157883-000-XN-PR-0001 Rev3

description

Transcript of 157883-000-XN-PR-0001 Rev3

PROCEDIMIENTO PARA EL VACIADO DE LA CIMENTACION DE LA TURBINA Y GENERADOR

ASSURANCE QUALITY PROCEDURERevisin : 2

GROUNDING SYSTEMDate : 27-09-08

CODIGO: 157883-000-XN-PR-0001Page : 13 of 13

LNG Plant Project

GYM E&I InstallationPeru LNG S.R.L.

Document Title:GROUNDING SYSTEM PROCEDURE

Document Number: 157883-000-XN-PR-0001

Revision: 3

DCC I.D.: 25249

Pages: 1 of 13

CB&I LNG Plant Project FAccepted.AAccepted subject to incorporation of comments. RRejected incorporate comments and resubmit.INot required.Subcontractor is to ensure that the design adheres to the contract requirements and all applicable codes, standards and permitted conditions.CommentsYesNoNext Issue of this document to be at revisionEngineer:Date:

Uncontrolled if PrintedPage 1 of 13REVISION NOTES AND HOLDS

RevisionDescription of Changes & Holds

Rev 3The text : Test point rods and tee joints above ground shall have bolted and/or compression connector per detail drawing. Was aggregated in page 11 in change of the text : connections shall include , but not be limited to, all cable splices, Ts, Xs, etc.; all cable to ground rods, ground rod splice, cable to steel and cast iron, and cable lug terminations..

INDEX

1.-OBJECTIVE

2.-SCOPE

3.-DEFINITIONS

4.-APPLICABLE DOCUMENTATION

5.-RESPONSABILITIES

6.-PROCEDURE

7.-RESOURCES

8.-MEASUREMENTS METHODS OF ADVANCE

9.-RECORDS

10.-SAFETY

11.-ENVIRONMENTAL PROTECTION

Prepared by : Technical OfficeRevised by: Construction ManagerApproved by: Project Manager

Name: Edwin De La Cruz HuaynatesName: Jos ZollaName: Ricardo Rodriguez

Signature:Signature:Signature:

Date:Date:Date:

1.-OBJECTIVEThis document establishes the applicable actions of Quality Control applicable to the grounding system, taking in reference the applicable standards to fulfil the demands of the Technical Specifications.

2.-SCOPE

Applicable to the Ground Systems of the Project CBI ELECTRICAL AND INSTRUMENT WORKS

3.-DEFINITIONS

Grounding Electric net configuration conformed by bare copper cable, bars, bridges, register box and rods of copper buried around treated soil, which allows to evacuate short circuit currents or currents remainders that could be present at the system.

Stranded Copper Cable

Bare copper cable used in grounding systems, protection of equipments and applications of general use. Lightning System will have a separated procedure.

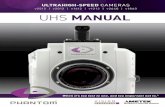

Exothermic Weld

The exothermic weld process is a method of making electrical connections of copper to copper or copper to steel in which no outside source of heat or power is required. In this process, granular metals (granular copper oxide and aluminum) are dumped from a container into a graphite crucible and ignited.

The reduction of the copper oxide by the aluminum (exothermic reaction) produces molten copper and aluminum oxide slag. The slag floats to the surface and the disk melts, allowing molten copper to flow into the weld cavity and complete the weld. The weld is allowed to solidify. The mold is removed and made ready for the next weld. The process takes seconds to complete.

4.-APPLICABLE DOCUMENTATION Contract Bases

Technical specifications Protocols T and A Checksheet Electrical

Quality Manual

NETA Standard Review Counsil NEC

IEEE Std. 142-1991

157883-000-IN-DR-0003 Rev. C1 Instrument Cable and Conduit Grounding

Philosophy

157883-000-IN-SP-0014 Rev.0 Specification for Instrument & Telecoms Cables

and Glands

5.-RESPONSABILITIES

Construction Area / Site Manager

To inform the Client appropriately through their representatives the beginning of the corresponding operations, as well as of the identification of the contractual restrictions if they exist.

Lead the organization, coordination and supervision of the operations to be performed directly in the field according to the present document and according to the drawings, standards and applicable technical specifications.

Construction Superintendent Organize, coordinate and supervise the operations directly in field according to the present document and according to the drawings, standards and applicable technical specifications.

To coordinate the daily activities of electrical grounding systems, fulfilling the work chronogram and according to the plans and technical specifications of the project.

To register the results of the inspections in the corresponding formats of insurance of quality.

To carry out the execution of the present procedure.

QA/QC Area

To verify the execution of the present procedure.

Technical Office Area

To supervise the execution of the technical documents (drawings, standards and applicable technical specifications).

6.- PROCEDURE6.1 GeneralBare copper cable will be removed from CBI warehouse according with the work needs. All grounding cables under the control of GyM and in transit to be installed will be stored in a designated area for GyM.

Wire coils that should be placed in an orderly way and with wooden wedges. Wire coils will be verified during their reception in the work area, in order to avoid having faulty materials.6.2 Transport and Unloading

Grounding system cables will be transported from CBI warehouse to GYM storage area in adequate transportation.

Before transport it will be inspected for external damage during transportation. Any damage found during the reception and during the installation will be reported immediately to CBI.

6.3 Grounding SystemThe configuration of the grounding system will be according to the drawings and technical specifications of CBI.

6.4 Exothermic Welds

The sequence to prepare an exothermic weld is the following :

1. PRELIMINARY ACTIVITIES

Dry the mold and the conductors.

Clean the conductors.

Place cable ends in the mold.

2. ASSEMBLE THE MOLD

Close the handles to lock the mold.

Drop the metal disk into the mold

3. PLACE THE WELD MATERIAL

Dump the weld material into the mold.

Sprinkle the starting material over the weld material and onto the lip of the mold.

4. EXECUTE THE WELD

Close the cover and ignite.

Open the mold after the metal solidifies.

Remove slag from mold before next connection.

5. COMPLETION OF EXOTHERMIC WELD

A completed exothermic weld connection.

All grounding system connections shall be made by the exothermic weld process.

Test point rods and tee joints above ground shall have bolted and/or compression connector per detail drawing.Procedures listed in the exothermic weld instructions shall be followed. Molds shall not be altered in the field.

All materials used (molds, weld material, tools, accessories, etc.) shall be approved materials. A exothermic weld mold is designed to last for an average of 50 connections. This will vary according to the care given the mold during use.

Inspect the mold regularly. Check the following items to determine if a mold should be replaced:

Cable Opening

The conductor should fit snugly. A loose fit will cause leakage.

The opening should not be chipped or worn.

Weld Cavity

The cavity should be well defined.

There should be no chips or gouges.

Tap Hole

The tap hole should be well defined.

Disk Seat

The seat should not be worn or chipped; the disk must seat properly.

Mold Parting Face

The parting face should not be chipped.

The parting face should always be cleaned properly. Use a clean shop towel or newspaper and wipe clean. Using a wire brush to clean the mold will cause erosion and quickly destroy the mold.

Proper inspection of a exothermic weld connection relies on the judgment of the field personnel.

Look closely at the size, color, surface finish, and porosity of the connection.

6.4 Electric Tests

To measure the grounding system resistance a grounding resistance meter will be used. Measurements will take place in each grounding wells with inspection covers and finally to the whole grounding system.The wire should be disconnected from the rod to take the measure. The measured value shall not be greater than 25 ohm for single electrode and 1-5 Ohm for general net.6.5 As Built Drawing

The As Built will be submitting in quantity and form of agreement to the requirements of the Contract.

7.-RESOURCES

Manpower

Foremen

Electricians

Semiskilled Laborers

Helpers

This persons will be defined according to the requirements of the activities.

Equipment Cadweld molds. Ignition source Telurometros8.-MEASUREMENTS METHODS OF ADVANCEWe will report the resources used by means of the following documents:

Daily Report Quantity measurements shall be done in a daily basis.

9.-RECORDSIt will be realized according to the specific formats of Quality Assurance and Quality Control

ET07AGrounding Test Record

E23AEarthing by Area

I14AInstrument Grounding

10.-SAFETY

All personnel involved in the daily works such as supervisors, foremen and workers will qualified and will fill the JSA (Job Safety Analisys) in order to be conscious of the risks associated with every activity. 11.-ENVIRONMENTAL PROTECTIONHazardous waste is the most significant risk that affects environment. The control and monitoring procedures are indicated in the following documents.

157883-000-HS AA-0004Waste Management PlanCOPPER CABLE

TAP HOLE

WELD CAVITY

GROUND ROD

STEEL DISK

WELD MATERIAL

MOLD

STARTING MATERIAL

COVER