WILDCAT - Mining Engineering, Design & Refurbishment · WILDCAT WILDCAT JAE42 CONTINUOUS MINER...

Transcript of WILDCAT - Mining Engineering, Design & Refurbishment · WILDCAT WILDCAT JAE42 CONTINUOUS MINER...

W I L D C AT

WILDCAT JAE42 CONTINUOUS MINER

Quality Excellence JAE Australia is ISO 9001 accredited for the supply, manufacturing and repair of Coal Mining Electro Mechanical Engineering Equipment.

JAE ‘s Design and Engineering team assist JAE Australia to implement very stringent quality processes through our manufacturing and supply, overhauls / upgrades and onsite technical support toensure we manage our quality to the highest standard every time.

Comprehensive reports are collated and submitted toour customers following each Project, providing assurance that each completed product / service is ofthe highest quality.

WILDCAT JAE42 CONTINUOUS MINER 5

The JAE Experience JAE Australia was established in 2006, following the growing demand in the Australian Coal Industry for alternative OEM suppliers of high quality equipment, overhauls / upgrades, parts / components. Over time, the company has grown extensively and is now manufacturing complete machines with our partners JA Engineering Works in South Africa.

Our foundation is built on service excellence and acommitment to build a strong long term relationship with each customer andsupplier.

Facilities and equipment■ 1500m2 floor space■ Large Hardstand ■ Overhead crane■ 1000V available as required■ AS3800 Overhauls – with our partner Rutherford

Vision Control Solutions ■ General Machining Capability ■ Dust Free Gearbox / Hydraulic and Electrical

Rebuild Area ■ Gearbox Testing Capability ■ Warehouse

T + 27 11397 3237E [email protected]

T + 61 7 4936 1788E [email protected]

Contact us Australia

Queensland 9 Bush Crescent Parkhurst Rockhampton

South Africa

Johannesburg

2 WILDCAT JAE42 CONTINUOUS MINER

Local Engineering DesignJA Engineering is proud to be a mining supplierwhich designs and manufactures world class mining technology products.

Design criteria for the new Wildcat CM:■ Ergonomic considerations ■ Safety and best operating practices considered at the start to identify and mitigate safety risks. ■ Some existing continuous miner limitations have been reduced. ■ Increased reliability / life of components.

■ Cutter drive designed for improved control and to reduce stalling tendency. ■ Some basic machine mining specifications can be altered by the changing of some components. ■ Advanced technologies have been used in the design and manufacture. ■ Newer advanced technologies relating to personnel proximity location are also being implemented. ■ A lower risk approach has been used aiming for Zero Harm.

W I L D C AT JAE42 CM

Performance The Wildcat CM is designed to meet the uniquehard cutting conditions within the global coal mining industry. JAE intently listened to our customers’ needs and requirements andincorporated these specifications into our design.

This resulted in an underground machinewhich has savagely fierce capability, hence thename “WILDCAT”.

Unleash the WILDCAT...

Wildcat JAE42 CMTotal miner length 12,1 (m)

Total miner mass 110 (t)

Minimum trammingheight 1,9 (m)

Width across main frame 3,32 (m)

Ground clearance 280 (mm)

Cutting width 3,65 (m)

Cutter drum diameter 1320 (mm)

Minimum cutting height 2,2 (m)

Maximum cutting height 3,95 (short barrel cylinder) (m)

Maximum cutting height 4,7 (long barrel cylinder) (m)

Cuttable rock strength (UCS. Lacing to suit) 70 MPa

Cutter motor power 2 x 200 (continuous S1rating) (kW)

Loading capacity 50 (t/min)

Spade loading width 3,36 (m)

Conveyor width 960 (mm)

Conveyor capacity 50 (t/min)

Hydraulic Oil Capacity 1500 (l)

Tram speed-variable 0 -20 (m/min)

Ground pressure 0,220 MPa

Total installed power 828 (1000 V / 50Hz) (kW)

Specification of MachineThe Wildcat JAE42 CM is a remote controlled mid-highseam double pass continuous miner. The machine is capable of transforming a high installed cutting power through the machine weight into real production and

cutting performance. The Wildcat JAE42 CM is designed to be used in a room and pillar coal mining operation, where a high cutting force is required.

WILDCAT JAE42 CONTINUOUS MINER 3

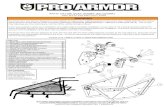

General Arrangement

Features and Benefits ■ 200kW S1 cutter motor delivering 300kW cutting power■ Variable Voltage Variable Frequency (VVVFD) AC

traction system (2 x 85kW)■ Pempek - AC traction control system■ Fully integrated collision avoidance system(“PDS”)

■ Traction brake to hold miner at face during cutting■ Wider tracks for lower ground bearing pressure■ Track pad design to improve slewing■ Higher power traction motor and cutter motor

design■ Improved cutter drive torque protection■ Cutter head feedback control in sump and shear

mode■ High inertia cutter drums for reduced stalling■ Cutter drum lacing custom designed to suit mine

conditions

PEMPEK – AC traction control system

ELECTRICAL

Voltage – line side Up to 1150V @ 45.65Hz

Voltage – load side 850V

Current / continuous rating 200A / 100kW

TEST STANDARDSClimatic test EN 60068-2-30 (Damp

heat, non-condensing)Mechanical stability EN 60068-2-6

(Vibration)Immunity to interfering fields EN 61000-6-2 2005

4 WILDCAT JAE42 CONTINUOUS MINER