QAP 220 132kV

-

Upload

nishith001 -

Category

Documents

-

view

242 -

download

2

Transcript of QAP 220 132kV

-

8/10/2019 QAP 220 132kV

1/90

QUALITY ASSURANCE PLAN

&

CHECK FORMATS

%%%%%%%%%%%%%%%%%%%%%%%%%%5%%%%%%%%%%%%%%%%%%%%5

^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^

-

8/10/2019 QAP 220 132kV

2/90

TRANSMISSION CORPORATION OF

ANDHRA PRADESH LIMITED

QUALITY ASSURANCE PLAN

&

CHECK FORMATS

FOR 220KV & 132KV TRANSMISSION LINES AND

SUBSTATIONS CONSTRUCTION

-

8/10/2019 QAP 220 132kV

3/90

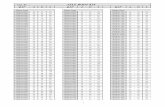

Sl.No. D E S C R I P T I O N P GE NO:

1. PREAMBLE 1

2. CLSSIFICATION OF FOUNDATIONS 3

3. STANDARD FIELD QUALITY PLAN 7

4. GENERAL GUIDELINES FOR IMPLEMENTATION 22

5. REGISTERS

(A) CEMENT REGISTER 40

(B) COARSE/FINE AGGREGATE REGISTER 42

(C) REINFORCEMENT STEEL REGISTER 50

(D) CONCRETE CUBE TESTS REGISTER 55

INDEX

A

-

8/10/2019 QAP 220 132kV

4/90

1

PREAMBLE

During the Quality Control Review Meeting on 03.08.2007 the

Chairperson and Managing Director/ APTransco has instructed to prepare the

quality assurance plan for erection of 132 KV and 220 KV lines & substations

for implementing in APTransco.

Accordingly, the Quality Assurance Plan is prepared for erection of

132 KV and 220 KV line & substations and approval accorded by technical

committee for implementing in APTransco.

-

8/10/2019 QAP 220 132kV

5/90

2

The following issues were deliberated to ensure quality duringe x ecution of works:

1. Check Survey

i) Verication of line deviation angle and bisection for p roper locationof towers.

ii) Verication of meeting statutory clearances.iii) Check spans on either side of the tower location.iv) Mark distances and angles from angle point at 3 conspicuous

places to identify the angle point location in case o f displacementof angle point peg.

v) At peg marks GPS marking should be done. This ensures correctposition of peg e ven if it is rem oved, as t he longitudes a nd latitudesare recorded.

2. Soil Investigation

i) Identify 75 locations for performing SPT.ii) SPT to be performed at all angle points, at locations where soil

strata changes, railway and national/state road crossings, powerline cros sings and special locations limiting to the 75 locations a sprovided in the con tract.

iii) Instead of identify 75 locations, it is better to perform soil investigation for every KM of soil. Investigation is done by way ofERM method, time is saved and soil investigation can be done

without disturbing standing crops.

3. Pit Marking

i) Mark position of all the four pits on t he ground as per pit markingdrawing for standard type of foundation and note levels of thecenter of each leg pit w.r.t center p eg of the tower.

ii) Assess volume of bench cutting or use of hill side extension

revetment if required and take approval of the SuperintendingEngineer /Chief Engineer.

4. Foundation Classication

i) One of the foundation pit to be used as a t rial pit and excavated asper normal soil dry t ype foundation.

ii) Observe following for classication- Type of cultivation surrounding tower and whether

encasement of stub required due to su rface water.- Type of strata and depth of each layer.- Water table/level.- Maximum water table in the near by vi llage well.

iii) Check and record soil classication and foundation classicationas per relevant clauses of the agreement and excavate pit as perapproved drawing for t he type of foundation classication. (Extractof T echnical Specication is en closed

).

-

8/10/2019 QAP 220 132kV

6/90

3

4.1 CLASSIFICATION OF FOUNDATIONS:

Classification of soil shall be made according to IS : 200 (Part I) 1 !" for footing cast ino#en #its$ he fo&ndation designs for 'ario&s t #es of o&ndations as gi'en belo* shall

be ado#ted in the constr&ction of all 1+2 , . 220 , ransmission /ines and shall be based on the follo*ing instr&ction$ he o&ndation ra*ings as finali ed b the Ci'il

ngineering 3ing for 'ario&s soil conditions s&itable for different #es of o*ers being de#lo ed in the constr&ction shall be follo*ed b all field officers strictl $

Sl$4o . Soil at the Location of Tower Classification of fo&ndation to be

ado#ted$1$ 3here normal dr cohesi'e or non-cohesi'e soils are met$ r

2(a)$ 3here s&b-soil *ater is met at 1$50 meters or more belo* the gro&ndle'el

3et

(b) 3here s&rface *ater co&ld stand for long #eriod *ith *ater #enetrationnot e ceeding 1$0 m belo* gro&nd le'el (e$g$ Padd fields6 S&garcanefields)

+(a)$ 3here s&b-soil *ater is enco&ntered bet*een 0$!5 meter and 1$50 metersde#th belo* gro&nd le'el$

Partiall S&bmerged 7Partiall 8lac,

Cotton(b) 3here to# la er of 8lac, Cotton soil e tends to 50% of the de#th *ithnormal soil thereafter

4ote 9 1 3here soil is cla e t #e6 not necessaril blac, in colo&r6 *hich shrin,s *hen dr 6 s*ells *hen*et$

"(a) 3here s&b-soil *ater able is *ithin 0$!5 m de#th from gro&nd le'el$ &ll S&bmerged 9 8lac, Cotton(b) 3here to# la er of 8lac, Cotton soil e ceeds 50% and e tends to f&ll

de#th or is follo*ed b normal soil$(c) 3here to# la er is normal soil to 50% of the de#th b&t the lo*er la er

is a 8lac, Cotton soil 4ote 9 2 In case of items "(a)6 (b) . (c) abo'e6 the concerned Serintending ngineer (Ci'il) shall

#ersonall ins#ect and certif on soil classification and shall not delegate this res#onsibilit toan s&b-ordinate officers$

5(a) 3here decom#osed or fiss&red roc,6 hard gra'el6 ,an,er6 limestone6laterite or an other soil of similar nat&re is met$

iss&red 7 soft roc,

(b) 3here to# la er of normal dr soil e tends to 5% of the de#thfollo*ed b fiss&red roc, *itho&t #resence of *ater$

;(a) 3here

-

8/10/2019 QAP 220 132kV

7/90

-

8/10/2019 QAP 220 132kV

8/90

58. Concrete Mixing

i) Ensure using coarse aggregate (metal) and ne aggregate (sand) asper IS-383.

ii) Check coarse aggregate for akiness, soft stone and laminar shape.iii) Check cement for approved brand.iv) Ensure proper mixing of concrete as per the guide lines.

v) After mixing and before placing the concrete in the foundation pit,take samples for checking compressive strength and slump test ofconcrete.

vi) Engage ready mix where even possible to enable execute fast work.

9. Placing of Concrete

i) Check providing lean concrete (M 10) base 100 mm thick at bottomof the ex cavated pit before p lacing reinforcement.

ii) Use pointing/poking rod and vibrator for compaction of concreteensuring vibrator head does not come in contact with steel,hardened concrete et c.,

10. Stripping of Form Work

Ensure stripping formwork after about 24 hrs an d check for any damage,honey combing and do necessary rectication.

11. Back Filling

i) Ensure back lling on foundation in layers and ensure properconsolidation.

ii) Ensure all top soils to be placed at the surface in case of towerslocated on cultivated land.

iii) Excess earth available over and above ground level (afterconsolidation) should be transported away from the si te.

12. Curing

Ensure proper curing by keeping adequate quantity of water and storingarrangement available a t site.

13. Earthing of Tower

i) Ensure tower footing resistance not to exceed 10 Ohms.ii) Use pipe earthing or counter poise earthing as per approved

drawings to ensure m inimum tower footing resistance.

14. Formats & QAP is revised with reference to the discussions and therevised formats & QAP are enclosed herewith. The SuperintendingEngineers should get the formats printed and bounded as registers andto en sure, they a re d istributed to Section Officer l evel.

15. All the foundation drawings, and other instructions shall be distributedupto Section Officer level.

-

8/10/2019 QAP 220 132kV

9/90

6

16. PENALTIES IMPOSED FOR DEFICIENCEIES IN QUALITY OF WORKS:

During execution of works , if any deficiencies in quality of worksis found in deviation to the specification / Agreement, a minimum penalty of Rs 5000 to Rs 0,000/! shall "e levied for deficiencies as per each categoryas mentioned "elow#

Category I : $ot using %i& prescri"ed shoring, shuttering and dewateringequipment, %ii& measurement "oxes, %iii& 'orm "oxes for different types of foundations and steel measuring "oxes, %iv& not providing adequate num"er of chairs to the steel reinforcements, %v& not carrying out "ack filling and compactionof the foundation pits in layers and leveling the tower footings properly, %vi& notensuring that the excavated earth is dumped at least ( meters away from the pitetc#, and %vii& not providing copings to the tower legs / stu"s,%viii& not providingwater tanker, )arth rammers/)arth vi"rators#

Category II : *se of reinforcement steel without + + marking, not usingvi"rators for effective consolidation of the concrete during foundation works, notusing proper templates for firmly keeping the stu"s in position when templatesare supplied "y the contractor - improper fixing of stu"s, non ensuring of tower verticality, use of rusted stu"s and tower parts if supply is "y the contractor, nonpainting of "utt .oints and rusted stu"s with inc rich paint immediately after erection of the towers - stringing, non fixing of earth flat to the stu", nondeployment of technical personnel for supervision of works "y the contractor#

Also not fixing of vi"ration dampers firmly, repair sleeves wherever necessary,not properly fixing of arcing horns "oth tower side and line side and "ird guardsetc#, as per specification#

Category III : *se of improper grade / quality of raw material like #1#2#metal, water and sand for concreting, using clogged and / or lump / clottedcement for concreting, not ensuring proper curing for foundation concrete, notensuring that all the mem"ers of the tower are placed in position and firmly fixedwith "olts and nuts immediately after erection of tower, not ensuring that alf round seam welding of the nuts "efore stringing of the line#

'or the deficiencies in the quality of works noticed "y the )ngineer ,penalties shall "e levied as given "elow3

4ype ofcategory

'irstinstance%Rs&

econdinstance%Rs&

4hirdinstance%Rs&

ategory + 5,000 /! 60,000/! 65,000 /!

ategory ++ 7,500 /! 65,000/! ((,500 /!

ategory +++ 60,000 /! (0,000/! 0,000 /!

+n the event of fourth instance of noticing the deficiency of quality of worksin any of the a"ove categories, the "idder shall "e de"arred from participating !

future tenders for a period of one year#T"e # $$er %"a&& g 'e a %(e) * ) +!$erta, !g a))e(t !g t" % )&a+%e.

-

8/10/2019 QAP 220 132kV

10/90

7TRANSMISSION CORPORATION OF AND-RA PRADES- LIMITED

QUALITY CONTROL INSPECTION DEPARTMENT

STANDARD FIELD QUALITY PLAN FOR //0 12/ K3 LINES SU45STATIONS

Se)t o!: SUR3EY SOIL IN3ESTI ATION

l#$o# omponent 8peration -Description of 4est ampling 9lanwith 1asis Reference Documents and Acceptance $orms 4esting Agency Remarks hecking Authority

1 DET A ILED SUR3EY A L I NMENT

%a& 'ield urvey/:alkover urvey

600; 4echnical specification2eogrphical 6 , and other relevantstandards# Approved Route6 and other relevantstandards Apprd# 4ower leglocation counters, approvedprofile

ontractor ounter check andapproval "y

)/?00@ /B- / A94RA$ 8

1enching"y ))/'ieldRevetment"y )

%f& 'inal 9rofile - tower schedule

600;

-

8/10/2019 QAP 220 132kV

11/90

C

l#$o#

omponent 8peration -Description of 4est

ampling 9lanwith 1asis

Reference Documents and Acceptance $orms

4esting Agency Remarks hecking Authority

2 So & I!'e%t gat o!

A At Nor7a& Lo)at o!%

%i& 1orelog/4rial 9it for o"tainingdetails/types of soil encountered#+ncluding gradation of samples atspecified levels, ground waterlevels etc# %at center of tower&

At locations asindicated "y A94RA$ 8

4echnical specification + 36? C,6C (, (7(0, ??>?, > 5, 9! >- and o ther relevant standards

ontractor/ A94RA$ 8approved Agency

ounter check andapproval "y A94RA$ 8 4helocations are to "eidentified andapproved "y

A94RA$ 8 "eforecarrying out soilinvestigation

A))/))/ )

4 So & Re% %t ' ty 8ne Bocation in astretch of ( to

@m or at locationsapproved "y A94ransco

+ 3(6 6, + (7(0 and 4echnicalpecifications

ontractor A94RA$ 8approved agency

ounter check andapproval "y

A94RA$ 8

))/ )

C Te%t o! So & a!$ Ro),Sa7(&e%

Approval "y A94RA$ 8

C1 Te%t o! %o & %a7(&e%

i isual and )ngineeringclassifications

D8 4echnical specification + 35>6 ,+ 36? C and other relevantspecifications

A))/))/ )

C/ Te%t% o! Ro), At locations asindicated "y

A94RA$ 8

4echnical specification + 3(6 6,+ 3(7(0, + 3?07C, ??7? andother relevant standards

ontractor A94RA$ 8approved la"

Approval "y A94RA$ 8

A))/))/)

i isual lassifications 4echnical specification + 36? C,5>6 and other relevantstandards

8 Se&e)t o! o* S te *or Mater a&Storage 600; 4echnical specification,utility/industry storagedocument :ooden sleepers,wooden planks, tarpaulin, steelsheets, "ricks, 1ar"ed wire forfencing etc site shall "e freefrom termites

ontractor Approval "y A94RA$ 8 ))/ )

9 C"e), !g o* Fo+!$at o!Mater a&%

A Ce7e!t upply source to "eapproved "y A94ransco

%i& 'ineness 'or each source

-

8/10/2019 QAP 220 132kV

12/90

l#$o#

omponent 8peration -Description of 4est

ampling 9lanwith 1asis

Reference Documents and Acceptance $orms

4esting Agency Remarks hecking Authority

1 Coar%e A ggregate% 8ne sample perlot of (00 um or part per each

source for eachsi eE

4echnical specification + 3 C ,+ 3( C> and + 3(? 0 - otherrelevant standards

A94RA$ 8 Approved Ba"

)ach source will "eapproved "y

A94RA$ 8 review

and acceptance of testresult "y A9 4ransco

A))/))/ )

%i& Determination of 9article si e%sieve analysis&

8ne sample perlot of (00 um or part per eachsource

4echnical specification + 3 C ,+ 3( C> and other relevantstandards

ontractor/ A94ranscoapproved la"

)ach source to "eapproved "y

A94ransco

A))/))/ )

%ii& 'lackiness +ndex D8 4echnical specification + 3 C ,+ 3( C> and other relevantstandards

ontractor/ A94ranscoapproved la"

D8 A))/))/ )

%iii& rushing alve D8 4echnical specification + 3 C ,+ 3( C> and other relevantstandards

ontractor/ A94ranscoapproved la"

D8 A))/))/ )

%iv& pecific gravity D8 D8 D8 D8 D8

v& 1ulk Density D8 D8 D8 D8 D8

vi& A"sorption alue D8 D8 D8 D8 D8

vii& ,C , ?5>, ( C>, (? 0 and other

relevant standards

ontractor/ A94ranscoapproved la"

)ach source will "eapproved "y

A94ransco

A))/))/ )

%i& 2radation/ Determination of 9article i e % ieve analysis&

D8 4echnical specification + 3( >,C , ?5>, ( C>, (? 0, ?0 6 and

other relevant standards

ontractor/ A94ranscoapproved la"

)ach source tol "e "yreview and acceptanceof test result "y

A94ransco

A))/))/ )

%ii& pecific gravity and density D8 4echnical specification + 3( >,C , ?5>, ( C>, (? 0, ?0 6 and

other relevant standards

ontractor/ A94ranscoapproved la"

D8 A))/))/ )

iii& ,+ 3 0(5 and other relevantstandards

ontractor )ach source to "eapproved "y

A94ransco

A))/))

%ii& leanliness % isual heck& 600; D8 D8 D8 A))/))

iii& 9# # alue 8ne sample per source

D8 and

-

8/10/2019 QAP 220 132kV

13/90

60

l#$o#

omponent 8peration -Description of 4est

ampling 9lanwith 1asis

Reference Documents and Acceptance $orms

4esting Agency Remarks hecking Authority

%ii& trength %4ensile test, Fieldstress/proof stress&

'or steel as per + 67C> under 60mm one

sample per each(5 mm onesample per each

5 mm 6 sample per each ?5 (50( and other relevant standards

ontractor/ A94ranscoapproved la"

D8 A))/))/ )

v& Reverse "end test for D:ires

+ 3? (, and other approvedspecification

ontractor/ A94ranscoapproved test la"

D8 ))/ )

vi& hemical analysis test 8ne sample per source

+ 3? (, + 366 , + 367C> andspecification

ontractor/ A94ranscoapproved test la"

D8 A)/))/ )

F Eart" !g 7ater a&%i& isual identification 600; 4echnical specification + 3 5>6

and other relevant standardsontractor Approval "y

A94RA$ 8)/ onst#

%ii& 1ill of material- installation 600; 4echnical specificationapproved drawings - + 5>6

ontractor D8 ))/ )

6 To ; er E6 , 1+ - 9 9u"lication$o#(>C and other relevantstandards

ontractor ounter check andapproval "y

A94ransco

A)/A))

%"& hecking of pit marking as per drawing and R+

600; )veryBocation

4echnical specification,+ 3?0 6, 5>6 - other relevantstandards Approved, profileexcavation and foundationdrawings

ontractor ounter check andapproval "y

A94ransco

A)/A))

= 4rial 9it D8 D8 D8 D8 A)/A))

%d& lassification of soil D8 D8 Goint inspection "y A94RA$ 8 -contractor

Approval "y A94RA$ 8

A))/ ))/ )

%e& 9it marking D8 ontractor Approval "y A94RA$ 8

A)/A))

%f& 9it levels with reference tocenter peg levels

D8 D8 D8 D8 A)/A))

%g& Depth of pits as per center peglevel %estimate&

D8 D8 D8 D8 A)/A))

%h& 1enching %:here required& :here required 4echnical specification + 5>6 ,approved 'oundation legcontour 9rofiles and otherrelevant standards

1enchingimplements/

ontractor

Approval "y A94RA$ 8

A)/A))

4 E

-

8/10/2019 QAP 220 132kV

14/90

66l#

$o#omponent 8peration -

Description of 4estampling 9lanwith 1asis

Reference Documents and Acceptance $orms

4esting Agency Remarks hecking Authority

%"& erticality - squareness of eachpit

)ach Bocation 4echnical specification + 3 7>? Goint inspection "y A94RA$ 8

Approval "y A94RA$ 8

A)/A))

= erification of classification ofsoil type and type of foundation

D8 D8 D8 D8 A)/A))/))/ )

%d& horing and trutting % heckdura"ility strength - soundnessof staging, fonts adequacy andspecific livels&

As required 4echnical specificationapplica"le state/ local "odysafety regulations

teel sheets,wooden planksstuts etc/contractor

outner check "y A94ransco

A)/A))/ ))

%e& Dewatering %:here required& As required 4ech# pecification# + 3?5> andother relevant standards

Diesel enginepumps# )tc#contractor

outner check "y A94ransco

A)/A))

C St+# Te7(&ate

%a& +dentification - Assem"ly 600; )very

Bocation

4echnical specification + 3

5>6 # Approved drawings of stu" template and foundationdrawing

tu" template,

water level tapes,sand "ags, Gacksetc/ ontractor

ounter check "y

A94ransco

A)/A))

%"& tu" etting 600; everylocation

D8 2reen concretepads, ad.usta"leGacks, and "agsetc# contractor

D8 A)/A))

= 4emplate levels width - diagonal 600; everylocation

D8 D8 D8 A)/A))

%d& 2round learance D8 D8 D8 D8 A)/A))

%e& tu" clearance D8 D8 D8 D8 A)/A))

%f& 4ightening of "olts and muts for

template, stu"s - cleats

D8 D8 D8 D8 A)/A))

D S-UTTERIN =For7;or, 'ixing of form "oxescheck for identificationdimensions parallisation andsquareness and equidistancefrom stu"s

600; Allcollapsi"lelocation

4echnical specification + ?5>and other relevant standardsapproved drawings

Goint inspection A94RA$ 8 -contractctor

ounter check andapproval "y

A94RA$ 8

A)/A))

E Co!)reet !g 600; 4echnical specification + ?5>and other relevant standards -approved drawings

Goint inspection A94RA$ 8 -contractctor

ounter check andapproval "y

A94RA$ 8

A)/A))

%a& ontrol, oncrete mixed design 4echnical specification + ?5>and other relevant standards -approved drawings

Goint inspection A94RA$ 8 -contractctor

ounter check andapproval "y A94RA$ 8

A)/A))/ ))

%i& +dentification of material andwater supply sources

600; 4echnical specification +C ,?5> + 3 0(5, 550 and

other relevant standards

ontractor ounter check andapproval "y

A94RA$ 8

A)/A))/ ))

%ii& Determination of characteristicsof aggregates, cement, wateretc#

600; 4echnical specification +(> , C ,?5>, 6(5, 550 andother relevant standards

ontractor/ A94RA$ 8approved testla"oratory

ounter check of testresults and approval"y A94RA$ 8

A)/A))/ ))

-

8/10/2019 QAP 220 132kV

15/90

6(l#

$o#omponent 8peration -

Description of 4estampling 9lanwith 1asis

Reference Documents and Acceptance $orms

4esting Agency Remarks hecking Authority

%iii& 9reperation of mix and taking of samples for strength %7days, 6?days - (C days & and slump

report

600; 4echnical specification + ?5>and other relevant standards

ontractor/ A94RA$ 8approved test

la"oratory

ounter check of testresults and approval"y A94RA$ 8

A)/A))/ ))

iv& Review of controlled concretemix report

600; 4echnical specification + ?5>and other relevant standards

ontractor/ A94RA$ 8approved testla"oratory

Approval "y A94RA$ 8

A)/A))/ ))

a& and other relevant standards

oncrete ,and other relevant standardsappoved Drgs#

A94RA$ 8 -ontractor

Reinforcement rodsshould not "e exposed1oxes should not "eopened after (? hours#

Approval "y A94ransco

A)/A))

-

8/10/2019 QAP 220 132kV

16/90

6

l#$o#

omponent 8peration -Description of 4est

ampling 9lanwith 1asis

Reference Documents and Acceptance $orms

4esting Agency Remarks hecking Authority

4a),* && !g 600; allBocations

4echnical pecification/+ 35>6 , and other relevant

standards 1oulder si e C0 mm%6 ,and other relevant standardsand approved drawing

ontractor At locations in thepaddy fields or in thelow lying areas, thechimney is to "eextended as per A94ransco Approveddrawing# 4he cornerreinforcement rods(00 mm "elow thefinal chimney level to"e left un concertedand the extensions of chimney for thisportion and copingshall "e done after tower erection# uringshould "e continuedfor minimum 65 days#

A)/A))

I: Lay !g o* Eart" !g =P e orCo+!ter(o %e ty(e . =4a%e$ o!7ea%+re7e!t o* %o &re% %t ' ty to;er *oot !gre% %ta!)e

600; allBocations

4echnical specification + ?0 Goint inspection "y A94RA$ 8 -contractor

)arthing type will "edecided "y

A94RA$ 8

A)/A))

6A:

Co!)rete C+#e% Te%t !g 600; one samplefor each location%8ne sampleconsists of min ?test cu"es for (Cdays strength

4echnical specification# + ?5>,56>, 66 and other relevantstandards

contractor/# Approvedla"oratory "y

A94ranscotandard u"e

-

8/10/2019 QAP 220 132kV

17/90

6?

%ii& lump test D8 D8 D8test 'unnel andpoking rod

D8 A))/))

iii& *nit weight of concrete D8 D8 D8 D8 A))/))

4 4r ),%

a& Ansorption trength After (? hoursimmersion in coldwater

+ 3 ? 5 ! 6 >>$ot more than (0; "y weight

ontractor /approved testingBA1 "y

A94RA$ 8

A))/))/ )

"&ompresive trength HH##doHH## $ot less than ?0

@g/ mHH##doHH## A))/))/ )

c& )fflorescence HH##doHH## $ot more than I %9art!6& HH##doHH## HH##doHH## )

c& 'lakiness index and elongationindex

6 test per (50um

+ 3 ( C> %9art!6& HH##doHH## HH##doHH## )

d& Atter"erg limits of "lindingmaterial

6 test per 50 um + 3 (7(0 %9art!5& HH##doHH## HH##doHH## )

e& :ater a"sorption 6 test per source + 3 ( C> %9art! 0& HH##doHH## HH##doHH## )

f& 4hickness Regularly HHH## HH##doHH## HH##doHH## A)/A))

> To ; er Ere)t o!

A Mater a& C"e), !g

i& hecking of tower mem"ers fordamage cleanliness, galvani ing- stacking

600- 4echnical pecifications+ 35>6 - other relevantstandards and approveddrawings

ontractor Approval "y A94RA$ 8

A)/A))/ ))

%ii& hecking of galvani ed "olts -nuts step "olts dJshackle * "olts

pring :asher - accessories

D8 D8 D8 D8 D8

iii& Dimensional check Random D8 D8 D8 D8

-

8/10/2019 QAP 220 132kV

18/90

B) Erection of SuperStructure

(i) Checking of legmembers/braci

ng/redun dantsize & properplacement

Random TechnicalSpecications

IS:5613 & otherrelevantstandards andapproveddrawings.

Tightening ofBolts & Nuts

with torque wrenches

Jointinspection by

AP Transco& contractor

Beforestarting

erection ofuppersectionensure that(i) the lowersection iscompletely

braced andall boltsprovided inaccordance

withapproveddrawing (ii)all plandiagonallyandredundantsplaced in

position.Support guysat mainpanels ar eused duringerect ion toavoidmember

AE/ AEE

(ii) Tightness of bolts

identicationcleanliness &galvanizing

100%eachlocation

TechnicalIS:5613 andother relevantstandards andother approved

Jointinspection by

AP Transco& contractor

- do - AE/ AEE

(iii) Punching oftihtened bolts

- do - - do- - do - - do- AE/ AEE

(iv) Checking ofassembly &

verticality

- do - - do- - do - - do- Verticalityshallnotexceed

15

-

8/10/2019 QAP 220 132kV

19/90

16(v) Tack Welding 100%

eachlocation

TechnicalIS:5613 andother relevantstandards andother approveddrawings

Jointinspection by

AP Transco& contractor

Approval by APTRANSCO

Tack weldin

g diametricallyopposite,lengthof each

welding atleast10mm,

2 coatsof Zincrichpainton

vi) Tower footingresistancemeasurement

before & after

- do - - do - Measurement by 4electrodemethods by

Approval by APTransco

AE/ AEE

vii) Fixing ofdanger plates,number plates& phase plates,circuit plates(i)Visual Check(ii)Dimensionalcheck

- do - - do - Bycontractor

Approval by APTransco

AE/ AEE

8 Line Stringing A) Stringing (Sag

Tension) chart100% Technical

SpecicationIS:5613, Sag

Tensioncalculations andstringing chartapproved by

Contractor Approval by APTransco

AE/ AEE/

EE

B) Checking ofinsulatorsidentication

cleanliness

100% TechnicalSpecicationIS:731,5613,IEC

383 and other

Jointinspection by

APTransco &

contractor

Approval notnecessary

- do-

-

8/10/2019 QAP 220 132kV

20/90

cracks & whitespots, securityclips

standardsapproved sagtensioncalculation andapprovedstringing chart

C) Measurementof IR Value

100% TechnicalSpecication,IS:5613, andother relevantstandardsapprovedinsulator meggerdbe drawing,

APTransco/contractor

Approval notnecessary

IRshall

bemorethan50 MOhms

D) Checking ofinsulatorshardwarettings andconductor &ground wireaccessories

100% TechnicalSpecication, IS:2121,2486,5613and otherrelevantstandards andapproved

APTransco/contractor

Approval notnecessary

(i) Identication,Cleanliness &

ackin

- do - - do- - do - - do-

(ii) Anymechanicaldamae

- do - - do- - do - - do-

(iii) Measurementof dimensions

before andafter making

joint

- do - - do- - do -HydraulicCompressor,measuringtape andscale verniercaliper/contractor &

Approval notnecessary

(iv) Checkingmechanicalstrength

Random Technicalspecication IS:2121,2486,5613and otherrelevantstandards andapproveddrawings

A rigging setup to befabricated inthe eld fortestingmechanicalstrength.Contractor

Approval notnecessary

Mech.Strength notto belessthan95% ofUTS of

conductor

-

8/10/2019 QAP 220 132kV

21/90

18E) Checking of conductor & Earth wire(i) Drum schedule

approval100% Technical

specication Approved Tower

schedules,

Sectionlengths,Drum invoicelot

wise/contrac

Countercheck andapproval by

APTransco

(ii) Identicationcleanliness &packing

100% Technicalspecication andIS:1778,5613 &other relevantstandards andother approved

Jointinspection by

APTransco &Contractor

Approval by APTransco

(iii) Damage ofconductor &earthwire

- do - - do- - do - - do-

(iv) Drum rubbingagainst ground& or any metal

- do - - do- - do - - do-

F) ConductorEarthwireStringing

EntireRoute

TechnicalspecicationIS:5613 & other

relevantstandards andapproved SAG &

Tension charts

Jointinspection by

APTransco &Contractor

Approval by APTransco

Use of TSE,

saggin

g winchHydraulicdynamometerandother

(i) Initial conductorposition

- do - - do- - do - - do-

(ii) Check for Temperature

- do - - do- - do - - do- Metalenclosedthermo

(iii) Finalconductor

osition

- do - - do- - do - - do- Consideringcree

(a) DimensionalContinuit

- do - - do- - do - - do-

-

8/10/2019 QAP 220 132kV

22/90

19(b) Joints in

conductor andEarthwire

- do - - do- - do - - do- No bend

curvein the

(iv) Jumpering(Performed)

- do - - do- - do - - do- Minimumclearance to

bemaintained as2.10mtfor 2 20

KVand1.54mt for

(v) TensionStringing (ifany).Installation ofpilot stri ng on

- do - - do- - do - - do- - do -

9 Final Checking EE/SE(a) i) Check for

Backllingii) Removingany storedmaterial nearto the toweriii) Store extra

back ll withinthe base of the

toweriv) Checkingof prospectiverevetment with

weep holes and

100% Specications,IS:5613 andother relevantstandards andapproved Drgs.

Joininspection by

APTransco &contractor

Approval & Acceptance by APTransco

Allexcessmaterialshould

beclearedawayas per

specication

(b) Check for ACD& all toweraccessories

EntireRoute

- do - - do- - do -

(c) Check for Tightening,

punching andtack welding of

bolts

- do - - do- - do - - do-

-

8/10/2019 QAP 220 132kV

23/90

20(d) Check for Final

ground andelectrical

- do - - do- - do - - do-

(e) Check foreffectiveness o fEarthin

- do - - do- - do - - do-

(f) Meggering ofthe Line

100% - do- - do - - do-

(g) Conductorcontinuit Test

- do - - do- - do - - do-

(h) Measurementof lineresistance

- do - - do- - do - - do-

(i) Phaseseuence

- do - - do- - do - - do-

10 Testing &Commissioningthe Line

100% TechnicalSpecication

Testingagency

APTransco

- do-

11 Postcommissioningchecksa) Check for

visual coronaat insulator,

hardware,conductor,accessories etc.(locationsto be identied

Note:1. Route Plan, approved proles, approved tower schedule sag

template etc will be made available by the purchaser if thedetailed survey is a lready ca rried out by the Purchaser

2. At the time of receipt of material i.e., Tower parts,Conductors, Hardware tting accessories, insulatorsearthwire etc. AP Transco clearance may be veried bycontractor.

3. APTRANSCO site office Engineers/Field quality Engineers to witness/review specied tests.

4. The T & P of the erection contractor shall be inspected at site by the APTRANSCO before their use.

-

8/10/2019 QAP 220 132kV

24/90

GENERAL GUIDE LINES FOR IMPLEMENTATION

-

8/10/2019 QAP 220 132kV

25/90

22

Section: GENERAL GUIDELINES FOR IMPLEMENTATION

11 CEMENT

11.1 In case su pply of cement is in the scop e of the con tractor, the sam e sh all be procured from sources approved by APTRANSCO site and got tested at

site on sample basis for specied acceptance tests as specied in thisFQP at a reputed Third Party Lab ap proved by APTRANSCO site.

11.2 The sam ples of cement for site testing shall be taken within three weeksof the delivery and all the tests sh all be commenced within one week ofsampling.

12. REINFORCEMENT STEEL

12.1 In case su pply of reinforcement steel is in the sco pe of the contractor, thesame shall be procured from the main producers i.e., SAIL, TISCO,HSCO or Rashtriya Ispat Nigam or the recollers approved by mainprocedures. The reinforcement steel shall be got tested at site on sample

basis for specied acceptance tests as specied in this FQP at a reputed Third Party Lab approved by APTRANSCO site.

12.2 The result of the testing of cement and reinforcement steel referred to in13.1 and 14.1 above shall be got approved from APTRANSCO site beforecement and reinforcement steel are put to use. However, in exceptionalcases due to exigencies of work. APTRASNCO site may authorize thecontractor to use Cement and Reinforcement Steel even before the testresults are received. However, in all such cases, if the test resultssubsequently received are found to be not complying with the speciedacceptance cri teria, the contractor sh all have to dismantle and recase a ll

such foundations cast with such non-conforming materials at his owncost. Conrmation to this effect shall be obtained from the contractor bythe Project authorities b eforehand in all such cases.

13. All the testing and measuring equipments used by the contractor fortesting are required to be calibrated. A copy of valid calibration reportshall be retained by APTRANSCO as records.

14. Calibration certicates to be got veried from APTRANSCO for tools andplants an d testing equipment before t heir use.

-

8/10/2019 QAP 220 132kV

26/90

23 TOWER FOUNDATION

1. CHECK SURVEY

Name of Line: Location No:Name of Contractor: Type of tower:

i) Approved Detailed Survey Prole Drg. Nos. ..ii) Reference level ..

iii) Peg Marked Suspension Locations w.r.tDetailed Survey Prole O.K./NOT O.K.

iv) Alignment of Loc. w.r.t previous and next loc O.K./NOT O.K.

v) Loc. Of center peg/position of various landmarksare matching as per prole O.K./NOT O.K.

vi) Any new features on grnd. w.r.t prolenecessitating realignment/shifting of loc. Yes/No

vii) Span on both sides of loc. As per prole Actual(Mtrs.) (Mtrs.)

a) Preceding span (Loc.No.) b) Succeeding span (Loc.No.)

viii) Angle of deviation and bisection at twer As per prol Actual

a) Angle of deviation b) Bisection

Certicate:- C leared for P it marking.

FOR CONTRACTOR FOR APTRANSCO

Signature Signature

Name Name

Designation Designation

Date.. Date.

-

8/10/2019 QAP 220 132kV

27/90

24

2.

i)

ii)

PIT MARKING

Name of Line:

Name of Contractor:-

Approved Pit Marking Drg. Nos.

Angle of Bisection

Location No:-

Type of tower:-

.

O.K./NOT O.K.

transverse direction O.K./NOT O.K.

iv) Position of leg pegs w.r.t center peg of tower O.K./NOT O.K.

v) Position of all four pits are on level Yes/No

vi) Dimensions of pit marking are per drgs. O.K./NOT O.K.

vii) Whether Benching/Revetment required if yes, then Yes/No

a) If contour maps/Revetment drgs. Prepared Yes/No

b) Calculate vol. .cu.m.

c) Approved by designated authority Yes/No

Certicate:- C leared for ex cavation.

FOR CONTRACTOR FOR APTRANSCO

Signature Signature

Name Name

Designation Designation

Date.. Date.

-

8/10/2019 QAP 220 132kV

28/90

25FOUNDATION CLASSIFICATION

Name of Line: Location No:-

Name of Contractor:- Type of tower:-

i) Strata wise pit details

STRATA DEPTH RECEIVING STRATA DEPTH

--------------- -------------------------------- -------------------------------- -------------------------------- -----------------

PIT C/3 PIT B/2STRATA DEPTH STRATA DEPTH

------------------------------------------------------------ SENDING END

--------------------------------------------------------------------

PIT D/4 PIT A/1

NOTE:CLASSIFICATION MAY ALSO BE GIVEN ON ONE PIT EXCAVATIONBASIS FOR NORMAL DRY SOIL FOUNDATION DIMENSION

a) Predominant soilii) Sub soil water table details as on date.

PIT A/1 PIT B/2 PIT C/3 PIT D/4

iii) Water table in near by well as on date mtrs.

iv) Maxm. Subsoil water table in monsoon season afterthrough local enquiry .mtrs.

v) Surface water table on grnd. In monsoonseason and its duration. ..mtrs.fordays

vi) Type of cultivation Paddy elds/cultivate land/barren land

Whether encasement of stubs reqdDue to surface water? Yes/No

If yes, ht. of encasement above grad.level. mtrs.

-

8/10/2019 QAP 220 132kV

29/90

26 vii) Whether soil investigation (SPT) carried out Loc.No..

loc. or n ear by loc. viii) If this loc. strata det

with above soil investigation report or any other loc. of this line. Loc. Noix) Details o f soil investigation report:-a) STRATA DEPTH

------------------------------------------------------------

b) Subsoil water table. .mtrs.

c) Ultimate Bearing capacity. ..mtrs.

d) Angle of Repose ( ) .degrees

x) Foundation classication proposed by contractor.

As per SPT/ Trial pit

Actual

Remarks/Reason:- ..

FOR CONTRACTOR FOR APTRANSCO

Signature Signature

Name Name

Designation Designation

Date.. Date. Approval

Site visited on..and details veried The classication of foundation is approved as

FOR APTRANSCOSignature

Name

Designation

Date.

-

8/10/2019 QAP 220 132kV

30/90

27

4. STUB SETTING

Name of Line:- Location No:-

Name of Contractor:- Type of tower:-

i) Approved drg.Nos.

a) Stub setting template .. b) Pit dimension ..

c) Stub assembly ..

ii) Pit Dimensions.

a) Depth of pits From Ref. Level Ground Level

Pit APit BPit CPit D

b) Pit dimensions are as p er approved foundationclassication Yes/No

c) Excavated soil is kept 2m away from pit edge. Yes/No

d) Under cutting done in case of partially dry,dry Fissured rocks & mixed dry Yes/No

iii) Alignment of template.

a) Tan ent Towera.a) In the direction of line Yes/No

b) Angle Tower b.a) Angle of deviation .degrees b.b) Alignment of template on bisection Yes/No

iv) Diagonals of template AC.m

BD.m

=Angle ofDeviation. PQ=Line ofBisection. (Lines ADand BC areperpendicular t o PQ)

-

8/10/2019 QAP 220 132kV

31/90

28

STUB SETTING ON BISECTION

v) Level of template checked by dumpy/water level Yes/No

vi) Ht. Of template above ground level. .Cms.

vii) Clearance between lowest part of stub and P.C.C.(not less than 15 cm in dry and 20 cm in wetfoundation or as sp ecied in the d rg.)

Leg A.cm.Leg B.cm.Leg C.cm.Leg D.cm.

viii) Jacks placed on rm ground Yes/No

ix) Template supports/jacks positioning causing anydanger to collapse of pit. Yes/No

x) Green concrete blocks placed below stubs to avoiddisplacement of stub. (only for Prop setting) Yes /No

xi) All members of template are xed as per drg.

and fully tightened Yes /No

xii) Checking of stubs

a) Stub dimensions are as per type of tower Yes /No

b) All plates/cleats xed with reqd.no.of Nut/boltsand are fully Yes /No

c) Is earth at xed (for tower earthing) Yes /No

Certicate: Stub Setting Approved.

FOR CONTRACTOR FOR APTRANSCO

Signature Signature

Name Name

Designation Designation

Date.. Date.

-

8/10/2019 QAP 220 132kV

32/90

QuantityRequired

Quantity Available ApprovedSource

Quality (Ok/NotOk)

1) Stacking2) Organic/foreign

material3) Lumps4) Fine Sand Siltand if no

Size QuantityReuired

Quantity Avail

ApprovedSource

Quality (Ok/Not Ok)

40mm(P.C.C)20 mm(Slabs&Chimney)10 mm (15 to

i) Stackingii) Organic/Prolematerialiii) Flackiness, softhammer shaper

29

Availability check of :

i) leveling instruments

ii) Theodo iii) sieves 0. 15, 0.3, 0.6, 1.18, 2.36, 4.75, 10,12,20 mmiv) screw gauge

v) slump cone vi) No. of cubes cost

5. CONSTRUCTION OF MATERIALSName of Line:- Location No.:-Name of Contractor:- Type of tower:-

i) Quality /Qty. of Cement as per approved Drgs./Specications/

Agreement /Booklet on Guidelines on Implementation of QAP

QuantityReuired

Quantity Availableat Location

ApprovedSource

Quality (Ok/NotOk

)1) Stacking2) Organic/foreign

material3) Lumps

ii) Quality /Qty. of Sand/Fine Aggregate as per approved Drgs./Specications / A greement / B ooklet on Guidelines on Implementation ofQAP

iii) Quality/Qty. of Metal/Coarse Aggregate as per approved drgs. And specications.

iv) Dimensions of the measuring Box. OK/NOT OK(30 cm x 30 cm x 39 cm Height)

-

8/10/2019 QAP 220 132kV

33/90

ix)

a

Lean concreting:-

Pits a re free f rom all Forei n Materials Yes/No b) Pits are free from standing water (Dewatering continued

in advance by Pumps / Buckets) Yes/Noc) Mix ratio 1:3:6 with 40 mm metal Yes/Nod) Concrete mixing by mixer as per specn. Yes/Noe) Mixture running time (mixing Time 2 mins.) Yes/Nof) De-watering done. Yes/Nog) Lean concreting done upto specied level and in all the

four pits. Yes/No

h) No. of cement bags consumed As per design Actua

30

v) Proportions of concrete Mix. by volume derived from controlled designmix by w eight.

Grade ofConcrete

Qty. ofCoarse

A re ate

Qty.of ne Aggregate

Qty. of Cement Qty. of Water

M-15 6 Boxes 3 Boxes 1 Bag 34.1 litres

M-20 4 Boxes 2 Boxes 1 Bag 28 Ltrs.

* Volume proportioning of material by boxes to be veried & conformedafter nalisation of Controlled Design Mix by weight.

vi) Quality & Qty. of water as per specns. OK/ NOT OK

vii) Reinforcement steel.a) Qty. & Quality as per Apprd. Drg./specns.

Dia.(MT) Qty.Re d.(MT)

Qty. Avail Apprd. Source Quality (Ok/Not Ok)

6 mm8 mm12 mm16 mm

22 mm32 mmmm

viii) From Boxes.a) Dimensions are as per Apprd. Drgs. OK /NOT OK

b) Oiling of inner wall of form boxes OK /NOT OK

Certicate:- Material & T &P cleared for lean concreting

l

-

8/10/2019 QAP 220 132kV

34/90

31

x) In case of excess excavation lling is done by leanconcrete & no loose soil is p ermitted for lling.

Vol. of excess lean concrete.

Certicate:- Pits a re cleared for installation of reinforcement an d form boxes.

FOR CONTRACTOR FOR APTRANSCO

Signature Signature

Name Name

Designation Designation

Date.. Date.

-

8/10/2019 QAP 220 132kV

35/90

32

6. INSTALLATION OF REINFORCEMENT STEEL & FORM BOXES

Name of Line:- Location No.:-

Name of Contractor:- Type of tower:-

i) Apprd.Drg.Nos. ----------------------------

----------------------------

ii) Reinforcement steel

a) Quality/Qty. as per specication Yes/No b) Bending /Placing as per approved drg. Yes/No

c) Required no. of chairs approved Yes/No(Min Dia-12 mm, Max. spacing-500mm)

d) Binding done as per specications. Yes/Noe) Any undue stress or bending of steel bars Yes/Nof) Steel is clean and free from loose rust or any

other foreign matls Yes/Nog) Position of bars w.r.t stub as per drg. OK /NOT OK

iii) Form Boxes:-

a) Dimensions as per approved drg. OK /NOT OK b) Placing w.r.t stub as per approved drg. OK /NOT OK

iv) Clear cover of 50 mm (or as per specication available) Yes/No

Certicate:- Cleared for foundation casting.

FOR CONTRACTOR FOR APTRANSCO

Signature Signature

Name Name

Designation Designation

Date.. Date.

-

8/10/2019 QAP 220 132kV

36/90

33

7. MIXING, PLACING AND COMPACTION OF CONCRETE

Name of Line:- Location No.:-

Name of Contractor:- Type of tower:-

i) Apprd.Drg.Nos. ----------------------------

ii) Mix Ratio ----------------------------

a) b)

c)

For Pyramid/base with 20 mm metal with specied ratioFor chimney with 20 mm metal with specied ratio

Water to cement ratio as per specication

Yes/No Yes/No Yes/No

iii) Mixing done by

iv)Mixer (Running time 2 mins.)Use of okin rod for com actin Yes/No

v) vi)

Use o f vibrator for com pactingChecking of templates l evels & its

Yes/No

viii)diagonals at regular i ntervalsCasting of legs done in continuity

OK /NOT OK Yes/No

ix) x)

No. of cement bags consumed As pRemoval of stub template, shoring &shuttering and stripping of form workafter 24 hours of concreting, observethe damage and make rectication

er drg. Actual

Yes/No

xi) Back lling and compaction of backlledas p er sp ecication Yes/No

xii) Curing of backlled earth & chimney carriedout for peri od as p er specn.(Minimum period of curing 14 days after concreting)

Yes /No

a) Availability of water pump with storingarrangement for curing purpose ------------------

b) Date of start of curing ------------------

c) Date of completion of curing -----------------

xiii) Cubes, last sent for testing as Yes/No

xiv) All the surplus materials removed from site Yes/No

Certicate:-Foundation is cl eared for t ower er ection subject to fulllment ofPart (I) before t ower erect ion and Part (II) in due co urse a s follows.

-

8/10/2019 QAP 220 132kV

37/90

34

Part-I Setting period (28 days) is allowed as per specication

Part-II (i) Revetment benching proposal status.

(ii) Revetment benching likely execution date..

FOR CONTRACTOR FOR APTRANSCO

Signature Signature

Name Name

Designation Designation

Date.. Date.

-

8/10/2019 QAP 220 132kV

38/90

35

CONCRETE CUBE TEST REPORT

Name of work :

Agreement No. :

Sample No. :

Identication Mark :

Portion of Work o r Qty. represented sample:

Date & Time of casting :

Proportion of Mix :

Duration of Curing at site an dSite temperature before

Transportation to test Laband Temperature

7 days 28 days

1. Due date of test ..

2. Actual date of testing ..

3. Delay in testing ..

4. Actual Average compressive strength .. .

5. Is average comp. Strength equal to or

more than specied comp.strength

Yes/No Yes/No

(Signature of Executing Agency) (Signature of APTransco Official)

Date. Date.

-

8/10/2019 QAP 220 132kV

39/90

36

CHECKING OF FOUNDATION MATERIAL

(A) CEMENT

i) Approved brand of cement (Ramco/Pennar/Raasi) OK/NOT OK

ii) Stacking of cement bags OK/NOT OK

a) Protective covering found OK/NOT OK

iii) Condition of cement bags Damaged/Undamaged

iv) No. of cement bags leaking ------------

(Signature of Executing Agency) (Signature of APTransco Official)

Date. Date.

(B) COARSE & FINE AGGREGARE

i) Stacking of aggregates OK/ NOT OK

ii) Size of aggregatedCoarse aggregate 20 mm (80 to 85%)

10 mm (15 to 20%)

Fine aggregate /sand 4.75 mm conforming to Grade Zone I sand.

iii) Organic m aterial and foreign material and if yesensure cleaning Yes/No

iv) Coarse aggregate-Flake ness, soft slice and laminar shape Yes/No

v) Fine aggregate/Sand-Lumps and silt and if yessieve a vailable for cl eaning

Yes/No Yes/No

(Signature of Executing Agency) (Signature of APTransco Official)

Date. Date.

-

8/10/2019 QAP 220 132kV

40/90

37

(C) REINFORCEMENT STEEL

i) Approved reinforcement bending schedule Drawing No.

ii) Dimensions and nos of the reinforcement bars and rigs Yes/No

iii) Cleanliness of reinforcement bars f rom rust, mill deposit etc.,Yes/No

iv) Binding wire availability Yes/No

v) adequate fabricated chairs and gitties for supportingof reinforce bars availability Yes/No

(Signature of Erection Agency) (Signature of APTransco Official)

Date. Date.

-

8/10/2019 QAP 220 132kV

41/90

Sl.No. Description Requireme

nt/Testedas er

Permissible limits (Max.)

1 Water Potable ---

2 Naturalization 100 mlH20

IS: 3025 5ml 0.02 Normal Na oH

* Using Phenolphthaleinas indicator

* Using Mixed indicator25ml 0.02 Normal Na oH

3 PH Value IS:456 Not less than 6

4 Solids a) Organic IS:3025 200 mg/l b) In Organic IS:3025 3000 mg/l

c) Sulphate (SO 3) IS:3025 4000 mg/ld) Chlorides IS:3025 2000 mg/l (for non-

reinforced concrete)e) Suspended Matter IS:3025 500 mg/l (for reinforced

concrete5 Compressor strength

(20 days) for three 150mm concrete cubes made

with proposed water Vis-a Vis similar cubes made

with distilled water

IS: 516 90%

38

FORMAT FOR TEST REPORT OF WATER

Name of line.. Source of water supply.

Sample Indent Mark..

Name of Executing Agency.. Date.

Name & address of Test Lab

Test Report Ref. No..

-

8/10/2019 QAP 220 132kV

42/90

39

6 No. Description Requirement/ Testedas per

Permissible limits (Max.)

7 a) Initial setting time fortest cube made with

ro osed water

IS: 4031 Not less than 30 months

b) Variation in initialsetting time for test cu bemade with proposed

30 months

Note: Latest values m ay be seen by referring th e latest IS code a samended as per Relevant standards (IS 3025, 456, 516, 4031) and

APTRANSCO Technical Specication.

(SIGNATURE OF LOCAL OFFICIAL) SIGNATURE OF ERECTION AGENCY

DATE. DATE.

SAMPLE IS APPROVED FOR CONCRETING

(SIGNATURE OF APTRANSCO OFFICIAL)

DATE..

-

8/10/2019 QAP 220 132kV

43/90

CEMENT REGISTER

-

8/10/2019 QAP 220 132kV

44/90

41

CHECKING OF FOUNDATION MATERIAL

(A) CEMENT

Records of cement testing as

Per approved SFQP

(a) Details of samples

per 200 MT from each source are

maintained as per SFQP --------------------------

(b) All the tests as per approved SFQP are

carried out and details m aintained --------------------------

(c ) Joint reports for collection of samples

in case of site testing a re ava ilable --------------------------

(Signature of Erection Agency) (Signature of APTransco Official)

Date. Date.

-

8/10/2019 QAP 220 132kV

45/90

COARSE/FINE AGGREGATE REGISTER

-

8/10/2019 QAP 220 132kV

46/90

43

CEMENT RECEIPT & TEST FREQUENCY RECORD

Name of Line.. Location of

Name of Erection Agency Source of supply

D a t e o f R e c e i p t

B a t c h N o . / L o t N o .

Q t y . R e c e i v e d B a g s / M T

C u m

Q t y . R e c e i v e d

s M T M

a n u f a c t u r e r s T e s t

D a t e

A P T R A N S C O A p p r o v e d

L a b t e s t R e p o r t N o . &

t e T e s t R e s u l t s a r e a s p e r

P

S i g n a t u r e

Note: (1) MTC shall be available for every 200 MT or part thereof(2) Lab Test Report shall be available for every 200 MT or part thereof

-

8/10/2019 QAP 220 132kV

47/90

44

FORMAT FOR JOINT SAMPLING OF CEMENT

We have collected the sample of Cement as per following de

1. Location of stores it:

2. Source of supply :

3. Type and Grade of cement:(OPC/PPC, grade 33.43.53)

4. Batch No. /Lot No. of cement

5. No. & Quantity of sample

6. Name & Address of Lab wheresamples a re b eing sen t for t esting(vide l etter N o. & date)

The samples have been sealed and one identication mark slip duly

been placed inside the bag & another slip duly signed has

bag.

(Signature of Erection Agency) Signature of APTransco Official

Date Date

-

8/10/2019 QAP 220 132kV

48/90

45

FORMAT FOR TEST REPORT OF CEMENT

Name of line Source of SupplyName of Executing Agency Sample Ident. Mark

Test Report Ref. No. Date:Name & Address of Test Lab

Sl.No Particulars Requirement as per As per 3 rd

party ApprovedLab. Test

Result

IS 269 33 GradeOPC

IS 8112 43 GradeOPC

IS 12269 53Grade OPC

IS 1489-I &II, Fly Ash or

Clay based A. Ch e mical Prop e rti e s --

1. Cao-0.7 SO3 0.66 to 1.02 0.66 to 1.02 0.8 to 1.02

2. 2.8SiO 2+1.2A1 2O3+0.65Fc 2O3

3. 20 3% Fc20 3 0.66 MIN 0.66 MIN 0.66 MIN --

4. Insoluble Residue(%by mass)

4.0 MAX 2.0 MAX 2.0 MAX 13.6 to 2.8**

5. Magnesia(%bymass)

6.0 MAX 6.0 MAX 6.0 MAX 6.0 MAX

6. Sulphuric Anhydrite(% by

mass

3.0 MAX 3.0 MAX 3.0 MAX 3.0 MAX

7. Total loss ofignition(%)

5.0 MAX 5.0 MAX 5.0 MAX 5.0 MAX

8. Chloride(%) 0.05 MAX 0.05 MAX 0.05 MAX --

B. Physical Prop e rti e s1. Fin e n e ss(SQM/Kg.)

225 MIN 225 MIN 225 MIN 300 MIN

2. S e tting time (minut e s)i) initial 30 MIN 30 MIN 30 MIN 30 MIN

ii) nal 600 MAX 600 MAX 600 MAX 600 MAX

3. Soundn e ss

a) Le-chatExpansion(MM)i) Unacratedcement

10.0 MAX 10.0 MAX 10.0 MAX 10.0 MAX

ii) After 7 days Acration

5.0 MAX 5.0 MAX 5.0 MAX 5.0 MAX

b) Auto clave expansion (%)i) Uncratedcement

0.8 MAX 0.8 MAX 0.8 MAX 0.8 MAX

ii) After 7 days Aeration

0.6 MAX 0.6 MAX 0.6 MAX 0.6 MAX

4. Compressive Strength (Mpa)

a) 72+/- 1 hour 16 MIN 22 MIN 27 MIN 16 MIN

b) 168 +/-2hours

22 MIN 33 MIN 37 MIN 22 MIN

c) 672+ /-4 hours 33 MIN 43 MIN 53 MIN 33 MIN

** X+4.0(100-X)/100 Where X is t he d eclared 1% of pozzolona in the given Portland pozzolona

cement. X Ranger from 10 to 25%.

Note: Latest values m ay be seen by referring the latest IS code as a mended.

-

8/10/2019 QAP 220 132kV

49/90

46

COARSE & FINE AGGREGATE

Record of Coarse Aggregates testing as p er approved SFQP

a) Details of samples per 200 cum fromEach source for each size (40mm, 20mm)

And ne aggregate are maintained as per SFQP ----------------------

b) All tests as per approved SFQPare ca rried out and detailsmaintenanced ----------------------

c) Joint Report for collection ofSamples for testing at APTRANSCO

Approved lab is available ----------------------

(Signature of Erection Agency) Signature of APTransco Official

Date Date

-

8/10/2019 QAP 220 132kV

50/90

47

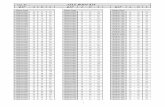

COARSE & FINE AGGREGATE CONSUMED & TEST FREQUENCY..

Name of Line --------------------------------- 40 mm metal------------20 mm metal

Name of Erection Agency --------------------

S l N o

D a t e o f

a s t i n g L

o c N o .

T y p e o f

d a t i o n 40 mm metal 20 mm metal Sand Signature

C o n s u m e d

C o m m u t a t i v e

C o n s u m e d

C o m m u t a t i v e

C o n s u m e d

C o m m u t a t i v e

E r e c t i o n

g e n c y

A P T R A N S C O

Note: One sample per lot of 200 MT or part there of (each for 40 mm, 20 mmmetal and sand)Date of sampling and test reportreference t o b e recor ded in this format.

-

8/10/2019 QAP 220 132kV

51/90

48

FORMAT FOR JOINT SAMPLING OF COARSE & FINE AGGREGATE

The sample of coarse line aggregate as per te collect ..

(1) Location of sit

(2) Source of supply

Size of Aggregate Source

40 mm

20 mm

Fine Aggregate

(3) No. & Quantity of Samples taken

(4) Name & address ofLab where samples areBeing sent for t esting(vide l etter N o. & date)

The samples have been sealed and identication mark slip duly signed has

been placed inside the bag & another slip duly signed has

bags.

(Signature of Erection Agency) Signature of APTransco Official

Date Date

-

8/10/2019 QAP 220 132kV

52/90

49

FORMAT FOR TEST REPORT OF FINE AGGREGATES

Name of Line Source of Supply

Name of Executing Agency Sample Ident.Mark

Name & address of Test lab Date

Test Report Ref.No.

SlNo

Description of test Acceptable Limits As per IS 383 TestResults

Remarks

Percentage of Passing Zone wise

Zone-I Zone-II Zone-III Zone-IV1. Sieve Analysis

10 mm 100 100 100 100

4.75 mm 90-100 90-100 90-100 95-100

2.36 mm 60-95 75-100 85-100 95-100

1.18 mm 30-70 55-90 75-100 90-100

600 micron 15-34 35-59 60-79 80-100

300 micron 5-20 8-30 12-40 15-50

150 micron 0-10 0-10 0-10 0-15

2. Silt content 8% Max. 8% Max. 8% Max. 8% Max.

3. Deleterious

Materials

5% Max. 5% Max. 5% Max. 5% Max.

Note: Latest values m ay be seen by referring the latest IS code as a mended.

Certicate: It is c ertied that test results m eet all the req uirements a sper IS383 and APTRANSCO Technical specications.

(Signature of the Lab Official) (Signature of Erection Agency)

Date:.. Date.

Sample is approved for concreting/masonary m ortar/plastering

(Signature of Powergrid Official)

Date:..

-

8/10/2019 QAP 220 132kV

53/90

REINFORCEMENT STEEL REGISTER

-

8/10/2019 QAP 220 132kV

54/90

51REINFORCEMENT STEEL

Record of reinforcement steel As per approved SFQP.

(a) Details of sample:from each sourcefor ea ch size a remaintained as p erapproved SFQP

(b) All tests as per

approved SFQP arecarried out anddetails m aintained

(c ) Joint Reports forcollection of samplesfor t esting a t powergridapproved lab is ava ilable.

(Signature of Erection Agency) Signature of APTransco Official

Date Date

-

8/10/2019 QAP 220 132kV

55/90

52

REINFORCEMENT STEEL RECEIPT & TEST FREQUENCY RECORD

Name of Line.. Location of store..

Name of Erection Agency Source of supply.

S.No. Date ofReceipt

Grade/type & Lot

No.

Diameter

Quantity received Manufacturers T est

CerticateNo. & date

APTRANSCO Approved Lab

test R eportNo. & date

TestResults

are As per Approved

SFQP

SignatureQty.

Regd.inLotMT

CumQty.MT

Note: MTC and APTRANSCO approved lab test report shall be available as p erapproved SMQP.

-

8/10/2019 QAP 220 132kV

56/90

53

FORMAT FOR JOINT SAMPLING OF REINFORCEMENT STEEL

The samples of reinforcement steel as per the collected jointly by us:

(1) Location of store/site

(2) Source of Supply

(3) Diameters of rods

(4) Length of rods

(5) Lot No.(s)

(6) No. of samples taken

(7) Name & Address of lab where samples are being sent for testing

(vide l etter N o. & date)

The samples have been wrapped together & placed inside the bag. One

identication mark slip duly signed the bag & another slip duly signed has

been pasted on the bag.

(Signature of Erection Agency) Signature of APTransco Official

Date Date

-

8/10/2019 QAP 220 132kV

57/90

54

FORMAT FOR TEST REPORT OF REINGORCEMENT STEEL

Name of Line Source of Supply

Name of Executing Agency Sample Ident.Mark

Name & address of Test lab Date

Test Report Ref.No.

SlNo

Description of test Acceptable Limits As per Test Results Remarks

IS 432 MSGrade I

Above 20

IS 1786Fc 415

Manufac. Specn. TMT 415

1. Chemical Analysis 0.23+/-0.02Max.

0.30+/-0.02Max

0.25 +/-0.02 Max

a) Carbon (C) % 0.055+/-0.005 Max

0.06 +/-0.005 Max

0.05+/-0.005Max

b) Sulphur (S) % 0.055+/-0.005 Max

0.06 +/-0.005 Max

0.05+/-0.005Max

c) Phosphorous(P)%

0.055+/-0.005 Max

0.06+/-0.005 Max

0.05+/- 0.005Max

d) Sulphur and %Phosphorous

0.11+/-0.01Max

0.11+/-0.01Max

0.10 +/- 0.01Max

2. Mechanical Properties

a) 0.2% proofstress N/SQ.MM

250 Min "15 @in$ "15 @in

b) Ultimate Tensile Stress N/SQ MM 410 Min" 5 @in 500 @in

c) Elongation 23 Min 1"$5 @in 22 @in

d) Bend Test Nocrack/Fracture at Bend

Nocrack/Fracture at Bend

Nocrack/Fracture a tBend visible

e) Rebend Test Nocrack/Fracture at Bend

Nocrack/Fracture at Bend

Nocrack/Fracture a tBend visible

Note: Latest value m ay be seen by referring the latest IS code as a mended.

Certicate: It is ce rtied that t est r esults m eet al l the requirements asper IS and APTRANSCO Technical specications.

(Signature of the Lab Official) (Signature of Erection Agency)

Date:.. Date.Sample is ap proved

(Signature of Powergrid Official)

Date

-

8/10/2019 QAP 220 132kV

58/90

CONCRETE CUBE TESTS REGISTER

-

8/10/2019 QAP 220 132kV

59/90

56

CONCRETE CUBE TEST REPORT

Name of work :

Agreement No. :

Sample No. :

Identication Mark :

Portion of Work or Qty represented sample:

Date & Time of casting :

Proportion of Mix :

Duration of Curing at site an dSite temperature before

Transportation to test Lab And Temperature

7 days 28 days

1. Due date of test

2. Actual date of testing

3. Delay in testing ..

4. Actual Average compressive strength ..

5. Is average comp. Strength equal ormore than specied comp. Strength Yes/No Yes/No

(Signature of Executing Agency) (Signature of APTransco Official)

Date.. Date..

-

8/10/2019 QAP 220 132kV

60/90

57

TOWER ERECTION

Name of the Line:- Location No:-

Name of Contractor:- Type of tower:-

Approved Drg.No:-

Approved Bill of Material:-

1.

Items Checked

Settin eriod of foundation is allowed

Results Observations

for a tleast 14 days (preferably 2 8 days)as per specication Yes/No

2. All tested tools and lants and safetequipments in working conditions areavailable at site Yes/No

3. All tower members, Nuts,/bolts areavailable at site without any damage, bentor r usting and kept on ground seriallyaccording to erection sequence Yes/No

4. Benching /revetment, if nay, completed.If not, then program of completion Yes/No

5. Shutdown of power line, if required,is arranged Yes/No

6. Reuired no.of safet helmets, safet belts& safety shoes are being used. Yes/No

7. First section is com letel braced and allplane diagonals are place in proper position Yes/No

8. Gu in of tower rovided as erapproved drawings and norms.Guying to be terminated on rm ground. Yes/No

9. All nuts/bolts, at/s rin washers areprovided as per approved drawings Yes/No

10. All bolts to have the nuts facin outside forhorizontal or n ear horizontal bolt connectionsand downwards for ver tical bolt connections(Cl.2.27.5.1.1 of the Technical Specication) Yes/No

11. All the inner contact surfaces at joints painted with zinc rice paint (Cl.2.28.3 of the Technical

Specification) Yes/No

-

8/10/2019 QAP 220 132kV

61/90

58

12. Subsequent section are erected only aftercomplete erec tion and bracing of previoussection Yes/No

13. Any undue stress, bending or damage ofmember du ring erection noticed Yes/No

14. Filling of holes or cutting of members duringerection observed Yes/No

15. Any heavy hammering of bolt causingdamage of threads n oticed Yes/No

16. Any substitute of tower member erected,if, yes, member nos. Yes/No

17. Tightening is done progressively from

top to b ottom Yes/No

18. All bolts at same level on all the four facestightened simultaneously staring from legto face o n right side b y four i ndividuals Yes/No

19. Slipping/running over nuts/bolts arereplaced by n ew ones Yes/No

20. Threaded portion of bolts projected outsideof nut is not less than 3 mm and not morethan 8 mm

Yes/No

21. Punching of threads p rojected outside isdone at three p ositions on dia Yes/No

22. Half round Tack w elding of bolts nuts at twodiametrically opposite places u pto the bottomcross arm and each weld length at least 10mm

Yes/No

22 a) Zinc rich (at least 90% zinc content) on thetack welds on the nuts Yes/No

23. Verticality of tower (1 in 360) is checked withhelp of T heodolite for bo th longitudinal &transverse d irection. This is within speciedlimits

Yes/No

24. Details of missin member, nut, bolts, etc. Yes/No25. Mention the tower taking resistance value: Yes/No

Certicate: Tower erect ion is co mplete i n all respects a nd footing resi stance is w ithinpermissible limit.

FOR CONTRACTOR FOR APTRANSCOSignature Signature

Name Name

Designation DesignationDate.. Date.

-

8/10/2019 QAP 220 132kV

62/90

59

TOWER ACCESSORIES

Name of the Line:- Location No:-

Name of Contractor:- Type of tower:-

Approved Drg.No:-

Items Checked Results Observations

1. GI bolts and nuts fully tightened andplaced as p er approved drawing.

a) Number Plate Yes/No b) Phase Plates(set of 3 per circuit) Yes/No

c) Danger Plates Yes/Nod) Circuit Plate (2 Nos.) Yes/Noe) Name plate Yes/Nof) Bird guards (Suspension tower only) Yes/Nog) Earthing bond (One on suspension

tower and two on tension towers) Yes/No

(37/7/0.417 mm Stranded Tinned Copper)h) Step bolts with spring washers 450 mmspaced on diagonally opposite legprovided 3.5m above the ground Yes/Nolevel to top of the t ower

i) Step bolt holes available upto 3.5m Yes/Noabove ground level.

2. Anti-climbing device including barbed wire, cleats, Barbed wire xing Galvanized

MS member with fully tightened bolts. Yes/No3. Aviation signals/Paints as per

requirement/specication provided where required. Yes/No

Certicate: All Tower a ccessories p rovided satisfactorily

FOR CONTRACTOR FOR APTRANSCO

Signature Signature

Name Name

Designation Designation

Date.. Date.

-

8/10/2019 QAP 220 132kV

63/90

60

PIPE TYPE EARTHING

Name of the Line:- Location No:-

Name of Contractor:- Type of tower:-

Approved Drg.No:-

Items Checked Results Observations

1) Earthing on leg A/1 Yes/No2) GI Pipe (25mm dia, 3m long) Flat

(50x6 mm, 5m Long) with nuts and bolts Yes/Nofully tightened and placed as perapproved drawing.

3) Placement of Flat along with stub and bending of at inside the form box as Yes/No

per approved drg.4) Burying of Flat 650mm below ground Yes/No5) Bore hole (300 mm dia) and depth

(3000 mm) Yes/No6) Gap (150 mm) between the GI pipe

bottom end and bottom of the bore hole Yes/No7) Finely broken coke (grain size not more

than 25 mm) and salt (proportion 10:1) Yes/Nolled in bore h ole arou nd the pipe.

8) Mix of Bentonite powder in 1:6 ratio Yes/No9) Back lling done Yes/No10) Earthing resistance measurement

(less than 10 Ohm) and if not so, then Yes/No11) Additional earthing pipe installed. Yes/No12) Repeat earthing resistance measurement

(less than 10 ohm) Yes/No

Certicate: Footing resi stance within permissible l imits.

FOR CONTRACTOR FOR APTRANSCO

Signature Signature

Name Name

Designation Designation

Date.. Date.

-

8/10/2019 QAP 220 132kV

64/90

61

COUNTER POISE EARTHING

Name of the Line:- Location No:-

Name of Contractor:- Type of tower:-

Approved Drg.No:-

1)

Items Checked

Earthing p rovided on all the four legs

Results Observations

Yes/No

2) GSS earth wire 7/3.15, 25m long),

MS rod (20 mm dia, 6mtrs long) withnuts a nd bolts fully tightened andplaced as p er approved drg.

Yes/No

3) Burying of GSS earthwire1000 mm below ground OK/NOT OK

4) MS rod (20mm dia, 600 mm length)at the en d of earthwire. Yes/No

5) Back lling done Yes/No

6) Earthing resistance measurement(not less than 10 ohm) Yes/No

7) Additional counter poise installed Yes/No

8) Repeat earthing resistancemeasurement ( less than 10 ohm) Yes/No

Certicate: Footing resi stance within permissible l imits.

FOR CONTRACTOR FOR APTRANSCO

Signature Signature

Name Name

Designation Designation

Date.. Date.

-

8/10/2019 QAP 220 132kV

65/90

62

STRINGING

Name of the Line:- section: Loc.Noto Loc. No:-

Name of Contractor:- Type of tower:-

Approved Tension Stringing Chart:-

Approved Drum Schedule:-

Items Checked Results Observations

1) Back lling of soil and revetment/ benching wherever required is done. Yes/No

2) Towers are tightened properly and all themembers, nut/bolts are provided. Yes/No

3) Tress in the ROW removed to facilitatesmooth stringing Yes/No

4) All line m aterials, tested and calibrated T &P safety equipments and relevantdrawings available for st ringing. Yes/No

5) Shutdown of Power line/Railway block if required, is arranged. Yes/No

6) Necessary Protection/scaffolding / warning signals provided for Railway/

Power line/P&T line/Road crossing. Yes/No

7) Towers vulnerable for one side load is gu yed properly. Yes/No

8) Tower footing resistance is withinpermissible limit of 10 Ohms. Yes/No

-

8/10/2019 QAP 220 132kV

66/90

63

B) Paving Out of Earthwire.

1) Work is being carried out withfully safety measures. Yes/No

2) All pulleys xed on towers for pavingout are moving freely. Yes/No

3) Effective communication existsthrough walkie-talkie and through Yes/Nopersons with red ags on towers.

4) Earthwire is being constantly checkedas it is u nwound, Damaged portion, if any,is removed. Yes/No

5) Necessary arrangement have beenprovided to avoid rubbing of earthwireagainst hard ground. Yes/No

6) Necessary details of earthwire,M.S.Joints Recorded as per Annex Yes/NoCFI & CF II

C) Paving Out of Conductor

1) Work is being carried out with fullsafety measures Yes/No

2) Conductor drums are placedproperly to avoid bird caging. Yes/No

3) Sequence of paving out is suchthat to avoid unbalancing ofload on tower Yes/No

4) Details of insulators an d tting arerecorded. As per Annex CF III and Yes/No

Annex CF IV.5) Travelers xed on towers are

moving freely Yes/No6) Effective communication exists through

Walkie-Talkie and through persons withred ags on towers. Yes/No

7) Conductors is checked continuously asit is unwound from drum. Damagedportion if any, is removed/repaired. Yes/No

8) Travelers xed on towers aremoving freely Yes/No

9) Effective communication exists through walkie-talkie and through persons with

red ags on towers. Yes/No10) Conductors is checked continuously as

it is unwound from drum. Damagedportion if any, is removed/repaired. Yes/No

-

8/10/2019 QAP 220 132kV

67/90

64

11) Pro er arran ements made to avoidrubbing of conductor on ground/hard Yes/No

surfaces.12) Details of conductor M.S.J. /repairsleeve are recorded as per Annex CF II Yes/Noand Annex CF II.

D) Final Sagging & Tensioning of Earthwire & Conductor

1) Sa Board is xed correctl aftertaking into account length of suspension Yes/Noclamp/ttings in case of Earthwire an dSuspension insulator st ring in case of

conductor.2) Sag/Tension is measured correctly at

prevailing temperature. D etails recorded Yes/Noas per Annex CF V.

3) Minimum Ground Clearance, clearanceover Power line/Railway Line/River Yes/Nocrossing/Telecom/Road are as p erspecication.

E) Dead Ending

1) Subsequent to nal sagging, dead end

work is done marking the length of

conductor cor responding to single/double

tension string for conductor and dead end Yes/No

clamp for ground wire.

2) Corresponding to dead end clamp drawing,

the aluminum strands over the steel coreare cut and steel portion and aluminum

portion of dead end clamp is compressed

as ap plicable to conductor an d only steel

clamps for ground wire. Yes/No

3) Clipping offsets marked with felt tip

marker and not with sharp instruments

denting conductor stands. Yes/No

-

8/10/2019 QAP 220 132kV

68/90

65

4) For power line crossing sectionprecautions taken before clipping. Yes/No

i) The existing power line conductors are grounded.ii) No person in series w ith the potential electric circuit.

5) Prior to installation/removing dead

end jumper on structure ear thing done

on both sides of the work and Yes/No

connected to st ructure.

6) Suspension clamps and dampers installed with in

36 hours after nal connected to structure Yes/No

7) Center of the body (cushioned) and clamp

body of AGS clamp coincides with the Yes/No

armor rods, marked point on the conductor.

8) No difference in length between the longest Yes/No

and shortest rod when applied n ot to

exceed 13 mm.F) Conductor Fittings and Attachments

1) Spacers and dampers xed immediately but with in 24 hours of conductor

clamping as per manufactures recommendations. Yes/No

2)a) Whether spacer cars/cycles are xed with metercounters for m easuring intra-spacing of spacers/spacer dampers during placement and if no. Yes/No

b) How the distance between spacers/spacerdamper in measured. Yes/No

3) Vibration dampers for ground wire installed asper manufactures recommendations immediately

but within 24 hours of clipping. Yes/No

4) Span marker on ground wire, if required,installed on ground wire after clamping and

xing of vibration dampers on the ground wire. Yes/No

-

8/10/2019 QAP 220 132kV

69/90

66

G) Tower Hardware

1) Tower Hardware viz phase plates, numberplates, circuit plates, copper ea rthing bond,phase plates and danger plate xed Yes/Noas p er approved drawing.

2) Anti-climbing devices xed as per approved drg. Yes/No

3) Step bolts with 2 Nos. nuts and one spring Yes/No washer xed as per approved drawing.

Certicate: Stringing is c ompleted in all respects.

FOR CONTRACTOR FOR APTRANSCO

Signature Signature

Name Name

Designation Designation

Date.. Date.

-

8/10/2019 QAP 220 132kV

70/90

67

ANNEXURE CF I

DETAILS OF EARTHWIRE/CONDUCTOR

1) Make

2) Batch No.

3) Quantity and Location as per approved drum schedule.

Sl.No

DrumNo.

LengthMarked

on Drum

(Km)

LengthPayOut

(Km)

Pay Out Between Phase Wire No.From

Loc.No. To Loc. No.

4) There is no damage to earthwire/conductor before or during stringingstandards a re in perfect position.

FOR CONTRACTOR FOR APTRANSCO

Signature Signature

Name Name

Designation Designation

Date.. Date.

-

8/10/2019 QAP 220 132kV

71/90

68

ANNEXURE CF II

DETAILS OF COMPRESSION TYPE MID SPAN JOINT FOR EARTHWIRE/CONDUCTOR AND REPAIR SLEEVE FOR CONDUCTOR

1) Make

2) Batch No.

3) Quantity and Location as per approved drum schedule.

Sl.No

Between Loc No. Phase Wire No.

4) Dimension Recorded as per Annex.

5) M.S. Joint has been p rovided at least 50 feet away from tower.

6) There is no M.S. Joint over Railway/River/Main Road crossing.

7) Not more than one M.S.Joint provided in one span for eachearthwire/conductor

8) Repair sleeve shall be used if number of damaged strands is not more than 2 strands in outer layer of the con ductor. No repa ir sleeve sh all beused in case of ground wire. If damage is in more than the perm issiblestrands, the damaged portion shall be removed and M.S. Joint provided.

FOR CONTRACTOR FOR APTRANSCO

Signature Signature

Name Name

Designation Designation

Date.. Date.

-

8/10/2019 QAP 220 132kV

72/90

69

ANNEXURE CF III

RECORDS OF INSULATORS

1) Type Glass/porcelain, Suspension /Tension/Pilot.

2) Make

3) Batch No. and Month of Manufacture.

4) With/without zinc sleeve.

5) Electro Mechanical Strength.

6) Quantity and Location

Sl.No.

Loc.No.

Qty.as perspecication

Qty. in Ckt I Qty. in CktII

Ckt I Ckt II

Phase(Conductor)

Phase(Conductor)

Jumper Jumper

R Y B R Y B R Y B R Y B

7) Insulator Meggered at site with 5 KV Megger and results ofmeasurement.

8) Insulators are cleaned with soft cloth. G lazaing is proper. There is no

crack, scratch or w hite sp ot on its su rface.9) R clips in insulators ar e tted properly.

10) While hoisting, no damage caused to insulators.

FOR CONTRACTOR FOR APTRANSCO

Signature Signature

Name Name

Designation Designation

Date.. Date.

-

8/10/2019 QAP 220 132kV

73/90

70 ANNEXURE CF IV

DETAILS OF HARDWARE FITTING

1) Make

2) Batch No.

3) Type of tting-I/V Single/Double, Suspension/Tension.

4) Quantity and Location

Sl.No.

Loc.No.

No. of Fittings Ckt I Ckt IIPhase

Ckt. I

Phase

Ckt II

Jumper Jumper

R Y B R Y B R Y B R Y B

5) All nuts/bolts properly tightened. Yes/No6)

7)