Yardlines, August 2012

-

Upload

newport-news-shipbuilding -

Category

Documents

-

view

213 -

download

0

description

Transcript of Yardlines, August 2012

Yardlines

A Publication of Newport News Shipbuilding August 2012

In ThIs Issue

nns engineers sail on CVn 77

submarine Builders set new Record

On the Move With the night Train

Phot

o by

Chr

is O

xley

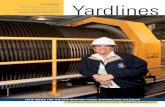

Most people are surprised to discover that Newport News Shipbuilding (NNS) has more than 15 miles of track within the shipyard’s 550 acres, with two active engines and six qualified locomotive operators/switchmen transporting materials as needed on first and second shift. But trains have always been an integral part of the shipyard.

In 1886, railroad magnate and NNS founder Collis P. Huntington needed a ship repair facility to support the business of shipping coal delivered on his railroad. As the

shipbuilding contracts grew larger, so did the materials. When a piece of ship weighs up to 300 tons and needs to be transported a mile away, the connection between trains and ships doesn’t seem so strange.

Alan Brinkley, who came to the shipyard 32 years ago, is the sole locomotive operator on the night shift. After working in nuclear laundry for eight years, Brinkley was approached about joining the locomotive team. “I had no idea what I was getting into!” joked Brinkley. “Many of

NIGHT TRAIN

the tracks run through busy intersections. Vehicles and pedestrians are constantly present, requiring a completely different set of skills and training than operators in other settings. Safety is our biggest challenge and number one priority.”

The newest locomotive at the shipyard, Engine 507, is capable of going up to 65 mph, but due to the unique environment, it rarely goes over 15 mph, even during the day. “Operating at night is even more of a challenge because of reduced visibility. Then there’s the challenge of traffic—we’re not the only ones transporting materials around the yard. It could take a quick 20 minutes to get something across the yard, but there’s always something in the way,” remarked Brinkley.

For this reason, the operators are never alone. “I always work with two ground men: Darrell James is my lead man and Maurice Owens is my back man. Their job is to direct

me, because they see what I can’t. Locomotives never move without eyes and ears in front and back,” explained Brinkley. With payloads weighing up to several hundred tons, the night train team works together to carefully navigate the maze of the shipyard. “You can work here for years as a ground man and still not know about some of the lesser-used tracks. The rail system is huge, and you appreciate that more after you have been doing this job for a couple years,” Brinkley said.

While trains are important to shipbuilding, so are the people who operate the trains. “I like this job,” Brinkley declared, with a big smile on his face. “I’ve been operating the night train for 17 years. I think I can do another 10.”

L to R: Maurice Owens, Alan Brinkley (cover photo) and Darrell James operate Engine 507 through the shipyard, navigating the maze of more than 15 miles of track to get materials where they need to be. Photo by Chris Oxley

Thanks to a new welding plan and collaboration between the Virginia-Class Submarine (VCS) Construction team, Welding Engineering, Dimensional Control and the Welding and Fitters departments, installation of the steering and dive guide tubes on the John Warner submarine were completed in record time.

“On the Minnesota, the guide tubes were welded in 93 days, and on the North Dakota, welding was reduced to 38 days,” said John Wagoner, VCS construction team leader. “Using what we learned on the previous two ships to develop a new welding sequence plan, we were able to complete the Warner’s guide tubes in 22 days.”

To reduce the construction and installation time, Welding Engineering developed a plan that outlined the sequence in which each frame of the guide tubes would be welded. This was important because there were precise dimensional control targets that had to be met.

“There was very little room for error,” said Fitter Michael Perry. “If the team missed the target on any one frame and had to cut it, we were looking at an extra week in the schedule per frame.”

This meant the project team had to make some critical decisions. From the start, the team agreed to utilize skills around the clock, weld on the port and starboard sides simultaneously, and meet every other day at 6:15 a.m. to fine-tune the plan as needed.

“We were also determined to finish a significant amount of welding each day and allow the frames to cool so that Dimensional Control could take their readings during the third shift,” said Welder Apprentice Kelli Vallez. “Because we had the data and the sequence prior to first shift, we were able to plan our welding and trim days off the schedule.”

Key contributors to the success of the project were the welding and fitting crews led by Todd Corr, Kim Kerins and Dino Martin, and welders Eric Barden, Lawrence Britt, Moses Cherry, Travis Jenkins, James Parham, Matthew Shilling, Kelli Vallez and Jered Wright. The fitters were Aaron Beckett, Michael Perry, and Welton Pierce, with crews led by Justin Crockett and Ryan Ritter from the Dimensional Control team and Lynn Showalter in Welding Engineering.

For Tony Davis, welding isn’t just a job. And it isn’t simply a skill he’s acquired.

“It’s an art to me,” said the 38-year shipyard veteran who co-workers call “The Legend.”

Davis has been welding since before he was old enough to drive, having trained in the profession at a vocational school before coming to work at Newport News. The shipyard placed him in the burning department when he arrived, but he convinced Human Resources to move him to welding.

“I told them I liked welding and I would be of more benefit to them in that area,” he said. And he was.”I’ve been welding ever since.”

But going from welder to “legend” took something more than just an aptitude for the job. It took a lot of pride, said Davis, something instilled in him at an early age.

As a youngster his dad would make him cut the grass, and if Davis didn’t do a good job, his dad would send him back out to do it again. “He would tell me if you are going to do something, then try to do it right.”

Over the years, Davis has mastered all forms of welding techniques and any new welding technologies that came along during his nearly four decades of building ships.

He’s worked on submarines, aircraft carriers, tankers, cargo ships and cruise ships. “Just about every ship that came to the shipyard,” he said.

On one particular day, Davis remembered he was welding on a ship, using three mirrors to ensure the job was done right. A co-worker stopped to watch what he was doing and told him he was good—that he was a “legend.” Then she wrote that word on his tool box. And

the name stuck. “Everywhere I go they say ‘here comes The Legend,’” said Davis.

Today, what Davis enjoys the most is sharing what he’s learned. “I like helping other people, seeing them progress and gain confidence in themselves. I know I’ve showed this guy something and now he can pass it on.”

But before he takes on new pupils, he first asks them if they take pride in their work. “If they do, then I’ll show them everything. But if they don’t want to learn it right, then I’ll tell them they’re wasting my time.”

And the young welders keep coming to Davis, asking for his help. “If you show one person, it’s like a chain reaction,” he said.

That’s the legacy Davis wants to leave in his wake.

During his nearly four decades at the shipyard, Tony Davis’ (left) artistry as a welder and mentor to new shipbuilders has earned him the nickname “The Legend.” Davis took Welder Terry Bryan Jr. (right) under his wing three years ago. Photo by Ricky Thompson Fi

le p

hoto

by

John

Wha

len

What is life like aboard an aircraft carrier at sea? Unless you are Navy personnel, the President of the United States or a distinguished guest—chances are you will never find out.

In June, 13 Newport News engineers were offered an experience of a lifetime—a trip aboard a commissioned carrier through Newport News Shipbuilding’s (NNS) Engineers to Sea program. The shipbuilders, predominately carrier engineers, spent five days and four nights exploring ship compartments and living as a sailor aboard the Nimitz-class carrier, USS George H.W. Bush (CVN 77).

“Historically, carrier engineers have not had the

opportunity to see the systems they design being used in their ship’s at-sea environment,” said Chuck Shirley, Engineers to Sea program coordinator. “Through this program, engineers are able to interact with Navy personnel, analyze ship systems, and observe sailors as they operate and maintain systems while at sea.”

The team boarded CVN 77 at Naval Station Norfolk and sailed out with the ship’s crew. “I had always heard family and friends talk about life at sea, but I had never been able to experience it. This was always ironic to me, since I have been designing ship models at NNS for eight years,” said Engineer Benjamin Price. “When stepping aboard the carrier, one of the first things I noticed was the huge difference in looking at deck plans on paper

RealityFrom Design To

Engineer Aris Vincent Picardo gets a view of the flight deck from the integrated catapult control station aboard CVN 77. Photo by Lauren Ward

or through a computer-simulated model versus actually being on the ship.”

Once under way, the team began touring various compartments and collecting data. “We got to see everywhere from the machinery rooms to the propulsion plant to the galley and food storage rooms,” said Engineer Aris Vincent Picardo, who joined NNS six year ago. “After talking with galley personnel, we discovered that a minor design change in the width of the doors leading to the storage room would make their lives a lot easier. This simple change would allow food pallets to more easily fit through the door and also use less manpower when transporting food to different locations throughout the carrier.”

Kayla Harris, who designs and programs modeling and simulation software applications added, “Another example is the location of the alarms throughout the ship. Some alarms may need to be located higher so that more people can be alerted, whereas others might need to be

lower so that they only alert people in one specific area. It’s very easy to look at a deck plan and make decisions; however, taking extra time to look into the location of every item could mean a tremendous difference in the quality of life a sailor experiences while at sea.”

The team toured more than 45 CVN 77 compartments. “I plan to take what I learned at sea and go back and discuss possible system changes with my peers,” said Harris. “This trip has given me a whole new perspective on my job. I hope more engineers are able to have this invaluable experience and come back to Newport News with their innovative ideas.”

To see video of the CVN 77 Engineers to Sea experience visit nns.huntingtoningalls.com/videos.

Firefighter James Hawkins practices rappelling and rescue skills in Dry Dock 2. Photo by Chris Oxley

On a hot day this past June, members of the Newport News Shipbuilding (NNS) Fire Department could be seen lowering themselves, one at a time, down into Dry Dock 2. The scenario—a shipbuilder was injured and needed to be rescued.

Outfitted with harnesses, ropes and other rescue gear, firefighters Jonathan Burcham, Jason Gray, James Hawkins, Wendy Sauro and Clinton Sullivan were taking part in a training exercise designed to practice rappelling skills. The NNS rescuers had to scale down the dry dock’s 41-foot interior wall then package and remove the simulated patient using rescue gear and a basket.

“With the complex work that our shipbuilders perform daily, our firefighters need to be ready for almost anything,” Lt. Michael Taylor explains. “Because our teams need to respond fast and with precision, continuing education and maintaining a high skill level are extremely important in being able to support shipyard operations.”

High angle and confined-space rescue exercises are just two of the many necessary skills NNS firefighters practice throughout the year to ensure they are ready for any possible situation.

NNS’ dedicated Fire Department works around the clock assigned to three six-person teams, each working 24-hour shifts. The department’s experience, skills and detailed knowledge of the 550-acre shipyard enable the 18 firefighters to respond quickly to any shipyard emergency.

Tony Mann is a happy, happy guy.

And for the 29 years he’s worked as a security officer at the shipyard, he’s been busy spreading that happiness around. In fact, it was his positive outlook that got him hired in the first place.

“He liked my attitude,” said Mann of the person who hired him some three decades ago. Formerly with the Hampton Police Department, Mann came to the shipyard in 1983. As part of the Security Department, he has worked all over the shipyard, from buildings to piers to aircraft carriers to patrolling the many acres of waterfront. Today he can usually be found at the front desk of Building 520, located at 41st Street and Washington Avenue.

But no matter where he is, Mann greets everyone he sees with a wish for a “happy, happy day.”

“Especially during the first part of morning from six to eight, I try to be as positive as I can,” said Mann. Whether it’s ‘happy, happy Monday’ or ‘happy, happy Thursday,’ every day of the week is a chance for him to wish the best to people coming through the door.

“I also give out quite a few high-fives while I’m there,” he said. “It helps set the tone for people coming in. We have a lot of fun. Wherever I’m at, I try to keep it happy for the people there.”

Mann credits his late mother and a favorite uncle, who was always giving out smiles and an encouraging word, for infecting him with a positive spirit.

“It just kind of sticks,” Mann said. “And I just like to see people smile.”

As employees, contractors and visitors come in and out of the shipyard, it’s Mann’s job to check IDs, sign in guests and keep the building secure. It can get hectic at times, but Mann keeps up the smiles. “It’s not tough to do,” he said.

His enthusiasm for his job can be infectious. “I’ve had people come up to me and say, ‘I felt down today, but you lifted my spirits.’ I just try to make a difference.”

Security Officer Tony Mann gives NNS employee Stacey Brand one of his signature greetings at Building 520. Photo by Ricky Thompson

A Happy Greeting

T.R. Sweat40 years

Bobby White45 years

Lindell Toombs40 years

Bill Wallace40 years

Charles Vassar40 years

Rick Woods40 years

Long ServiceMASTER SHIPBUILDERS JULY

Ed Smithwick45 years

Larry Raynor40 years

Thomas Smith40 years

Bill Rhodes45 years

Ed Price45 years

Alex Perry40 years

Larry Munn40 years

Pernell Newby50 years

Lonnie Peele40 years

Michael Weirich40 years

Clinton Moore40 years

Willie M. Jones40 years

Skip Kilburn 45 years

Jim Keenehan40 years

Keith Joyner40 years

Bill Boyd40 years

Charles Barkley40 years

D. Billy Boyd40 years

Billy Beebe40 years

Davie Banks40 years

David Compton45 years

Jim Corliss40 years

Tom Drye40 years

Larry Davis40 years

Doc Ellis40 years

Allen Fincher45 years

Alfred Jones45 years

Paul Jones55 years

Leonard Harper40 years

Eddie Garris40 years

Long ServiceMASTER SHIPBUILDERS

55 YeArSPaul D. Jones X84 50 YeArS John B. Jeffries Jr. X42Pernell Newby X36 45 YeArS David L. Compton O43John T. Drake X36Allen T. Fincher X31Alfred Jones X15Dale K. Jones X53Skip Kilburn O57Ed Price E45Bill Rhodes Jr. E14Ed Smithwick X88Bobby R. White O46 40 YeArS Ronald D. Bailey X43Davie B. Banks X71Charles E. Barkley X33Billy K. Beebe X89D. Billy Boyd X42Bill C. Boyd X32Jim E. Corliss E58John Daidola AMSECLarry Davis X82Tom Drye O04Jack W. Dunn X18Doc Ellis O46Eddie L. Garris X18Leonard E. Harper O61Willie M. Jones X18Keith S. Joyner X70James R. Keenehan X31Clinton R. Moore O31Larry F. Munn E42Lonnie Peele X42Alexander Perry O15Larry D. Raynor X33Thomas E. Smith O31

T. R. Sweat X32Lindell C. Toombs X33Charles E. Vassar X31Bill Wallace X75Michael E. Weirich E65Rick Woods X42 35 YeArS Hasan Abdul Malik X32Gilbert L. Ackes X36William M. Adkins O43Fernando T. Bailey X10Joseph Banks III X31Douglas Barrow X18Herman L. Batts Jr. X11Edward M. Belbin II X18Fred H. Bell X18Michael K. Bezek X76George A. Boone O53Joe C. Boyd X36William W. Byrum O46Luther W. Cartwright O43Stephen D. Crampton O64John W. Deloatch X11Neal V. Edwards X88Max J. Elliott-Blount X36Rudolph Futrell X36Richard A. Gent X36Ricky M. Grandison X11Craig A. Harlan X11William F. Harris Jr. T54Vicky Holden O12Ivan N. Huneycutt X71Beverly L. Jones X67Ricky E. Jordan X11Mark R. Keafer X36Linda E. Kerlin O51Bradley J. Kiehner O14Richard S. Lemons O37Sherry L. Lusby O53Gregory Marshall X11Richard L. Messick X36Eric A. Miller O57

Catherine B. Mintz O26Reginald K. Moore O46Cleavin B. Mungin O53Wallace W. Payne Jr. X11Michael A. Perron O39Jerry C. Person X11John A. Phillips Jr. X36William D. Philpott Jr. X10Reginald A. Pierce O43Lynn W. Poland M53Clarence L. Pope X32Anthony J. Robinson X31Willie Rumble Jr. X33Jacob Ryan Jr. X11Billy Scott X18Mark L. Simons O14Robert M. Smallwood X33Curtis L. Taylor X18Jarvis C. Wade X32Martin A. Walsh Jr. X54Lee E. Warren X18Paul J. Weishaar O19Matthew H. White O43Ronnie L. White X36Calvin L. Wilson X71 30 YeArS Albert N. Amundsen E62Thomas G. Anthony E82Connie J. Asby E81John H. Babb Jr. X33Curtis W. Babcock X42Arthur G. Bagley X32Ralph M. Bailey X18Matthew P. Bass Jr. O15David H. Bazemore X18Ruth B. Bean O58Robert W. Belcher E42Susan K. Biron E81William C. Blomstrom E25Ralph D. Bowden Jr. X87George A. Bryant X11Leslie L. Bryant Jr. M53

Patrick D. Buskee X84Michael J. Byrum X74Danny L. Calkins X43Carl T. Carro X18Gary M. Carter X88Keith R. Christensen E82Gene R. Clayton Jr. X58Charles D. Cook X18Madison L. Corbin X42Ricardo B. Corpuz X43Frank C. Davis Jr. X71David E. Dickey III E25Thomas C. Everett O64John A. Firgau E84Charles E. Flemings X36Vernon A. Floyd O67Melvin J. Fogg X18John E. Fritschi E75David G. Green O26Mark P. Gresik O37Anthony L. Griffin O53Mary W. Haughey O35Gregory M. Hayes X33William L. Hayes X80Glen D. Henley X73Michael E. Hoffler X32Randall K. Howard X87Kenneth T. Hudson X71Vickie B. Hunt O64Shelby B. Jackson O21Douglas E. Jones O43Marvin L. Jones X88Steven W. Katona E22Tracy L. Kelly X11Robert D. Kennedy E60Michael D. Konrad E74David M. Krewson X31Kimberly P. Lackey E20Douglas G. Leckey O43Steven M. Lulofs E64William J. McCarter O19Mark C. Miller E75Mark G. Miller X32

Kathryn M. Monds X76Barry S. Narron X54Michael A. Nelson X18Ronald F. Orme O57Randy C. Pak X18Carl M. Parker X11Dirk A. Parker X18Russell S. Phaup X36Ray D. Pierce X43David E. Powell X10Robert M. Richardson E82Marvin B. Richmond O53Jeffrey M. Robertson E17Francis M. Rowe E88David L. Ruark AMSECThomas W. Ruzic E33Brooks J. Ryno O19Frederick M. Schmidt E82William B. Scouten Jr. X11Wayne E. Silver Jr. O09Douglas W. Smith Jr. E84Joseph A. Smith Jr. K03Robert C. Spears X43Christopher A. Stanley E81Michael D. Stephenson O64Ricky R. Stevenson O68Mark D. Stumpo E83Christopher W. Vitarelli K89Terry H. Voltz O50Melvin H. Wade X32John K. Walters X88James E. Whitaker Jr. O14Brenda A. Williams T55David W. Woerner X42James L. Woods X43Stephen A. Wos E86James W. Yost Jr. M10 25 YeArS Robert E. Alliet E17Carol E. Barnes O51Brenda J. Barrow E68Rudolph Bartie Jr. E13

Jacqueline V. Beale E85Kelly W. Brown O64Daniel J. Callahan E82Douglas P. Carlson E83Clifford J. Carr T54Vince M. Fleming O27Melonie D. Fluet T55Robert W. Holtzer E65Sherry C. Jeffries E85Douglas H. Jones E86Peggy L. Little E83Mark R. Madler E83James E. Martin Jr. E82Terry A. Miller E83Maria K. Mingee O48Debra L. Motton E18Lori A. Pearman T55Stephen P. Philipps O83Thomas J. Piperata E81Mark D. Piskorski E82Michael D. Pyrtle X88David M. Riddle X71Robert R. Ross E86Michael R. Routon E14Scottie L. Sanders E56Joseph H. Schaffer Jr. X10William B. Surber O43Robert Svensson AMSECJudy Tyler O22Pieter A. Van De Graaf E17Lynne M. Walker K75Mark T. Wertz X58Lois H. Wilhelm E17Ingrid B. Wright E07 20 YeArS Robert Frybarger AMSECGeorge Lamb II AMSECJeremy B. West E84

Retirements JUNEAndrew Boone Jr. X36Merelyn Britton M53Albert E. Bush X33Ralph L. Byrd X89Thomas C. Cash X42James E. Chapman X42David A. Coates E56

Robert L. Costello O81Lloyd W. Craig Jr. X31Otis L. Dickerson X32David R. Farries X74James C. Fike O21Richard M. Gurtis E74William R. Harris X11

Tuson Harvey X87Robert J. Hills Jr. E83Eugene E. Hutchens O48Harold N. Jenkins X32Patricia R. Jones O53Daniel R. Keefer X32Linda H. Kindred X36

Jerry L. Lawson Jr. O54Steven F. Leffel O43Jennings L. Lyon O27Charles W. Mason O55James A. Messick X57Robert P. Minter E21Larry D. Moody X18

Clifford L. Price X32Ralph E. Roberts X70Timothy B. Saunders X43Larry E. Scalf E65Earl H. Slade Jr. O14Joel D. Stitzel Sr. O11Lorenzo Waters X31

Gary A. Werlau X82Willie B. White Jr. M53Richard V. Wood E45Edmund S. Zavada E44

Thomas Ruffin45 years

Mike Lowrie 45 years

Allen “Old School” Jordan40 years

Robert Chappell40 years

Jim Albert40 years

John Temple40 years

Willis Griffin40 years

Daniel Fontaine40 years

The Master Shipbuilders on this page celebrated anniversaries in June. They were unintentionally omitted from the July issue.

Newport News Shipbuilding (NNS) and Northrop Grumman Electronic Systems (NGES) will share an exclusive day of fun on Saturday, September 15, at Kings Dominion Park. All NNS and NGES employees, Bayport Credit Union members, along with family and friends are invited to attend.

Tickets, now on sale, may be purchased at any Bayport Credit Union location for $22.00 or at eTickets online for $25.00. For eTickets, type KingsDominion.com/KDNNSB into your browser, then log into the site with the Username: KDNNSB and Password: KDNNSB. Place your credit card order, then print out the ticket(s) and bring them to the park.

Only special NNS tickets dated September 15 will be valid for this event. The park will open from 10 a.m. and close at 8 p.m. Tickets for an online offer to add an All-You-Can-Eat Picnic Lunch is only available until September 11.

A limited number of tickets are available for this exclusive day. Purchase tickets early as they may sell out.

KINGS FOR A DAY

At 6 a.m., Rodney Huffman prepared bait, rods and reels for the start of the Annual Children’s Fishing Clinic at the James River Bridge Fishing Pier.

For the last six years, Huffman and more than a dozen Newport News shipbuilders have volunteered to help Hampton Roads children, ages 8-12, learn the sport of fishing. The free event is sponsored by Newport News Parks, Recreation and Tourism, the Newport News Rotary Club, and the Coastal Conservation Association.

Tracey Arzu, the lead for coordinating NNS’s participation, said the children receive t-shirts, hats, fishing poles, and fishing instruction. “After the clinic, they’re allowed to take home their fishing poles,” said Arzu. “They are filled with excitement to have their own pole to catch their own fish.”

Huffman values the clinic as a time to potentially have

an impact on the children’s future. “Volunteering with the children provides the opportunity to teach a skill and inspire volunteerism to continue passing on knowledge,” said Huffman. “As these children grow older, they may remember fun childhood memories, like the day they spent learning to fish at the clinic. I truly believe that the four hours of teaching stay with the children longer than just that day. Not only are the children learning, but they’re also having fun.”

NNS employee Joseph Maddox Sr., his wife, Hailey, and three sons look forward to the event and memories made each year. “This fishing clinic is a great way for Newport News shipyard families to serve the community,” said Maddox. “This family-oriented event puts smiles on the faces of so many children.”

Fishing inspires Life Lessons

Making a Difference

Virginia-class submarine builder rodney Huffman enjoys teaching fishing skills to Ethan Remington at the Annual Children’s Fishing Clinic. Photo by Dar Deerfield Mook

Yardlines is published 10 times a year for the employees of Newport News Shipbuilding.

This issue of Yardlines was produced by: Jordan Bryan, Gina Chew-Holman, Troy Cooper, Mike Dillard, Christie Miller, Eugene Phillips, LaMar Smith, Peter Stern, Susan Sumner and Lauren Ward. Additional writing services by Barlow Communications. Photographs by: Chris Oxley, Ricky Thompson and John Whalen

Send comments, questions and story ideas to Yardlines editor: [email protected] or call 757-380-2627.

To stop receiving Yardlines, go to nns.huntingtoningalls.com/Yardlines to unsubscribe.

huntingtonIngalls hIIndustrieshuntingtonIngallsIndustries Look for more news at nns.huntingtoningalls.com.

August 2012

4101 Washington Ave.

Newport News, VA 23607

PRST STD U.S. POSTAGE

PAID EAU CLAIRE WI PERMIT NO. 366

Yardlines is printed on recycled paper with vegetable-based inks.

Don’t forget to call the Newport News Shipbuilding Employee Information Phone Line for up-to-date information on shipyard operations. If severe weather or other types of emergencies impact

the shipyard work schedule, the phone line will be updated accordingly with a new message. If there are no changes, the message will say, “We are conducting normal operations.”

The Employee Information Phone Line is a toll-free number and employees must dial “1” to be connected. The phone line is frequently updated.

1-877-871-2058