possible cases of operation. Indication of the service intervals. Limit value recording

as fault indication archives. Serial interface (RS 485) for data transmission (e.g. telediagnostic service, linkage of several machines among each other). (Design not ex-proof).

6

7

Belt drive • Aerzen Screw compressor stage with reinforced bearing of the driving shaft (female rotor) suitable for belt drive. Forced-feed lubrication including oil pump, oil filter, oil return flow valve, turbo filter for oil chamber release.• Base support as suction silencer with hinged motor plate (three-phase current motor)• Intake filter (single-stage) integrated in the base frame• Belt drive with guard

Scope of supply and performances The scope of supply of a DELTA SCREW compressor unit made by Aerzener for air operation (basic unit) includes the following items:

Gearbox• Aerzen Screw compressor stage with integrated

step-up gearbox, forced-feed lubrication including oil pump, oil filter, oil return flow valve, air/oil cooler, turbo filter for oil chamber release.

• Base support for compressor stage and driving motor (three-phase current motor)

• Intake filter (double-stage) with intake manifold• Flexible coupling with guard

Items also belonging to the basic unit: (applies for belt drive and gearbox) • Discharge silencer• Safety relief valve (type-tested)• Non-return valve• Expansion joint with tie-rod, discharge side• Flexible machinery mountings with anchor bolts• Instrument panel for protection of the machine with indication and monitoring for suction-, discharge- and oil pressure, discharge- and oil temperature, single-fault indication and operating hour meter

Extended scope of instrumentation same as for VM possible even for VML against extra price.

Accessories: Options (belt drive and gearbox)• Driving motor as three-phase current motor including assembly in Aerzen• Acoustic hood for the complete compressor unit for indoor and outdoor installation• Start-up unloading valve for VML-compressors (self-medium controlled)• Constant-speed unloading device for VM-compressors including suction throttle, relief valve and pressure switch PSLH (self-medium controlled)• switch cabinet with electrical interconnection (e.g. star-delta)• Frequency converter, designed as separate cabinet (installation and external wiring at site)• Overflow-regulating valve (self-medium controlled) for keeping the discharge pressure or vacuum constant, loose supply, for installation into the pipe provided at site• separate after-cooler, loose supply, for installation into the pressure pipe provided at site, designed as air-/air cooler or air-/water cooler, in case of danger of condensation on request even with cyclone separator and automatic drain.

Modifications: Options (belt drive and gearbox)• Nitrogen design including suction silencer, starting strainer, expansion joint suction side, suction pressure gauge• Ex-proof design with intrinsically safe instrumentation, main- and aux. drives in EEx e or EEx de• Special instrumentation in co-ordination with the customer’s specification• Deviating finish• ANSI-flanges at battery limit• Vacuum design (even with pre-inlet) incl. suction silencer, starting strainer, expansion joint suction side, suction pressure gauge, suction valve, vacuum filter as option

3KL-48

8

Flow diagram VML-R (belt drive)

1. air filter monitoring 2. intake pressure switch 3. contact thermometer (discharge temperature) 4. contact thermometer (oil temperature) 5. discharge pressure gauge 6. discharge pressure switch 7. oil pressure gauge 8. oil pressure switch 9. oil level sight glass10. intake filter11. compressor stage11a. sound-absorbing connection chamber12. discharge silencer13. check valve14. expansion joint15. safety relief valve16. oil pump19. oil filter20. oil overflow valve21. oil drain valve22. oil demister32. belt drive33. suction silencer

The following items are not included in the standard scope of supply and are available at extra costs:

28. relief valve30. acoustic hood with fan31. electric motor

Flow diagram VM-R (belt drive) 1. air filter monitoring 2. intake pressure switch 3. contact thermometer (discharge temperature) 4. contact thermometer (oil temperature) 5. discharge pressure gauge 6. discharge pressure switch 7. oil pressure gauge 8. oil pressure switch 9. oil level sight glass10. intake filter11. compressor stage12. discharge silencer13. check valve14. expansion joint15. safety relief valve16. oil pump18. oil air cooler19. oil filter20. oil overflow valve21. oil drain valve22. oil demister32. belt drive33. suction silencer

The following items are not included in the standard scope of supply and are available at extra costs:

30. acoustic hood with fan31. electric motor23. intake pressure gauge24. pressure switch25. throttle flap regulation26. 3-way solenoid valve27. pressure selection relay28. relief valve

compressed air outlet

compressed air outlet

3VK-037

3VK-038

compressed air outlet

compressed air outlet

9

Flow diagram VML... with start-up unloading device

1. air filter monitoring 2. intake pressure switch 3. contact thermometer (discharge temperature) 4. contact thermometer (oil temperature) 5. discharge pressure gauge 6. discharge pressure switch 7. oil pressure gauge 8. oil pressure switch 9. oil level sight glass10. intake filter11. compressor stage12. discharge silencer13. check valve14. expansion joint15. safety relief valve16. oil pump17. oil temperature regulator18. oil air cooler *19. oil filter20. oil overflow valve21. oil drain valve22. oil demister

The following items are not included in the standard scope of supply and are available at extra costs:

25. electric motor28. start-up unloading device30. acoustic hood with fan * * For VML 150/ 250 electrically driven

Flow diagram VM... with regulation

1. air filter monitoring 2. intake pressure switch 3. contact thermometer (discharge temperature) 4. contact thermometer (oil temperature) 5. discharge pressure gauge 6. discharge pressure switch 7. oil pressure gauge 8. oil pressure switch 9. oil level sight glass10. intake filter11. compressor stage12. discharge silencer13. check valve14. expansion joint15. safety relief valve16. oil pump17. oil temperature regulator18. oil air cooler19. oil filter20. oil overflow valve21. oil drain valve22. oil demister

The following items are not included in the standard scope of supply and are available at extra costs:

30. acoustic hood with fan31. electric motor23. intake pressure gauge24. pressure switch25. throttle flap regulation26. 3-way solenoid valve27. pressure selection relay28. relief valve29. blow-off silencer

We always distinguish 1. in drive mode belt drive or gearbox 2. in discharge pressure For performance data up to 2 bar overpressure ➯ VML-compressors For performance data up to 3,5 bar overpressure ➯ VM-compressors The performance charts are in chronological order according to compressor sizes. First it has to be decided which drive mode is preferred. To distinguish the type designations the belt driven machines end with an “R” concerning their designation. The performance charts have the same structure. Depending on compressor type the possible perform-ance data were entered in the corresponding chart (in the upper section up to 2 bar applicable for compressor types VML, in the lower sec-tion up to 3,5 bar applicable for compressor types VM). The volume flow increases from the left to the right side. We are always trying to use the smallest-pos-sible machine. The applicable performance data of the corresponding case of operation result from “column” (referring to the volume flow) and “line” (referring to the requested discharge pressure).

Explanations:Sum of the individual moments of inertia of com-pressor, gearbox and coupling, based on the drive speed.

Noise data

10

Using the performance chartsp1 intake pressure (abs.) t1 intake temperature pe discharge pressure, gauge i1 to i14 standard gear ratiosIn order to meet the requested volume flow even more closely, intermediate gear ratios are available between each standard ratio, e.g. i9/10 between i9 and i10.Lp (A) o.H./m.H. sound pressure level as machine noise acc. to DIN 45635 - without hood / with hood.

The data applicable to intermediate step-up gear ratios can be interpolated, as in these ranges the operating data are of linear relationship and can be calculated proportionally.The data shown are based on the compression of air at p1 = 1,0 bar and t1 = 20 °C. Data concerning deviating suction conditions, vacuum operation, compression of gas and multi-stage compression configurations are available on request.

The fan power for acoustic hood depends on the particular operating conditions.Oil demister operating requirements: 0,37 kW 50 m³/h 3000 rpm.

Our sales department shall be at your disposal at any time concerning questions on the necessary equipment and possibilities of application.

100

90

80

70

60

50

100

90

80

70

60

without hood

with hood

Noise ratingcurves according to ISO 1996

31,5 63 125 250 500 1000 2000 4000 8000(Hz) mean frequencies

The sound frequency analysis in 1/1 octave bands was carried out on a VM 21 R package. Measurements in free field, at a distance = 1.0 m.Measuring height = 1.5 mDischarge pressure pe = 3.5 barnmot= 2950 rpmStep-up gear ratio B7

soun

d pr

essu

re le

vel i

n dB

bas

ed o

n 2

x 10

-5 N

/m2

Performance data based on the compression of air (p1= 1.0 bar, t1 = 20 °C)

B6

287141622930167

17,5 / 18,57,3

0,19989/73

282141622930183

19,1 / 227,3

0,19989/73

280141622930198

20,7 / 2210,90,19989/73

277142342945213

22,3 / 3010,90,20191/74

273142342945229

23,7 / 3010,90,20192/75

269142342945245

25,2 / 3010,90,20194/78

B6/7

312150022930164

18,6 / 228,1

0,21589/73

307150022930180

20,3 / 228,1

0,21489/73

307150782945194

22,2 / 3011,90,21489/73

303150782945208

23,7 / 3011,90,21491/74

298150782945223

25,2 / 3011,90,21493/75

294150782945238

26,7 / 3011,90,21494/79

B7

338158612930161

19,8 / 228,8

0,25491/75

333158612930177

21,6 / 228,8

0,25491/75

333159422945191

23,6 / 3013

0,25691/76

329159422945205

25,2 / 3013

0,25692/76

324159422945219

26,8 / 3013

0,25693/77

320159422945233

28,4 / 3013

0,25695/80

B7/8

366168022930159

21,1 / 229,8

0,27193/77

364168882945174

23,1 / 309,8

0,27393/78

361168882945189

25,2 / 3014,50,27393/79

357168882945201

26,9 / 3014,50,27393/79

353168882945215

28,5 / 3014,50,27393/79

349169172950228

30,2 / 3714,50,27395/81

345169172950242

31,9 / 3714,50,27397/82

B8

392179352945160

23,3 / 3011,10,33494/78

387179352945174

25,4 / 3011,10,33494/80

382179352945189

27,4 / 3011,10,33494/81

380179352945202

29,5 / 3016,20,33494/81

377179652950215

31,3 / 3716,20,33494/81

372179652950229

33,1 / 3716,20,33496/82

368179652950242

34,9 / 3716,20,33498/83

B8/9

415189992945161

25,6 / 3012,60,35695/80

410189992945175

27,8 / 3012,60,35695/80

405190312950190

30,2 / 3712,60,35695/81

404190312950204

32,5 / 3718,40,35695/81

399190312950216

34,4 / 3718,40,35695/81

395190312950229

36,3 / 3718,40,35697/83

389189672940243

38 / 4518,40,37599/84

B9

441202122945163

28,5 / 3014,40,43395/81

436202472950177

30,9 / 3714,40,43395/81

431202472950191

33,4 / 3714,40,43395/81

430202472950205

36,1 / 3720,80,43395/81

424201782940218

37,9 / 4520,80,46695/81

420201782940230

39,9 / 4520,80,46697/83

415201782940243

42 / 4520,80,46699/84

B9/10

468214482950165

31,5 / 3716,50,46195/82

462214482950178

34,1 / 3716,50,46195/82

456213752940192

36,5 / 4516,50,49495/82

451213752940207

39,2 / 4516,50,49496/82

450213752940219

41,7 / 4523,80,49496/82

446213752940231

43,9 / 4523,80,49498/84

444214842955244

46,5 / 5523,80,494100/85

B10

497228132950167

35,2 / 3718,9

0,57997/84

490227362940180

37,8 / 4518,9

0,57897/84

485227362940194

40,6 / 4518,9

0,63697/84

480227362940208

43,5 / 4518,9

0,63697/84

482228522955221

46,8 / 5527,1

0,63697/84

478228522955233

49,2 / 5527,1

0,63698/85

473228522955245

52 / 5527,1

0,662100/85

VM 8 R

11

Compressor size

belt drive ratio

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

Dischargepressurepe [bar gauge]

0,75

1,00

1,25

1,50

1,75

2,00

2,25

2,50

2,75

3,00

3,25

3,50

B [ - ]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

Compressor size

belt drive ratio

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

Dischargepressurepe [bar gauge]

0,75

1,00

1,25

1,50

1,75

2,00

2,25

2,50

2,75

3,00

3,25

3,50

B6/7

655143912950160

33,3 / 3715,40,49695/80

644143422940174

36,6 / 4515,40,49695/80

636143422940189

38,6 / 4515,40,49695/80

638144152955202

42,9 / 5522,30,51595/80

631144152955215

45,4 / 5522,30,51595/80

624144152955228

48 / 5522,30,51595/80

617144152955241

51 / 5522,30,51595/80

B7

706152152940159

36,1 / 4517,20,58896/81

698152152940172

39,2 / 4517,20,58896/81

693152922955186

42,5 / 5517,20,61996/81

691152922955200

45,9 / 5524,90,61996/81

684152922955212

48,5 / 5524,90,61996/81

681153702970225

52 / 7524,90,61996/81

674153702970238

54 / 7524,90,61996/81

B7/8

749161342940160

38,7 / 4519,10,63896/82

745162162955173

42,2 / 5519,10,66896/82

736162162955187

45,5 / 5519,10,66896/82

734162162955201

49,2 / 5527,60,66896/82

731162992970213

53 / 7527,60,66896/82

724162992970225

55 / 7527,60,66897/82

717162992970238

58 / 7527,60,66898/83

B8

801172362955162

41,9 / 5521,50,76497/83

793172362955175

45,3 / 5521,50,76497/83

784172362955188

48,8 / 5521,50,76497/83

780173232970202

53 / 7521,50,8

97/83

779173232970214

57 / 7530,70,8

97/84

772173232970226

60 / 7530,70,8

97/84

766173232970238

62 / 7530,70,8

98/84

B8/9

850182762955163

45,3 / 5523,90,82798/83

842182762955176

48,9 / 5523,90,82798/83

838183692970190

53 / 7523,90,86298/84

830183692970203

57 / 7523,90,86298/84

829183692970216

61 / 7534,10,86298/84

822183692970227

64 / 7534,10,86298/84

815183692970239

67 / 7534,10,91799/85

B9

904194182955165

49,2 / 5526,81,01398/84

901195162970178

54 / 7526,81,04498/84

893195162970191

58 / 7526,81,04499/84

884195162970204

62 / 7526,81,04499/84

884195162970218

66 / 7537,91,04499/84

877195162970229

69 / 9037,91,12399/84

870195162970240

72 / 9037,91,12399/85

B9/10

966206982970168

54 / 7529,9

1,12499/85

958206982970180

58 / 7529,9

1,12499/85

949206982970193

62 / 7529,9

1,124100/85

941206982970206

66 / 7529,9

1,198100/85

933206982970219

70 / 9029,9

1,198100/85

933206982970230

74 / 9042,1

1,198100/85

926206982970241

78 / 9042,1

1,198100/86

Performance data based on the compression of air (p1= 1.0 bar, t1 = 20 °C)

VM 15 R

12

B5/6

561128512950163

29,7 / 3712,60,39294/78

553128072950179

32,5 / 3712,60,39294/78

546128072940194

35,3 / 4518,40,39294/79

540128072940208

37,6 / 4518,40,39294/79

533128072940222

39,9 / 4518,40,39294/79

526128072940236

42,2 / 4518,40,39294/79

B6

605135702950161

31,6 / 3713,90,45694/79

597135702950176

34,4 / 3713,90,45694/79

586135242940192

37,2 / 4513,90,45695/79

583135242940205

39,9 / 4520,20,45695/79

577135242940218

42,3 / 4520,20,45695/79

574135932955232

45 / 5520,20,45695/79

B [ - ]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

Compressor size

belt drive ratio

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

Dischargepressurepe [bar gauge]

0,75

1,00

1,25

1,50

1,75

2,00

2,25

2,50

2,75

3,00

3,25

3,50

B3

4665626293096

12,5 / 155,3

0,15690/71

45756262930119

15,8 / 18,57,9

0,15690/71

44656262930140

18,8 / 227,9

0,16491/71

43956542945163

21,9 / 307,9

0,16491/73

42856542945186

24,9 / 307,9

0,16492/73

B4

5446251293093

13,9 / 18,56,1

0,20391/71

53562512930115

17,8 / 229,30,2192/72

52862832945134

21,1 / 309,30,2192/73

51762832945155

24,4 / 309,30,2192/74

50862932950176

27,7 / 379,30,2292/74

49762932950198

31 / 379,30,2296/75

B5

6397001293090

15,7 / 18,57,40,2792/72

62970372945112

20,2 / 307,40,2892/73

62370372945130

23,9 / 3011,00,2893/74

61470492950148

27,5 / 3711,00,2893/75

60370492950167

31,1 / 3711,00,3

94/75

58970252940188

34,5 / 4511,00,3

97/77

B6

7427813293088

17,7 / 228,80,3492/73

73378532945108

22,6 / 308,80,3892/73

72978672950126

27,1 / 3713,10,3893/75

71878672950143

30,9 / 3713,10,3894/76

70378402940161

34,7 / 4513,10,4

96/76

69278402940180

38,6 / 4513,10,4

98/78

B7

86887962945

8720,4 / 30

10,50,4892/74

85487962945106

25,6 / 3010,50,4893/74

84988112950124

30,8 / 3715,70,4893/76

83487812940140

34,9 / 4515,70,5296/77

82387812940156

39,2 / 4515,70,5297/78

81888262955173

43,7 / 5515,70,5299/79

B8

10089895294587

23,5 / 3012,80,6793/75

99699122950104

29,3 / 3712,80,6793/75

97798782940122

34,9 / 4512,80,7293/77

98199292955137

40,2 / 4519,20,7296/78

96999292955152

44,9 / 5519,20,7297/78

95899292955168

49,6 / 5519,20,7299/80

B9

116911171295087

27,9 / 3715,70,8

94/76

1150111332940103

33,9 / 4515,70,8

94/76

1136111332940120

39,9 / 4515,70,8794/78

1140111902955136

46,3 / 5523,70,8898/78

1135112462970151

52 / 7523,70,8899/79

1124112462970165

57 / 7523,70,94

100/80

B9/10

125211833295088

30,4 / 3717,50,9394/76

1232117932940104

36,6 / 4517,51,0394/76

1225118532955120

43,7 / 5517,51,1395/78

1219119142970150

51 / 7526,11,2

98/78

1218119142970150

56 / 7526,11,2

99/79

1207119142970164

61 / 7526,11,2

100/80

Performance data based on the compression of air (p1= 1.0 bar, t1 = 20 °C)

VML 18 R

13

B2

38950012930101

11 / 154,5

0,11889/69

38050012930125

13,9 / 18,56,6

0,11889/70

37050012930149

16,6 / 18,56,6

0,12389/70

35950012930174

19,3 / 226,6

0,12390/72

35150262945201

22,2 / 306,6

0,12390/72

B [ - ]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

Compressor size

belt drive ratio

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

Dischargepressurepe [bar gauge]

0,75

1,00

1,25

1,50

1,75

2,00

2,25

2,50

2,75

3,00

3,25

3,50

B5/6

879128722955157

44,4 / 5527,30,56195/73

870128722955169

47,7 / 5527,30,56196/73

861128722955181

52 / 5527,30,56196/74

858129382970193

55 / 7527,30,56196/74

857129382970204

59 / 7541,10,56196/74

849129382970214

61 / 7541,10,56198/75

842129382970224

64 / 7541,10,56198/75

B6

943135932955157

47,4 / 5529,70,67595/73

934135932955168

51 / 5529,70,67596/73

931136622970180

55 / 7529,70,67597/74

922136622970192

59 / 7529,70,67597/74

921136622970203

62 / 7544,60,67597/75

913136622970212

65 / 7544,60,67598/75

906136622970222

68 / 7544,60,67599/75

B6/7

1016144172955156

52 / 5532,90,72196/74

1014144902970167

56 / 7532,90,72298/74

1005144902970178

59 / 7532,90,72298/75

996144902970190

63 / 7532,90,72298/75

995144902970201

67 / 7549

0,72298/75

987144902970210

70 / 7549

0,72299/76

980144902970220

73 / 7549

0,72299/76

B7

1098153702970157

56 / 7536,30,86496/76

1089153702970167

60 / 7536,30,86499/77

1080153702970178

64 / 7536,30,86499/77

1071153702970189

68 / 7536,30,86499/77

1070153702970201

73 / 7554,60,86599/77

1062153702970209

76 / 9054,60,865100/77

1055153702970218

79 / 9054,60,865100/77

B7/8

1160163012970159

61 / 7540,30,92598/78

1151163012970170

65 / 7540,30,925100/78

1142163012970180

69 / 7540,30,925100/78

1133163012970191

73 / 7540,30,925101/78

1124163012970203

78 / 9040,30,925101/78

1125163012970212

81 / 9059,60,963101/79

1117163012970220

85 / 9059,60,963101/79

B8

1229173212970168

67 / 7544,81,11899/83

1220173212970172

71 / 7544,81,118100/84

1211173212970183

75 / 9044,81,119101/84

1202173212970194

80 / 9044,81,119101/84

1193173212970205

84 / 9044,81,119101/84

1194173212970214

88 / 9065,51,119102/85

1188173512975223

96 / 11065,51,18

102/85

B8/9

1300183712970165

72 / 7550

1,195101/84

1291183712970175

77 / 9050

1,195100/84

1282183712970185

81 / 9050

1,257101/84

1273183712970196

86 / 9050

1,257101/85

1267184022975207

91 / 11050

1,257101/85

1267184022975217

96 / 11072,91,257102/85

1260184022975225

99 / 11072,91,257102/86

B9

1379195172970168

79 / 9056

1,454101/84

1370195172970178

84 / 9056

1,454102/85

1363195502975188

89 / 11056

1,539102/85

1354195502975199

94 / 11056

1,539102/85

1345195502975210

99 / 11056

1,539102/85

1346195502975219

104 / 11079,61,54

102/85

1338195502975227

107 / 11079,61,54

102/86

B9/10

1461207002970171

86 / 9063

1,637102/85

1454207352975181

92 / 11063

1,636102/85

1445207352975191

97 / 11063

1,637102/85

1436207352975202

102 / 11063

1,637102/85

1427207352975212

107 / 11063

1,637102/85

1428207352975222

112 / 13287,7

1,637102/85

1420207352975230

116 / 13287,7

1,637102/86

VM 21 R

14

Performance data based on the compression of air (p1= 1.0 bar, t1 = 20 °C)

B [ - ]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

Compressor size

belt drive ratio

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

Dischargepressurepe [bar gauge]

0,75

1,00

1,25

1,50

1,75

2,00

2,25

2,50

2,75

3,00

3,25

3,50

B4

109110566294589

26,2 / 3014,60,48193/76

1079105842950106

32,4 / 3714,60,48394/76

1060105482940124

38,4 / 4514,60,48394/77

1063106022955140

44,5 / 5522,00,48396/78

1052106022955155

49,6 / 5522,00,48397/78

1048106562970170

55 / 7522,00,48399/80

B4/5

117111207294589

28,3 / 3716,30,52793/76

1159112262950106

34,8 / 4516,30,52894/77

1162112682965122

41,1 / 4516,30,52895/78

1143112452955140

47,8 / 5524,30,5396/79

1132112452955154

54 / 5524,30,5397/79

1128113022970169

59 / 7524,30,5399/81

B5

124711815295090

30,3 / 3717,80,60293/77

1227117752940106

36,9 / 4517,80,60294/77

1213117752940123

43,6 / 4517,80,60295/78

1217118352955140

51 / 5526,60,60497/79

1214118952970154

57 / 7526,60,60498/79

1202118952970168

63 / 7526,60,604100/81

B5/6

133612529295090

32,9 / 3720,00,68694/77

1317124872940106

39,7 / 4520,00,68695/77

1310125502955123

47,1 / 5520,00,68895/78

1304126142970140

55 / 7520,00,68897/79

1304126142970154

61 / 7529,40,68898/79

1293126142970168

67 / 7529,40,688100/81

B6

1425132302950

9135,5 / 45

22,20,80694/77

1405131852940107

42,6 / 4522,20,80695/78

1399132532955123

51 / 5522,20,80996/79

1393133202970140

59 / 7522,20,80997/79

1393133202970154

66 / 7532,40,80998/80

1382133202970167

72 / 7532,40,809100/81

B6/7

152013983294092

38,5 / 4524,80,87694/78

1515140552955108

46,5 / 5524,80,87695/78

1510141262970123

55 / 7524,80,87696/79

1496141262970140

63 / 7524,80,87697/80

1495141262970154

71 / 7536,00,87698/80

1484141262970168

77 / 9036,00,876100/81

B7

162914834294094

42,1 / 4528,01,0395/78

1624149092955109

51 / 5528,01,03396/78

1619149852970124

59 / 7528,01,0397/79

1605149852970140

68 / 7528,01,0398/80

1605149852970155

76 / 9040,11,03399/81

1594149852970168

83 / 9040,11,033100/82

B7/8

175415811295596

46,5 / 5531,31,11595/79

1750158912970110

56 / 7531,31,11596/79

1735158912970125

64 / 7531,31,11597/79

1721158912970141

73 / 7531,31,11898/80

1721158912970156

82 / 9044,61,11899/81

1713159182975169

90 / 11044,61,164

101/82

VML 25 R

15

Performance data based on the compression of air (p1= 1.0 bar, t1 = 20 °C)

B [ - ]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

Compressor size

belt drive ratio

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

Dischargepressurepe [bar gauge]

0,75

1,00

1,25

1,50

1,75

2,00

2,25

2,50

2,75

3,00

3,25

3,50

B4

1390104782970154

70 / 7539,60,94694/77

1378104782970166

75 / 9039,60,94695/77

1366104782970177

80 / 9039,60,94696/77

1355104782970189

85 / 9039,60,94698/77

1356104962975200

91 / 11060,90,986

100/78

1346104962975209

94 / 11060,90,986

100/78

1336104962975218

98 / 11060,90,986

100/79

B4/5

1505111682970154

76 / 9045,11,09594/78

1493111682970165

81 / 9045,11,09595/78

1481111682970176

86 / 9045,11,09596/79

1473111682975187

92 / 11045,11,13299/79

1471111862975198

98 / 11067,61,132100/79

1461111862975207

102 / 11067,61,132100/79

1451111132975216

106 / 11067,61,132100/79

B5

1609117882970154

82 / 9050,31,21295/79

1597117882970165

87 / 9050,31,21296/79

1588118082975175

93 / 11050,31,25897/79

1577118082975186

98 / 11050,31,25899/80

1565118082975198

104 / 11075,31,258100/80

1565118082975206

109 / 13275,31,388100/80

1555118082975215

113 / 13275,31,388100/80

B5/6

1733126072975155

90 / 11057,31,40396/79

1721126072975166

95 / 11057,31,45797/79

1709126072975176

101 / 11057,31,45798/79

1697126072975187

107 / 11057,31,457100/80

1685126072975198

113 / 13285,51,642100/80

1686126072975207

119 / 13285,51,642100/80

1676126072975215

123 / 13285,51,642100/80

B6

1828133072975157

97 / 11063,71,61297/80

1817133072975167

103 / 11063,71,61298/80

1805133072975178

109 / 13263,71,74799/80

1793133072975188

115 / 13263,71,747100/80

1781133072975199

121 / 13263,71,747100/80

1782133072975208

127 / 13294,51,748100/80

1772133072975216

132 / 16094,51,748100/80

B6/7

1952142052975160

107 / 11073,11,88298/80

1940142052975170

113 / 13273,12,35398/80

1928142052975180

119 / 13273,12,35399/80

1916142052975190

126 / 13273,12,353101/81

1904142052975201

132 / 16073,12,354101/81

1905142052975210

139 / 160106,92,354101/81

1895142052975218

144 / 160106,92,354101/81

B7

2061149942975162

116 / 13281,42,48699/80

2049149942975172

122 / 13281,42,48699/80

2037149942975182

129 / 13281,42,487100/80

2025149942975192

135 / 16081,42,487101/81

2013149942975202

142 / 16081,42,412101/81

2014149942975212

149 / 160117,62,412101/82

2004149942975220

154 / 160117,62,412101/82

B7/8

2198159802975165

129 / 13292

2,84899/81

2186159802975175

135 / 16092

2,84899/81

2174159802975185

142 / 16092

2,848100/81

2163159802975195

149 / 16092

2,993101/82

2151159802975205

156 / 16092

2,993101/82

2151159802975214

163 / 200129,82,993102/82

2141159802975222

168 / 200129,82,994102/82

B8

2323168682975168

141 / 160101,53,01799/81

2311168682975177

147 / 160101,53,162100/81

2299168682975187

154 / 160101,53,162101/81

2287168682975197

161 / 200101,53,163101/82

2275168682975207

168 / 200101,53,163102/83

2276168682975217

176 / 200140,73,163102/83

2266168682975224

182 / 200140,73,163102/83

VM 37 R

16

Performance data based on the compression of air (p1= 1.0 bar, t1 = 20 °C)

B [ - ]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

Compressor size

belt drive ratio

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

Dischargepressurepe [bar gauge]

0,75

1,00

1,25

1,50

1,75

2,00

2,25

2,50

2,75

3,00

3,25

3,50

B4

11676283294587

27,9 / 3013,20,4

94/75

114962932950106

35,2 / 3713,20,4

96/75

113562722940124

41,9 / 4519,50,4297/76

112663042955141

48,1 / 5519,50,4298/76

111863362970159

55 / 7519,50,4299/77

110263362970177

62 / 7519,50,4299/78

B6

15317840294087

36,7 / 4519,50,6497/78

152078802955104

45,6 / 5519,50,6699/79

150979202970122

55 / 7519,50,68

100/79

150479202970137

63 / 7528,70,68

101/79

148879202970153

71 / 7528,70,68

101/80

147279202970169

78 / 9028,70,71

102/81

B7

176288202940

8743 / 4524,20,8298/80

175388652955104

53 / 5524,20,84

100/80

174389102970120

63 / 7524,20,87

100/80

173889102970136

73 / 7535,70,92

101/80

172289102970151

81 / 9035,70,92

101/80

171089252975167

90 / 11035,71,08

102/81

B8

20119992295589

52 / 5530,71,0999/82

2033100432970104

63 / 7530,71,12

101/81

2013100432970120

73 / 7530,71,18

102/81

1993100432970137

84 / 9030,71,18

102/81

1996100592975151

94 / 11045,11,35

102/81

1980100592975166

104 / 11045,11,35

103/81

B9

231811314297093

63 / 7539,91,46

100/82

2298113142970107

74 / 9039,91,53

101/82

2277113142970123

86 / 9039,91,53

102/82

2261113332975139

98 / 11039,91,99

103/82

2260113332975154

110 / 13258,21,99

103/82

2244113332975169

120 / 13258,21,92

104/82

B10

259212727297098

77 / 9053

2,04100/82

2575127492975113

89 / 11053

2,38101/82

2555127492975128

102 / 11053

2,38103/83

2535127492975143

111 / 13253

2,54105/83

2515127492975160

129 / 13253

2,54105/83

VML 40 R

17

B2

8915050294590

21,8 / 309,4

0,25891/73

86850502945111

27,9 / 3013,70,25893/73

85450582950129

32,9 / 3713,70,25895/74

83450412940149

37,8 / 4513,70,26595/74

81850412940170

43 / 4513,70,26595/75

80850672955191

48,6 / 5513,70,28396/75

B5

13407025295087

31,9 / 3715,80,5196/77

132470012940105

39,7 / 4515,80,5298/77

131370372955123

48 / 5523,60,5299/78

130570732970138

55 / 7523,60,53

100/78

128970732970155

62 / 7523,60,53

101/79

127370732970173

69 / 7523,60,53

101/80

B3

10115611294588

24,5 / 3011

0,3292/73

99356212950109

31,2 / 3711

0,3293/73

97956022940127

36,8 / 4516,30,3395/74

96356022940144

42,2 / 4516,30,3396/74

95456302955163

48,2 / 5516,30,3496/75

94556592970183

55 / 7516,30,3497/75

Performance data based on the compression of air (p1= 1.0 bar, t1 = 20 °C)

B [ - ]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

Compressor size

gear ratio

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

Dischargepressurepe [bar gauge]

0,75

1,00

1,25

1,50

1,75

2,00

2,25

2,50

2,75

3,00

3,25

3,50

i4

101646552950176

57 / 7528,50,86

97 / 77

100046552950188

62 / 7528,50,86

97 / 77

99446552950201

67 / 9044,40,86

97 / 77

98046552950214

71 / 9044,40,86

97 / 77

96746552950228

75 / 9044,40,86

98 / 78

95446552950242

79 / 11044,40,86

98 / 78

i5

118351982950172

64 / 9031

1,00497 / 78

116851982950187

70 / 9031

1,00497 / 78

115251982950203

75 / 9031

1,00497 / 78

114851982950216

80 / 11042,71,00497 / 78

113451982950229

84 / 11042,71,00498 / 78

110851982950250

93 / 13242,71,00499 / 78

i6

137758232950168

73 / 9035,61,19

98 / 78

136158232950182

79 / 11035,61,19

98 / 78

134558232950197

85 / 11035,61,19

98 / 78

134158232950210

91 / 11049,21,19

98 / 78

132858232950222

95 / 13249,21,19

98 / 78

131558232950234

100 / 13249,21,19

98 / 78

130258232950246

105 / 13249,21,19

99 / 78

i7

160565552950165

83 / 11042,21,42498 / 78

158965552950178

89 / 11042,21,42498 / 78

157365552950192

96 / 13242,21,42499 / 78

156965552950205

104 / 13257,81,42499 / 78

155665552950216

109 / 13257,81,42499 / 78

154365552950227

114 / 13257,81,424

100 / 78

152965552950239

119 / 16057,81,424

100 / 78

i8

184873312950163

94 / 13249,61,70499 / 78

183273312950175

101 / 13249,61,70499 / 78

181773312950188

109 / 13249,61,70499 / 78

180173312950201

116 / 16049,61,704

100 / 78

179973312950212

123 / 16068

1,704101 / 78

178673312950223

129 / 16068

1,704101 / 78

177373312950233

134 / 16068

1,704101 / 78

i9

211781832950162

107 / 13257,72,034

100 / 78

210281832950174

115 / 13257,72,034

100 / 78

208681832950186

123 / 16057,72,034

100 / 78

207081832950198

131 / 16057,72,034

102 / 80

206881832950210

140 / 20078,62,034

103 / 80

205581832950219

146 / 20078,62,034

103 / 80

204281832950229

152 / 20078,62,034

103 / 80

i10

246492722950163

125 / 16068

2,501102 / 80

244892722950173

133 / 16068

2,501102 / 80

243292722950185

142 / 20068

2,501102 / 80

241792722950196

151 / 20068

2,501102 / 80

240192722950208

160 / 20068

2,501103 / 80

240292722950217

168 / 20092,52,501

103 / 80

238992722950226

175 / 20092,52,501

103 / 80

i11

2766102132950164

141 / 20078,22,95

103 / 83

2751102132950174

150 / 20078,22,95

103 / 84

2735102132950184

160 / 20078,22,95

103 / 84

2719102132950195

169 / 20078,22,95

104 / 84

2703102132950206

179 / 20078,22,95

105 / 84

2704102132950216

189 / 2501052,95

106 / 84

2691102132950225

196 / 2501052,95

107 / 84

i12

3161114312950160

164 / 2001153,57

104 / 83

3146114312950169

174 / 2001153,57

104 / 84

3107114312950187

184 / 2501153,57

104 / 84

3091114312950196

194 / 2501153,57

105 / 85

3075114312950202

204 / 2501153,57

106 / 85

3059114312950209

216 / 2501153,57

107 / 85

3063114312950217

215 / 2501663,57

108 / 85

VM 45

18

Performance data based on the compression of air (p1= 1.0 bar, t1 = 20 °C)

i [ - ]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

[m3/h]

nH [1/min]nM [

1/min]t 2 [ °C]PK/Mot [kW]PLeer [kW]J [kgm2]

[dBA]

Compressor size

gear ratio

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

flow at inletcompressor speedmotor speeddischarge temperaturepower at shaft / motor ratingpower, idling p1= p2= 1,0 bar reduced moment of inertiaLp(A) w/o.h./w.h.

Dischargepressurepe [bar gauge]

0,75

1,00

1,25

1,50

1,75

2,00

2,25

2,50

2,75

3,00

3,25

3,50

i 3

16634180295085

37,8 / 5519,1

193 / 75

163141802950105

48,3 / 7519,1

193 / 75

161641802950121

58 / 7522,6

194 / 77

159141802950128

66 / 9022,6

195 / 76

156541802950156

75 / 9022,6

196 / 78

154041802950176

83 / 11022,6

196 / 78

i 4

19054655295084

42,6 / 55221,2

94 / 76

187246552950102

54 / 75221,2

94 / 76

185846552950119

65 / 9026,31,2

95 / 78

183246552950135

74 / 9026,31,2

95 / 80

180746552950152

83 / 11026,31,2

96 / 81

178146552950170

93 / 13226,31,2

97 / 82

i 5

21825198295083

48,3 / 7525,61,4

96 / 76

215051982950101

61 / 7525,61,4

96 / 77

213551982950118

73 / 9030,81,4

97 / 79

211051982950133

84 / 11030,81,4

97 / 80

208451982950149

94 / 13230,81,4

98 / 81

205951982950165

104 / 13230,81,4

98 / 82

i 6

25045823295083

56 / 7530,11,8

97 / 81

247158232950100

69 / 9030,11,8

97 / 81

243958232950117

83 / 11030,11,8

98 / 81

243158232950131

95 / 13236,41,8

98 / 81

240658232950146

106 / 13236,41,8

99 / 82

238058232950162

117 / 16036,41,8

99 / 82

i 7

28826555295084

65 / 9035,92,2

99 / 81

28506555295099

79 / 11035,92,2

99 / 81

281765552950116

95 / 13235,92,2

100 / 82

281065552950131

109 / 13243,62,2

100 / 82

278465552950145

121 / 16043,62,2

101 / 83

275965552950159

134 / 16043,62,2

102 / 84

i 8

328773312950

8575 / 9042,92,6

100 / 82

325473312950100

91 / 11042,92,6

100 / 82

322273312950115

108 / 13242,92,6