Welds Edited

-

Upload

praveen-kumar-r -

Category

Documents

-

view

224 -

download

0

Transcript of Welds Edited

8/13/2019 Welds Edited

http://slidepdf.com/reader/full/welds-edited 1/12

8/13/2019 Welds Edited

http://slidepdf.com/reader/full/welds-edited 2/12

(

• "here is no need for holes in members connected by welding e&cept possibly for erection purposes. "his has direct influence in the case of tension members as the problem ofdetermining the minimum net section is eliminated. "his also results in a member with asmaller cross section.

• Welded structures are more rigid compared to structures with riveted and bolted connections."he rigidity of welded structures is due to the direct connection of members by welding. In

bolted or riveted structures, the connection is established through angles or plates, whichdeflect under loads, making the structure fle&ible.

• It is easier to make design changes and to correct mistakes during erection, if welding is used.It is also a simple procedure to strengthen the e&isting structures with welding.

• ) truly continuous structure is formed by the process of fusing the members together. "hisgives the appearance of a one*piece construction. +enerally welded joints are as strong orstronger than the base metal, thereby placing no restriction on the joints. ue to this

continuity advantage, a very large number of steel frames have been constructed all over theworld.

• Stress concentration effect is considerably less in a welded connection. Some of the lesserimportant advantages of the welding processes are- relative silence of the process of weldingand fewer safety precautions.

Some of the disadvantages of welding are-

• Welding process re%uires highly skilled manpower • &perienced manpower is needed for inspection of welded connections. )lso, non*destructive

evaluation may have to be carried out to detect defects in welds• Welded joints are highly prone to cracking under fatigue loading• /ostly e%uipment is essential to make welded connections• 0roper welding can not be done in the field environment• !arge residual stresses and distortion are developed in welded connections

In the earlier days, combination of bolting, riveting and welding was not practiced. Structureswere completely welded, bolted or riveted. 0resently both are used in a structure e&cept that bothconnection techni%ues are not used in one and the same joint.

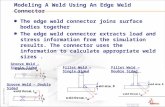

FUNDAMENTALS OF WELDING

) welded joint is obtained when two clean surfaces are brought into contact with each other andeither pressure or heat, or both are applied to obtain a bond.

BASIC WELDING PROCESSES

In general, gas and arc welding are employed but, almost all structural welding is arc welding.In gas welding a mi&ture of o&ygen and some suitable gas is burned at the tip of a torch held inthe welder2s hand or by an automatic machine. )cetylene is the gas used in structural weldingand the process is called o&yacetylene welding. "he flame produced can be used both for cutting

8/13/2019 Welds Edited

http://slidepdf.com/reader/full/welds-edited 3/12

3

and welding of metals. +as welding is a simple and ine&pensive process. ut, the process is slowcompared to other means of welding. It is generally used for repair and maintenance work."he most common welding processes, especially for structural steel, use electric energy as theheat source produced by the electric arc. In this process, the base metal and the welding rod areheated to the fusion temperature by an electric arc. "he arc is a continuous spark formed when alarge current at a low voltage is discharged between the electrode and the base metal through athermally ionised gaseous column, called plasma. "he resistance of the air or gas between theelectrode and the objects being welded changes the electric energy into heat. ) temperature of3344 4 / to ##44 4 / is produced in the arc."he welding rod is connected to one terminal of the current source and the object to be welded tothe other. In arc welding, fusion takes place by the flow of material from the welding rod acrossthe arc without pressure being applied.

TYPES OF JOINTS AND WELDS

y means of welding, it is possible to make continuous, load bearing joints between the membersof a structure. ) variety of joints is used in structural steel work and they can be classified intofour basic configurations as shown in 'ig. (.

"hey are-

1. !ap joint(. "ee joint3. utt joint, and5. /orner joint

'or lap joints the ends of two members are overlapped, and for butt joints the two members are placed end to end. "he "* joints form a "ee and in /orner joints, the ends are joined like the letter!. "he common types of welds are shown in 'ig. 6. 7ost common joints are made up of filletweld and the groove weld. 0lug and slot welds are not generally used in structural steel work.'illet welds are suitable for lap joints and "ee joints and groove welds for butt and corner joints.+roove welds can be of complete penetration or incomplete penetration depending upon whetherthe penetration is complete through the thickness or partial. +enerally a description of welded

joints re%uires an indication of the type of both the joint and the weld.

"hough fillet welds are weaker than groove welds, about 64$ of the connections are made with

fillet welds. "he reason for the wider use of fillet welds is that in the case of fillet welds, whenmembers are lapped over each other, large tolerances are allowed in erection. 'or groove welds,the members to be connected have to fit perfectly when they are lined up for welding. 'urthergroove welding re%uires the shaping of the surfaces to be joined as shown in 'ig. 3. "o ensurefull penetration and a sound weld, a backup plate is temporarily provided as shown in 'ig. 5.

Welds are also classified according to their position into flat, hori8ontal, vertical and overhead9'ig. #:. 'lat welds are the most economical to make while overhead welds are the most difficultand e&pensive.

(a) Butt joint (b) Lap joint (c) Tee joint

(d) Corner joint Fig.2 Types of joints

8/13/2019 Welds Edited

http://slidepdf.com/reader/full/welds-edited 4/12

5

GROOVE WELDS

"he main use of groove welds is to connect structural members, which are in the same plane. )few of the many different groove welds are shown in 'ig. ;. "here are many variations of groove

A A

Ends shall be semicircular

Section A-A

(c) Slot weld

Fig.3 Common types of welds

(a) roo!e welds (b) "illet welds

A A

Section A-A

(d) #lug weld

(a) "lat

(b) $ori%ontal (c) &ertical

(d) '!erhead Fig. 5 Classification based on position

Bac up plateFig. 4 S aping of s!rface and bac"!p plate

8/13/2019 Welds Edited

http://slidepdf.com/reader/full/welds-edited 5/12

#

welds and each is classified according to its particular shape. ach type of groove weld re%uires aspecific edge preparation and is named accordingly. "he proper selection of a particular typedepends upon

• Si8e of the plate to be joined.• Welding is by hand or automatic.• "ype of welding e%uipment.• Whether both sides are accessible.• 0osition of the weld.

"he aim is to achieve the most economical weld of the re%uisite efficiency and strength. "he buttweld whether of full penetration or partial penetration should attain the re%uired strength of the

joined parts. "he si8e of the butt weld is defined by the thickness i.e. the thickness of theconnected plate for complete penetration welds or the total depth of penetration for partial

penetration welds.

+roove welds have high strength, high resistance to impact and cyclic stress. "hey are most direct joints and introduce least eccentricity in the joint. ut their major disadvantages are- high residualstresses, necessity of edge preparation and proper aligning of the members in the field. "herefore,field butt joints are rarely used.

"o minimise weld distortions and residual stresses, the heat input is minimised and hence thewelding volume is minimised. "his reduction in the volume of weld also reduces cost. Hence forthicker plates, double groove welds and < welds are generally used.

Single be!el groo!e weld

(a) Corner joint

S uare groo!e weld

*ouble & groo!e weld (b) Butt joint

S uare groo!e weld

(c) Edge +oint

Fig.# Typical connections wit groove weld

8/13/2019 Welds Edited

http://slidepdf.com/reader/full/welds-edited 6/12

;

Edge Preparatio !or B"tt We#d

"ypical edge preparations are shown in 'ig.=

'or a butt weld, the root opening, , , is the separation of the pieces being joined and is providedfor the electrode to access the base of a joint. "he smaller the root opening the greater the angle ofthe bevel. "he depth by which the arc melts into the plate is called the depth of penetration >'ig.69a:?. @oughly, the penetration is about 1 mm per 144) and in manual welding the current isusually 1#4 A (44 ). "herefore, the mating edges of the

plates must be cut back if through*thickness continuity is to be established. "his groove is filledwith the molten metal from the electrode. "he first run that is deposited in the bottom of a grooveis termed as the root run >'ig.69 c:?. 'or good penetration, the root faces must be melted.Simultaneously, the weld pool also must be controlled, preferably, by using a backing strip.

"he choice of edge preparation depends on

*epth o penetration Electrode

Arc ,oot ace

,oot gap

.ncludedangle

,oot run

Cappingrun

"illing run

Fig.$ %roove weld details

(a) *epth o penetration (b) ,oot gap

(c) ,oot run

,oot opening ,(a) Be!el with eathered

edge

,

(b) Be!el with bac up plate

, Land (root ace )

(c) Be!el with a land (d) *ouble be!el with a spacer

,

Fig.& Typical edge preparation for b!tt weld

8/13/2019 Welds Edited

http://slidepdf.com/reader/full/welds-edited 7/12

=

1. "ype of process(. 0osition of welding3. )ccess for arc and electrode5. Bolume of deposited weld metal#. /ost of preparing edges;. Shrinkage and distortion.

"he s%uare groove joint is used to connect thin material up to about 6 mm thick for thickermaterial, single*vee groove and the double*vee groove welds have to be used.

FILLET WELDS

) typical fillet weld is shown in 'ig.C9a:

Dwing to their economy, ease of fabrication and adaptability, fillet welds are widely used. "heyre%uire less precision in the fitting up because the plates being joined can be moved about morethan the groove welds. )nother advantage of fillet welds is that special preparation of edges, as

re%uired by groove welds, is not re%uired. In a fillet weld the stress condition in the weld is %uitedifferent from that of the connected parts.

"he si8e of a fillet weld is defined by the length of the two sides of the largest right triangle,which can be inscribed within the weld cross section. ) major share of welds of this type hase%ual legs i.e. they form right isosceles triangle shown in 'ig. C9 c:. "he typical fillet weldconnections are shown in 'ig. C9 b:. "he critical dimension of a fillet weld is its throat, theshortest distance from the root to the hypotenuse of the defining triangle shown in 'ig. C9 c:.

s

,oot o weld

"ace o weld

Theoretical throat(t/01202s)

Weld and leg si%e

Fig. '(a) Typical fillet weld

Fig.' (b) Typical fillet weld connections

8/13/2019 Welds Edited

http://slidepdf.com/reader/full/welds-edited 8/12

6

"he root of the weld is the point where the faces of the metallic members meet. "he theoreticalthroat of a weld is the shortest distance from the root to the hypotenuse of the triangle. "he throatarea e%uals the theoretical throat distance times the length of the weld. "hough a fillet weld isspecified by defining the two sides of the inscribed triangle, its actual cross section will be %uitecomple&. ) fillet weld must penetrate the base metal and the interface of the weld is eitherconcave or conve& >'ig .149 a:E9 b:?.

"he concave shape of free surface provides a smoother transition between the connected parts andhence causes less stress concentration than a conve& surface. ut it is more vulnerable toshrinkage and cracking than the conve& surface and has a much reduced throat area to transfer

stresses. Dn the other hand, conve& shapes provide e&tra weld metal or reinforcement for thethroat. ut while making a conve& surface there is always the possibility of causing undercut atthe edges, which undermines the strength of the joint >'ig. 149 c:?. "he stress concentration ishigher in conve& welds than in concave welds. It is generally recommended that for staticallyloaded structures, a slightly conve& shape is preferable, while for fatigue A prone structures,concave surface is desirable.

!arge welds are invariably made up of a number of layers or passes. 'or reasons of economy, it isdesirable to choose weld si8es that can be made in a single pass. !arge welds scan be made in asingle pass by an automatic machine, though manually, 6 mm fillet is the largest single*pass layer.

(3) 4ne ual legs

Fig.' (c) *ne+!al and ,+!al legs fillet welds

Throat /01202s

,oot s

s

Si%e / s

(.3) E ual legs

Throat

,oott

s

Si%e / s5 t

s

(a) Conca!e

s

(b) Con!e6

s

(c) 4nder cutting

Fig.1- Cross section of fillet weld

8/13/2019 Welds Edited

http://slidepdf.com/reader/full/welds-edited 9/12

8/13/2019 Welds Edited

http://slidepdf.com/reader/full/welds-edited 10/12

14

acking run back or backing weld

'illet weld

0lug weld plug or slot weld

Spot weld

Seam weld

Table 2. S!pplementary Symbols

'lat 9flush: single A B butt weld

/onve& double A B butt weld

/oncave fillet weld

'lat 9flush: single A B butt withflat 9flush: backing run

8/13/2019 Welds Edited

http://slidepdf.com/reader/full/welds-edited 11/12

11

Table 3 Combination of ,lementary and S!pplementary Symbols

S,ape O! We#d S"r!a+e $()*o#9a: flat 9usually finished flush:

9b: conve&

9c: concave

Po$itio o! $()*o#$ i dra-i g$

)part from the symbols as covered earlier, the method of representation 9'ig. 11: also includethe following-

+oint

3

7a8

7b

Fig. 11 et od of /epresentation

3/arrow line7a/re erence line(continuous line)7b/identi ication line(dashed line)

8/welding s9mbol

0rrow line Arrow line

(a)Weld on the arrow side (b)Weld on the other side

:Arrow side;:Arrow side; :'ther side;:'ther side;

Fig. 12 T oint wit one fillet weld

8/13/2019 Welds Edited

http://slidepdf.com/reader/full/welds-edited 12/12