1.3.2.03 ARK QAP Digital Governor[1]

Transcript of 1.3.2.03 ARK QAP Digital Governor[1]

-

8/9/2019 1.3.2.03 ARK QAP Digital Governor[1]

1/7

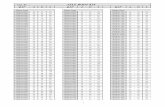

PROJECT : ARKUN H.E. PROJECT CLIENT: DOKA ELEKTRK RETM A.. Page 2 of 8

Perform Witness Verify

1 Digital Electronic Cubicle

1.1 Bought out Items/Components,Programming Kit,Video Display Unit

a) Type, Make and Rating Visual 100% Tech. Spec./ Apprd. Drawing /

Relevant Standard

TC 3/2 - 1 TC

b) Accuracy & Calibration of Measuring

Instruments

Test 100% -do- TC 3/2 - 1 TC

1.2 Assembled Digital Electronic Cubicle

a) Dimension , Thickness of Sheet & Door

lock arrengement and Paint Shed

Measurement 100% -do- TC 3/2 - 1 TC

b) Scheme & BOM Checking Measurement 100% -do- TC 3/2 - 1 TC

c) Routine Test Measurement 100% -do- TC 3/2 - 1 TC

2 Hydro-Mechanical Cabinet2.1 Bought out Item

a) Make, Type & Rating Visual 100% -do- TC 3/2 - 1 TC

b) Routine Test Test 100% -do- TC 3/2 - 1 TC

c) Accuracy & Calibration of measuring

instruments

Test 100% -do- TC 3/2 - 1 TC

2.2 Valves, Pipes & fittings, Pressure

Switche, Mainfold Block etca) Pressure Test Test 100% -do- TC 3/2 - 1 TC

Note: a. In Inspection Agencycolumn figure 1,2,or 3 to be fi lled. 1- will indicate EMPLOYER, 2- will indicate supplier & 3- will indicate sub-supplier.

b. In Remarks column following abbreviations shall be used - RR-Review of Records, T.C. - Test Certificate Submission & CHP - Customer Hold Point.

c. Test certificates shall be submitted at the time of final inspection.

Signature Signature & SealEMPLOYER ( QA&I DEPT.) (VENDORS Q.C. DEPT. OR REPRESENTATIVE)F/IQA/0740/01/01 Rev. 01

QUALITY ASSURANCE PLAN (MODEL)

VENDOR :NIT/P.O. REFERENCE :

EQUIPMENT : Digital Governing System (FRANCIS TURBINE)NAME OF

SR. NO. ITEM /COMPONENTS &CHARACTERISTICS

NATURE OFCHECKS

QUANTUM OFCHECKS

INSP. AGENCYRECORDFORMAT

REMARKSREFERENCEACCEPTANCE DOCUMENTSNORMS

-

8/9/2019 1.3.2.03 ARK QAP Digital Governor[1]

2/7

PROJECT : ARKUN H.E. PROJECT CLIENT: DOKA ELEKTRK RETM A.. Page 3 of 8

Perform Witness Verify

2.3 Auto Clean Strainera) Mesh Size Visual 100% Tech. Spec./ Apprd. Drawing /

Relevant Standard

TC 3/2 - 1 TC

b) Pressure Test Test 100% -do- TC 3/2 - 1 TC

2.4 Assembled Hydro -Mechanical Cabinet

a) Dimension , Thickness of Sheet & Door

lock arrengement and Paint Shed

Measurement 100% -do- TC 3/2 - 1 TC

b) Layout & BOM Checking Measurement 100% -do- TC 3/2 - 1 TC

c) Routine Test Measurement 100% -do- TC 3/2 - 1 TC

d) Functional Check on Auto & Manual Mode Measurement 100% -do- TC 3/2 - 1 TC

e) Functional Check of Shuttle Valve Measurement 100% -do- TC 3/2 - 1 TC

3 Combined Testing of Hydro-MachanicalCabinet, Digital Electronic Controller, PCBased Micro Processor & Servomotor

3.1 Check for Restoring Arrangement Test 100% -do- JIR 3/2 1 -

3.2 Functional Check

3.3 Range of Command Signal Adjustment Test 100% Tech. Spec./ Apprd. Drawing /

IEC 60308

JIR 3/2 1 - CHP

3.4 Speed Droop

a) Maximum Stroke Speed Droop Test 100% -do- JIR 3/2 1 -

b) Temporary & Permanent Speed Droop Test 100% -do- JIR 3/2 1 -

Note: a. In Inspection Agencycolumn figure 1,2,or 3 to be fi lled. 1- will indicate EMPLOYER, 2- will indicate supplier & 3- will indicate sub-supplier.

b. In Remarks column following abbreviations shall be used - RR-Review of Records, T.C. - Test Certificate Submission & CHP - Customer Hold Point.

c. Test certificates shall be submitted at the time of final inspection.

Signature Signature & SealEMPLOYER ( QA&I DEPT.) (VENDORS Q.C. DEPT. OR REPRESENTATIVE)

F/IQA/0740/01/01 Rev. 01

VENDOR :

NAME OF

REFERENCEACCEPTANCE DOCUMENTS

RECORDFORMAT

INSP. AGENCYEQUIPMENT : Digital Governing System (FRANCIS TURBINE)

ITEM /COMPONENTS &CHARACTERISTICS

NATURE OFCHECKS

QUANTUM OFCHECKS

NIT/P.O. REFERENCE :

QUALITY ASSURANCE PLAN (MODEL)

REMARKSSR. NO.

-

8/9/2019 1.3.2.03 ARK QAP Digital Governor[1]

3/7

PROJECT : ARKUN H.E. PROJECT CLIENT: DOKA ELEKTRK RETM A.. Page 4 of 8

Perform Witness Verify

c) Time Constant of damping Device Test 100% Tech. Spec./ Apprd. Drawing /

IEC 60308

JIR 3/2 1 -

d) Wicket Gate Closing & Opening Time Test 100% -do- JIR 3/2 1 -

e) Dead Band and Governor Inaccuracies Test 100% -do- JIR 3/2 1 - CHP

4 Over Speed Limiter

4.1 Functional Test Test 100% Tech. Spec./ Apprd. Drawing /Relevant Standard

JIR 3/2 1 -

5 Control and Power Cable

5.1 Routine Test Test 100% -do- TC 3/2 - 1 TC

Note: a. In Inspection Agencycolumn figure 1,2,or 3 to be fi lled. 1- will indicate EMPLOYER, 2- will indicate supplier & 3- will indicate sub-supplier.

b. In Remarks column following abbreviations shall be used - RR-Review of Records, T.C. - Test Certificate Submission & CHP - Customer Hold Point.

c. Test certificates shall be submitted at the time of final inspection.

Signature Signature & SealEMPLOYER ( QA&I DEPT.) (VENDORS Q.C. DEPT. OR REPRESENTATIVE)

F/IQA/0740/01/01 Rev. 01

NAME OFEQUIPMENT : Digital Governing System (FRANCIS TURBINE)

NIT/P.O. REFERENCE :

SR. NO.

QUALITY ASSURANCE PLAN (MODEL)

VENDOR :

ITEM /COMPONENTS &CHARACTERISTICS

REFERENCEACCEPTANCE DOCUMENTS

RECORDFORMAT

INSP. AGENCY REMARKSNATURE OFCHECKS

QUANTUM OFCHECKS

-

8/9/2019 1.3.2.03 ARK QAP Digital Governor[1]

4/7

PROJECT : ARKUN H.E. PROJECT CLIENT: DOKA ELEKTRK RETM A..VENDOR :

NAME OF CONTRACT/P.O. REFERENCE :

Perform Witness Verify

1 Sump Tank1.1 Material for Tank

a) Chemical Composition Chemical Sample Tech. Spec. / Relevant Std. /Appd. Drg.

TC 3/2 - 1 TC

b) Mechanical Strength Mechanical -do- -do- TC 3/2 - 1 TC

1.2 NDT of weld joints UT/DPT 100% -do- TC 3/2 - 1 TC

1.3 No Leak Test for Tank Test 100% -do- TC 3/2 - 1 TC

1.4 Dimensional Check Measurement 100% -do- TC 3/2 - 1 TC

2 Pressure Vessel

2.1 Material of Tanka) Chemical Composition Chemical Sample -do- TC 3/2 - 1 TC

b) Mechanical Strength Mechanical -do- -do- TC 3/2 - 1 TC

2.2 NDT of weld joints UT / DPT 100% -do- TC 3/2 - 1 TC

2.3 Post weld Stress Relieving Temp. Regulation 100% -do- TC 3/2 - 1 TC

2.4 Hydrostatic Pressure Test for Pressure Vessel Test 100% -do- TC 3/2 - 1 TC

2.5 Dimensional Check Measurement 100% -do- TC 3/2 - 1 TC

3 Pipes & Fittings3.1 Chemical Composition Chemical Sample -do- TC 3/2 - 1 TC

3.2 Mechanical Strength Mechanical -do- -do- TC 3/2 - 1 TC3.3 Hydro Static Pressure Test Test 100% -do- TC 3/2 - 1 TC

3.4 Dimensional Check Measurement 100% -do- IR 3/2 - 1 RR

Note: a. In Inspection Agencycolumn figure 1,2,or 3 to be filled. 1- will indicate EMPLOYER, 2- will indicate supplier & 3- will indicate sub-supplier.

b. In Remarks column following abbreviations shall be used - RR-Review of Records, T.C. - Test Certificate Submission & CHP - Customer Hold Point.

c. Test certificates shall be submitted at the time of final inspection.

F/IQA/740/01/01(VENDORS Q.C. DEPT. OR REPRESENTATIVE)

QUALITY ASSURANCE PLAN (MODEL)

RECORDFORMAT

INSP. AGENCY REMARKSNATURE OFCHECKS

QUANTUMOF CHECKS

REFERENCE DOCUMENTS /ACCEPTANCE NORMS

EQUIPMENT : Oil Pressure Unit (OPU)

Page 5 of 8

SR.NO.

Signature & SealSignature

ITEM / COMPONENTS & CHARACTERISTICS

EMPLOYER (QA&I DEPT.)

-

8/9/2019 1.3.2.03 ARK QAP Digital Governor[1]

5/7

PROJECT : ARKUN H.E. PROJECT CLIENT: DOKA ELEKTRK RETM A..

VENDOR :NAME OF CONTRACT/P.O. REFERENCE :

Perform Witness Verify

4 Pressure Gauge, Pressure Switch, Float Switch,Temperature Switch etc.

4.1 Make, Model & Type Visual 100% Appd. Drg/Tech. Spec./

Relevant Standard

TC 3/2 - 1 TC

4.2 Calibration Test Test -do- -do- TC 3/2 - 1 TC

4.3 Functional Test Test -do- -do- TC 3/2 - 1 TC

5 Unloader Valve, Check Valve, Pilot Valve, SafetyValve, Air Blow-off Valve, By pass Valve,Solonide Valve and Isolating Valve etc.

5.1 Make, Model & Type Visual -do- -do- TC 3/2 - 1 TC

5.2 Functional Check Test -do- -do- TC 3/2 - 1 TC

5.3 Hydro Static Pressure Test Test -do- -do- TC 3/2 - 1 TC

6 Oil Pump6.1 Make, Model, Type & Capacity Visual -do- -do- TC 3/2 - 1 TC

6.2 Routine Test Test -do- -do- TC 3/2 - 1 TC

7 Electric Motor7.1 Make, Type & Rating Visual -do- -do- TC 3/2 - 1 TC

7.2 Routine Test Test -do- -do- TC 3/2 - 1 TC

8 Strainer

8.1 Mesh Size Measurement -do- -do- TC 3/2 - 1 TC

8.2 Chemical composition Chemical Sample -do- TC 3/2 - 1 TC

9 Oil9.1 Make & Type Visual -do- -do- TC 3/2 - 1 TC

Note: a. In Inspection Agencycolumn figure 1,2,or 3 to be filled. 1- will indicate EMPLOYER, 2- will indicate supplier & 3- will indicate sub-supplier.

b. In Remarks column following abbreviations shall be used - RR-Review of Records, T.C. - Test Certificate Submission & CHP - Customer Hold Point.

c. Test certificates shall be submitted at the time of final inspection.

F/IQA/740/01/01

REFERENCE DOCUMENTS /ACCEPTANCE NORMS

RECORDFORMAT

INSP. AGENCYSR.NO.

ITEM / COMPONENTS & CHARACTERISTICS NATURE OFCHECKS

QUANTUMOF CHECKS

REMARKS

Signature Signature & SealEMPLOYER (QA&I DEPT.) (VENDORS Q.C. DEPT. OR REPRESENTATIVE)

Page 6 of 8

EQUIPMENT : Oil Pressure Unit (OPU)

QUALITY ASSURANCE PLAN (MODEL)

-

8/9/2019 1.3.2.03 ARK QAP Digital Governor[1]

6/7

PROJECT : ARKUN H.E. PROJECT CLIENT: DOKA ELEKTRK RETM A..VENDOR :

NAME OF CONTRACT/P.O. REFERENCE :

Perform Witness Verify

10 Complete Assembly of Oil Pressure Unit withControl Panel

10.1 Dimensional Check Measurement 100% Appd. Drg/Tech. Spec./

Relevant Standard

JIR 3/2 1 -

10.2 Capacity Measurement -do- -do- JIR 3/2 1 -

10.3 Functional Test/Operational Test of Pumps, Motors,Electromagnetic Valves, Pressure Switch &

Accessories.

Test -do- -do- JIR 3/2 1 -

10.4 Pressure Tank Relief Valve setting Visual -do- -do- JIR 3/2 1 - CHP

11 Control Panel

11.1 Verification of Bill of Material Visual -do- -do- JIR 3/2 1 -

11.2 Functional Test Test -do- -do- JIR 3/2 1 -

11.3 IR & HV Test Test -do- -do- JIR 3/2 1 -

12 Painting & Preservation Visual &

Measurement

100% -do- TC 3/2 - 1 TC

Note: a. In Inspection Agencycolumn figure 1,2,or 3 to be filled. 1- will indicate EMPLOYER, 2- will indicate supplier & 3- will indicate sub-supplier.

b. In Remarks column following abbreviations shall be used - RR-Review of Records, T.C. - Test Certificate Submission & CHP - Customer Hold Point.

c. Test certificates shall be submitted at the time of final inspection.

F/IQA/740/01/01

Signature & Seal

REMARKS

QUALITY ASSURANCE PLAN (MODEL)

EQUIPMENT : Oil Pressure Unit (OPU)

SR.NO.

ITEM / COMPONENTS & CHARACTERISTICS NATURE OFCHECKS

QUANTUMOF CHECKS

SignatureEMPLOYER (QA&I DEPT.)

Page 7 of 8

(VENDORS Q.C. DEPT. OR REPRESENTATIVE)

REFERENCE DOCUMENTS /ACCEPTANCE NORMS

RECORDFORMAT

INSP. AGENCY

-

8/9/2019 1.3.2.03 ARK QAP Digital Governor[1]

7/7

PROJECT : ARKUN H.E. PROJECT CLIENT: DOKA ELEKTRK RETM A..VENDOR :

NAME OF CONTRACT/P.O. REFERENCE :

Perform Witness Verify

1 Leakage Oil Unit (If Required)

1.1 Pumpa) Make, Model & Capacity Visual 100% Tech. Spec / App. Drg. /

Relevent Std.

TC 3/2 - 1 TC

b) Routine Test Test 100% -do- TC 3/2 - 1 TC

1.2 Motor

a) Make, Model & Rating Visual 100% -do- TC 3/2 - 1 TC

b) Routine Test Test 100% -do- TC 3/2 - 1 TC

1.3 Float Switch

a) Make, Model & Rating Visual 100% -do- TC 3/2 - 1 TC

1.4 Oil Tanka) Leakage Test Test 100% -do- TC 3/2 - 1 TC

b) Dimensional Check Measurement 100% -do- TC 3/2 - 1 TC

1.5 Functional Test on Complete Oil Leakage Unit Test 100% -do- TC 3/2 - 1 TC

1.6 Dimensional & BOM Check Visual &

Measurement

100% -do- TC 3/2 - 1 TC

1.7 Painting & Preservation Visual &Measurement

100% -do- TC 3/2 - 1 TC

Note: a. In Inspection Agencycolumn figure 1,2,or 3 to be filled. 1- will indicate EMPLOYER, 2- will indicate supplier & 3- will indicate sub-supplier.

b. In Remarks column following abbreviations shall be used - RR-Review of Records, T.C. - Test Certificate Submission & CHP - Customer Hold Point.

c. Test certificates shall be submitted at the time of final inspection.

F/IQA/740/01/01

REMARKS

Signature Signature & Seal

RECORDFORMAT

INSP. AGENCY

EMPLOYER (QA&I DEPT.) (VENDORS Q.C. DEPT. OR REPRESENTATIVE)

QUALITY ASSURANCE PLAN (MODEL)

EQUIPMENT : Oil Leakage Unit

SR.NO.

ITEM / COMPONENTS & CHARACTERISTICS NATURE OFCHECKS

QUANTUMOF CHECKS

REFERENCE DOCUMENTS /ACCEPTANCE NORMS

Page 8 of 8

![download 1.3.2.03 ARK QAP Digital Governor[1]](https://fdocuments.in/public/t1/desktop/images/details/download-thumbnail.png)