Yardlines no. 23

-

Upload

norfolk-naval-shipyard -

Category

Education

-

view

519 -

download

0

description

Transcript of Yardlines no. 23

“The official electronic newsgram of Norfolk Naval Shipyard” June 24, 2011

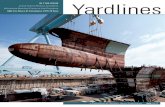

“Great teamwork” across Norfolk Naval Shipyard ensures success on Truman’s mast upgrade project

By Michael Brayshaw, Code 1160 Public Affairs Specialist

See Truman teamwork, next page

Who does it take at Norfolk Naval Shipyard to move a 90,000-lb. load off a ship in a single lift? Almost everyone as it turns out, given the extensive coordination and collaboration required to remove the main mast off USS Harry S Truman (CVN 75) on Saturday, June 18. The Shipfitter (x. 11), Welding (x. 26), Electrical (x. 51), Electronic (x. 67), Wood/Fabric (x. 64) and Temporary Services (x. 99) Shops are all par-ticipating in the carrier’s mast upgrade effort, as well as Codes 106 (Safety), 200 (Engineering and Planning),

Who does it take at Norfolk Naval Shipyard to move a 90,000-lb. load off a ship in a single lift?

Almost everyone as it turns out, given the extensive coordination and collaboration required to remove the main mast off USS Harry S Truman (CVN 75) on Saturday, June 18. The Shipfitter (x. 11), Welding (x. 26), Electrical (x. 51), Electronic (x. 67), Wood/Fabric (x. 64) and Temporary Services (x. 99) Shops are all participating in the carrier’s mast upgrade effort, as well as Codes 106 (Safety), 200 (Engineering and Planning), 300 (Operations), 900 (Production Resources), and Truman’s Ship’s Force. Leading the effort in the mast removal was the shipyard’s Lifting and Handling Department (Code 700).

“The first issue was de-populating the mast and getting all the antennas off while working to the schedule as much as possible,”

Code 700 Lifting and Handling employees finish guiding down USS Harry S Truman’s (CVN 75) 89,000-lb. main mast off the carrier on June 18. (Photos by Tony Anderson, a Code 1170 Photographer.)

300 (Operations) 900 (Production Resources), and Truman’s Ship’s Force. Leading the effort in the mast removal was the shipyard’s Lifting and Handling Department (Code 700). “The first issue was de-popu-lating the mast and getting all the antennas off while working to the schedule as much as possible,” said Kenny Sasser, rigging zone manager for Truman. Shop 51 Zone Manager Matthew Rienerth and Shop 67 Supervisor Steve Brooks took the lead in removing all the electrical cables and antennas. Helping this large-scale, exten-sive effort was that several person-nel involved in this mast removal also participated in NNSY’s last mast removal, which happened in November 2006 during USS George Washington’s (CVN 73) availability. The mast was re-moved by a 450-ton Liebhern crane, similar to cranes used to build roller coasters. “As big as this job is, these folks have been knocking the ball out of the park with staying on schedule. It’s been a lot of great teamwork!” said Truman project superinten-dent, Matt Durkin. “We had a good plan in place. One of the biggest things we stressed was safety and keeping the pier clear,” said George Sears, Truman’s assistant project super-intendent. Ever appreciate of the project team and assisting depart-ments, Sears added, “These are the ones getting it done, I’m just giving them the assistance they need!” Removal of the mast marked a major milestone in Truman’s 13-month Drydocking Planned In-cremental Availability (DPIA) . An essential component of the carrier’s Capstone project, Truman will be receiving a new mast in August that

will stand 10 feet higher and is ap-proximately 30,000 lbs. heavier. As part of Naval Sea Systems Command’s One Shipyard Concept that shares personnel and resources across all four public shipyards, Puget Sound Naval Shipyard and Intermediate Maintenance Facility fabricated the main mast stick, with NNSY performing the rest of the work fabricating the new mast. Sears commended Code 920 Zone Manager Alvin Allen and

Supervisor Claude Banks who are supervising the new mast construc-tion, and Shop 26 Supervisors Joe Harris and Joy Wiggins who are overseeing its welding. Capt. Joe Clarkson, Truman’s commanding officer said, “This is a Main Mast Correction as part of Capstone, which includes upgrades to the combat systems, new radars, and upgrade and refurbishment of radars for our weapons systems. It’s a very important upgrade.”

Norfolk Naval Shipyard, as well as tenant command employees, seek leave through the Leave Donor Program:Jimmy L. Waller, Training Instructor; Wil-liam L. White, Sheet Metal Mechanic; Rich-ard C. Harrell, Training Instructor; Shanita Tynes, Rigger; Kenneth J. Donivan, Painter; Hollis Boone, Shipfitter; Juan Dejesus, Pipefitter; Joseph T. Horan, Jr.; Eric Salley, Rigger; Robin Salugao, Occupational Safety Specialist. To donate leave to any of the listed personnel, please contact E. Allen at 6-9023.

Employees seeking leave for personal, family emergencies

Swapshop

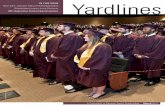

Leading the effort on USS Harry S Truman’s (CVN 75) mast upgrade include, from left to right: Front row--Rigging Zone Manager Antonio Lamb; Capstone Electrical/Electronics Zone Manager Matt Rienerth; Rigger Supv. Andrew Manigo; Assistant Project Superintendent George Sears; Shop 11 Supv. Claude Banks; Shop 26 Supv. Joy Wiggins; Capstone Electrical Supv. Brandon Fields; Shop 26 Welder Tyrone Bryant. Second row--Shop 11 Work Leader James Brinkley; Capstone Electrical Supv. Bob Carraher; Rigging Zone Manager Kenny Sasser; Shop 11 Shipfitter Eric Harris; Shop 26 Welder Leon Blount; and Structural Zone Manager Alvin Allen.

1995 Prowler 5th Wheel Fleetwood Travel Trailer, 30 foot with super slide-out, new AC & tires, great cond., $6,500. Call Cheryl at 621-8640.

Wedding Gown: Sz-18. Drycleaned. Minimal alteration. Eggshell; sleeveless, fitted bodice w/ embroidered leaves & flowers. Pearl bead accents. Full skirt, crinoline. Chapel lgth train. Over-bustle added. Zipper hidden. David’s bridal. Paid $650, asking $300. Call Allison for info at 675-6910. Please leave msg.