WATER BATH HEATER - Autometers Energitec · A typical water bath heater consists of the following...

Transcript of WATER BATH HEATER - Autometers Energitec · A typical water bath heater consists of the following...

Autometers Energitec Limited

Formerly: RMG Autometers Gas Technologies Ltd.

www.autometersenergitec.co.in

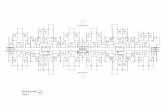

INDIRECT WATER BATH HEATER

GAS INLET

EXPANSIONTANK

FLARE STACKGAS OUTLET

PROCESS COIL

HEATER SHELL

FIRE TUBE

BURNER

Overview

Application

Principle of Operation

Heater Components

Indirect Water Bath Heaters are used in utility, processing and upstream oil and gas industry application. The main application of Indirect Water Bath Heaters is to heat high pressure gas prior to pressure reduction. This inhibits hydrate formation that can occur because of the temperature drop.

The process gas to be heated flows through a serpentine configured coil that is mounted in the upper reaches of the heater shell. A controlled amount of heat is liberated in to the fire tube which is located in the lower portion of the heater shell. Heat is efficiently transferred from the fire tube in the bath media. The heat contained in the bath media is then transferred by natural convention into the process stream which flows through the process coil.

A typical water bath heater consists of the following components each designed to meet specific design criteria:

The Heater Shell is an atmospheric vessel containing process coil, firetube and heat media. Fire tube allows a heat transfer from the flame to the hot medium. The heat is transferred from the water bath to coil/tube bundle and then safely to the Gas/Oil.

••

••

Heating of upstream natural gas pressure regulation.

Heating of Produced Crude oil to enhance the degassing and dewatering, prevent hydrate and maintain temperature above the paraffin pour point.

Heating of turbine fuel gas to maintain above the dew point temperature.

Heating of highly viscous fluids to enhance the pumping efficiency.

INDIRECT WATER BATH HEATER

The Fire tube is mainly of U-tube configuration. The tube is removable and designed to efficiently transfer heat to surrounding heat media.

The process coil is a pressure containing part designed in accordance with API-12K or ASME VIII Div. 1 code.

The flue gas stack is designed to provide positive flue gas flow (draft).

The expansion tank allow the hot medium to be contained for the thermal expansion due to temperature increase. Level gauge/transmitters indicate when additional water or hot medium is required.

Burners are available in Natural draft or Forced draft design depending on process conditions and power supply availability.

Natural draft burner relies on a stack to create negative pressure at the burner inlet, which induces controlled air as is required for combustion. These burners are mainly used for remote locations or location where no power supply is available.

Forced draft burner are used whenever low emission is required. Small bore fire tubes are used in conjunction with a combustion air fan.

Applicable code & regulatory specification

Main Features - Water Bath Heaters

Safety

Field service

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

ASME Section VIII, Div.1

ANSI B31.3

API - 12K

Other National / International code as per requirement of the project.

Turn down ratio 4:1 with natural draft and 15:1 with forced draft burners.

Shell is duly insulated to reduce heat losses.

Individually removable fire tubes and process coil bundle.

100% Radiography of the process coil.

Gas train with safety interlock

PLC based Electronic control / remote monitoring for better efficiency.

Heat media temperature and level measurement.

Manu al OR Automatic pilot ignition design

Alternate MOC available.

Flame arrestor at stack.

Alarmsfor systems.

Dual Temperature control.

Our well trained & equipped team of engineers to serve the customer.

B - 15 Sector 80, Noida 201 305 IndiaPhone : 91 120 4059 950Fax. : 91 120 4059 951Email : [email protected] : www.

Autometers Energitec Limited

autometersenergitec.co.in

colo

r.zo

ne@

yahoo.in

-M

arc

h-2

016

Electric process heaters are designed for heating flowing liquids and gases, such as: air, nitrogen, natural gas and oil.

Capacity up to 2000 KW Element are specially sealed to prevent moisture ingressMOC of Heating Element can beCopper, Titanium, SS all grades, Incoloy 800, Inconel etc.Terminal box is CMRI /ATEX/IEC approved

Electrical heaters can be installed vertically or horizontally.Each electrical heater unit consists of a flanged immersion heater mounted in an ASME code -designed heating chamber.

Heater vessel with PED / ASME Sec. VIII Div1/2, AS 1210.Vessel with ASME U stamp codeThe chamber is equipped with flanged inlet and outlet connections, mounting studs, high temperature insulation.

Flanged rating 150# - 2500#Electrical heaters are supplied with Thyristor or on-off control panel.

Features

Construction

AEL Electric Heater Features

····

···

··

···

··

Welded Heating ElementsWelded Terminal Housings and SpacersExplosion Resistant Terminal Enclosure Sheath Sensing Thermocouple attached to one - element for overheat protection.

ELECTRIC HEATER

Our distributor