4. Part Load Operation of Steam Turbines - ENGSoft Lab - · PDF file ·...

Transcript of 4. Part Load Operation of Steam Turbines - ENGSoft Lab - · PDF file ·...

Steam Turbine 4. Part Load Operation 1 / 81

HIoPE

4. Part Load Operation of Steam Turbines

Control V/V

(1.5% p @ VWO)

Nozzle

First stage

shell pressure

Fully Open

Stop V/V

(1.5% p)

Partially Open

Closed

Bucket

#1

#2

#3

#4

Steam

Flow

#1

#2 Closed

Steam Turbine 4. Part Load Operation 2 / 81

HIoPE

Partial Arc Admission 37 4

Hybrid Operation 64 6

Basics for the Control of Steam Flow 2 1

Full Throttling 29 3

Sliding Pressure Operation 57 5

Valves 11 2

Load Changes 76 8

Startup System of Steam Power Plants 73 7

Steam Turbine 4. Part Load Operation 3 / 81

HIoPE

Steam Turbine Control

Change power by changing steam flow rate (m) or steam inlet enthalpy (hin).

outin hhmP

Steam Turbine 4. Part Load Operation 6 / 81

HIoPE

HP Turbine LP Turbine

MS R

100% Power

75% Power

50% Power

25% Power

Pre

ssure

C/V

A Basic Concept for Part Load Operation

Steam Turbine 4. Part Load Operation 7 / 81

HIoPE

Output and Efficiency at Part Load

49.0

48.3

47.6

46.9

46.2

45.5

44.8

44.1

43.4

42.7

42.0

45 50 55 60 65 70 75 80 85 90 95 100

200

500

470

440

410

380

350

320

290

260

230

Load, %

Effic

iency,

%

Pow

er,

M

W

Power

Efficiency

Example: 460 MW, supercritical power plant

Output and Efficiency at Part Load

Steam Turbine 4. Part Load Operation 8 / 81

HIoPE

A turbine has different expansion lines as the load is

decreased.

But the part load expansion lines are generally parallel

to the full load expansion line.

This means that the internal efficiency under part load

conditions is very close to that under full load

conditions. That is, design efficiency of the turbine

blades is maintained during part load operations by

using the control valve.

However, the cycle efficiency is reduced under part

load conditions.

Throttling Process

p1

Ava

ilab

le E

ne

rgy

pc

p0

T0

h

s

Partial-flow expansion line

Expansion lines are

essentially parallel

Design-flow expansion line

p1’

p0: Inlet pressure

p1: Throttle pressure 1 1′

2′

2

U 100% load

Nozzle Row

25% load

100%

25%

Bucket Row

U

75% load

50% load

[ Velocity Diagram at Various Loads ]

[ Effect of Throttling on Non-Reheat

Steam Turbine Expansion Line ]

Steam Turbine 4. Part Load Operation 9 / 81

HIoPE

1) Full throttling (= Single admission )

• Constant pressure mode

• Throttling by pressure reducing valves

• All control valves are activated at the same time

• This is the simplest way to control the power, but this gives a large throttle

(pressure) loss because of using the pressure throttle valves

2) Partial arc admission (Throttling by a control stage)

• Constant pressure mode

• Divided the first stage nozzle arc into several segments having its own control valve

• Lower throttle loss

• The control valves are activated in a sequential mode

3) Sliding (or variable) pressure operation

• Variable pressure mode

• Controlling throttle flow by varying boiler pressure

4) Hybrid operation

• A combination of partial arc admission and sliding pressure operation

4 Methods Used in Steam Flow Control

Control of Steam Flow in HP Turbines

Steam Turbine 4. Part Load Operation 10 / 81

HIoPE

Exhaust Loss during Part Load

AN

ANA

YmV

3600

01.01

= annulus velocity

= steam mass flow rate

= saturated dry specific volume

= annulus area

= percent of moisture at ELEP

ANV

m

ANA

Y

[Exercise 4.1]

부분부하운전 시 배기손실 크기 변화를 비교하시오. 아울러 그 결과를 heat balance에서 확인하시오.

0 500 1000 1500 2000

610 457 305 152 0

80

60

40

20

0

186

139

93

47

0 E

xhaust Loss, B

tu/lb

Exh

au

st L

oss, kJ/k

g

Annulus Velocity (VAN), ft/s

Annulus Velocity (VAN), m/s

Thermodynamic

Optimum

Economic

Optimum

Total

Exhaust

Loss

Axial

Leaving

Loss

VAN proportional to:

rating

1/exhaust pressure

1/exhaust area

Steam Turbine 4. Part Load Operation 11 / 81

HIoPE

Partial Arc Admission 4

Hybrid Operation 6

Basics for the Control of Steam Flow 1

Full Throttling 3

Sliding Pressure Operation 5

Valves 2

Load Changes 8

Startup System of Steam Power Plants 7

Steam Turbine 4. Part Load Operation 12 / 81

HIoPE

Valves

[ A Typical Power Plant Steam Flow Diagram ]

Gen

Stop V/V

Control V/V

HP IP LP

Condenser

Reheater

Reheat

Stop and

Intercept

V/V

Main Steam

Hot Reheat

Cold

Reheat

Crossover

Ventilation

V/V

Exciter

Steam

Generator

Front

Standard

Steam Turbine 4. Part Load Operation 14 / 81

HIoPE

Typical Individual Stop and Control Valve Assembly

Valve 개수(표준화력 500MW 기준) - Stop v/v : 2 - Control v/v : 4 Stop valve = on-off valve Control valve = throttle valve라고도 불리며, load 연동 Typical closing time during emergency - Stop v/v : 0.09초 10% - Control v/v : 0.11초 10%

Generals

MSV

MCV

Actuator

Actuator

GE

Steam Turbine 4. Part Load Operation 15 / 81

HIoPE

Main Stop Valves [1/4]

High-pressure steam is admitted to the main turbine

through two parallel main stop valves.

The primary function of the main stop valves is to

quickly shut off main steam flow to the turbine under

emergency conditions.

The stop valves also provide a second line of defense

against turbine overspeed in the event the control

valves fail.

The main stop valve bypass valves are also used for

full arc operation during startup and shutdown of the

turbine.

The main stop valves are located in the main steam

piping between the boiler and the turbine control valve

chest.

The outlet of each stop valve is welded directly to the

valve chest.

The main steam stop valves are operated and

controlled by the turbines Electro Hydraulic Control

System in concert with the units DCS control system.

The bypass valve disk is fastened to the end of the

stem by special coarse threads strong enough to

withstand full closing force, yet designed to permit

freedom of disk movement relative to the stem so that

the valve will seat.

GE

Steam

Inlet

Steam

Strainer

Valve Seat

Valve Stem

Valve Disc

Steam

Outlet

Pressure

Seal Head

Actuator

Closing

Spring

[ Main Stop Valve ]

Steam Turbine 4. Part Load Operation 16 / 81

HIoPE

The steam from the steam generator flows to the main steam stop or throttle valves.

The primary function of the stop valves is to provide backup protection for the steam turbine during turbine

generator trips in the event the main steam control valves do not close.

The energy contained in the main steam can cause the turbine to reach destructive overspeed quickly when

generator loose the load.

The main stop valves close from full open to full closed in 0.15 to 0.5 s.

The main stop valves are closed on unit normal shutdown after the control valves have closed.

A secondary function of the main stop valves is to provide steam throttling control during startup.

The main stop valves typically have internal bypass valves that allow throttling control of the steam from

initial turbine roll to loads of 15% to 25%.

During this startup time, the main steam control valves are wide open and the bypass valves are used to

control the steam flow.

Some recent and current designs do not have these bypass valves.

Initial turbine speed runup is controlled by the main stop valves.

Main Stop Valves [2/4]

Steam Turbine 4. Part Load Operation 17 / 81

HIoPE

The bypass valve is held in the valve disk by a

bolted cap. Holes are located in the cap for steam

entrance, and holes in the valve disk pass the

steam when the bypass valve is utilized.

When the stop valve is opened the bypass valve

opens first as the valve stem moves in the open

direction.

When the bypass valve is fully open it contacts a

bushing on the stop valve and pulls it open. When

the stop valve is fully open, a bushing seats on the

inner end of the valve stem bushing and prevents

steam leakage along the valve stem.

Main Stop

Valve Stem

Main Stop

Valve Disc

Seating

Surface

Main Stop

Valve Disc

Bypass

Valve Disc

Bypass

Valve Ports

(8 ea)

[ Stop Valve Bypass ]

Each stop valve has two steam leakoff points where the stop valve stem passes through the stop valve

casing.

The first leakoff point located closest to the stop valve is referred to as the high-pressure leakoff and is

routed to the steam seal header.

During startup or low loads steam is supplied to this leakoff to assure a seal. After the turbine is loaded,

steam is fed through this line from the stop valve stem into the steam seal header.

The second leakoff point is referred to as the low-pressure leakoff and is routed to the gland steam

condenser.

Bypass Valve GE

Main Stop Valves [3/4]

Steam Turbine 4. Part Load Operation 19 / 81

HIoPE

The steam from the stop valves flows to the

main steam control or governor valves.

The primary function of control valves is to

regulate the steam flow to the turbine and thus

control the power output of the steam turbine

generator.

The control valves also serve as the primary

shutoff the steam to the turbine on unit normal

shutdowns and trips.

MHI

Main Steam Control Valves [1/3]

MSV

MCV

Actuator

Actuator

Siemens

Steam from

No.1 C/V

Steam from

No.3 C/V

Steam from

No.4 C/V

Steam from

No.2 C/V

HP

Inner

Shell

HP

Inner

Shell

HP

Inner

Shell

HP

Inner

Shell Snout

Pipe

Seal

Rings

HP

Inner

Shell

HP

Inner

Shell

Snout Pipes

Snout Pipes

180 Degree Nozzle Box

180 Degree Nozzle Box

Upper

Lower

Snout

Pipe

Seal

Rings

Steam Turbine 4. Part Load Operation 20 / 81

HIoPE

GE

The control valves regulate the steam flow to the turbine to

control the main turbine speed and/or load. The four control

valves are mounted in line on a common external valve chest.

Steam is supplied to the external valve chest through the main

stop valves. The valve chest is separated from the turbine, and

individual steam leads from the valve chest are provided from

each control valve to the inlet of the HP turbine. Each control

valve is operated by a hydraulic power actuator which positions

the control valves in response to signals from the Electro

Hydraulic Control System.

During startup, the control valves are wide open (full arc), and

the stop valves’ internal bypass valves control the steam flow to

the turbine. Under these conditions, steam is admitted through

all four steam leads around the entire periphery of the HP

turbine inlet. The purpose of this full arc admission is to reduce

thermal stresses caused by unequal steam flow through the

nozzle sections. During full arc admission, throttling of the

steam occurs at the stop valve bypass valves only, and there is

uniform steam flow into the HP turbine. This also results in

lower steam velocities at the turbine inlet. Because of the lower

steam velocities the temperatures cannot change as rapidly.

Full arc admission is used until the high transfer point is

reached, at which time transfer to partial arc will occur. [ Main Steam Control Valve ]

Closing

Spring

Balance

Chamber

Valve

Seat Valve

Disc

Steam

Chest

Main Steam Control Valves [2/3]

Steam Turbine 4. Part Load Operation 21 / 81

HIoPE

During normal operation, the main stop valves are wide open and the control valves control steam flow to

the turbine. The control valves operate sequentially to control steam flow to the turbine and the unit load.

All four control valves are never open the same amount for any given load up to full load with wide-open

control valves. This is referred to as partial arc admission.

Transfer to partial arc admission is normally automatically performed by the low transfer and high transfer

micro- switches but may also be initiated by the operator when the OK TO TRANSFER light comes on.

The control valves are throttled until they have control of steam flow and the stop valves then automatically

run full open.

Number l and 2 control valves are balanced type, with internal pilot valves. Number 3 and 4 control valves

are unbalanced single disk type.

The balanced type valves are equipped with an internal pilot valve connected to the valve stem. When

opening, the pilot valve is opened first to equalize the pressure across the main valve disk. Further opening

of the stem opens the main disk.

The disk of the unbalanced type valve is directly connected to the stem.

Each control valve is provided with two steam leakoff points where the control valve stem passes through

the external steam chest wall. The first leakoff point located closest to the external steam chest is referred to

as the high-pressure leakoff and is routed to the hot reheat steam line. The second leakoff point is referred

to as the low-pressure leakoff and is routed to the steam seal header.

GE

Main Steam Control Valves [3/3]

Steam Turbine 4. Part Load Operation 22 / 81

HIoPE

Reheat Stop and Intercept Valves [1/4]

[ Combined Reheat Stop and Intercept Valve, GE ]

Steam Turbine 4. Part Load Operation 23 / 81

HIoPE

Balance

Chamber

Intercept

Disc Reheat

Stop Disc

Steam Out

Steam

In

Intercept

Actuator

Closing

Spring

Reheat Stop

Actuator

Steam

Strainer

GE Two combined reheat stop and intercept

valves are provided, one in each hot

reheat line supplying reheat steam to the

IP turbine.

As the name implies, the combined

reheat intercept valve is actually two

valves, the intercept valve (IV) and the

reheat stop valve (RSV), incorporated in

one valve casing.

Although they utilize a common casing,

these valves have separate operating

mechanisms and controls.

The function of the intercept valves and

reheat stop valves is to protect the

turbine against overspeed from stored

steam in the reheater.

[ Reheat Stop and Intercept Valves (SKODA) ]

Reheat Stop and Intercept Valves [2/4]

Steam Turbine 4. Part Load Operation 24 / 81

HIoPE

The intercept valve disk is located above the reheat stop valve disk, with its stem extending through the

upper head. The reheat stop valve stem extends downward through the below-seat portion of the casing.

Both valves share a common seat; however, the intercept valve is designed to travel through its full stroke

regardless of the reheat stop valve position, while the intercept valve must be in the “closed” position for the

reheat stop valve to open.

During normal operation of the turbine-generator unit, the intercept valves are fully open.

The purpose of the intercept valve is to shut off steam flow from the reheater, which, because of its large

storage capacity, could possibly drive the unit to overspeed upon loss of generator load.

The intercept valve is capable of reopening against maximum reheat pressure and of controlling turbine

speed during reheater blowdown following a load rejection.

The primary function of the reheat stop valves is to provide a second line of defense (backup protection)

against the energy storage of the reheater in the event of failure of the intercept valves or the normal control

devices.

However, note that the reheat stop valves also close upon a routine shutdown, or by operation of certain

boiler and electrical trips whenever the main stop valves are closed.

The reheat stop valve power actuators are sized so that the reheat stop valves are capable of reopening

against a steam pressure differential of approximately 15 percent of maximum reheat pressure.

Reheat Stop and Intercept Valves [3/4]

Steam Turbine 4. Part Load Operation 25 / 81

HIoPE

The function of the reheat stop and intercept valves is similar to the main steam stop and control valves.

The reheat stop valve offer backup protection for the steam turbine in the event of a unit trip and failure of

the intercept valves to close.

The intercept valves control unit speed during shutdowns and on large load changes, and protect against

destructive overspeeds on unit trips.

The need for these valves is a result of the large amount of energy available in the steam present in the HP

turbine, the hot and cold reheat lines, and the reheater.

On large load changes, the main steam control valves start to close to control speed, however, energy in the

steam present after the main steam control valves may be sufficient to cause the unit to overspeed.

The steam after the main steam control valves could expand through the IP and LP turbines to the

condenser, supplying more power output than is required, causing the turbine to overspeed.

The intercept valves are used to throttle the steam flow to the IP turbine in this situation to control turbine

speed.

During unit shutdowns, a similar situation could occur, and the intercept valves are used to control speed

under these conditions as for the trip condition.

During unit trips, both the reheat stop and the intercept valves close, preventing the reheat-associated steam

from entering the IP turbine.

During normal unit operation, the reheat stop and intercept valves are wide open, and load control is

performed by the main steam valves only.

Reheat Stop and Intercept Valves [4/4]

Steam Turbine 4. Part Load Operation 26 / 81

HIoPE

During unit trips, the closure of the main stop and control valves and of the

reheat stop and intercept valves traps steam in the HP turbine.

During the turbine overspeed and subsequent coastdown, the HP turbine

blades are subject to windage losses from rotating in this trapped steam.

The windage losses cause the blades to be heated.

This heating, in combination with the overspeed stress, can damage the HP

turbine blades.

To prevent this, a ventilation valve is provided to bleed the trapped steam to

the condenser.

On a unit trip, the valve is automatically opened.

The bleeding action causes the trapped steam to flow through the HP turbine,

maintaining the HP turbine temperature within acceptable limits by preventing

heat buildup from the windage losses.

Ventilation Valve

[ Ventilation Valve, CCI ]

Steam Turbine 4. Part Load Operation 27 / 81

HIoPE

Stop V/V

Control V/V

HP IP LP Gen

Condenser

Reheater Reheat Stop and

Intercept V/V

Main Steam

Hot Reheat

Cold

Reheat

Crossover

Ventilation

V/V

HRH bypass station

(HRH: Hot Reheat)

HP

byp

ass

sta

tio

n

[ Turbine Bypass Diagram ]

Ventilation Valve

Steam Turbine 4. Part Load Operation 28 / 81

HIoPE

0.2 0.4 0.6 0.8 1.0

2

4

6

8

Equivalent throttle flow ratio

Th

rott

le to

bo

wl p

ressu

re d

rop

(%

)

Pressure Drop in Valves

The efficiency of a steam turbine is governed by the efficiency of the individual stages and the pressure

drop through valves, cross-over pipes, and exhaust hoods.

Throttle steam from the boiler first pass through the stop valve and then control valves.

The stop valve pressure

drop is 2% and the control

valves in the wide open

position also have a

pressure drop of 2%.

Therefore, total pressure

drop occurred in the

valves is 4%.

The total loss in overall

heat rate of these pressure

drops is about 0.4%.

Steam Turbine 4. Part Load Operation 29 / 81

HIoPE

Partial Arc Admission 4

Hybrid Operation 6

Basics for the Control of Steam Flow 1

Full Throttling 3

Sliding Pressure Operation 5

Valves 2

Load Changes 8

Startup System of Steam Power Plants 7

Steam Turbine 4. Part Load Operation 30 / 81

HIoPE

All control valves have a same position in full throttling operation

Control V/V

(1.5% p @ VWO)

Nozzle

First stage

shell pressure

Stop V/V

(1.5% p)

Bucket

Steam

Flow

#1

#2

#1

#2

#3

#4

Concept of Full Throttling

Steam Turbine 4. Part Load Operation 31 / 81

HIoPE

Generals for Full Throttling

Load

Ahead of First

Stage Nozzles

(Bowl Pressure)

After First Stage

(Shell Pressure)

Initial (Main Steam)

Throttling 0 Steam condition entering the control valves

1 Steam condition entering the first stage

2 Steam condition entering the second stage

0

h

s

1

p0 p1

p2

2

Steam Turbine 4. Part Load Operation 32 / 81

HIoPE

Full throttling is the simultaneous operation of all main steam control valves at the same time.

The main steam supplied during part load operation has a same pressure with that supplied during full load

operation.

Therefore, throttling loss is occurred whenever the plant is operated with part load.

The steam turbine output increases as the valves are opened and full load is reached when the valves are

wide open.

During the part load operation, full throttling is the least efficient of all control modes because the available

energy in the expansion process is reduced greatly by the throttling process. For this reason, the HP turbine

with full throttling has a greater entropy increase than that with partial arc admission.

This method is also called as ‘full arc admission’, ‘single admission’, or ‘throttling control’ because of the

steam admission to all portions of the control stage.

During the startup of some units, the control valves are wide open.

Steam is initially admitted to the turbine by throttling the steam flow by using the bypass valves internal to

the main steam stop valves.

This flow control method is used up to 15% to 25% load.

Above this load, the main steam control valves are used to control the steam flow and the main steam stop

valves are wide open.

The complex control stage design is not required.

Generals for Full Throttling

Steam Turbine 4. Part Load Operation 33 / 81

HIoPE

For 50% reaction turbines with throttling control, the pressure ratio across the first stage is about 1.13 at all

loads.

This value of pressure ratio is too low to produce sonic velocity.

Thus, an advantage of throttling control is no solid particle erosion in the first stage.

The solid particle erosion would be in the control valves, which are less expensive to repair than the first

stage.

Another advantage of throttling control is lower stress levels due to low first stage velocities and the absence

of inactive arcs.

Advantages of Full Throttling

Steam Turbine 4. Part Load Operation 34 / 81

HIoPE

Ab

so

lute

ste

am

pre

ssu

re

[ Variation of stage-shell pressure ]

m1

m0

Stage pressure is roughly proportional to the mass flow

rate to the following stage, the throttle flow minus

leakages, and all extractions from the preceding stages

and stage in question, plus any steam returned to the

turbine ahead of this stage.

Therefore, mathematical relationship is

di

idii

m

mpp

,

,

= steam pressure at the nozzle of stage i

= design steam pressure at the nozzle of stage i

= steam mass flow rate to the stage i

= steam mass flow rate to the stage i

ip

dip ,

im

dim ,

Stage Pressure during Part Load

Steam Turbine 4. Part Load Operation 35 / 81

HIoPE

3566457 lb/hr

131561 lb/hr

60.6 psia

LP Turbine

2701136 lb/hr

105869 lb/hr

46.21 psia

LP Turbine

[Exercise 4.1]

아래 그림은 각각 설계조건과 부분부하운전조건에서 LP터빈 첫 번째 추기 지점에서의 조건이다. 부분부하운전조건에서 추기압력을 계산하고 검토하시오.

[ Full load ] [ Part load ]

Stage Pressure during Part Load

Steam Turbine 4. Part Load Operation 36 / 81

HIoPE

[Solution]

Design conditions are

pd = 60.6 psia

md = 3,566,547131,561 = 3,434,986 lb/hr

md means the steam mass flow rate to the next stage.

Under the part load conditions this mass flow rate becomes

m = 2,701,136105,869 = 2,595,267 lb/hr

Extraction pressure can be calculated

p = 606.6 2,595,267/ 3,434,986

= 45.8 psia

This calculated pressure is very close to extraction pressure shown in heat balance, 46.21 psia.

di

idii

m

mpp

,

,

Stage Pressure during Part Load

Steam Turbine 4. Part Load Operation 37 / 81

HIoPE

Partial Arc Admission 4

Hybrid Operation 6

Basics for the Control of Steam Flow 1

Full Throttling 3

Sliding Pressure Operation 5

Valves 2

Load Changes 8

Startup System of Steam Power Plants 7

Steam Turbine 4. Part Load Operation 38 / 81

HIoPE

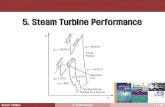

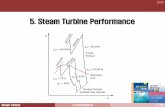

Concept of Partial Arc Admission

Control V/V

(1.5% p @ VWO)

Nozzle

First stage

shell pressure

Fully Open

Stop V/V

(1.5% p)

Partially Open

Closed

Bucket

#1

#2

#3

#4

Steam

Flow

#1

#2 Closed

Steam Turbine 4. Part Load Operation 39 / 81

HIoPE

Nozzle Box

43

43

42

42

#1

#2 #4

#3

Number of nozzle

Turbine C.W.

[ 500 MW (3,500 psig, 1,000F) ]

Steam Turbine 4. Part Load Operation 40 / 81

HIoPE

Full Arc (Single Admission)

Partial Arc

The dimensions of turbine blades and flow channels are primarily a function of the volumetric

flow rates passing through the machine

Inactive

arc

#1 v/v

#2 v/v #4 v/v

#3 v/v #1 v/v

#2 v/v #4 v/v

#3 v/v

Concept of Partial Arc Admission

Steam Turbine 4. Part Load Operation 41 / 81

HIoPE

Pressure Variation

Full

Arc Partial

Arc

Load

Ahead of

Nozzle

Box #1

Ahead of

Nozzle

Box #2

Ahead of Nozzle Box #3

Ahead of

Nozzle

Box #4

After First Stage

Initial (Main

steam

pressure)

Load

Ahead of First Stage

Nozzles (Bowl

Pressure)

After First Stage

(Shell Pressure)

Initial (Main steam pressure)

Throttling

Steam Turbine 4. Part Load Operation 42 / 81

HIoPE

Generals for Partial Arc Admission

The inlet annulus area of the first stage nozzle is divided into several segments (vary from 4 to 6 to 8) along

tangential direction.

Typically, the first stage divides the annulus into four to eight segments (arcs) having different angles

depending on the guarantee points.

Partial arc admission (PAA) is the sequential operation of the main steam control valves.

PAA varies the output of the steam turbine by increasing or decreasing the arc of admission of steam flow to

the turbine control (first) stage. (The first admission stage in steam turbines often referred to as governing or

control stage)

Each control valve feeds a separate segment of the control stage, and the amount of arc in use is

determined by the number of valves open.

The valves are opened in a particular order that is determined by the allowable stresses on the control stage.

PAA is also called as governing control.

Rated throttle conditions are used throughout the load range to the extent allowed by the steam generator.

- to be continued -

Steam Turbine 4. Part Load Operation 43 / 81

HIoPE

The first stage is of impulse design because it gives only a small circumferential pressure gradient after

nozzle so the spreading of the jets circumferentially may be attenuated. For the 50% reaction turbine, the

first stage is the same as for the impulse turbine.

Partial arc admission can cause high impulse loads on the nozzle and buckets, possibly leading to high cycle

fatigue failures.

If the partial arc admission is applied for small turbine, the blade height can be increased in order to increase

stage efficiency.

Normally, entropy production becomes higher for small turbines than large machines. This is because of

higher endwall losses for shorter blades, and the substantial part of the endwall losses caused by the

secondary flow formed in both nozzle and bucket row.

One way to prevent this is to increase the dimension of the turbine blades and adopt partial admission. Even

though extra losses due to the employment of partial admission is introduced, it might be beneficial due to

the decreased endwall losses.

Generals for Partial Arc Admission

Steam Turbine 4. Part Load Operation 44 / 81

HIoPE

Secondary Vortices in Short and Long Blades

(a) Short Blades (b) Long Blades

Hub

Tip

Vortex

Vortex

Ra

dia

l h

eig

ht

Bucket efficiency

Hub

Tip

Vortex

Vortex

Ra

dia

l h

eig

ht

Bucket efficiency

Hig

h

Effic

ien

cy

Steam Turbine 4. Part Load Operation 45 / 81

HIoPE

Advantages of Partial Arc Admission

PAA is more efficient than full throttling because the throttling

process loss is minimized by reducing the number of control

valves throttling at any one time.

If the PAA is employed, the inlet flow rate can be controlled

and a high inlet pressure and temperature can be maintained

as high as for the fully admitted arcs, even for low flow rates.

Considerably less pressure is lost due to throttling by PAA so

that more pressure is available to produce power in the first

stage, with a corresponding improvement in overall heat rate.

Inactive

arc

#1 v/v

#2 v/v #4 v/v

#3 v/v

Steam Turbine 4. Part Load Operation 46 / 81

HIoPE

Comparison of Throttling Methods

(a) Full throttling (b) Partial arc admission

0

h

s

1

2a

p0 p1

p2

2b 2c

0

h

s

1

p0 p1

p2

2

0 1 Flow in the control valves

1 2b Flow across the first stage in an

arc segment

0 2a Flow across the first stage in

the fully opened segments

2c Steam condition into the

second stage

0 Steam condition entering the control

valves

1 Steam condition entering the first

stage

2 Steam condition entering the second

stage

Steam Turbine 4. Part Load Operation 47 / 81

HIoPE

0 0.2 0.4 0.6 0.8 1.0

(VWO)

10

20

30

40

50

60

70

80

90

100

0

IP Turbine

LP Turbine

HP 2nd Stage to Cold Reheat

HP 1st Stage

Throttle Flow Ratio

Effic

iency [%

]

Turbine Section Efficiency

Steam Turbine 4. Part Load Operation 48 / 81

HIoPE

0 0.2 0.4 0.6 0.8 1.0

(VWO)

55

60

65

70

80

85

90

Throttle Flow Ratio

HP

Turb

ine E

ffic

iency [%

]

HP Turbine Efficiency

75

Full Throttling

Partial Arc

Admission

Steam Turbine 4. Part Load Operation 49 / 81

HIoPE

Heat Rate

Actual turbine cycle performance is shown on a

valve loop basis heat rate curve.

This curve reflects the steam throttling effect as

the steam passes through a partially closed

steam admission.

The throttling pressure drop reduces the

available energy of the steam as the throttled

admission steam expands across the control

stage.

An alternative method of representing turbine

heat rate impact due to turbine valve losses at

part load is by a mean of valve loop method.

Generator output

He

at ra

te

40 0 20 60 80 100

Valve Loop Basis (True Curve)

Mean of Valve Loop Basis

Valve Point Basis

(Locus-of-valve best points)

This method is an approximation of the heat rate impact illustrated on the valve loop basis curve and

represents a mean of the turbine heat rate and passes through the valve loop curve.

Turbine heat balance developed on the basis of this assumption are considered to be on a locus-of-valve

best points basis. This heat balances describe heat rates assuming an infinite number of small valves

having a 3% pressure drop.

Steam Turbine 4. Part Load Operation 50 / 81

HIoPE

Partial Admission

The control stage should be designed with

impulse turbine in order to avoid circumferential

flow of steam after passing through the first

stage nozzle

Steam Turbine 4. Part Load Operation 51 / 81

HIoPE

0.3

60

Velocity Ratio [U/C]

HP

Turb

ine E

ffic

iency [%

]

50

70

80

0.4 0.5 0.6

A

B C

D

E

F = 85/170

A

B

C

D

E

Efficiency at Partial Arc Admission

Steam Turbine 4. Part Load Operation 52 / 81

HIoPE

Stagnation Region Stagnation

Region

Sector-End Loss Axial

Tangential Ventilation Loss

Partial Admission Losses

Steam Turbine 4. Part Load Operation 53 / 81

HIoPE

Tangential Blade Force under Partial Arc Admission

over Time

The large unsteady forces acting on the buckets in tangential

direction are produced when the buckets enter and leave the

admission jets

Time

0 2 4 6 8

t=0

t=1 Tref

t=2 Tref

t=6 Tref

t=7 Tref

t=8 Tref

10

0.00

- 0.05

- 0.10

0.05

0.10

0.15

0.20

0.25

0.30

Fo

rce

Actin

g o

n a

Bla

de

in

Tangential D

irection Unsteady Forces

Steam Turbine 4. Part Load Operation 54 / 81

HIoPE

• It can employ longer blades which give better

aerodynamic turbine efficiency.

• It gives smaller entropy increase during part

load operation.

• Therefore, the HP turbine efficiency is better

during part load operation.

• The better part load performance for partial

admission must be balanced against the

increased potential for high cycle thermal

fatigue in the first stage.

• The first stage is called as governing stage or

control stage.

Partial Arc Admission Single Admission

• As load is decreased on the single admission

unit, an increasing amount of throttling takes

place in the control valves.

• It gives better efficiency than partial arc

admission at VWO because there is no inactive

arc.

• Many of the large nuclear units are designed full

throttling.

Partial Arc vs. Single Admission

Steam Turbine 4. Part Load Operation 55 / 81

HIoPE

The HP turbine efficiency is better during part

load operation with sequential valve operation

than throttling condition. However, at valve wide

open, the throttling controlled turbine gives better

performance. This is because single admission

has no inactive arc.

Comparison of HP Turbine Performance

Valve-loops are the result of changes in HP

turbine efficiency as the valve goes from closed to

fully open.

Steam Turbine 4. Part Load Operation 56 / 81

HIoPE

2400 psig/1000/1000F

4valves, first 3 valves open together

4valves, first 2 valves open together

Effect of Admission Modes

Single Admission (Full Throttling) +4

+3

+2

+1

0

1

20 30 40 50 60 70 80 90 100

% VWO Load

2 Admissions

3 Admissions

4 Admissions

1st 2nd 3rd v/v pt. VWO

Base Line is Locus of “Valve

Best Point” (Partial Arc

Admission)

Valve Loop

2

Steam Turbine 4. Part Load Operation 57 / 81

HIoPE

Partial Arc Admission 4

Hybrid Operation 6

Basics for the Control of Steam Flow 1

Full Throttling 3

Sliding Pressure Operation 5

Valves 2

Load Changes 8

Startup System of Steam Power Plants 7

Steam Turbine 4. Part Load Operation 58 / 81

HIoPE

Load

Ahead of First

Stage Nozzles

After First Stage

Main Steam

Load

Ahead of First

Stage Nozzles

After First Stage

Main Steam

[ Full Throttling ] [ Sliding Pressure Operation ]

Sliding Pressure Operation

Comparison with Full Throttling

Steam Turbine 4. Part Load Operation 59 / 81

HIoPE

Generals for Sliding Pressure Operation

In a sliding pressure operation mode, which is also called as variable pressure operation, the steam flow is

controlled by varying boiler pressure with the main steam control valves are always fully open. Therefore, no

throttling occurs and control stage is not needed.

The steam pressure is proportional to the load, not only within the turbine but also as the inlet to the turbine

(main steam line), and in the steam generator.

Main steam pressure is controlled by the boiler firing rate.

The main advantage of sliding pressure operation is that the main steam temperature remains relatively

constant across the load range which shortens startup times and increases turbine rotor life.

The disadvantages of sliding pressure operation are poorer thermodynamic efficiency and limited load

response capability.

It may require a forced circulation boiler to have a fast response capability.

A sudden load increase is not possible because all control valves are always fully open.

The lower main steam pressures of this operating mode result in less available energy than in the partial arc

admission operation, but more than in the full throttling operation.

Both feed pump power and throttling losses in the turbine control valves can be reduced during the sliding

pressure operation because of lower pressure.

Steam Turbine 4. Part Load Operation 60 / 81

HIoPE

Sliding pressure operation has a reduced

thermodynamic efficiency during part load

operation because of reduced available energy

caused by reduced boiler pressure.

However, there are two important facts to be

considered in terms of efficiency of plant. Firstly,

boiler feedwater pump power at low load

operation with variable pressure can be

reduced significantly. Secondly, the moisture

loss at low load operation with variable pressure

can be reduced. These two facts contribute to

increase efficiency of the plant.

T

s

2

1

2

3

a b

4

b

4

3

increase in wnet

decrease in wnet

increase in qout

c

Generals for Sliding Pressure Operation

Steam Turbine 4. Part Load Operation 61 / 81

HIoPE

Items 결과 이유 효율변화

밸브 교축손실 모든 출력에서 VWO상태이기 때문에 교축손실 매우 작음

HP Turbine 효율 HP 1단에서 full arc 운전이며, 밸브에서 교축손실 작음

Rankine cycle 효율 부분부하운전에서 사이클 압력 저하로 available energy 감소

급수펌프 동력 부분부하운전에서 펌프 동력 절감 (출력이 낮아질수록 보일러 운전압력이 낮아지기 때문에 펌프 동력 절감 크기 증대)

효율변화 분석

Steam Turbine 4. Part Load Operation 62 / 81

HIoPE

First S

tag

e E

xit T

em

pe

ratu

re

Throttle Flow

100% adm.

50% adm.

62.5% adm.

75% adm.

Sliding Pressure

Sliding Pressure

Partial Arc Admission

First Stage Shell Temperatures

Sliding pressure operation decreases the

potential for low cycle thermal fatigue in the

turbine during load changes as compared to

constant initial pressure operation.

In sliding operation, first stage exit

temperature is almost constant over the load

which reduces thermal stress.

Steam Turbine 4. Part Load Operation 63 / 81

HIoPE

Comparison of Heat Rate

Single Admission (Full Throttling) +4

+3

+2

+1

0

1

20 30 40 50 60 70 80 90 100

% VWO Load

2 Admissions

3 Admissions

4 Admissions

1st 2nd 3rd v/v pt. VWO

Constant Pressure

Sliding Pressure

2

Base Line is Locus of “Valve

Best Point” (Partial Arc

Admission)

Valve Loop

Steam Turbine 4. Part Load Operation 64 / 81

HIoPE

Partial Arc Admission 4

Hybrid Operation 6

Basics for the Control of Steam Flow 1

Full Throttling 3

Sliding Pressure Operation 5

Valves 2

Load Changes 8

Startup System of Steam Power Plants 7

Steam Turbine 4. Part Load Operation 65 / 81

HIoPE

% VWO Load

20 40 60 80 100

2400

2000

1000

600

3

1. Full variable pressure with all control valve wide open.

2. Variable pressure with one control valve closed.

3. Variable pressure with two control valves closed.

2

1

Variable Pressure Operation Mode

Hybrid Operation

With a partial admission unit, it is attractive to close one or two valves and then vary

pressure with one or two valves closed. This is called as hybrid operation.

Steam Turbine 4. Part Load Operation 66 / 81

HIoPE

Korea Standard 500MW Fossil Power

분류 VWO MGR NR 75 50 30

Constant Pressure Operation Sliding Pressure Operation

출력 (kW) 550,000

(110%)

541,650

(108.3%)

500,000

(100%)

375,000

(75%)

250,000

(50%)

150,000

(30%)

유량 (lb/hr) 3,757,727

(112.7%)

3,684,046

(110.5%)

3,335,116

(100%)

2,389,835

(71.7%)

1,564,131

(46.9%)

980,271

(29.4%)

복수기 압력

(in.Hga) 1.5 1.5 1.5 1.5 1.5 1.5

주증기 온도 (F) 1000 1000 1000 1000 1000 1000

주증기 압력

(psia)

3514.7

(100%)

3514.7

(100%)

3514.7

(100%)

2860.2

(81.38%)

1870.2

(54.47%)

1152.6

(32.79%)

1st STA Bowl P.

(psia)

3409.3

(100%)

[97.00%]

3409.3

(100%)

[97.00%]

3409.3

(100%)

[97.00%]

2774.4

(81.39%)

[97.00%]

1814.7

(54.49%)

[97.03%]

1118.0

(32.79%)

[97.00%]

1st STA Shell P.

(psia)

2630.8

(113.9%)

2573.8

(111.5%)

2309.0

(100%)

1683.5

(72.9%)

1128.0

(48.9%)

723.9

(31.4%)

FWPT 동력 (kW) 18,755

(3.41%)

18,390

(3.40%)

16,611

(3.32%)

9,622

(2.57%)

4,125

(1.65%)

1,523

(1.02%)

Steam Turbine 4. Part Load Operation 67 / 81

HIoPE

Hybrid Operation

The hybrid operation adopts advantages of both sliding pressure operation and partial arc admission through

the combination of partial arc admission operation and sliding pressure operation.

Sliding pressure operation has the advantage of no throttling loss, and partial arc admission operation has

the advantage of fast load response.

At low loads, some of the main steam control valves are wide open and steam flow is controlled by sliding

pressure operation.

The main steam pressure is increased with steam turbine load until the main steam pressure rated

conditions.

The steam turbine load is increased further by maintaining the rated main steam pressure and sequential

opening of the remaining main steam control valve as in the partial arc admission operation.

Starting from full load, load reductions are initially achieved by closing control valves sequentially and

maintaining constant initial pressure.

When a particular valve point is reached, further load reductions are achieved by holding valve position

constant and decreasing initial pressure.

The best point for the change from constant to sliding pressure depends on the boiler characteristics and the

value of design initial pressure.

The optimum point usually occurs at about 50 to 60% load.

Steam Turbine 4. Part Load Operation 69 / 81

HIoPE

Comparison of Heat Rate

Single Admission (Full Throttling) +4

+3

+2

+1

0

1

20 30 40 50 60 70 80 90 100

% VWO Load

2 Admissions

3 Admissions

4 Admissions

1st 2nd 3rd v/v pt. VWO

Constant Pressure

Sliding Pressure

1

2

3

2

Hybrid Operation

Base Line is Locus of “Valve Best

Point” (Partial Arc Admission) Valve Loop

Steam Turbine 4. Part Load Operation 70 / 81

HIoPE

The full throttling has the worst overall heat rate because of throttling losses.

The sliding pressure operation has a slightly better heat rate than full throttling operation, but still has poor

performance because of the lower main steam pressures.

The partial arc admission operation shows the best heat rate at higher loads because of the high main steam

pressures and minimized throttling losses resulting from throttling with only one control valve at a time.

The hybrid operation gives the most efficient operation because the unit life is extended by maintaining

relatively constant temperatures at low loads, reducing cycling effects.

Heat rate for the partial arc admission is typically plotted as a “locus of best valve points,” that is, the line

passing through the heat rate points where any valves open are wide open.

The actual heat rate curve for the partial arc admission is represented by a valve loop that incorporates the

throttling losses associated with a valve throttling between full closed and full open.

Theoretically, the more control valves, the smaller valve loop, the greater the possibility of operating without

throttling, and the better the heat rate.

Comparison of Heat Rate

Steam Turbine 4. Part Load Operation 71 / 81

HIoPE

Modified Sliding Pressure Operation

Steam Turbine Load, %

Main

Ste

am

Pre

ssure

, %

0 20 40 60 80 100 0

25

50

75

100

• Today, modern power plants are operated in natural

sliding pressure mode or modified sliding pressure mode.

• Primary electrical power response (additional

electrical power within seconds) is produced by

condensate throttling.

• At a certain part load, the control valves can to be

throttled to improve the primary response capacity

Fixed Pressure Mode

Fixed Pressure

Mode

Modified sliding pressure operation uses throttle valve reserve so the valves are slightly closed at 90% to

95% load and some boiler stored energy can respond more quickly to rapid load change near full load.

Steam Turbine 4. Part Load Operation 73 / 81

HIoPE

Partial Arc Admission 4

Hybrid Operation 6

Basics for the Control of Steam Flow 1

Full Throttling 3

Sliding Pressure Operation 5

Valves 2

Load Changes 8

Startup System of Steam Power Plants 7

Steam Turbine 4. Part Load Operation 74 / 81

HIoPE

Startup System of Steam Power Plants

Boiler-internal startup systems and unit startup system

The purpose of boiler-internal startup systems is to drain off the excess water discharged from the

evaporator and to ensure flow through once-through evaporators.

Excess water is defined as the quantity of water which must be removed from a water-filled heat-exchange

system due to increased volume as a result of steam formation and increased temperature.

Steam Turbine 4. Part Load Operation 75 / 81

HIoPE

Natural-circulation boilers only have equipment for removing the excess water from the drum.

During startup of once-through boilers, a circulation flow is combined with the once-through flow in the

economizer and evaporator until the minimum evaporator flow level.

The water that does not evaporate is separated from the steam in HP separators and then fed either to a

recirculation pump, a drain heat exchanger, the feedwater tank, or an atmospheric flash tank.

The unit startup system ensure cooling of the superheater heating surfaces and supplies steam to the

turbine at the required startup pressure and temperature.

In modern power plants, separate turbine bypass systems for the HP and IP/LP casings of the turbine,

respectively, are seeing increased use.

Essential advantages of this system are the result of the uniform heatup of the superheater heating surfaces

– preventing flaking of the protective coating on the inside of the tubes caused by thermal shock and

carryover of corrosion products into the turbine (solid particle erosion) – short startup time, and the same

basic startup procedure for cold, warm and hot starts.

If bypass systems are dimensioned appropriately ( 60% steam flow at full load), the steam generator can be

kept in operation even when there is a turbine-generator load rejection to the station auxiliary power level,

thus in most cases preventing a unit trip.

Startup System of Steam Power Plants

Steam Turbine 4. Part Load Operation 76 / 81

HIoPE

Partial Arc Admission 4

Hybrid Operation 6

Basics for the Control of Steam Flow 1

Full Throttling 3

Sliding Pressure Operation 5

Valves 2

Load Changes 8

Startup System of Steam Power Plants 7

Steam Turbine 4. Part Load Operation 77 / 81

HIoPE

Load Changes

Sudden loss of other power plants or grid disturbances require step increase of the load in those power

plants still on line of about 2 to 5% within seconds to maintain a stable grid frequency. Since it takes 2 to 3

minutes for increased firing in coal-fired units to achieve the desired electric power output, the storage

capacity of the water/steam system is used for making such step load changes. The various methods

applied vary with regard to dynamic behavior and economics:

1) Opening the control valves: A drop in pressure

upstream of the turbine activates the storage capacity

of the main steam line and the steam generator. The

magnitude of the possible load step increase

depends on the throttle setting on the turbine valves,

while the duration of the load step change depends

on the storage capacity. The storage capacity of a

drum boiler is about 2 to 3 times that of a once-

through boiler. On the other hand, the permissible

pressure transient is only 6 to 8 bar/min as apposed

to 20 to 30 bar/min for a once-through boiler. The

curve given in the figure depicts throttling

corresponding to 5% of the main steam pressure at

100% load.

Dynamic impact of various measures

taken to activate load reserves

Steam Turbine 4. Part Load Operation 78 / 81

HIoPE

2) Opening of multistage valve: With respect to the load step change, the behavior of the multistage valve is

similar to throttling of the turbine control valves. Compared to throttling of the turbine control valves,

however, the implementation of the multistage valve requires additional investment cost, but on the other

hand provides a lower heat rate in steady-state operation.

3) Condensate throttling: Reducing the condensate flow reduces the extraction-steam flow and therefore

increases the steam turbine output. A steam-side shutdown of the LP feedwater heaters is also possible

and makes the additional output available somewhat more quickly than does the throttling of the

condensate. The heat rate in steady-state operation is not affected by this measure, and only a small

additional investment is required.

4) Shutdown of HP feedwater heaters: This measure can be applied without duration restrictions. Initially,

however, it causes considerable thermal stress in the thick-walled components of the steam generator due

to the large feedwater temperature transients. In normal operation, the heat rate is not affected.

5) Increased injection flow into the steam generator: This measure primarily makes use of the thermal

storage capacity of the heating surfaces and the headers based on a reduction of steam temperature. The

heat rate in steady-state operation is not affected.

Load Changes

Steam Turbine 4. Part Load Operation 79 / 81

HIoPE

During load changes, temperature changes occur in the turbine and in the steam generator which cause

temporary thermal stresses in the thick-walled components and which thus limit the load transients. In the

HP turbine, the temperatures change on constant-pressure mode. In Fig. 3.49, the values are plotted

downstream of the first stage. In sliding-pressure mode, in which no throttling takes place, the temperatures

are nearly constant. Sliding-pressure mode is therefore the more favorable operating mode for the steam

turbine.

Load Changes

Steam Turbine 4. Part Load Operation 80 / 81

HIoPE

The temperature in the steam generator remain nearly constant in constant-pressure mode but change in

sliding-pressure mode due to the pressure-dependent saturated-steam temperature in the evaporator and

the primary superheater region. Moreover, a load increase in sliding-pressure mode as a result of increased

pressure stores energy in the system, which also reduces the load transients. For the drum-type boiler with

its thick-walled drum and the large storage capacity of the evaporator system, constant-pressure mode is

therefore the more favorable operating mode. The once-through boiler is well suited for either operating

mode.

Unit behavior under continuous load changes is determined by the two main components the boiler and the

turbine as well as the control system on the one hand, and by the operating mode on the other. Table 3.11

shows the feasible load transients for these two main components and the resulting unit values.

Load Changes

Steam Turbine 4. Part Load Operation 81 / 81

HIoPE

질의 및 응답

작성자: 이 병 은 (공학박사) 작성일: 2015.02.11 (Ver.5) 연락처: [email protected]

Mobile: 010-3122-2262 저서: 실무 발전설비 열역학/증기터빈 열유체기술