5. Steam Turbine Performance - · PDF fileSteam Turbine 5. Performance 3 / 93 HIoPE Major...

Transcript of 5. Steam Turbine Performance - · PDF fileSteam Turbine 5. Performance 3 / 93 HIoPE Major...

Steam Turbine 5. Performance 1 / 93

HIoPE

5. Steam Turbine Performance

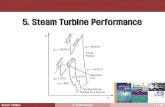

Nuclear Reheat

HP = 88-90%

LP = 90-91%

LP = 87%

LP = 85%

HP = 82%

Nuclear Non-Reheat

Fossil

Reheat

IP = 90-94%

Saturation

Line

h

s

Steam Turbine 5. Performance 2 / 93

HIoPE

Thermal Kit 65 4

Steam Turbine Section Efficiencies 15 2

Factors Affecting Cycle Performance 21 3

Heat Balance 2 1

Steam Turbine 5. Performance 3 / 93

HIoPE

Major Parameters Affecting Steam Turbine Performance

Steam Turbine Performance

Thermodynamic Efficiency

Working fluids

• Throttle pressure and temperature (enthalpy)

• Throttle flow (specific heat)

Steam Cycles

• Reheating (non-, single-, double)

• Regenerating

Exhaust pressure

• The amount of enthalpy drop

Others

• Air preheating

• Desuperheating

• Part load operation mode

Mechanical (Fluid Dynamic) Efficiency

Section efficiencies (in terms of energy conversion)

• Throttling losses occurred in valves

• Stage losses (profile, secondary flow, leakage loss)

Advanced airfoil shapes for nozzle and bucket

Advanced vortex blades

• Exhaust loss, and interface loss

Mechanical and electrical losses

• Bearing loss

• Generator loss

Power for auxiliary system in plant

• Fan power

• Power for a lube oil pump

Others

• LSB

• Makeup flow

• Pressure drop in boiler and extraction lines

Heat Balance

Steam Turbine 5. Performance 4 / 93

HIoPE

Turbine (Generator) Output [1/2]

Required generator output = plant net output + plant auxiliary loads.

Steam turbine output = generator output + generator electrical losses + turbine generator mechanical losses.

Historically, turbines have been designed to have 5% margins above required rated steam flows and

pressure to provide for manufacturing tolerances and variations in flow coefficients.

Therefore, the steam flow is 5% greater than that required for rated output with rated steam pressure (normal

pressure).

Under VWO-NP (VWO, normal pressure) condition, the turbine generator output is approximately 104% of

rated.

The pressure margin is included to operate safely and continuously at 105% of rated pressure (overpressure)

with VWO.

Under VWO-OP (VWO, overpressure) condition, the turbine generator output is approximately 109% of rated

and the main steam flow is 110% to 111% of rated.

Steam Turbine 5. Performance 5 / 93

HIoPE

Recent trends indicate that some manufacturers are not including all of the 5% steam flow margin. The

designer may want to include only a part of the steam flow margin with consideration of the full over-pressure

operation margins.

The designers should specify that the turbine be capable of operation at VWO-OP because operators

typically attempt to operate at those conditions.

The designer needs to design the steam generator and balance of plant equipment to support the VWO-OP

conditions if he has included them in the establishment of the steam turbine generator rating.

Designing for the VWO-OP condition is recommended even if not included in the rating definition, because

significant output increase can be achieved at little cost by being capable of operating at VWO-OP.

Turbine (Generator) Output [2/2]

Steam Turbine 5. Performance 6 / 93

HIoPE

Typical Power Plant Steam Flow

Gen

Stop V/V

Control V/V

HP IP LP

Condenser

Reheater

Reheat

Stop and

Intercept

V/V

Main Steam

Hot Reheat

Cold

Reheat

Crossover

Ventilation

V/V

Exciter

Steam

Generator

Front

Standard

Steam Turbine 5. Performance 7 / 93

HIoPE

Heat Balance

Fossil, 700 MW, 3500 psig/1000F/1000F

Steam Turbine 5. Performance 8 / 93

HIoPE

Fossil, 500 MW, 2400 psig/1000F/1000F

Heat Balance

Steam Turbine 5. Performance 9 / 93

HIoPE

Nuclear, 1000 MW

Heat Balance

Steam Turbine 5. Performance 10 / 93

HIoPE

Heat balances are provided by the turbine manufacturer.

Cycle performance is represented in the heat balance diagram which shows the steam/condensate flows,

pressures, temperatures, and enthalpies. These parameters are used to determine equipment design

conditions.

A complete heat balance provides enough information to balance the energy distribution.

Heat balance diagram also indicates ELEP and UEEP, generator losses and net generator output.

On the basis of this information, the engineer can perform an energy balance for the major equipment

associated with the turbine, feedwater, condensate, and heat rejection systems.

A number of heat balance computer programs are commercially available. However, it also can be performed

by hand calculation.

Hand calculation, which is time consuming caused by iteration, is instructive because it permits the engineer

to gain an understanding of the interrelationships of the various equipment.

Heat Balance

Steam Turbine 5. Performance 11 / 93

HIoPE

Establishing a Heat Balance

Reheater

Generator

Condenser

2.0 in.Hga

SSR

HTR1

5F

5 F

HTR2

5F

10 F

HTR3

2F

10 F

HTR4

2F

10 F

HTR5

(DA)

0 F

HTR6

0F

10 F

HTR7

-3F

10 F

10%P 3%P

3%P

3%P 6%P 6%P 6%P 6%P

6%P

BFP

BFP = 87%

Main Steam BFPT

HP IP LP

Make U

p

3%P

SPE

99

99

BFPT = 82.6%

51

2 1

4 5

3

6

4

20

21

86

52 52

86

20

21

54 51

2

6

5

54

Steam Turbine 5. Performance 12 / 93

HIoPE

Typical Assumptions Made in Establishing a Heat Balance

1. The boiler feed pump suction conditions will be the temperature and pressure of the deaerator. Boiler feed

pump discharge pressure is 125% of the turbine throttle pressure.

2. The boiler feed pump efficiencies will vary with load as follows:

Condition BFP Efficiency

VWO-OP, VWO-NP, and rated load 84%

75% of rated 83%

50% of rated 67%

25% of rated 40%

3. For a turbine cycle with a motor-driven boiler feed pump, the variable speed coupling efficiency will vary with

load as follows:

Condition Coupling Efficiency

VWO-OP 85%

VWO-NP, and rated load 82%

75% of rated 76%

50% of rated 73%

25% of rated 68%

The combined motor and transmission efficiency will vary with load as follows:

Condition Motor and Transmission Efficiency

VWO-OP, VWO-NP, and rated load 94%

75% of rated 93%

50% of rated 92%

25% of rated 89%

Steam Turbine 5. Performance 13 / 93

HIoPE

4. For a turbine with a turbine-driven boiler feed pump exhausting to the main condenser, the BFPT(Boiler Feed

Pump Turbine) will operate at an exhaust pressure 0.5 in.Hga greater than the exhaust pressure of the main

turbine. BFPT expansion efficiencies will vary with load as follows:

Condition BFPT Efficiency

VWO-OP, VWO-NP, and rated load 80%

75% of rated 78%

50% of rated 77%

25% of rated 77%

The pressure drop in the extraction line to the BFPT is 3% of the inlet pressure.

At low loads, the BFPT will require steam from a source of higher pressure than is available in the

crossover line. Below approximately 0.35 TFR(Throttle Flow Ratio), the BFPT takes steam as required

from the main steam line.

5. There is a pressure drop between the turbine stage and the extraction flange. This value is typically 3% of

stage pressure. A pressure drop also occurs from the turbine extraction flange to the heater. This value is

usually 3% or 5% of the extraction flange pressure. For extractions at a turbine exhaust or at the crossover

pipe, no pressure drop due to an extraction flange exists, only an extraction line pressure drop.

6. There is a pressure drop from the HP turbine exhaust to the intercept valves of the IP turbine because of hot

and cold reheat piping and the reheater. This value is normally taken to be 10% of the HP turbine exhaust

pressure.

7. The condensate leaving the condenser will be at saturation temperature corresponding to the turbine

exhaust pressure.

8. The condensate will be considered to be saturated liquid at the heater inlet and outlet temperatures.

9. Calculations will consider the feedwater downstream of the boiler feed pump as compressed liquid.

Typical Assumptions Made in Establishing a Heat Balance

Steam Turbine 5. Performance 14 / 93

HIoPE Approximate Flow Distribution for Typical Regenerative/Reheat Cycles

1. The reheater flow is approximately 90% of the throttle flow.

2. The BFPT extraction flow from an IP to LP turbine crossover is 4% to 6% of the throttle flow.

3. The turbine exhaust flow is 65% to 75% of the throttle flow, with the remaining flow being taken for heating

the feedwater and driving the BFPT.

4. Rules of thumb, when the temperature rise across a heater is known:

a. For the low pressure (LP) heaters and deaerator, the extraction flow is approximately 1% of throttle flow

for each 14F temperature rise.

b. For the high pressure (HP) heaters, the extraction flow is approximately 1% of throttle flow for each 10F

temperature rise.

5. If a heat balance is available for other than the desired load, ratio the extractions by the ratio of the throttle

flows for a first guess. However, these may differ up to 30% from the final calculations.

Steam Turbine 5. Performance 15 / 93

HIoPE

Thermal Kit 4

Steam Turbine Section Efficiencies 2

Factors Affecting Cycle Performance 3

Heat Balance 1

Steam Turbine 5. Performance 16 / 93

HIoPE

The Rankine cycle, the basic cycle used for electric power generation, mainly consists of four components:

steam generator, turbine, condenser, and pump.

The performance of a power plant is influenced not only by the steam turbines, but also by the choice of

steam turbine cycle.

Thermal efficiency of the cycle can be increased either by reducing the condenser pressure or by

increasing the turbine inlet pressure and temperature.

The principal cycle considerations are those of regenerative feedwater heating by turbine extraction steam

and of reheating.

The performance of the steam turbine is governed by the losses occurred in it.

Steam Turbine Performance

3

4

2 1

46

45

44

43

42

41

43

42

41

40

39

% %

1.15

1.25

120C

130C

300 bar/600C

250 bar/540C

Single

reheat

Double

reheat

1.9 in.Hga

0.88 in.Hga

Excess Air Discharge

Flue Gas

Temperature

Main Steam

Condition

Reheat Back

Pressure

Pla

nt N

et

Eff

icie

ncy B

ased o

n L

HV

Pla

nt N

et

Eff

icie

ncy B

ased o

n H

HV

USC

Steam Turbine 5. Performance 17 / 93

HIoPE

발전시스템에서의 열역학 제2법칙

TH

TL

QL

W

QH

에너지 변환

외부에 어떠한 영향도 남기지 않고 한 사이클 동안에 계가 열원으로부터 받은 열을 모두 일로 바꾸는 것은 불가능하다. (열효율이 100%인 열기관을 만들 수 없으며, 작동유체는 반드시 공급된 에너지의 일부를 주위와 열교환시켜야 한다).

모든 열기관은 고온의 열원에서 열을 흡수하여 역학적 일을 하고 저온의 열원으로 열을 방출한다.

발전시스템의 경우 증기발생기에서 고온의 열을 공급받고 복수기에서 열을 방출한다.

그러나 열기관 주변에 있는 자연상태의 온도보다 낮은 온도로 열을 버릴 수는 없다.

H

L

H

LH

H

thQ

Q

Q

Q

W

1

T

s

1

2

3

4 qout

wturbine qin

qin

qin

wpump

Steam Turbine 5. Performance 18 / 93

HIoPE

Stage Efficiency

Ava

ilab

le E

ne

rgy

Usefu

l E

ne

rgy

(Sta

ge W

ork

)

1

2s a

2

p1

p2

Stage Loss

h

s

b

Nozzle profile loss

Bucket profile loss

Secondary flow loss +

leakage loss

s

sthh

hh

21

21

Stage efficiency is defined as the ratio of mechanical work produced by the

stage to the thermal energy available.

Steam Turbine 5. Performance 19 / 93

HIoPE

545 psia

534 psia

180 psia

175 psia

92.7%

89.1%

91.2%

1378.2 h

1367.1 h

1364.6 h

1361.0 h

Pressure drop in the IP

exhaust hood, the cross-over

pipe, or the LP turbine inlet

Pressure drop in

intercept valve (2%)

h

s

IP Turbine Section Efficiencies

Nuclear Reheat

HP = 88-90%

LP = 90-91%

Nuclear Non-Reheat

IP = 90-94%

Saturation

Line

h

s

Fossil Reheat

Steam Turbine Section Efficiencies

Steam Turbine 5. Performance 20 / 93

HIoPE

In general, HP turbine efficiency includes the losses occurred in the stop valves, control valves, and HP

exhaust hood.

Blade profile loss increases with blade length. However, the amount of secondary loss is not changed,

although blade length increases. This is same for the leakage loss. Therefore, stage efficiency increases with

blade length(height).

For this reason, the efficiency of HP turbine is lower than that of IP turbine.

LP turbine has longer blades, but its efficiency is lower than IP turbine. This is because the last several

stages of LP turbine are operated in the wet steam region. Typically, every 1% of wetness gives a 1% loss in

isentropic efficiency.

The efficiency of nuclear HP turbine is lower than that of fossil HP turbine because of moisture loss. This fact

is same for LP turbines.

Nuclear LP turbine uses moisture removal buckets to reduce the moisture loss as well as water droplet

erosion.

The turbine section efficiencies may have different values because the losses occurred at the interface are

included or not.

Steam Turbine Section Efficiencies

Steam Turbine 5. Performance 21 / 93

HIoPE

Thermal Kit 4

Steam Turbine Section Efficiencies 2

Factors Affecting Cycle Performance 3

Heat Balance 1

Steam Turbine 5. Performance 22 / 93

HIoPE

Effects of Cycle Parameters

Base

A. Condenser Pressure, in.Hga 2.0 2.5 3.0 3.5 4.0

Relative net output (kW) 2,914 --- -4,073 -9,078 -14,091

Relative net heat rate (Btu/kWh) -31.3 --- 44.1 99.0 154.8

B. Pressure Drop in Boiler (including piping

to the turbine), % 15 17 19 21

Relative net output (kW) 346 --- -345 -732

Relative net heat rate (Btu/kWh) -4.0 --- 3.9 8.3

C. Pressure Drop in Reheater, % 5 7 9 11

Relative net output (kW) 1,403 --- -1,445 -2,935

Relative net heat rate (Btu/kWh) -17.8 --- 18.3 37.1

D. Pressure Drop in Crossover Pipe, % 0 3 5 7

Relative net output (kW) --- -1,824 -3,037 -4,318

Relative net heat rate (Btu/kWh) --- 19.7 33.2 46.8

E. Boiler Steam Temperature, F 950 1,000 1,050 1,100

Relative net output (kW) -35,474 --- 34,585 68,738

Relative net heat rate (Btu/kWh) 118.9 --- -106.0 -202.9

F. Use of Air Preheater Yes No

Relative net output (kW) --- 8,291

Relative net heat rate (Btu/kWh) --- -88.3

Data is produced using the fossil power plant, 726 MW, 3500 psig/1000F/1000F

Steam Turbine 5. Performance 23 / 93

HIoPE

The higher the equivalent cycle hot temperature, the greater the cycle efficiency.

The average temperature where heat is supplied in the boiler can be increased by superheating the

steam.

T

s

1

2

3

4

Equivalent

Carnot Cycle

Equivalent Cycle

Hot Temperature T

s

1

2

3

4

Equivalent Cycle

Hot Temperature

[Ideal Rankine Cycle for a Typical Nuclear Power] [Ideal Rankine Cycle for a Typical Fossil Power]

1. Superheating [1/3]

Steam Turbine 5. Performance 24 / 93

HIoPE

T

s

heat

added

heat

lost 1

2

3

3

4

4

The overall efficiency is increased by

superheating the steam. This is because the

mean temperature where heat is added

increases, while the condenser temperature

remains constant.

Increasing the steam temperature not only

improves the cycle efficiency, but also reduces

the moisture content at the turbine exhaust end

and thus increases the turbine internal efficiency.

The turbine work out is also increased by

superheating the steam without increasing the

boiler pressure.

When the superheating the steam is employed in

the cycle, the important thing is that the quality

of the steam at the turbine exhaust is higher than

90%.

1. Superheating [2/3]

Steam Turbine 5. Performance 25 / 93

HIoPE

T

s

Early 20th century

1940s

1960

Ultra Supercritical

Supercritical

Evolution of Rankine Cycle

1. Superheating [3/3]

Steam Turbine 5. Performance 26 / 93

HIoPE

2. Condenser Pressure [1/3]

2.5

3.5

4.5

100%

90%

80%

70%

60%

Throttle Flow Rate

Condenser

Pressure

(in.Hga)

Turbine output, kW

Tu

rbin

e h

ea

t ra

te, B

tu/k

Wh

1001

HR

HRKW

KW = change of generator kW

output, %.

HR = change of heat rate, %

T

s

2 p4

1 1

2

3

a b

4

p4

a

4

Except for choked turbine exhaust conditions, the lower the turbine exhaust pressure, the higher the

cycle efficiency.

Steam Turbine 5. Performance 27 / 93

HIoPE

Condenser Pressure, in.Hga

2 F-40.0"LSB

2 F-33.5"LSB

2 F-30.0"LSB

D-11 steam turbine for GE 207FA,

1800 psia / 1050F / 1050F

Ste

am

Tu

rbin

e O

utp

ut,

MW

0.5 1.5 1.0 2.5 2.0 3.5 3.0 0.0 175

195

190

185

180

4.0

2. Condenser Pressure [2/3]

Steam Turbine 5. Performance 28 / 93

HIoPE

[Exercise 5.1]

복수기 압력을 2.5 in.Hga로 운전했을 때 발전기 출력이 700 MW, heat rate가 7826 Btu/kWh이다. 주증기

조건을 그대로 유지시킨 상태에서 복수기 압력을 4.5 in.Hga로 운전하였더니 열율이 7980 Btu/kWh가 되었다. 이때 나타나는 출력변화율을 계산하시오.

[Solution 1]

증기터빈 출력변화율은 다음 식으로 구할 수 있다.

HR = {(7980–7826)/7826}100 = 1.97%

KW = –1.97/(1+1.97/100)= –1.93%

1001

HR

HRKW

[Solution 2]

HR = Q/W Q = 700,000 kW 7826 Btu/kWh = 5,478.2106 Btu/hr

W′ = Q/HR′ = 686,491 kW

W = {(700,000–686,491)/700,000}100 = –1.93%

2. Condenser Pressure [3/3]

Steam Turbine 5. Performance 29 / 93

HIoPE

The cycle maximum temperature is constant.

Increased boiler pressure has a higher mean

temperature of heat addition.

However, the temperature of heat rejection is

unchanged.

Usually, the amount of the cycle work is not

changed although boiler pressure is increased.

This is because the amount of the increased work

(top side) and the amount of the decreased work

(right hand side) caused by pressure increase is

almost same.

However, the amount of heat rejected is

decreased. Thus, the cycle efficiency increases

with boiler pressure.

The only one drawback is that the quality of the

exhaust flow become worse.

T

s

2

1

2

3

a b

4

b

4

3

decrease in qin

increase in qin

decrease in qout

c

3. Increasing Steam Pressure [1/5]

Steam Turbine 5. Performance 30 / 93

HIoPE

3. Increasing Steam Pressure [2/5]

Throttle Pressure

2400 psia

3500 psia 6 Flows, 30” LSB

Throttle steam 2400 or 3500 psia, 1000F/1000F

Nominal output 700 MW at 1.5 in.Hga

Turbine output, MW

Tu

rbin

e h

ea

t ra

te, B

tu/k

Wh

200 400 600 800

9000

8000

7000

Main steam conditions strongly influence

the turbine performance.

At a given maximum cycle temperature,

the turbine performance can be improved

by increasing the main steam pressure.

The higher the steam pressure, the better

the turbine performance.

However, there is a temperature limit

beyond that turbine and boiler will

become less reliable.

An increase in steam pressure at turbine

inlet will increase the cycle thermal

efficiency.

The casing becomes quite thick as the steam pressure increases, and consequently steam turbines exhibit

large thermal inertia. Therefore, steam turbine must be warmed up and cooled down slowly to minimize the

differential expansion between the rotating blades and the stationary parts. Large steam turbine can take

over ten hours to warm up.

Steam Turbine 5. Performance 31 / 93

HIoPE

T

s

1

2

3

4

USC

Subcritical

2

3

Tmax, subcritical

Tmax, USC

3

2

Critical

Point

3. Increasing Steam Pressure [3/5]

Steam Turbine 5. Performance 32 / 93

HIoPE

Normally, the manufacturing companies indicate the guaranteed and expected performance of steam

turbines.

In the guaranteed performance the steam turbine is specified to produce a certain number of kilowatts while

operating at rated steam conditions, 3.5 in.Hga exhaust pressure, 0% cycle make-up, and other cycle

feedwater heating conditions.

To assure that the steam turbine will pass the guaranteed throttle flow, the turbine is frequently designed for

a steam flow rate larger than the guaranteed value.

This new value is sometimes called the expected steam flow and is usually around 105% of the guaranteed

value. For this reason, the actual output of the turbine is expected to be larger than the guaranteed value.

The turbine is guaranteed to be safe for continuous operation with valve wide open.

Furthermore, the turbine is also capable of operating continuously with VWO and at the same time at 105%

of rated initial pressure.

Under these conditions the expected steam flow would become maximum (approximately 110% of the

guaranteed value) and thus the expected turbine output.

3. Increasing Steam Pressure [4/5]

Steam Turbine 5. Performance 33 / 93

HIoPE

분류 VWO MGR NR 75 50 30

Constant Pressure Operation Sliding Pressure Operation

출력 (kW) 550,000

(110%)

541,650

(108.3%)

500,000

(100%)

375,000

(75%)

250,000

(50%)

150,000

(30%)

유량 (lb/hr) 3,757,727

(112.7%)

3,684,046

(110.5%)

3,335,116

(100%)

2,389,835

(71.7%)

1,564,131

(46.9%)

980,271

(29.4%)

복수기 압력 (in.Hga) 1.5 1.5 1.5 1.5 1.5 1.5

주증기 온도 (F) 1000 1000 1000 1000 1000 1000

주증기 압력

(psia)

3514.7

(100%)

3514.7

(100%)

3514.7

(100%)

2860.2

(81.38%)

1870.2

(54.47%)

1152.6

(32.79%)

1st STA Bowl P.

(psia)

3409.3

(100%)

[97.00%]

3409.3

(100%)

[97.00%]

3409.3

(100%)

[97.00%]

2774.4

(81.39%)

[97.00%]

1814.7

(54.49%)

[97.03%]

1118.0

(32.79%)

[97.00%]

1st STA Shell P.

(psia)

2630.8

(113.9%)

2573.8

(111.5%)

2309.0

(100%)

1683.5

(72.9%)

1128.0

(48.9%)

723.9

(31.4%)

FWPT 동력 (kW) 18,755

(3.41%)

18,390

(3.40%)

16,611

(3.32%)

9,622

(2.57%)

4,125

(1.65%)

1,523

(1.02%)

[ Operating conditions for Korean standard 500 MW fossil power ]

3. Increasing Steam Pressure [5/5]

Steam Turbine 5. Performance 34 / 93

HIoPE

The steam from boiler flows to the HP turbine where it expands and is exhausted back to the boiler for

reheating.

The efficiency of the Rankine cycle can be improved by reheating on the right hand side of the T-s diagram.

An improvement in cycle efficiency from a single reheat is only 2-3%. Although this is not dramatic, it is a

useful gain which can be obtained without major modification to the plant.

4. Reheating [1/6]

T

s

qRH

qH

3

qL

2

5

4

4 1 6

wP

wT A

B Condenser

Pump

Steam

generator

Turbine

qRH

qH

G LP

qL

1 2

3

4

5

6

wP

wT

Reheater

HP

Steam Turbine 5. Performance 35 / 93

HIoPE

[Exercise 5.2]

재열압력의 크기에 따른 증기터빈 출력 및 사이클효율을 비교하시오.

4. Reheating [2/6]

Steam Turbine 5. Performance 36 / 93

HIoPE

h

s

4%

8%

16%

12% C

E

B

A

D

A-B-C: Nonreheat

A-B: HP Turbine

B-D: Reheater

D-E: IP and LP Turbine

4. Reheating [3/6]

Steam Turbine 5. Performance 37 / 93

HIoPE

1-nuclear reactor, 2-steam generator, 3-HP turbine, 4-moisture

separator, 5-reheater, 6-LP turbine, 7-generator, 8-condenser,

9-condensate pump, 10-LP FWH, 11-LP FWH, 12-BFP,

13-HP FWH, 14-main circulating pump

G

1

10

9

8

7

6

5 4

3

2

11 12 13

14

Schematic of Nuclear Power Plant

4. Reheating [4/6]

Steam Turbine 5. Performance 38 / 93

HIoPE

HP Turbine

Condensate

Pump

Main Steam

To

Feedwater

Heaters

Steam

Dryers LP Turbines

From

Main

Steam

Moisture Separator Reheater

To

Feedwater

Heaters

Condensers

Main

Electrical

Generator Generator

Exciter

To Main

Transformer

[ Steam Turbine (APR 1400) ]

이 그림에서 잘못 그려진 부분 ?

4. Reheating [5/6]

Steam Turbine 5. Performance 39 / 93

HIoPE

In an ideal Rankine cycle for saturated steam

with Moisture separator and reheater, steam

expands in the HP turbine to pressure p4 and is

reheated to superheated steam (T6<T3).

It is clear that the equivalent Carnot cycle

temperature is this case is lower than for the

initial cycle. Thus, such steam reheat does not

improve the thermal efficiency.

Practically, however, thermal efficiency is

improved by using the MSR because of much

less moisture loss in LP turbine caused by an

improved LP turbine exhaust quality.

T

s

1

2

3

7

4

5

6

7

4-5: Steam separator

5-6: Reheater

Ideal Saturated-Steam Rankine Cycle with MSR (Nuclear)

4. Reheating [6/6]

Steam Turbine 5. Performance 40 / 93

HIoPE

5. Regenerative Feedwater Heating [1/5]

T

s

1

2

3 4

5 1 5

a b c d

Condenser

Pump

Boiler

G

Turbine

1

2 3

4

5

If the liquid heating could be eliminated from the boiler, the average temperature for heat addition would be

increased greatly and equal to the maximum cycle temperature.

In the ideal regenerative Rankine cycle, the water circulates around the turbine casing and flows in the

direction opposite to that of the steam flow in the turbine.

Because of the temperature difference, heat is transferred to the water from the steam. However, it can be

considered that this is a reversible heat transfer process, that is, at each point the temperature of steam is

only infinitesimally higher than the temperature of water.

Steam Turbine 5. Performance 41 / 93

HIoPE

At the end of the heating process the water enters the boiler at the saturation temperature.

Since the decrease of entropy in the steam expansion line is exactly equal to the increase of entropy in the

water heating process, the ideal regenerative Rankine cycle will have the same efficiency as the Carnot

cycle.

The boiler, in this case, would have no economizer, and the irreversibility during heat addition in the boiler

would decrease because of less temperature difference between the heating and heated fluids.

Unfortunately, however, this ideal process is practically impossible.

Instead, the turbine is furnished with the definite number of heaters to heat feedwater with extracted steam in

some stages.

This improves the cycle efficiency significantly, even though it remains lower than the Carnot cycle efficiency.

This cycle is called as a regenerative cycle.

The heat input in the boiler decreases as the final feedwater temperature increases and the heat rejected in

the condenser getting smaller as the feedwater is heated higher using the extracted steam.

5. Regenerative Feedwater Heating [2/5]

Steam Turbine 5. Performance 42 / 93

HIoPE

Reversible heat transfer and an infinite number of feedwater heaters would result in a cycle efficiency equal

to the Carnot cycle efficiency.

The greater the number of feedwater heaters used, the higher the cycle efficiency. This is because if a large

number of heaters is used, the process of feedwater heating is more reversible.

However, each additional heaters results in lower incremental heat rate improvement because of the

decreasing benefit of approaching an ideal regenerative cycle.

The economic benefit of additional heaters is limited because of the diminishing improvement in cycle

efficiency, increasing capital costs, and turbine physical arrangement limitations.

The amount of steam flow into condenser can be reduced dramatically by the employment of regenerative

Rankine cycle.

The LSB problems, such as water droplet erosion and longer active length, could be solved by the

regenerative Rankine cycle, which is made by steam extraction in many turbine stages.

Regenerative Rankine cycle also diminish the influence of the LP turbine, which has worst performance.

5. Regenerative Feedwater Heating [3/5]

Steam Turbine 5. Performance 43 / 93

HIoPE

Cycle No. of Feedwater

Heaters HARP Heat Rate Benefit

Single Reheat

(4500 psi, 1100F/ 1100F)

7

8

8

9

No

No

Yes

Yes

Base Case

+0.2%

+0.6%

+0.7%

Double Reheat

(4500 psi, 1100F/ 1100F/1100F)

8

9

9

10

No

No

Yes

Yes

Base Case

+0.3%

+0.2%

+0.5%

Heat Rate Impact of Alternative Feedwater Heater Configurations

HARP means that steam extraction to a heater above reheat point.

If HARP is involved in the cycle, the percentage of reheat flow to main steam flow is 75 to 80% instead of 85

to 92% as with the earlier designs without HARP.

When HARP is included in the cycle, the cycle efficiency is improved because feedwater temperature

becomes higher.

5. Regenerative Feedwater Heating [4/5]

Steam Turbine 5. Performance 44 / 93

HIoPE

SSR: Steam Seal Receiver, SPE: Steam Packing Exhaust

HARP: Heater Above Reheat Point

Single Reheat Cycle with HARP

5. Regenerative Feedwater Heating [5/5]

Steam Turbine 5. Performance 45 / 93

HIoPE

6. LSB

LSB strongly influence the turbine

performance.

The length of the LSB is determined by the

number of exhaust flows.

In general, the longer LSB, the lower the full-

load heat rate.

However, under the part-load operation,

turbines having longer LSB deteriorate more

rapidly in performance.

LSB = 26

6 Flows, 2400 psia / 1000 F/ 1000F

Nominal output 700 MW at 1.5 in.Hga

Turbine output, MW

Tu

rbin

e h

ea

t ra

te, B

tu/k

Wh

200 400 600 800

9000

8000

7000

30

33.5

Steam Turbine 5. Performance 46 / 93

HIoPE

7. Pressure Drop in Reheater System

Reheater pressure drop, %

Output

Ch

an

ge

, %

10 15 5 -3

1

0

-1

-2

20

2

Turbine Heat

Rate

The total reheater pressure drop includes

the pressure drop associated with the

cold reheat piping from HP turbine

exhaust to the reheater section of the

boiler, the reheater section of the boiler

itself, and the hot reheat piping from the

reheater to the IP turbine intercept valves.

A typical design value for total reheater

system pressure drop is 10% of the HP

turbine exhaust pressure.

For a 1% decrease in reheater pressure

drop, the heat rate and output improve

approximately 0.1% and 0.3%,

respectively.

Steam Turbine 5. Performance 47 / 93

HIoPE

8. Pressure Drop in Extraction Line [1/2]

Reheater

Generator

Condenser

2.0 in.Hga

SSR

HTR1

5F

5 F

HTR2

5F

10 F

HTR3

2F

10 F

HTR4

2F

10 F

HTR5

(DA)

0 F

HTR6

0F

10 F

HTR7

-3F

10 F

10%P 3%P

3%P

3%P 6%P 6%P 6%P 6%P

6%P

BFP

BFP = 87%

Main Steam BFPT

HP IP LP

Make U

p

3%P

SPE

99

99

BFPT = 82.6%

51

2 1

4 5

3

6

4

20

21

86

52 52

86

20

21

54 51

2

6

5

54

Steam Turbine 5. Performance 48 / 93

HIoPE

The extraction line pressure drop occurs between the turbine stage and the reheater shell.

For extractions not at turbine section exhausts (HP exhaust and IP exhaust), 6% of the turbine stage

pressure is a typical design pressure drop.

Three percent is the drop across the extraction nozzle, and 3% is for the extraction piping and valves.

(Extraction nozzle pressures are typically 2% to 3% lower than the shell pressure. Heater operating

pressures are typically 3% to 5% lower than the nozzle pressure.)

For extractions at the turbine exhaust section, no extraction nozzle loss occurs and the total pressure drop is

3%.

The higher the extraction line pressure drop, the worse the cycle heat rate.

For a 2% increase in extraction line pressure drop for all the heaters (from 6% to 8%), the change in output

and heat rate would be approximately 0.09% poorer.

8. Pressure Drop in Extraction Line [2/2]

Steam Turbine 5. Performance 49 / 93

HIoPE

9. Makeup Flow

The makeup is necessary to offset the steam losses in the cycle and losses in the boiler associated with

boiler blowdown and steam soot blowing.

Typical amounts of the steam used for makeup are from 1% to 3% of the throttle flow.

Boiler blowdown is necessary to maintain proper boiler chemistry.

Consideration should also be given to process extractions that involve less than 100% return of condensate.

The makeup water is typically supplied to the condenser hot well, increasing the total flow through the

heaters and pumps, and therefore must be heated in the feedwater cycle on the way to the boiler.

This additional flow results in higher feedwater heater thermal duties and therefore higher extraction flows,

and higher pump power requirements.

This results in a negative effect on cycle performance.

The effect of makeup on net turbine heat rate is approximately 0.4% higher per percent makeup. The effect

of makeup on output is approximately 0.2% lower per percent makeup.

These values are based on boiler blowdown at saturated conditions at the boiler drum pressure.

Steam Turbine 5. Performance 50 / 93

HIoPE

Air Heater

Gas Out

Air In

Furnace

Gas

Recirculating

Fan

Pulverizer Primary Air

Fan

Forced

Draft Fan

Induced

Draft Fan

Steam

Coil

Air

Preheater

10. Air Preheating [1/3]

Air Preheater Using Steam Coil

Steam Turbine 5. Performance 51 / 93

HIoPE

10. Air Preheating [2/3]

Steam Turbine 5. Performance 52 / 93

HIoPE

The combustion air is heated by flue gas leaving the boiler prior to entering the boiler in order to improve

boiler efficiency by lowering the flue gas exit temperature.

Preheating of the combustion air prior to air heater is used to keep the flue gas exit temperature above its

dew point temperature.

The water dew point occurs at approximately 120F, and the flue gas dew point varies with the quantity of

sulfur trioxide in the flue gas. The acid dew point occurs at a higher temperature than the water dew point.

If the flue gas temperature falls below the dew point temperature, sulfuric acid which can damage the air

heater and flue gas duct is formed.

LP extraction steam or hot water from the turbine cycle is often used as the preheating source. These

heating sources are readily available and minimize the impact on the turbine cycle because the

thermodynamic availability of the supply source is low.

The air preheater steam supply is often supplied from the deaerator extraction point which is normally the

IP/LP turbine crossover point.

If the air preheater has steam coils, crossover steam is used directly and condenses in the preheater.

If the air preheater use hot water, saturated water from the deaerator is supplied to the air preheater.

The condensate is either pumped back to the deaerator, returned to the condenser, or returned to an

intermediate LP feedwater heater point such as flash tank (고압 증기의 드레인을 모아 감압하여 저압의 증기, 즉 재증발 증기를 발생시키는 탱크).

10. Air Preheating [3/3]

Steam Turbine 5. Performance 53 / 93

HIoPE

11. Condensate Subcooling

Condensate subcooling is the cooling of the cycle condensate in the condenser hot well below the saturation

temperature corresponding to the turbine exhaust pressure.

Condenser are normally specified to provide condensate at the condenser saturation temperature (0F

subcooling).

When subcooling occurs, the duty on the first feedwater heat increases, causing the extraction flow to the

heater to increase.

This decreases the turbine output and increases the turbine heat rate.

.024

.023

.022

.021

.020

.019

.018

.017

.016

.015

.014

.013 30 40 50 60 70 80 90 100 110

Throttle Flow, %

He

at R

ate

In

cre

ase

, %

Correction for 5F

Condensate Subcooling

Steam Turbine 5. Performance 54 / 93

HIoPE

12. Spray Flows for Desuperheating [1/2]

One method used to control the main steam and reheat steam temperatures is desuperheating by the spray

water into steam.

The source of spray water is typically boiler feed pump discharge for main steam spray, and an interstage

bleed off the boiler feed pump for reheat spray.

Alternatively, the spray water is taken from after the final feedwater heater.

Both main steam and reheat steam spray flows have an adverse effect on the turbine heat rate when the

spray water is taken from the boiler feed pump discharge.

The reason for this, in the case of main steam spray, is that the spray flow evaporates in the boiler and

becomes part of main steam flow. However, it bypasses the HP feedwater heaters, thus makes the cycle

less regenerative (using only five feedwater heaters).

In the case of reheat spray, the effect on heat rate is worse because cycle becomes less regenerative and

reheat spray flow bypasses the HP turbine and expands only through the reheat turbine section; thus, for the

steam flow that is reheat spray, the cycle is nonreheat.

Steam Turbine 5. Performance 55 / 93

HIoPE

Throttle flow, %

Co

rre

ctio

n fo

r 1

%

de

su

pe

rhe

ating

flo

w, %

60 90 40

.4

.3

.5 Load Correction Reheat Steam Desuperheat

Heat Rate Correction Reheat Steam Desuperheat

Load Correction Main Steam Desuperheat

Heat Rate Correction Main Steam Desuperheat

50 70 80 100 110

.1

0

.2

.6

.7

12. Spray Flows for Desuperheating [2/2]

Steam Turbine 5. Performance 56 / 93

HIoPE

13. Removing Top Heaters [1/2]

Feedwater heaters may need to be removed from service due to tube leaks.

Removing the top heater(s) from service eliminates turbine extraction for these heaters and increases steam

flow through the remaining sections of the turbine.

For a given throttle flow, turbine output increases because of the increased steam flow and cycle heat input

increases because of the lower final boiler feedwater temperature.

The turbine and cycle heat rates are poorer when removing the top heaters from service.

Some power plants are designed for removal of the top feedwater heaters to increase net plant output.

In this case, the boiler has higher heating duty because the boiler produces the steam having same throttle

steam conditions with maximum continuous rating under the condition with the lower final feedwater

temperature.

The turbine would need to be designed to accommodate the higher HP turbine exhaust pressure, increased

shaft power requirements in the IP and LP turbines, increased electric power generation, and increased

steam flow in the LP turbine last stage.

If the turbine specification requires increased output with removal of top heaters, the manufacturer may have

to select a larger last stage blade than optimal.

For existing units, the steam loading limit on LSB may prohibit increased output.

The engineer or operator should check with the turbine manufacturer’s literature or contact the manufacturer

directly for limitations on operation with heater removed from service.

Steam Turbine 5. Performance 57 / 93

HIoPE

Parameter

(500 MW, 7 feedwater heaters)

Case

All heaters in service Heater 7 out of

service

HP turbine output, kW

IP and LP turbine output, kW

Generator and mechanical losses, kW

Net turbine output, kW

Net turbine heat rate, Btu/kWh

Final feedwater temperature, F

Turbine cycle heat input, MBtu/h

Turbine cycle heat rejection, MBtu/h

Steam loading on LSB, lb/h/ft2

151,400

379,583

8,707

522,316

8,001

482

4,179

2,373

14,233

142,823

416,512

9,206

550,129

8,136

413

4,476

2,574

15,459

[ Effect on turbine cycle performance with removal of top heater from service]

When the heater removed from service, the HP turbine output decreases because turbine expansion

is reduced as a result of higher exhaust pressure caused by the greater cold reheat flow.

However, the output of the IP and LP turbine increases significantly because of increased steam flow.

13. Removing Top Heaters [2/2]

Steam Turbine 5. Performance 58 / 93

HIoPE

A closed feedwater is a heater where the feedwater and the heating steam do not directly mix.

Open feedwater heaters (deaerators) directly mix the feedwater and the heating steam.

A closed feedwater heater may consist of three zones: the desuperheating zone, the condensing zone, and

the drain cooling zone.

All closed heaters have a condensing zone where the feedwater is heated by the condensation of the

heating steam.

Feedwater heaters that receive highly superheated steam require a desuperheating zone to reduce the

steam temperature to approximately 50F above saturation temperature before it enters the condensing

zone.

14. Feedwater Heater Design Parameters [1/6]

Steam Turbine 5. Performance 59 / 93

HIoPE

A desuperheating zone may not be required

for heaters that receive heating steam with

less than 100F superheat.

Usually, a drain cooler is also included in a

feedwater heater to recover the heat

contained in the drains before the drains leave

the heater.

The feedwater heater performance is

determined by DCA (drain cooler approach)

and TTD (terminal temperature difference).

The DCA is the difference between the

temperature of the drains leaving the heater

and the temperature of the feedwater entering

the heater.

The TTD is the difference between the

saturation temperature at the operating

pressure of the condensing zone and the

temperature of the feedwater leaving the

heater.

Travel Distance

Te

mp

era

ture

Feedwater Inlet Extraction

Steam Outlet

Feedwater Outlet

Extraction Steam Inlet

Extraction

(Ne

ga

tive

) T

TD

Desuperheating

Zone Condensing Zone

Drain

Cooling

Zone

TSAT

DC

A

[ Temperature profile for a closed feedwater heater ]

14. Feedwater Heater Design Parameters [2/6]

Steam Turbine 5. Performance 60 / 93

HIoPE

By decreasing the DCA of a heater, cycle efficiency is improved while the heater surface area is increased,

resulting in higher capital cost.

The practical minimum DCA for an internal drain cooler is 10F. But, the minimum practical limit is 5F for an

external drain cooler.

The heater may have a negative TTD when the temperature of the feedwater leaving the heater is higher

than the saturation temperature of the condensing zone because of the desuperheating zone.

If the desuperheating zone of the heater is removed, the feedwater temperature leaving the heater would be

less than the saturation temperature, resulting in a positive TTD.

The practical lower limit of TTD on a heater without a desuperheating zone is +2F.

The negative TTD limit for a heater with a desuperheating zone depends on the amount of superheat in the

extraction steam entering the heater.

The lower the TTD and DCA, the higher the cycle efficiency and the larger the heater surface area.

The more efficient cycle results in a lower heat rate and reduced fuel consumption, while the larger surface

area of a heater results in a higher capital cost.

14. Feedwater Heater Design Parameters [3/6]

Steam Turbine 5. Performance 61 / 93

HIoPE

[ Effect of TTD on net turbine heat rate – Heater 7 (500 MW)

cycle, HP heaters 6 and 7 ]

TTD, F

Ne

t tu

rbin

e h

ea

t ra

te

co

rre

ctio

n fa

cto

r

4 1 6

1.0000

0.9995

1.0005

5 3 2 0

0.9985

0.9980

0.9990

1.0010

TTD varied independently from

base for each heater

Heater 6

Heater 7

14. Feedwater Heater Design Parameters [4/6]

Steam Turbine 5. Performance 62 / 93

HIoPE

Ne

t tu

rbin

e h

ea

t ra

te

co

rre

ctio

n fa

cto

r

3 6 1

1.0000

0.9995

1.0005

2 4 5 7 8

0.9985

0.9980

0.9990

1.0010

1.0015

TTD, F

TTD for LP heaters 1,2,3, and 4

varied as a group from base

[ Effect of TTD on net turbine heat rate – Heater 7 (500 MW)

cycle, LP heaters 1, 2, 3, and 4 ]

14. Feedwater Heater Design Parameters [5/6]

Steam Turbine 5. Performance 63 / 93

HIoPE

Ne

t tu

rbin

e h

ea

t ra

te

co

rre

ctio

n fa

cto

r

11 14 9

1.00010

1.00005

1.00015

10 12 13 15 16

0.99995

0.99990

1.00000

1.00020

1.00025

DCA, F

DCA varied on closed heaters 7, 6,

4, 3, and 2 as a group. External

heater 1 drain cooler DCA

remained fixed.

Heater 5 is the deaerator.

[ Effect of DCA on net turbine heat rate – Heater 7 (500 MW)

cycle ]

14. Feedwater Heater Design Parameters [6/6]

Steam Turbine 5. Performance 64 / 93

HIoPE

How to best apply the capital funding available on a power plant project is a critical question for the plant

designer.

The cost basis of technological improvements must be known to make an economic evaluation in today’s

competitive marketplace.

One open literature investigated that the ranking of several technology improvement steps for better plant

efficiency. From least cost to highest cost per efficiency improvement, million US$ / % net LHV efficiency,

these were.

1) Reducing condenser back pressure, 4.6

2) Increasing to 8th extraction point feedwater heater, raising feedwater temperature, 5.7

3) Raising main steam temperature and reheat steam temperature, 12.3

4) Raising main steam temperature, 12.7

5) Using separate BFPT instead of main turbine driven pump, 14.2

6) Raising main steam pressure, 39.1

7) Changing from single to double reheat, 56.7

8) Using separate BFPT condenser, 60.7

Economic Efficiency Improvement

Steam Turbine 5. Performance 65 / 93

HIoPE

Data is provided based on a GE steam turbine having output of 412 MW and main

steam condition of 2,400 psig/1,000F/,1000F. The turbine is a reheat, tandem

compound, four-flow with 26LSB.

Thermal Kit 4

Steam Turbine Section Efficiencies 2

Factors Affecting Cycle Performance 3

Heat Balance 1

Steam Turbine 5. Performance 66 / 93

HIoPE

Turbine Thermal Kit

The turbine thermal kit is provided by the turbine manufacturer and consists of numerous characteristic

curves those are used to determine the steam turbine performance for various steam cycle conditions.

These curves are used to develop computer programs or to perform hand calculation of steam turbine

performance.

In addition, the turbine thermal kit includes correction curves that can be used to adjust actual turbine test

data to design or guaranteed turbine performance conditions.

These correction curves facilitate the comparison of actual performance to guaranteed performance.

The turbine manufacturer should supply a complete set of these curves to permit the adjustment of all cycle

parameters that may vary between guaranteed conditions and actual operating conditions.

These correction curves should be obtained and their use understood prior to conducting the performance

test.

In addition, turbine test procedures should be developed and agreement reached on their use prior to testing.

These procedures should illustrate methods of adjustment to reference conditions.

Steam Turbine 5. Performance 67 / 93

HIoPE

Characteristic curves Correction curves

• Extraction stage shell pressures versus flow to the

following stage

• Gland leakage and mechanical losses

• Expansion lines

• HP turbine internal efficiency

• HP turbine expansion line end points

• Reheat turbine internal efficiency

• Reheat turbine expansion line end points

• Correction to expansion line end points

• Exhaust loss curve

• Generator losses

• First-stage shell pressure versus throttle flow

• Throttle pressure correction

• Throttle temperature correction

• Reheat pressure drop correction

• Reheat temperature correction

• Exhaust pressure correction factors

This information can be used to estimate changes in unit performance at off-design conditions.

These estimations can be performed by hand. However, some calculations can be lengthy, and if several

conditions are being evaluated, a detailed computer model is typically used with this information to predict

the performance of the actual turbine purchased.

Turbine Thermal Kit

Steam Turbine 5. Performance 68 / 93

HIoPE

3. Expansion Lines

[ Expansion lines for HP turbine ]

Turbine expansion lines, drawn on Mollier diagram, are

lines depicting the thermal state of the steam that has

different thermal state as it expands through the turbine.

These lines are developed based on throttle, governing

stage, and reheat conditions to determine the steam

enthalpy at the various extraction points on the turbine.

These lines are used in conjunction with a heat balance

and the extraction stage shell pressure curves or constants

to establish the extraction pressure at which to read the

expansion line enthalpy for a given extraction point in the

turbine.

In a thermal kit, the expansion line for the HP turbine is

given only for the steam expansion downstream of the first

stage.

A pressure drop from turbine throttle conditions of

approximately 3% is usually indicated to describe pressure

losses between the main stop valve and the HP turbine

bowl conditions.

sT

Pressure Drop through

Control Valves

Exit from Governing

Stage

Parallel Expansion

Line

Partial Flow

Expansion Line

Design Flow

Expansion Line ELEP

ELEP

AE

AE

pT pB

p1

pX

pX

hT

hXS

TT

p1

hXS

HP Turbine

Steam Turbine 5. Performance 69 / 93

HIoPE

1

p1

Availa

ble

Ene

rgy

p6

p5

p4

p3

p2

p0

T0

h

s

2

3

4

5

6

3. Expansion Lines

Steam Turbine 5. Performance 70 / 93

HIoPE

The assumption of 3% is typical for turbine

operation in partial arc admission mode.

The steam entering the turbine then expands from

the HP turbine bowl conditions to the exhaust

conditions of the first stage.

Turbine heat balance developed on the basis of

this assumption are considered to be on a locus-

of-valve best points basis. This heat balances

describe heat rates assuming an infinite number of

small valves having a 3% pressure drop.

Generator output

He

at ra

te

40 0 20 60 80 100

Valve Loop Basis (True Curve)

Mean of Valve Loop Basis

Valve Point Basis (Locus-of-valve best points)

Actual turbine performance is shown on a valve loop basis heat rate curve. This curve reflects the steam

throttling effect as the steam passes through a partially closed steam admission.

The throttling pressure drop reduces the available energy of the steam as the throttled admission steam

expands across the control stage.

Depending on the steam turbine manufacturer, curves of heat rate effect due to control valve position are

provided in the thermal kit.

HP Turbine

3. Expansion Lines

Steam Turbine 5. Performance 71 / 93

HIoPE

An alternative method of representing turbine heat rate impact due to turbine valve losses at part load is by a

mean of valve loop method.

This method is an approximation of the heat rate impact illustrated on the valve loop basis curve and

represents a mean of the turbine heat rate and passes through the valve loop curve.

For units operating with constant throttle pressure in partial arc admission mode, the pressure ratio through

the control stage is not constant.

As a result of the variation in pressure ratio, the available energy across the stage and the control stage

efficiency vary with throttle steam flow and conditions.

Therefore, expansion lines at different flow conditions for the control stage are not parallel to one another.

However, HP turbine stages downstream of the control stage operate with essentially constant pressure ratio,

and their expansion efficiency is essentially constant.

Therefore, at lower steam flows, the expansion line of the HP turbine stage group downstream of the control

stage is typically described as a straight line that is drawn parallel to the VWO expansion line.

HP Turbine

3. Expansion Lines

Steam Turbine 5. Performance 72 / 93

HIoPE

[ Expansion lines for reheat turbines ]

The expansion line for the reheat turbine (IP and LP

turbines) typically includes a 2% pressure drop between

the reheat stop valve inlet and IP turbine bowl to account

for the pressure drop across the stop/intercept valves.

In addition, for combined HP/IP turbines, the steam

leakage from the HP turbine is mixed with the hot reheat

steam to determine the reheat bowl steam conditions.

The steam then expands through the IP turbine to LP

turbine.

The steam exiting the IP turbine is often conveyed to the

LP turbine through a crossover pipe.

A 2% allowance for crossover pipe pressure drop is

typically included by the turbine manufacturer to

determine the LP turbine inlet conditions.

sm

Pressure Drop Through

Intercept Valves, 2%

For Machines with No

Leakage Entry

hm = hIV

sm = sIV

Expansion Line AE

pB

pIV

pX= 1.5 in.Hga

hm TIV

hXS

hIV

sIV

pX= 1.0 in.Hga

ELEP1.5 in.Hga

ELEP1.0 in.Hga

ELEP 1.5 in.Hga to

1.0 in.Hga

Reheat Turbine

3. Expansion Lines

Steam Turbine 5. Performance 73 / 93

HIoPE

On a Mollier diagram, the turbine expansion line is drawn to a ELEP.

ELEP is plotted at the turbine back pressure used as the basis of the heat balance and represents a

complete expansion of the steam to the condenser pressure.

However, the steam leaving the LP turbine never actually reaches ELEP steam conditions because there is

exhaust loss occurring in the LP exhaust hood.

The actual exhaust condition, referred to as UEEP, is calculated as the sum of the ELEP and the exhaust

loss.

Since the stages upstream are unaffected by the exhaust loss, the expansion line describing the steam

condition in the IP and LP turbine stages is drawn to the LP turbine ELEP.

This permits determination of the steam condition for the reheat turbine extractions.

The expansion line for the IP turbine is essentially a straight line.

However, the expansion line for the LP turbine exhibits a curvature or varying slope. This variation in the

expansion line represents efficiency degradation caused by moisture loss.

Reheat Turbine

3. Expansion Lines

Steam Turbine 5. Performance 74 / 93

HIoPE

[ HP turbine internal efficiency, GE ]

4. HP Turbine Internal Efficiency

The HP turbine internal efficiency represents the overall

efficiency of it and is applied to the calculation of the

available energy from the turbine throttle conditions to

the HP turbine exhaust pressure.

A composite of the effect of throttle valve pressure drop,

first-stage efficiency, and HP turbine stage group

efficiency are represented by this curve.

Since the curve is drawn using the assumption of locus-

of-valve best point, the curve does not reflect the

throttling losses of partially open control valves for flows

above the throttling flow ratio of the first admission.

These throttling losses are small at high load because of

the relatively small portion of flow that is throttled

compared to the flow that is passing through the valves

those are fully open.

However, as load is decreased, a greater portion of

turbine flow becomes throttled, further impacting turbine

efficiency.

This curve is on a valve best point basis.

TFR = (throttle flow at any steam conditions)/ (VWO

throttle flow at same steam conditions)

Apply the efficiency from this curve to the available

energy from the turbine stop valves to the HP turbine

exhaust.

Break in curve is first admission point, throttling

control occurs at all lower throttle flow ratios.

For off-rated steam conditions use equivalent TFR.

ratedoff

ratedeq

p

p

flowDesign

flowratedOffTFR

)/(

)/(

HP

Tu

rbin

e In

tern

al E

ffic

ien

cy,

%

.3 .6 .1

70

65

75

.2 .4 .5 .7 .8

55

50

60

80

85

Throttle Flow Ratio (TFR)

.9 1.0

Steam Turbine 5. Performance 75 / 93

HIoPE

The throttle flow ratio at first admission point

with respect to the number of admission is

approximately as follows:

1 admission (full throttling) ------

2 admissions -----------------------

3 admissions -----------------------

4 admissions -----------------------

8 admissions -----------------------

1.0

0.85

0.60

0.35

0.30

[ Throttle flow ratio at

first admission point, GE ]

Turbines are provides with a limited numbers of

valves, some of those are operated in unison.

The actual number of valves and turbine admission

is a function of the mode of operation and the

manufacturer’s design practice.

Steam flow control at throttle flow ratios below the

first admission point is accomplished by throttling

process using valve(s).

In this mode, all flow to the turbine is throttled which

results in a decrease of efficiency.

Because of throttling losses at lower loads, the

throttle flow ratio at the first admission has a

significant impact on performance at loads below

this point.

4. HP Turbine Internal Efficiency

Steam Turbine 5. Performance 76 / 93

HIoPE

HP

Tu

rbin

e E

LE

P, B

tu/lb

2.0 3.5 1.0

1320

1310

1330

1.5 2.5 3.0 4.0 4.5

1290

1280

1300

Intercept Valve Pressure – 100 psia

5.0 5.5

This curve assumes a pressure drop of 10 percent from high pressure

turbine exhaust to intercept valve. These high pressure expansion line

end points cannot be used for other pressure drops.

6.0

5. HP Turbine ELEPs

This curve is limited to

applications with rated steam

conditions and further based on

the assumption of a 10%

reheater pressure drop from HP

exhaust to intercept valve.

The curve is provided as a quick

reference for the leaving

enthalpy of the steam exhausting

the HP turbine.

The HP turbine efficiency curve

discussed previously provides a

more versatile method for

determining expected HP turbine

exhaust conditions.

Steam Turbine 5. Performance 77 / 93

HIoPE

Intercept valve pressure, 100 psia

Re

he

at tu

rbin

e th

erm

al

effic

ien

cy,

%

2.0 0.0 1.0 3.0 4.0 5.0

Reheat Temp., F

94

93

92

91

90

89

88 6.0

1000

950

900

850

800

750

700

[ Reheat turbine internal efficiency, GE ]

Apply efficiency to available energy between intercept valve

pressure and bowl enthalpy (including packing leakage mixture if

any) and 1.5 in.Hga.

ELEP1.5 = hbowl – Eff. (AE)

See ASME paper 62WA209 for construction of expansion line

6. Reheat Turbine Internal Efficiency

The reheat turbine internal

efficiency curves are plotted

as a function of pressure

ahead of the intercept valve

because it relates to steam

flow.

The turbine efficiency is

applied to the available energy

between the intercept valve

pressure and mixed bowl

enthalpy and a reference LP

turbine exhaust pressure of

1.5 in.Hga.

Steam Turbine 5. Performance 78 / 93

HIoPE

7. Reheat Turbine ELEPs

The end points are plotted as a function of intercept

valve pressure and are based on a turbine exhaust

pressure of 1.5 in.Hga.

This curve conveniently provides the end point

conditions for rated reheat steam temperature;

however, it is not as flexible as the internal

efficiency curve because end points are valid only

for 1,000F reheat steam.

These ELEPs are for heat balance calculations in which

grand leakage steam is used in the feedwater heating cycle.

To obtain the enthalpy of the steam entering the condenser,

read the curve at 1.5 in.Hga and correct to the desired

exhaust pressure, and correct for exhaust loss.

Reh

ea

t T

urb

ine

EL

EP

s a

t 1

.5 in.H

ga

, B

tu/lb

3 6 1

1030

1020

1040

2 4 5 7 8

1000

990

1010

1050

1060

Intercept Valve Pressure, 100 psia

9

1070

Steam Turbine 5. Performance 79 / 93

HIoPE

8. Correction to ELEPs for Exhaust Pressure

1. When ELEP at 1.5 in.Hga is in the moisture region, use the following equation:

ELEP = ELEPY=0(0.87)(1-0.01Y)(1-0.0065Y), Y=percent moisture at ELEP at 1.5 in.Hga.

2. When ELEP at 1.5 in.Hga is in the superheat region, multiply the change in ELEP at 0 percent

moisture both by the factor 0.87 and the ratio of specific volume at ELEP under consideration to

the dry saturated specific volume at 1.5 in.Hga.

0.5

0.6

0.7

0.8 0.85

0.85

0.9

1.0

1.1

1.2

1.3

1.4

1.5

1.5

1.6

1.7

1.8

1.9

2.0

2.1

2.2

2.3

2.4

2.5

2.5

2.6

2.7

2.8

3.0

3.1

3.2

3.3

3.4

3.5

3.6

3.7

3.8

3.9

4.0

4.0

4.1

4.2

4.3

4.4

4.5

4.6

4.7

4.8 4.9

5.0

-64

-62

-60

-58

-56

-54

-52

-50

-48

-46

-44

-42

-40

-38

-36

-34

-32

-30

-28

-26

-24

-22

-20

-18

-16

-14

-12

-10

-8

-6

-4

-2

0

0

+2

+4

+6

+8

+10

+12

+14

+16

+18

+20

+22

+24

+26

+28

+30

+32

+34

+36

+38

+40

+42

+44

+46

+48

+50

+52

+54

+56

+58

+60

+62

+62

+64

+66

+68

+70

+72

+74

+76

E

LE

PY

=0 -

Cha

nge

in E

LE

P w

ith

o%

Mo

istu

re, B

tu/lb

Exhaust Pressure, in.Hga

Steam Turbine 5. Performance 80 / 93

HIoPE

9. Exhaust Loss Curve

UEEP = ELEP + Exhaust Loss per unit steam flow

The exhaust loss plus the ELEP

defines the UEEP, that is also

called as TEP (Turbine End Point).

The UEEP is the actual leaving

enthalpy of the LP turbine steam

and includes losses associated

with the hood loss, leaving loss,

and restriction loss or turn up loss.

It is clear that the work produced

by the turbine should be

determined by performing an

energy balance with the use of the

UEEP, not the LP turbine ELEP.

Exh

au

st L

oss, B

tu/lb o

f d

ry

flo

w

0

Annulus Velocity, fps Sonic

200 400 600 800 1000 1200 1400 1600 0

10

20

30

40

50 Annulus

Restriction

Loss

Gross Hood

Loss

Actual

Leaving

Loss

Turn-up

Loss

Total

Exhaust

Loss

Steam Turbine 5. Performance 81 / 93

HIoPE

Annulus Velocity, ft/s

Exhaust Loss, B

tu/lb o

f dry

flo

w

200 400 600 800 1000 1200 1400

6

50

46

42

38

34

30

26

22

18

14

10

2 0

Bucket Pitch Last stage

Curve length diameter annulus area

no. (inches) (inches) single flow (ft2)

1 14.3 52.4 16.3

1 16.5 57.5 20.7

1 17 52 19.3

1 20 60 26.2

2 23 65.5 32.9

3 26 72 41.1

4 30 85 55.6

5 33.5 90.5 66.1

(1) Read the exhaust loss at the annulus velocity obtained from

the following expression:

Van = m(1-0.01Y) / 3600Aan

(2) The enthalpy of steam entering the condenser is the quantity

obtained from the following expression:

UEEP = ELEP + (Exhaust loss)(0.87)(1-0.01Y)(1-0.0065Y)

(3) This exhaust loss includes the loss in internal efficiency

which occurs at light flows as obtained in tests.

Van = Annulus velocity (fps)

m = Condenser flow (lb/hr)

= Saturated dry specific volume (ft3/lb)

Aan = Annulus area (ft2)

Y = Percent moisture at ELEP

ELEP = Expansion line end point at actual

exhaust pressure (Btu/lb)

UEEP = Used energy end point (Btu/lb)

1

1 2 3 4 5

2 3 4 5

9. Exhaust Loss Curve

Steam Turbine 5. Performance 82 / 93

HIoPE

511,000 kVA at 45 psig H2 pressure

Conductor cooled 3600 rpm

Note: Generator losses assume rated hydrogen pressure at all loads.

Generator loss at reduced hydrogen pressure (P) = Loss at rated hydrogen pressure –

11.2(Prated – P).

Use generator reactive capability curve to determine generator capability at reduced

hydrogen pressure.

Turbine generator mechanical losses are not included in the generator loss curve.

If hydrogen and stator liquid coolers are located in the condensate line, the loss

transferred to the coolers is 474 kW les than the generator loss at all loads.

Ge

nera

tor

Loss,

1,0

00

kW

100 250 0

6

5

7

50 150 200 300 350

3

2

4

Generator Output, 1,000 kVA

400 450 500 550

10. Generator Losses

The generator losses are a function of

generator kVA (not kW).

Therefore, if generator losses at a

power factor other than design is

required, the curve should be read at

desired output (in kilowatts) multiplied

by the rated power factor divided by

the desired power factor.

Generator losses do not include the

turbine generator fixed or mechanical

losses.

The mechanical losses should be

accounted for separately and do not

vary with unit load.

Steam Turbine 5. Performance 83 / 93

HIoPE

11. 1st Stage Shell Pressure vs. Throttle Flow

To estimate the first stage shell pressure at

other than rated initial temperature, the

following equation should be used to

determine an equivalent throttle flow before

entering the curve.

design

actualactualthcorrectedth mm

__

correctedthm _

actualthm _

actualdesign

corrected turbine throttle flow, lb/hr

actual turbine throttle flow, lb/hr

actual throttle steam specific volume, ft3/lb

design throttle steam specific volume, ft3/lb

Flow, lbs/hr x 1,000

Pre

ssu

re, p

sia

1000 2500 0

2000

1500

500 1500 2000 3000

500

0

1000

Steam Turbine 5. Performance 84 / 93

HIoPE

Correction Curves

There are five typical correction curves as follows:

• Initial pressure correction

• Initial temperature correction

• Reheat pressure drop correction

• Reheat temperature correction

• Exhaust pressure correction factors

The correction curves typically found in a thermal kit are intended to give approximate output and heat rate.

The correction curves are often provided for correction turbine test date to guaranteed conditions.

Steam Turbine 5. Performance 85 / 93

HIoPE

Decre

ase

, %

3

4

2

-5

6

5

1

Rated Load

½ Load ¼ Load

Incre

ase

, %

+5

4

3

5

1

0

2

6

Change in initial

pressure, %

Rated Load

½ Load ¼ Load

Change in Kilowatt Load, %

Change in Heat Rate, %

Poorer, % 2

-5

1

Rated Load ½ Load ¼ Load

Better, %

+5

2

1

Rated Load ½ Load

¼ Load

Change in initial

pressure, %

Method of Using Curves

These correction factors assume constant control

valve opening and are to be applied to heat rates

and kilowatt loads at rated steam conditions.

1. The heat rate at desired condition can be found

by multiplying the heat rate at rated conditions

by the following:

2. The kilowatt load at the desired conditions can

be found by multiplying the kilowatt load at rated

conditions by the following:

3. These correction factors are not guaranteed.

% change in gross heat rate

100 1 +

% change in kilowatt load

100 1 +

1. Initial Pressure Correction

Steam Turbine 5. Performance 86 / 93

HIoPE

The curve allows for the correction of turbine output and heat rate for changes in throttle pressure.

The curve is developed based on holding a constant control valve opening while varying the turbine throttle

pressure.

A similar curve is provided in the ASME PTC(Power Test Code) 6.1, Interim Alternative Test Procedure for

Steam Turbines.

The manufacturer may provide a curve specifically developed for the turbine.

Increased throttle pressure at constant valve opening increases the mass flow to the turbine, which

increases the output of the unit.

The increased throttle pressure improves the turbine cycle efficiency as a result of increased available

energy.

1. Initial Pressure Correction

Steam Turbine 5. Performance 87 / 93

HIoPE

2. Initial Temperature Correction

Increasing the throttle temperature results in an increased specific volume, a decreased mass flow, and

decreased output.

The increase in throttle temperature increases the available energy to the turbine, increases the turbine cycle

efficiency, and reduces heat rate.

Method of Using Curves

These correction factors assume constant control

valve opening and are to be applied to heat rates

and kilowatt loads at rated steam conditions.

1. The heat rate at desired condition can be found

by multiplying the heat rate at rated conditions

by the following:

2. The kilowatt load at the desired conditions can

be found by multiplying the kilowatt load at rated

conditions by the following:

3. These correction factors are not guaranteed.

% change in gross heat rate

100 1 +

% change in kilowatt load

100 1 +

Change in Heat Rate, %

Poorer, % 2

-5

1 Rated Load

¼ Load

Better, %

+5

2

1 Rated Load ¼ Load

Change in initial

temperature, F

Change in Kilowatt Load, %

Increase, % 2

-50

1

Rated Load

½ Load ¼ Load

Decrease, %

+50

2

1

Rated Load

½ Load ¼ Load Change in initial

temperature, F

Steam Turbine 5. Performance 88 / 93

HIoPE

3. Reheat Pressure Drop Correction

The decrease in reheater pressure drop

results in an increase in turbine output

and a decrease in turbine heat rate.

HP turbine output increases, and the

HP turbine expansion end point

becomes lower.

As a result, the reheater duty increases.